Media | Articles

Dissecting the four-cylinder engines that helped Toyota dominate the world

The pandemic aside, Toyota sold more than 9 million cars and trucks last year around the world. The key to this company’s prosperity is its broad portfolio of affordable models and a list of attributes that is topped by value and followed closely by quality, reliability, and durability—QRD, in industry shorthand. No other brand has polished QRD to such a brilliant sheen. Peel back the Toyota onion and you’ll find 1001 seemingly trivial things that register positively in the back of every owner’s mind: tight panel gaps, no ruckus as the transmission cycles through its gears, and faithful service over years of use.

Tracing Toyota’s impeccable QRD to its origin could fill a book, but one waypoint is well-known: the 20R four-cylinder engine introduced for the 1975 model year. No stranger to inline-fours, Toyota built 14 four-banger families in the 20th century. Its R series, manufactured from 1953 through 1997, was offered in nine different displacements ranging from 1.5 to 2.4 liters.

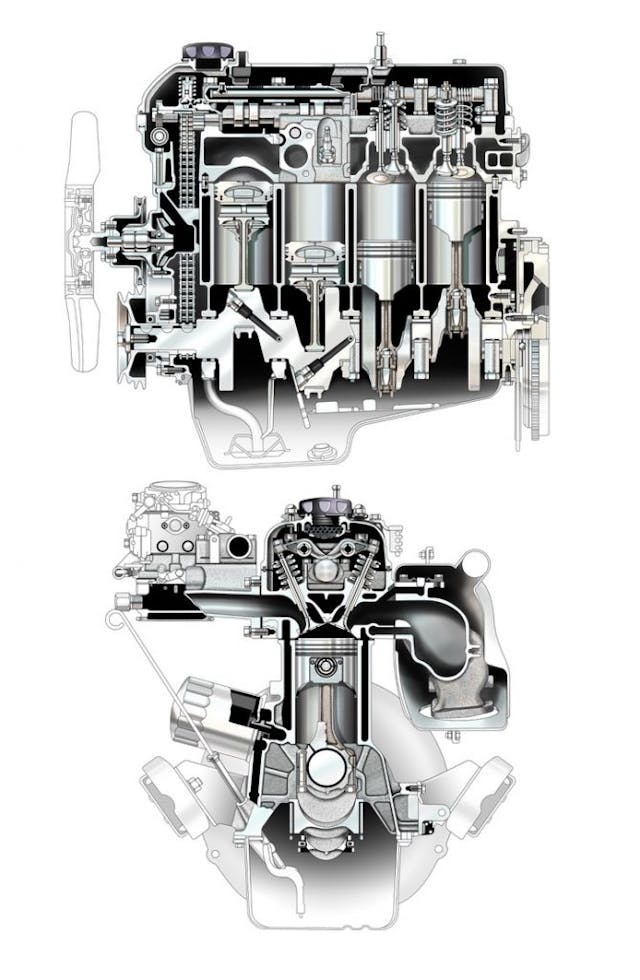

In 1968, Toyota’s 1858-cc 8R engine came with two notable advancements: a five-main-bearing crankshaft and a cam elevated from the block to the head. Cranks with only three mains save cost, weight, and friction, but they lack the rigidity needed for smooth running in engines topping 100 horsepower. Eliminating pushrods with an overhead camshaft trims the valvetrain mass, which enables higher rpm, and clears space for straighter, more efficient intake and exhaust ports. Higher rpm plus greater flow-through yields more torque and horsepower.

