Media | Articles

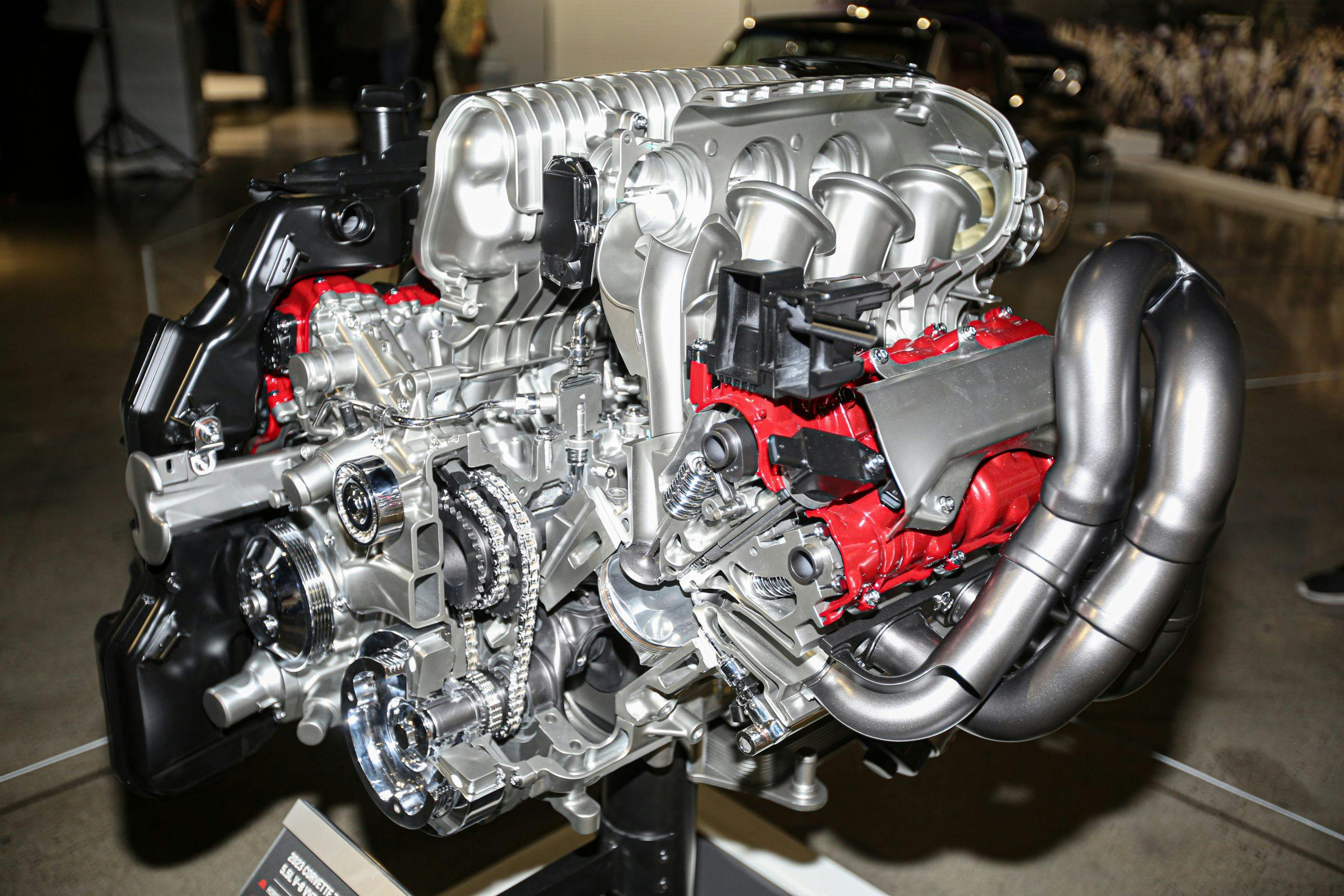

13 details to know about the Z06’s 670-hp LT6 V-8

When Chevrolet unveiled the 2023 Corvette Z06 at the Petersen Automotive Museum, several development engineers were on hand to answer our feverish questions. Corvette chief engineer Tadge Juechter fielded them with grace, but the man of the hour was Chevrolet small-block assistant chief engineer Dustin Gartner. A group of current Corvette owners was in attendance, and the nuts and bolts of the recently revealed LT6 and its astonishing 670-hp output—making it the most powerful production naturally aspirated V-8 ever—was all they wanted to talk about. The DOHC engine did indeed steal the show, and Gartner was a real sport about diving into its nitty-gritty details. Naturally, we pestered Gartner with our own questions to learn about some of the LT6’s details that weren’t in Chevrolet’s press release. Let’s take a look!

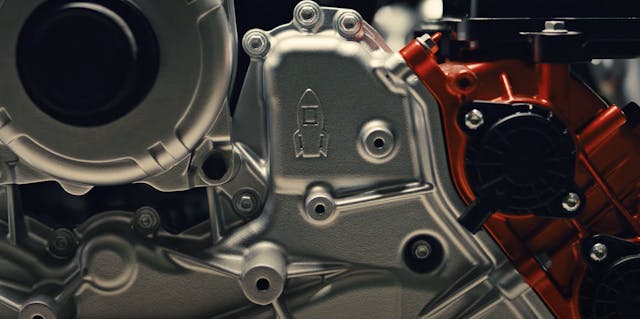

The LT6 is nicknamed “Gemini”

If you watched Chevrolet’s launch video for the Z06, you likely caught a glimpse of a rocket that was very conspicuously placed on the engine’s front cover. In order to keep information from slipping by using any sort of identifiable nomenclature that might tip anyone off, engineers nicknamed the LT6 “Gemini.” It’s a nod to the Corvette’s link to NASA astronauts and a highlight that this Corvette team’s “moonshot”—a lofty goal to build a naturally aspirated V-8 that would surpass the LT4. In addition, Gemini is represented by the Roman numeral II to represent the constellation’s famous twins, and the LT6 has twin intake plenums and twin throttle bodies. The rocket cast into the engine’s front cover—which also has a Roman numeral II—is one among dozens of easter eggs found in the engine bay. Gartner didn’t tell us how many exactly but gave us a hint: “There are actually more inside the engine than outside.” The Gemini rocket is used on each piston and just about anywhere inside the engine where a part would need to be marked for proper installation orientation.

