Media | Articles

According To You: What’s Hard to Reach on Your Car?

The Hagerty Community has embraced the According To You series even more fully than I expected, and last week’s question spoke to many of you personally. Your answers were both entertaining and enlightening, including many from folks who offered priceless advice for my personal issue with oil filters on a MN-12-derived Ford product. This series is officially the gift that keeps on giving!

We had a lot (I mean a LOT) of comments last week, and we had to trim them down to a much smaller list for this week’s publishing. So don’t be shy, do yourself a favor and read every comment from last week when you have a chunk of time to spare. But in the meantime, here’s a list of answers you will truly enjoy.

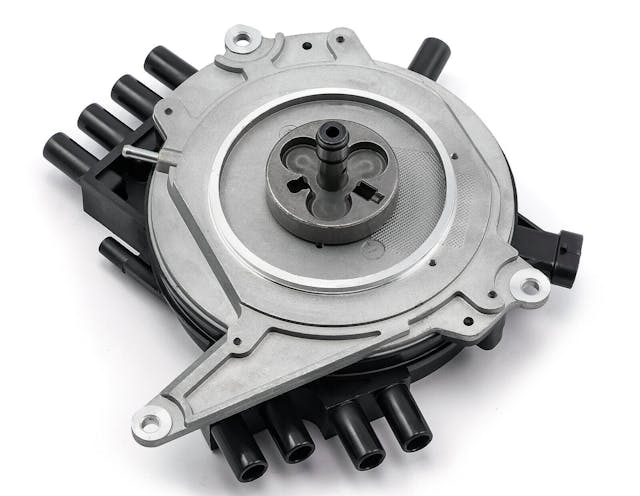

Opti-Spark Stress

@Kenny: Mine was a ’93 Corvette OptiSpark replacement without removing the radiator and fans. Blind access to bolts, greasy hands, impossible back position, and skinned knuckles were a given. Worst part, I had to do it 3 times due to bad parts from a discount auto parts store. Hard to stand straight for several days.

@Hank: Distributor Cap, Rotor Cap, Plugs and Plug wires on a 1996 Buick Roadmaster.

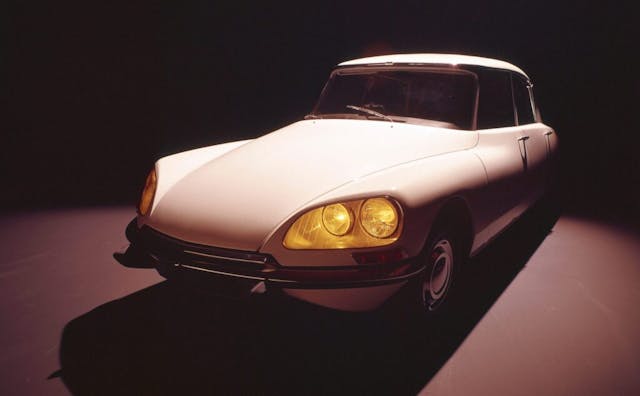

Sacre Bleu! (Two from France)

@Ken: The toughest job I ever had to do was to change the water pump on a Citroen. The pump sits on a bracket less than a quarter inch from the radiator. I tore up my knuckles trying to get the water pump out and the new one in. Next time, which will never happen, I would take out the radiator first. I did learn how to swear and curse like a French sailor! MERDE!!!

Marketplace

Buy and sell classics with confidence

@Duckcanuck: Here’s one that I doubt will have come up: on a Citroën 2CV, the front brakes are mounted inboard, on the gearbox transaxle. If you have model with drum brakes, it is close to impossible to get a finger behind the drum to hold the center pin for the shoe hold-down spring. Of course while you are trying to hold the pin in place, you have to be pushing and twisting the spring-and-cup from the other side. And remember, all of this is happening with your arms outstretched, due to the inboard location of the brakes. It probably took me 20+ attempts, over several hours to get all four springs in place.

Rue The Day (Four from The UK)

@Dan: The Series I Jag XJ6 heater core. As the Haynes Manual states, strip entire car to the bare uni-body and reassemble in reverse order. You may also be required to smite briskly with mallet.

@Gareth: It’s easier to remove the axle than it is to do the rear brakes in the car on my XJ-S.

@Mike: Think that’s hard? It’s impossible to do the brakes WITHOUT dropping the rear axle on my E-Type.

