Media | Articles

America’s Most Wanted 4×4: Jeeps Meet Mopar Muscle

On the way to lunch at a local Mexican joint, our marketing and business development contact Ethan Siegwart mats the throttle. The unmistakable supercharger whine of a Hellcat engine emanates from under the hood of the Jeep Gladiator he pilots. But unlike a Hellcat Challenger or Charger, which like to shift and squirm under full throttle, the Gladiator just squats and accelerates at a frightening rate.

But wait a minute. Despite the willingness of parent company Stellantis to Hellcatify seemingly everything, it never had the gumption to put the venerable 6.2-liter supercharged V-8 in a Jeep Gladiator or Wrangler.

Enter America’s Most Wanted 4×4. Located in Holly, Michigan, about 30 minutes northwest of Stellantis North American Headquarters, AMW is an outfit that has been converting Jeeps into high-dollar, big-power off-road machines since 2012.

Even before you walk in to the heart of AMW’s operation, you can tell business has been good. The parking lot is filled with Jeeps awaiting delivery to their owners. Inside, the 32,000-square-foot manufacturing facility packed tight with crate engines, suspension components, and and Jeeps in various stages of completion.

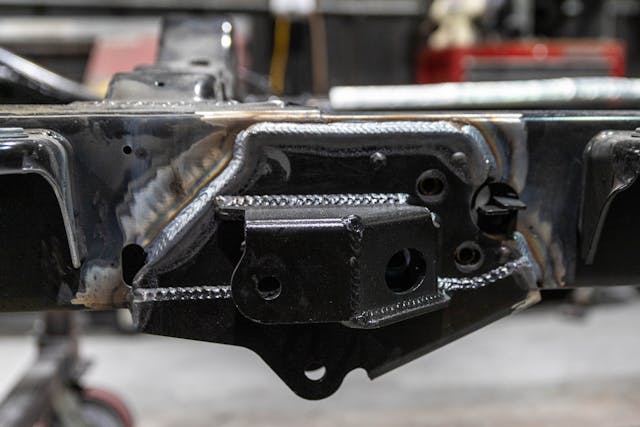

“I dislike the word ‘swap’,” says company founder Jared Petiprin. Indeed, to call the work America’s Most Wanted 4×4 does “a V-8 swap” would be an injustice. Its turnkey Jeeps are about as close to a factory Hellcat Gladiator or Wrangler that you can get. AMW utilizes a plethora of Mopar parts—which includes the crate engines and transmissions—and adds custom-engineered and -manufactured adapters, exhaust systems, and proprietary engine calibration. Stuff that often gets overlooked in an engine conversion, like brackets, tubing kits, and bolts, come from tier 1 and 2 automotive suppliers. Think factory coatings and metallurgy, rather than hardware store specials.

Petiprin’s turnkey mentality comes from a bad experience after installing a lift kit on his 1997 TJ Wrangler. He didn’t understand why he was spending money on the vehicle for it to drive worse, and the lift kit company was unwilling to help solve the drivability problems. Thus, the goal of America’s Most Wanted 4×4 is “to produce an A-to-Z product with 100 percent reliability and accountability,” i.e. deliver a sorted Jeep that you don’t have to futz with.

Marketplace

Buy and sell classics with confidence

Which engine AMW installs depends on how much horsepower you want. Packages range from the 505-hp, naturally aspirated 392 Hemi crate to the 1000-hp, supercharged Hellephant. The demo Gladiator Siegwart sped us to lunch in was a 707-horsepower model, which is one of the most popular packages for AMW’s builds.

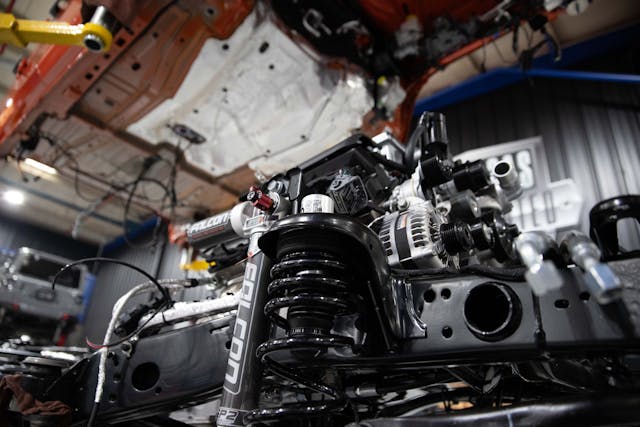

The engine is only half the package for AMW’s turnkey Jeeps, however. Full-float 8-lug axles with ARB Air Lockers are added front and rear. These beefcake axles (8LUG in AMW parlance), which secure the hub with two bearings rather than the stock axle’s single bearing, are added because these builds run 40-inch tires. That extra rotational mass doesn’t play well with the factory axles on or off road—especially when your Jeep is capable of such high speeds. Eight-piston brake calipers front and rear help keep all of that power in check. For suspension, there are two options: the base long-arm setup that utilizes Falcon shocks, or a more off-road-centric, long-travel setup that uses Fox coilovers.