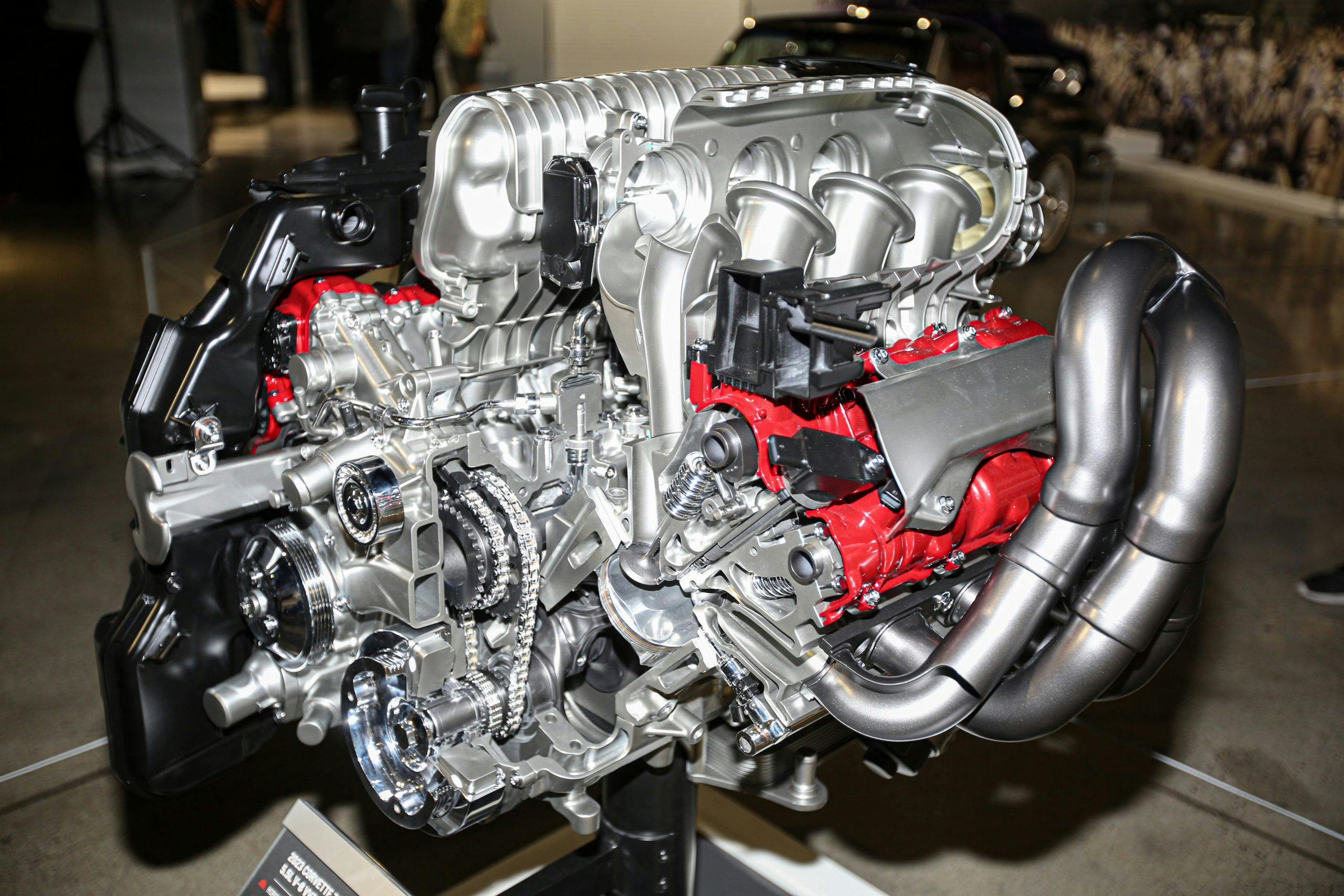

Five camshafts

Yeah, there are two camshafts mounted above each cylinder head, each activating two valves per cylinder as you’d expect on a 32-valve V-8—but there’s also a camshaft mounted in the valley. This isn’t some kind of vestigial leftover from the small-block’s evolution to an overhead-cam valvetrain, either. Instead, this short, two-lobe cam drives a pair of high-pressure fuel pumps that each supply fuel for one bank’s direct injection system. Nestling the pumps in the valley between the cylinder heads and below the sizable intake manifold helped to muffle the noise inherent in those high-pressure pumps.

It has virtually nothing in common with Cadillac’s Blackwing V-8

Some early rumors indicated that the LT6 would be based on Cadillac’s twin-turbo V-8, which also happens to use DOHC architecture. That’s not the case. The block, heads, cams, and intake are all unique to the LT6, although there are some ancillary parts shared with other engines, like the twin 87-mm throttle bodies, which actually are found on the Blackwing V-8.

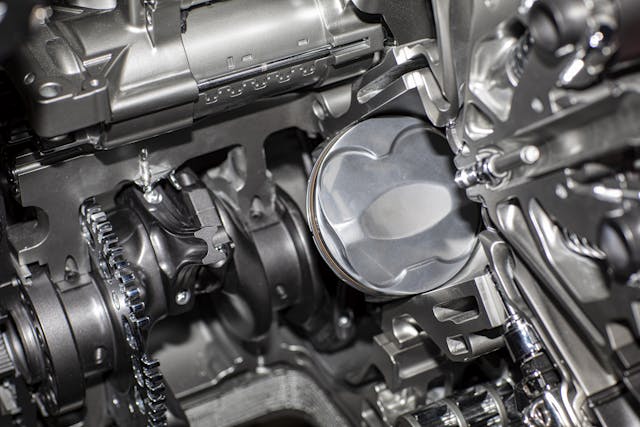

The pistons are made by CP Carrillo

CP Carrillo is known in the aftermarket for making tough, reliable pistons for racing applications and the LT6 demanded lightweight, low-profile pistons that would survive at high engine speeds. CP Carrillo is one of the most esteemed aftermarket manufacturers and seems like a good partner for supplying a tough forging for the LT6.