@Fred: 2006 LTI TX2 London Taxi Cab, removing starter to access solenoid.

So Many Spark Plug Problems

@Albert: On a 1969 Corvette 350 with air conditioning, the number 2 and 4 spark plugs are next to impossible to access. It’s a little easier now that I have a lift. I can’t imagine accessing these on a big block with air conditioning.

@Andy: I have a ’69 350 as well. Agree on the spark plugs. Even worse is getting under the dash to do any work there. Feet up, head down, no room to move and if you need another tool, well you get to climb in out again.

@Eric: Even finding the spark plugs on my C8 Audi RS6. Thank God that I have Audi Care which covers parts and labor to replace them at 30K miles.

@Bruce: The last 2 spark plugs on my V-12 Jag.

@Jeff: Jaguar XJS V-12 spark plugs. I started. Never finished.

@Bob: Does anyone remember the Chevy Monza? Its engine bay was never intended to house a small-block V-8 and access to the rear spark plugs was such that, on many cars, they never got changed.

@Prof+X: My father-in-law had an early seventies Ford truck with a 390. The passenger rear spark plug was physically impossible to remove, without somehow removing the inner fender or dropping the drivetrain, disconnecting the motor mounts, and jacking up the engine. This was in the mid-eighties and I don’t think it had been changed since new.

@Papa: Getting the rear plug wires off of my 2006 Monte Carlo 3.8 was a 2 hour, 8 different style “wire pullers” and 4 different screwdrivers, P.I.T.A. Job. They are holding on for dear life! Never seen boots hold like that one, the front ones fortunately are right there but still needed a puller.

@David: The half of the spark plugs on my Nissan Frontier’s 4.0L V-6 that require you to remove the upper intake manifold to get to them…

@Richard: The rear plugs on my ’04 Toyota Solara. The official way is to drain the coolant and remove the intake manifold and pile of miscellaneous parts. I was able to do it by removing everything at the back and driver’s side of the engine and with a large assortment of adapters, extensions, wrenches, sockets etc. 1 hour per plug! Thankfully it is a rare occurrence—every 400k km (250k miles).

@Dan: The plugs on a Sunbeam Tiger.

@BeamerBob: The rear most spark plug on a Sunbeam Tiger. Changed from under the steering wheel through a hole in the drivers side toe board. Also, the one under the generator.

@William: Changing the spark plugs and adjusting the valves on an original Sunbeam Tiger. There is a grommet through the firewall to give access to the #8 plug, and removing the valve covers is a horror…

@Richard: Passenger front spark plug on 1973 Trans Am with 455 and A/C. Not visible under compressor and difficult, if not impossible, to get a ratchet with spark plug socket down there without risk of breaking ceramic tip of plug or worse, cross-threading it. The simple solution was to remove passenger front tire and go in through wheel well above the upper A-arm. It was a straight shot with a long socket extension(s) and you could easily see what you were doing. it became one of the easier plugs to replace.

@Tim: Two spark plugs on my ’75 Pacer were buried in the firewall.

@Jim: The later model Lexus RX350’s are a joy to change the rear spark plugs and coils on. Not only does the intake manifold have to come off, but the windshield wipers, motor and panels above it. It took hours and hours the first time I did one. Even had to fabricate a tool to pop the windshield wipers off. Even with everything removed it’s a b%$#@ to get to the plugs and bolts holding the coils down.

@Robert: Here is an old school one: The center 2 spark plugs on each side of a 1969 Mustang or Fairlane/Torino Cobra with a 428 Cobra Jet, complete with original smog system and tubes in place. The center plugs are canted towards each other, you have to work under the steel smog tubes that enter the exhaust manifolds, and you are tight to the shock towers. It’s a challenge, actually it’s a PITA.

@miataman5: Changing the plugs on my parent’s ’73 Chrysler New Yorker with the 440 engine was no fun.

@Glenn: I had a ’74 Corvette with a 454. Changing plugs was a challenge.

Mustang Fastbacks

@Chuck: Cleaning the inside of the rear window on my 1965 Mustang Fastback. Very steep angle and a roll cage.

@Espo70: Where the rear deck panel and the sharply raked back window meet on my S197 Mustang. Trying to clean that area is difficult.