If this sounds expensive, that’s because it is. Turnkey builds start at $160,000. A fully packaged, 1000-horsepower build with long-travel suspension, accessories, and custom paint have neared $350,000.

If that’s too much dough for your budget, AMW offers engine conversions and suspension packages for older Wranglers, like the TJ (1997–2006), JK(2007–18), and current JL. Prices start at around $30K. These conversions have proven to be more popular than the turnkey models, in fact, with 250–300 of them completed by AMW and its 40 certified installers last year.

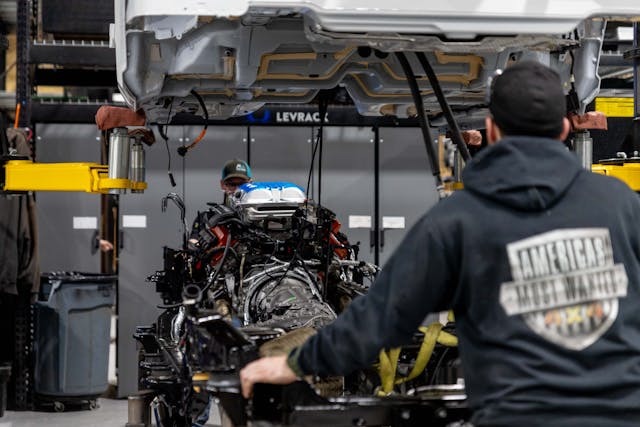

“I build Jeeps because nobody will pay me to build Legos,” muses Petiprin. Indeed, the process for building an AMW Jeep is a bit like a putting together a Lego set. Each new Jeep that comes in to the shop is disassembled and the body is removed from the frame. The frame is then fitted with the engine mounts, suspension, axles, and related components. Next, sound deadening is added to the body, and the seats get wrapped in Tuscany leather. The body eventually gets reunited with the chassis, and everything is reassembled and checked over. It’s a bit like an assembly line, and everything is tagged and organized, depending on what part of the process it’s in.

With the help of 52 full-time employees, over 250 hours of labor go into each Jeep. From the time the vehicle pulls in to the time it leaves the shop, 500 different parts are changed or modified.

So, who’s buying these things? The client archetype for AMW is an American owner of a construction company who wants a high-performance 4×4, but might not want to pull up to a job site in a Mercedes G-Wagen. But AMW’s Jeeps have also been sold to far-flung places like China, the UAE, and Australia. Siegwart says the clients skew more toward daily-driving their Jeeps, but also stated that many of AMW’s creations have logged thousands of miles off road.

And in this context, the AMW makes sense. Why deal with the stigma of a G-Wagen, when you could have a more capable Jeep built with a crazy supercharged engine? Also, you’ll be less afraid to use an AMW Jeep as intended. If you bash a body panel off road, no worries, Jeep parts are cheap and widely available.

Even if you don’t have the money for an AMW Jeep, the world is a little bit brighter with these high-powered off-roaders roaming around.

***

Check out the Hagerty Media homepage so you don’t miss a single story, or better yet, bookmark it. To get our best stories delivered right to your inbox, subscribe to our newsletters.

I understand wanting crazy horsepower but the Wrangler is a poor handling vehicle and with a V8 is a good recipe to die. Supercharged Hellcat motor, 0 – Death = How Long?

Agreed!!!

As an owner of many RT and SRT8 cars and Jeeps it baffles me why there are no factory Hemi 5.7 Wranglers (I mean I even had a Hemi 5.7L Commander), guys were doing swaps before the JK refit in 2012, driven a few they seem like a great setup for them, the weights not much more and the power band is much better then the minivan 3.6L. The 392’s are just overkill in them, but the 5.7 is the sweet spot. For those saying they handle bad, once you change to aftermarket suspension they handle 100 times better, and ride much smother. The real problem is the braking, defiantly want to upgrade that with a bigger motor.

I currently have a 2023 Rubicon 392 Hemi, it’s fast real fast especially for not having the supercharger. Your right about the brakes they could be a little better, I also have a 21 diesel Gladiator the brakes on that are excellent not sure what the difference is. The Gladiator is the one I’m going to build I want to go all out with AMW full treatment 1000 hp, long travel off road lift, axles, trans, brakes, 40” tires, bobbed bed for better approach and departure angles and whatever else they recommend. Does anyone have something similar to this build and can you tell me what you think about it. Thank you for anyone who can leave me good accurate info on their build and no I don’t need the opinions of anyone who thinks it’s a waist or any other negative comments unless it has to do with AMW product itself.