Marketplace

Buy and sell classics with confidence

Diamond-like carbon coatings are used on multiple engine surfaces

Diamond-like carbon (DLC) coating gives metal a tough, thin, low-friction surface to reduce heat and wear. You will find it on many of the wear surfaces inside the LT6 including the mechanical finger followers, which transmit lift from the camshaft to the valve, and the piston rings.

It’s not designed for short service intervals with lots of maintenance

Gartner was adamant that the LT6 is not like a typical exotic car engine “that you have to take apart every 10,000 miles” for valvetrain adjustment or some kind of rebuild. “At the end of the day, this is a Chevy. Our expectations are that of any other Corvette we’ve sold.” Thank the DLC coating for part of that durability. “It’s long-term bulletproof,” Gartner said. “Even though we have a true mechanical valvetrain that’s lashed at the plant, the surface treatments, the DLC coating, and all our validation … it’s lashed for life.”

The LT6’s front damper is aluminum

A flat-plane crank removes a lot of mass, somewhere in the range of 30 to 40 percent compared to a cross-plane unit. According to Gartner, the aluminum, viscous-filled front damper on the LT6, is also “drastically lighter” than an iron elastomer damper like the one found on the LT2. The rear flywheel-side damper is similar to the one on the LT2 but is also lighter.

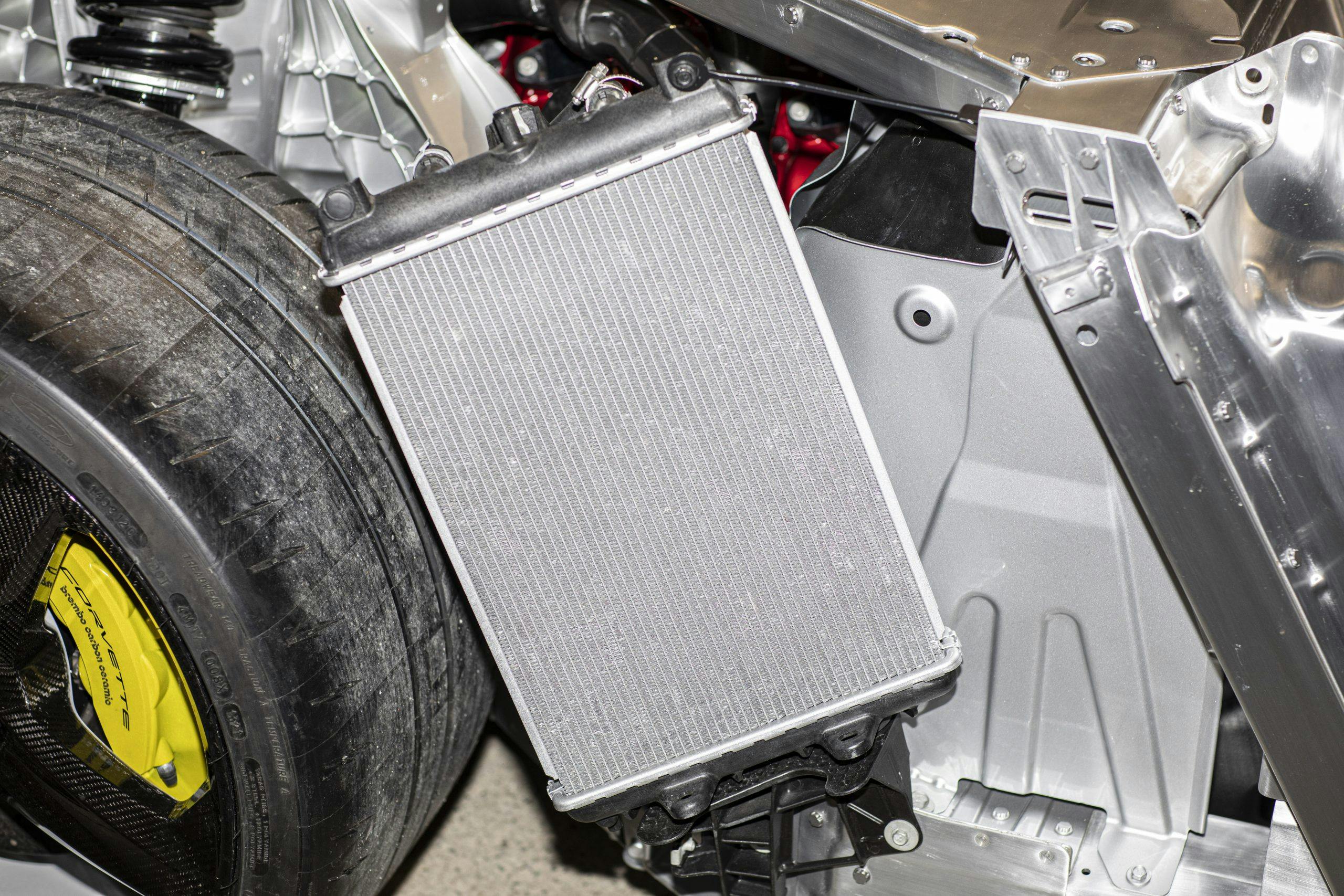

It runs a 70° Celsius (158° F) thermostat and has an abundance of coolers