Bedauerlich! (Three Regrets from Germany)

@David: BMW 2002 owners who have not relocated their battery to the trunk (or under the rear seat as I did) know the struggle of trying to remove the oil filter with the full size battery in place.

@Ray: Porsche 356B: In the engine bay the two front spark plugs are hidden behind the intake manifolds. They are literally out of sight and are changed using the braille method. Have dropped more than one plug into the engine tin and am now totally paranoid about installing a new plug without cross threading. In the interior, the fuel lever is hidden under the right-side dash in the passenger’s foot well. The lever is for on-off-reserve, moving from on to reserve while driving is dangerous. I have turned the gas supply off trying to do this and this is dangerous and requires a rather quick do over. More sticking your hand under the passenger side dash and further groping while trying to watch the road and other traffic. The markings are in German, even for the made for USA cars so its still a bit confusing even if the car is not moving. i.e. Auf is On!

@Peter: My problem is with my ‘74 super beetle. 1835cc with two Webbers which put the carbs out towards the fender well. And just try to get to those 2 front spark plugs out. Or trying to get to the jets on those carbs, you gotta have child hands! I may have to make an access panel on the inside of the wheel well.

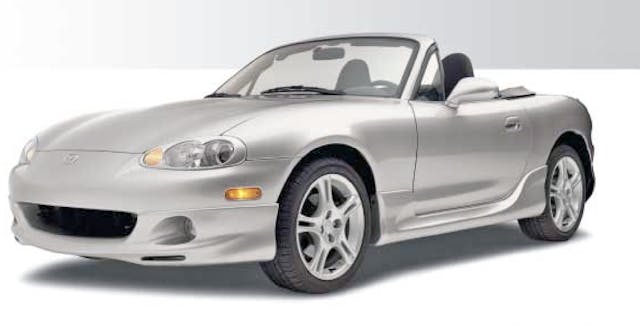

So Miata Is NOT The Answer?

@James: I have a 2004 Mazda Miata NB and the oil filter is very difficult to get to. Under the air intake, behind the alternator and blocked by the right strut tower. You feel a little bit like a racoon fishing in muddy water and I found a pair of filter pliers at Home depot that make it a cinch. Although there is no turning back as they do pierce the casing.

@Alison: NC Miata driver side headlight bulb cannot reach from under hood. Remove inner fender or front bumper cover for access.

@John: Reaching the oil filter on NA and NB Miata’s (1990-2005) is a pain.

@MiataRoss: I’ve got an NB and I completely agree the oil filter is difficult to see let alone replace.

@Mike: Just try to replace the driver side headlamp on an NC.

@GL: I agree. I have a NA and I still wonder if it`s easier by removing the front passenger wheel. There is no easy way.

@BG95PreludeSRV: The wheelwell access is a myth on the NA. At least on my ‘97 1.8.

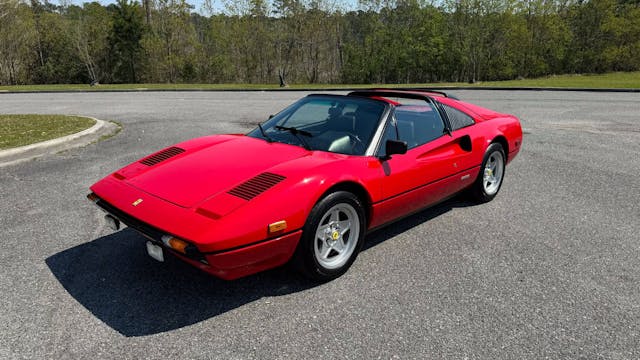

Oddio! (Two from Italy)

@mph: Ferrari 308 GTS: the front pan under frunk is the Cavern of Satan if you drop small fasteners while fiddling with the grill, horns, etc. I was able to retrieve a lost grill fastener by thumping the plastic tray to locate the general whereabouts of the piece & then taking a strong magnet to “drag” the piece forward to a point where I could fetch the little rascal!

@Cory: My Ferrari 355 has the battery located in the front right wheel well requiring you to remove the wheel and tire and wheel well inner fender panel to access it. Also, the same car requires you to remove a belly pan 2/3 the size of the undercarriage to get to the oil sump reservoir plug to drain it for an oil change. If the car is not perfectly level, the draining oil will hit a cross member and you will be getting a dirty oil facial you hadn’t planned on. They could have engineered a small access panel or cutout to make the oil changes far easier. I wonder why they didn’t? Well, not really.