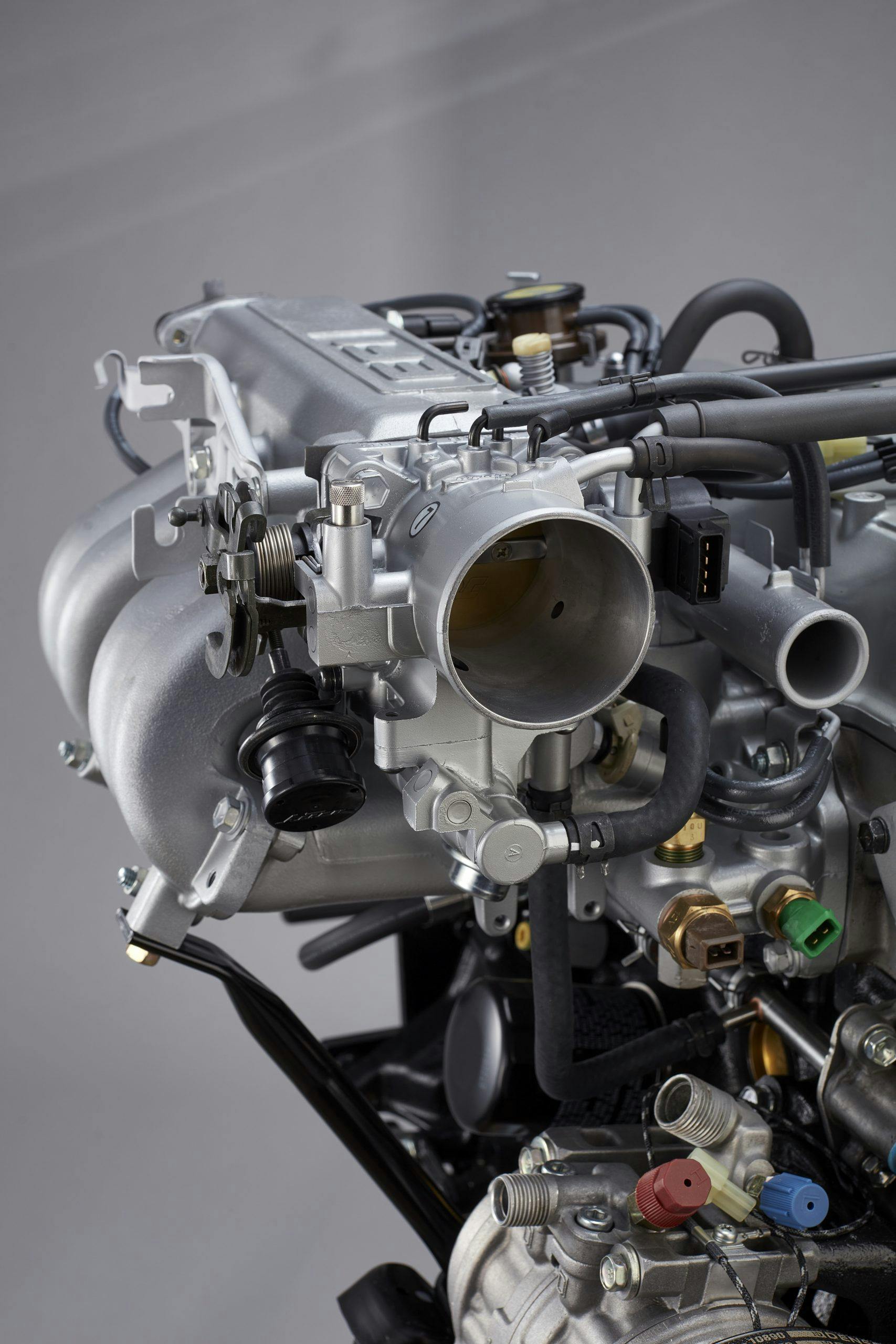

Enter the 20R inline-four under the hoods of 1975 Toyota Coronas, Celicas, and Pickup trucks (the previous Hilux nameplate became Pickup in the ’75 model year). A 9-millimeter stroke increase over the immediate predecessor 18R’s 80-millimeter stroke upped the displacement to 2190 cc. The distributor was relocated, and other technological strides lowered exhaust emissions and improved gas mileage, the most pressing issues of the mid-1970s.

The new cast-aluminum cylinder head was a crossflow design—fuel and air in one side, exhaust out the other. This facilitated efficient airflow and assured that exhaust heat wouldn’t reduce the intake charge’s density. The spherically domed combustion chambers accommodated larger valve diameters and allowed locating the spark plugs near the center of the cylinder to shorten flame travel during combustion.

Marketplace

Buy and sell classics with confidence

The 20R’s cast-iron cylinder block had deep skirts to securely support the crankshaft and the cylinder head. The five main bearing caps were extra-robust, and the overhead cam was driven by a stout double-row timing chain. In the interest of longevity, both the crankshaft and the connecting rods were made of forged steel instead of the more common cast iron. To save weight, the head and cam drive covers were tidy aluminum castings.