While the engine is designed to run around “mid-90s to 100° C” (as you’d expect), the thermostat is actually a bit cooler than most. “It’s hard to get this engine hot, hot.” Gartner said, noting that the two radiators on the side pods are dedicated to the engine and the transmission oils.

“The bulk of the hot coolant comes out of the engine, goes forward, gets cooled by three radiators, and comes back to the water pump. Most of that then goes to cool the engine. The water pump pulls off fresh coolant to the two side radiators, which then step it down even colder.” The driver-side heat exchanger is dedicated to the oil cooler, which circulates the coolant to the biggest engine oil cooler Chevrolet has ever installed. It keeps the 5W-50 oil—specifically selected because it provides ample lubrication and allowed engineers to optimize bearing widths—very cool. The passenger-side heat exchanger does the same but cools the transmission. “This is rock solid from a thermal perspective,” Gartner promised.

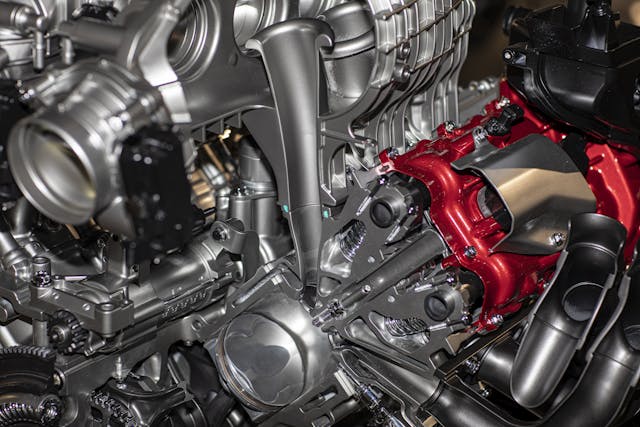

The intake and exhaust tuning virtually supercharge the engine

The plenum and large, tapered velocity stacks definitely work as intended and, as Gartner pointed out, are unique to each valve. At the engine’s 6300-rpm torque peak, volumetric efficiency is at 110 percent, and at the horsepower peak 2100 rpm later, it’s still 106 percent. What does more than 100 percent mean? Answer: Each cylinder is being crammed full of air so efficiently that it’s moving more air than the cylinder displaces. That’s possible by tuning the intake and exhaust tract so that the incoming air has enough momentum to cram air into the engine as the valves are closing.