Det ligger en hund begraven (Four from Sweden)

@Whitman: Have you every tried to access the wiring behind the dash of a Volvo P1800? Being a contortionist would be an asset!

@RJ: Two Volvo issues—heater fan motor on a 140/240 from 1973-’93. Hard, but harder by the book.

@sAlty 240: The blower fan on these cars is legendary (the joke is the engineers built the car around the blower box). Mine never failed but multiple forum posts indicated it was far faster to just sawz-all the housing open then glue it back together.

But the crank position sensor on my 1991 manual 240? It took multiple 1/4″ extensions and u-joints to even get a socket on the retaining bolt, which came out easily enough, but the sensor itself would not budge and there’s zero space in there between the firewall and the block to pry on anything. If you ever have the engine or trans out, change this thing proactively (it turned out my misfire was bad plug wires, not the CPS) if your car has one.

@Keith: 1993 Saab 900—The belts infamously are between the engine and the firewall thanks to the ‘backwards’ design. Busted knuckles and lost sockets are a guarantee. At least the clutch assembly is right up front!

I Didn’t Order this Apple Pie (Two from Chevrolet)

@Rider79: The hardest place to reach on my 1973 Nova 350 was one of the heater hoses. One had to either remove the inner fender (or at least a liner, I don’t recall), or cut a hole in the inner fender. The factory put a special textured hose there that lasted well over 10 years (a long time for hoses in those days), before it had to be replaced; I guess they realized how hard it would be!

@daddy stev: Considering its modest nature, worst so far has been an inaccessible lousy leaky oil pan gasket on a 96 Chevy Blazer V-6 4.3 with a 4WD automatic—sorry but just couldn’t replace it myself at that time, so had to get help from the dealer. They must have had to take most of the front half of the vehicle apart just to get to it, over more than a work day, and at a cost of more than $2000—yikes! That was nearly the value of the then 21 year old but low mileage daily driver truck. Such simple basic things oughta be better designed to allow easier repairs, seems to be a frequent problem with Chevys.

Bikkuri Shita! (Grab Bag from Japan)

@Gman1954: The Honda S2000 great car but quirky: The clutch pedal has a breakable switch on the backside. Car won’t start without it. & Americans cannot fit in there to change it. The trick is to use sticky tape on a screwdriver to hold it in place, while you screw the bolt on while you are on your back wedged head in under the steering wheel half in, half out of this very small car. Also I haven’t replaced my slowly leaking clutch slave cylinder because of the same lack of space issue.

@JoePags: On a Z32 Nissan 300ZX, that would be everything other than the dipstick. It is the epitome of 10 gallons of “stuff” in a 5 gallon bucket. It is literal origami how Nissan fit it all under the hood.

@BG95PreludeSRV: Starter motor on any Honda or Acura with a 2.4 liter 4 cylinder engine. Two long bolts that you can only turn 10 degrees at a time almost always are galled with aluminum. Takes half an hour each bolt.

@Bob: 2004 Mazda 6 with the 6 cyl. The serpentine belt was difficult. Transverse mounted engine, and the frame rail was so close to the engine most wrenches (and forget your arm) wouldn’t fit. Also the headlights. In the owners manual it said the dealer had to replace them. You had to remove the battery to get to one of them.

@ChrisH: I have a 1991 Toyota MR2 Turbo. EVERYTHING is hard to reach! But there is one particular item that is so notoriously hard to reach that it has been named “The Hose From Hell.” It is a coolant hose on the block, behind the turbo and underneath the exhaust manifold – essentially buried in the center of the engine. Some people say that it can be changed by removing the turbo and manifold. Ant Anstead replaces The Hose From Hell in the Season 16 Episode 2 of Wheeler Dealers—he removed the entire engine to get to it.

@PaulY: Oil filter on first-gen Honda CR-V. Horizontal, back of block facing firewall. You have to snake your arm in to even touch it, barely enough room for a strap wrench and you will have oil running down your arm as you remove it. Obviously designed for mechanics half my size.

@Nathaniel: 2nd-gen Acura Integra, when you have to replace the alternator. Unbolting the thing is easy enough, but once it’s removed you have to drop the suspension and drive axle on the driver’s side in order to physically remove it from the engine bay and insert the new one. A lot of cursing once into the job and I discovered that.