A new transistorized ignition system, then fast becoming the standard industry practice, assured quick starts and more miles between tuneups. An electric fuel pump reduced the chance of vapor lock in hot weather. Squirting extra air into the exhaust manifold cut emissions by continuing combustion of the unburned fuel exiting the cylinders. To minimize weight and clutter, the air-injection plumbing was neat and tidy. The choke mechanism of the 20R’s two-barrel carburetor was heated by engine coolant instead of exhaust gas for more consistent operation. Intake air was warmed by heat radiated from the exhaust manifold following a cold start. A large-diameter seven-blade fan drew ample air through the radiator in traffic, its temperature-sensitive viscous drive allowing the fan to free-wheel to diminish power loss during cruising. While these measures seem rudimentary compared to today’s era of electronic controls, in 1975, they helped achieve Toyota’s high standards of driving poise.

Less evident is the development effort Toyota invested in 20R engines using the painstaking trial-and-error methodology necessary before the advent of engine design by computer. Thousands of durability test miles were logged on experimental engines. Hot, cold, and high-altitude environments were used to validate every possible driving circumstance. Hours of flat-out running in dyno cells proved the concept, and fine-tuning minimized the need for valve-lash adjustments and oil additions between changes. The engine mounts were calibrated to dampen vibrations from the four-cylinder. Then the design was turned over to Toyota’s famously lean, just-in-time production system, which used the Japanese concept of kaizen, or continuous improvement, to hone the manufacturing precision to a level as yet unseen in the auto industry. Unlike in U.S. factories, where the production rate was king, assembly workers in a Toyota plant could stop the line when a defect was discovered, a signboard called an andon lighting up to alert the plant of the station having the problem. Thus, defects were caught and fixed much sooner by a quality-obsessed system that would eventually be copied around the world.

In production form, Toyota’s 20R combined a 3.48-inch (88.5-millimeter) bore with a 3.50-inch (89.0-millimeter) stroke, yielding 133.6 cubic inches, or 2190 cc. Peak power ranged from 90 horsepower with California emissions controls including a catalytic converter, to 97 horsepower at 4800 rpm in 49-state applications. Maximum torque ranged between 119 and 122 lb-ft at 2400 to 2800 rpm. The 20R served faithfully during its six-model-year run powering U.S. Coronas, Celicas, and Pickups. A Car and Driver test of a ’76 Celica GT clocked the 0–60 run in 9.6 seconds, a quarter-mile time of 17.6 seconds at 77 mph, and a 102-mph top speed, beating a Dodge Colt GT and a Ford Capri II S. City and highway mpg figures were in the mid-20s. Reviewer Ted West griped about his test Celica’s poor throttle response and rubbery-feeling driveline but was impressed by the value represented by Toyota’s reverential salute to the Mustang.

The 20R’s legendary reliability and low maintenance requirements were instrumental in Toyota motoring past Datsun to become America’s largest importer. Many served repeat assignments after the vehicles they were born with were totaled and dispatched to the salvage yard.

The 20R engine’s successor, the 22R, brought a larger 92-millimeter bore, lifting displacement to 144 cubic inches, or 2366 cc, and boosting output to a maximum 135 horsepower. This edition hosted both electronic fuel injection and turbocharging during its 1981–97 lifetime. The R series forged an empire by branding Toyotas with an unshakable quality reputation and giving generations of Toyota vehicles, and especially Toyota trucks, higher resale values than their counterparts. First-gen Toyota 4Runners from the 1980s have some of the fastest rising values of any vehicles tracked by Hagerty.

George Nodarse of Escondido, California, has a typical story: He logged over 370,000 miles—equivalent to nearly 15 laps around the Earth—in his 1985 Toyota 1-Ton Pickup powered by a 22RE equipped with fuel injection. Nodarse bought the vehicle in 1986 for use in his custom cabinet business. A local upfitter replaced the factory bed with a stake bed and added a dualie rear axle. Nodarse’s son Tanner recently commenced a nut-bolt restoration. Upon completion, George and Tanner plan on presenting their handiwork at the All Toyotafest show held annually in Long Beach, California.

A rare Toyota misstep was converting the cam drive chain from a double-row design in the 20R to a less durable single-row arrangement. Nonetheless, the 22R played an instrumental role in the final phase of the 1983–87 conflict between Chad and Libya, nicknamed the Toyota War because both sides used Toyota Hiluxes for transport. Four hundred of these trucks were armed with antitank guided missiles. In this instance, the oft-quoted bulletproof tribute fits.