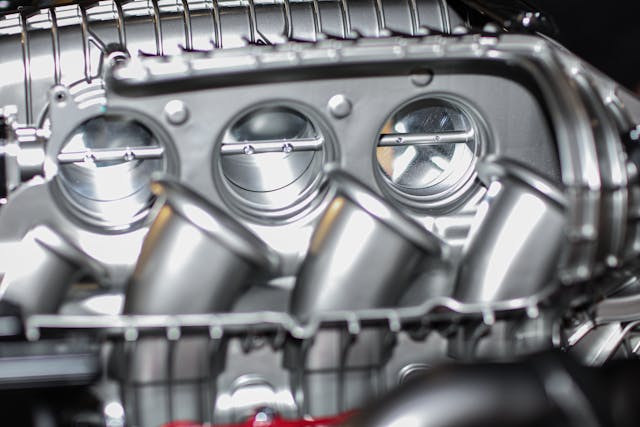

The plenum is tuned for peak volumetric efficiency, most of the time

The twin plenums atop the LT6 work in unison by breathing through 87-mm throttle bodies. There’s also another set of valves that open up between the two plenums to allow them to truly work as one. Three equally-sized butterfly valves link the two sides of the plenum. Two of the three are linked together and the rear valve operates independently. Gartner explains: “At different speeds you want a different amount of communication between the two plenums to maximize the tuning at that speed. Otherwise, it would only want to tune at one engine frequency, one rpm. With the communicator valves, we can open up that tuning window where we get volumetric efficiency greater than one. Throughout the rpm band, those valves will change half a dozen times.”

That tuning will also vary depending on which drive mode has been selected. “We found at full load, if you’re tuning for max torque, you get a lot of good induction noise,” he said. That’s great for all-out performance, but it might be distracting if you’re cruising, so the communicator valves operate under a different schedule in Tour mode to keep things a bit more subdued.

Each engine will have a 20-minute dyno break-in cycle

While the car will likely have a suggested 500-mile break-in period before it should be subjected to any all-out track shenanigans, the engine will already have a 20-minute dyno break-in where it’s warmed up and put through its paces and finally run at 7600-rpm for a WOT pull.

It uses a cartridge-style oil filter

Being the largest flat-plane V-8 in production means that there will be inevitable vibrations. Having a light rotating and reciprocating assembly will reduce the severity of these vibrations, but at some point, as Gartner put it, “you have to tolerate it.” A low-torque, spin-on oil filter canister is in danger of vibrating itself loose on an engine like this, so Chevrolet opted for a cartridge-style oil filter for the LT6.

The dry sump lets the crankshaft spin in a near-vacuum

The LT6’s bottom end is divided into four bays, one for each throw of the crankshaft, with each one isolated from the others. A pump pulls oil and air from each bay to evacuate oil. Not only does the crankshaft not have to whip through oil, which saps power, but at nearly 80 kPa of vacuum, it meets very little air resistance. A side benefit is that the arrangement keeps the rings at the bottom of their grooves as the pistons approach BDC for better sealing.

Two additional pumps pull oil from the front cover and the cylinder heads, but those are low-vacuum. The entire system is designed to put oil back into the tank so that it can be ready to be pumped out to where it’s needed. It’s not sitting around where it’s getting in the way or not doing any good. As Gartner explains, “At max engine speed, there’s more oil in the tank than at any other time.”

This is the most impressive car/engine combination which people like me are all waiting for to drive and enjoy.

GM/Corvette is becoming the Beacon of the World because of this special engine it has created. I expect mine to come home early next year, cannot wait to sit and sleep in it, then wake me up for another ride. Kudos to Corvette for creating another major milestone achievement of a car.

Impressive on paper, I hope it’s as great in practical application as it has been in oral. Looking forward to owning one and really putting it through the paces.

I picked up my Z06/Z07 a week ago. 216 miles into break in and I love it. , Amazing and gets the looks and sounds amazing.