Quality Isn’t Job 1? (Seven from Ford)

@Steve: As the owner of a 60’s Lincoln Continental convertible, everything!! Very few things are easily accessible and those that are, are probably connected to something that isn’t. As John Cashman once said, “the engineers didn’t design these cars for maintenance.”

@Gary: The transmission dipstick on Gen 1 Ford Raptors. It’s a part the filler cap on the transmission itself, right side, only inches away from the catalytic converter. While the engine is running to check transmission oil, slide under the truck, reach up and unscrew the dipstick cap (the dipstick is only a few inches long) whilst trying not to burn your hand. Small hands are a benefit. Try to read the oil level on the dipstick (flashlight needed) then replace it whilst not burning your hand.

@Alan: Changed out my battery on a 2014 Ford Escape. This should be a 10 minute job. Nope. They buried it so far back that you have to remove the windshield wipers, a bunch of screws and clips and 2 sections under the windshield to get access.

@Slow Joe Crow: On my 2002 Ford F-150 a 5.4 Triton, anything at the back of the engine, the cowl is basically shrink wrapped around it so cylinder head work is horrendous. On the bright side you can still reach in there, later F150s are engine out or cab off.

@Rick J: 1999 Ford F-250. Just about anything in the engine bay except the alternator. The engine sits so far back that plugs, coils, and injectors are ridiculously difficult to get to. I have replaced those components on seven of eight cylinders. If and when those things need replacing on cylinder #4 I’m taking it to a mechanic. It might be easier to replace the entire engine.

@Kyle B: Anything contained in the Subframe for a 1997 Mercury Cougar, exhaust manifolds, oil pan, steering rack and lines, anything to do with the front suspension.

@JU: I just replaced the thermostat housing and temperature sensors on a 2002 Mazda B4000 Pickup. IT was 5 hours to get the housing out, sensors etc. and 5 hours to put back. Wiggle room is almost nil to get parts in and out.

It’s a Jeep Thing?

@George: The wire connector for the coil pack on my 2000 Jeep Cherokee. The freaking thing is barely reachable behind the valve cover and the connector has one of the cantankerous red keepers that are near impossible to set free without breaking.

@Boss302: The flywheel position sensor on my 1995 six cylinder Jeep Grand Cherokee. I had my 10 year old daughter reach up underneath the car through the engine to get the socket on. Her mom never knew!

@Wayne: Jeep Wrangler JK clutch slave cylinder bleed screw. It’s on top of the transmission, and very difficult to get a wrench on. And its impossible to bleed without taking a bath in DOT3, definitely not designed with service in mind.

E V E R Y T H I N G

@Norm: At 81 years old, EVERYTHING.

@Bazemore23: When you are 72 and have had five back operations, anything underneath the dash is a major problem repairing!

@Brian: At my advanced age I find anything under the dash that needs attention is reluctantly taken care of. Major jobs require removing the seat/seats to give the body a bit of relief.

***

Check out the Hagerty Media homepage so you don’t miss a single story, or better yet, bookmark it. To get our best stories delivered right to your inbox, subscribe to our newsletters.

A horse and buggy is starting to look good.

My first car was a ’66 Mustang with the 289 V-8 that had the California smog pump. Even with a swivel head attachment on my socket it was still a knuckle scraper to change the spark plugs

Great article; I did not see anyone mention heater cores – my view is that these are installed first on the factory assembly line, then the rest of the car is built around it.

Until I read all the issues with spark plug access, I had forgotten about access to the rear 3 plugs on an 89 Pontiac Grand Prix with a 2.8 liter v6. Since the engine is installed sideways, the rear 3 plugs are tight up against the firewall with no access to them. You actually need to remove the 2 “dog bone” engine mounts at the front of the engine and then rock the engine forward into the “maintenance position” and then reinstall the dog bone mounts using a different set of bolt holes to hold the engine in position while you change the plugs. This was actually designed this way by GM, but if you don’t know the procedure, you would never figure it out. I had purchased the car used, so didn’t have an owner’s manual and needed to call a dealer to get the procedure. All of the similar GM cars of that era had the same design, so there’s probably thousands of them that never had the rear spark plugs changed.

We had an ‘89 Cutlass International, same design. OTOH I changed the alternator at the side of the road.

I love parts that clearly were not designed with repairing in mind. Put this hard to reach thing against the firewall? Why not, you can always drop the motor, which was the joke with many Audi V8’s. You want to change the headlight bulbs? Drop the motor! lol

Having to remove the passenger side front fender (to replace a heater core) on a late 60’s Camaro or Chevelle is beyond disappointing especially if the paint work is as new and in pristine condition. Yes, I realize a person or person’s can take extraordinary measures and a ton of time to get to this component out but couldn’t the designers and engineers have come up with a fix that would be much less convoluted? When I was restoring my vehicle I made sure that I installed a new core and pressure tested it well in advance prior to the final assembly. I see why ‘some’ folks bypass the heater core rather than pull so much apart. In my situation (if I ever had a core failure) I would have a body shop perform this type of replacement over a conventional mechanical shop. I would be concerned about scratching and body panel fitment during the removal and reassembly process. I also installed ‘Evans’ waterless coolant as a precautionary measure in ‘hopes’ of eliminating / delaying a headache of this nature. Without question there are far worse oversights than this. A neighbor of mine pointed out how ugly a job it was to replace the two rear spark plugs on his V-8 Chevrolet Monza. Rather than mess around with motor mounts, jacks & hoist he wound up cutting access ports on the inside firewall to get to the back ones. Obviously he wasn’t concerned about asthetics. Not something for the faint of heart. Once G.M realized that the rear plugs were not reachable from under the hood why didn’t they make a provision like my buddy (oh sorry, I forgot about the bean counter control over the engineering staff)? This article clearly pointed out which vehicles I’d stay clear of. I can’t help but wonder how many more nightmare repair stories weren’t captured?

Mercedes Solex PHH44 carbs. Two-barrel progressive side drafts. Pair of ’em on the car.

Bottom attaching bolts. If you never bleed on a car it never is truly yours.

XJS- Heater valve on the firewall. Spark plug helper- just accept that you’ll have to loosen and move the a/c compressor a bit.

Oh! Forgot- Any windshield wiper rack on any British car ever built.

The simple task of replacing the oil filter on the 3.0 Liter Ford Ranger was the most difficult simple task I’ve ever had to deal with—as far as simple tasks go. They managed to hide it under the steering box and exhaust manifold and brake lines, and it was barely visible from under the vehicle. There was a funnel built into the frame because as you loosened the filter which was on a 45 degree angle, would immediately start leaking all over the place. You also had a tiny opening from above to pull the old leaking filter up through all this plumbing. It became my 3000 mile nightmare.

Impossible situations force you to get creative, you learn from it and accomplish the task. There`s always somebody else who ran into the same situation and found a way to get around it and may have posted something on You Tube or a specific vehicle/ club blog that can help.

R/R heater box on BMW 2002. Before I did the first one, a mechanic told me ” the way you build a BMW is to put the heater box in the middle of the floor and build the car around it.” He only mildly exaggerated.

Headlight bulbs on a 09 Tahoe & battery R&R (or anything else) on a 07 Saturn Sky.

I owned a 1978 Triumph Spitfire and needed to replace the clutch and slave cylinder. Also had to swap out the transmission because the previous owner drive it with a stuck clutch, destroying all the synchros and gears!

Because of the Spitfire’s X frame construction, the only way to do this job is to remove both seats, the carpet and a large floor panel. Once those were out, the job was easy, except for having to LIFT OUT THE TRANSMISSION BY HAND! The placement if the windshield made a hoist unusable.

On the positive side, the whole front clip of the car (hood and fenders) opens forward to allow the most beautiful access to the motor and front suspension you’ll ever see!

I dropped a McDonalds french fry down between the seat and console about 7 months ago. It’s not even moldy yet. I can see it. I want it. Sadly will never reach it. Someday far in the future some guy in a scrapyard will pull that drivers seat and eat that french fry and enjoy it. And laugh at me……

You have to remember that cars were not designed to take apart. They were designed to be built quickly and efficiently. This is where sub-assemblies come into play. They don’t start with a frame and just add parts one at a time. If you’ve have never worked on an assembly line it’s hard to understand. I never curse at some seemingly impossible part I have to replace because I have no clue as to how or why ìt was put together in that fashion, but believe me there was a reason at the time it was built. Those sparkplugs everyone is complaining about were put in way before the engine was ever dropped in the chassis.