Media | Articles

Model Kids: Decades Ago, GM Put a Call Out For Young Car Designers. Thousands Answered

This article first appeared in Hagerty Drivers Club magazine. Click here to subscribe and join the club.

Once upon a time, industrialists and educators came together to form a national organization for the advancement of artisanal craft skills among young boys. It was heavily promoted in high schools, youth groups, auto shows, and car dealerships across the country. It annually paid out thousands—and then millions—of dollars in college scholarships, and it grew to become second only to the Boy Scouts of America in membership. Its board of directors included the most powerful and influential industry leaders of the day, and invitees to its annual awards banquet in Detroit were flown in first class and chauffeured around in limousines.

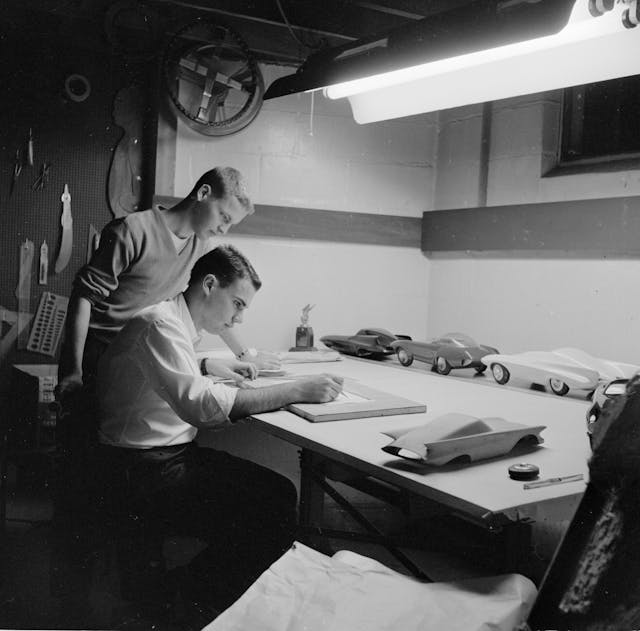

And all a kid had to do to take a shot at securing his educational future was to build a miniature model. Not a plastic job out of a box, as most of us have attempted at one time or another, but an exacting replica of an ancient carriage or a wholly unique creation of their own design, conceived, sketched, measured, clay-modeled, and then constructed entirely from scratch. No help from Dad allowed.

From 1930 until 1968, the Fisher Body Craftsman’s Guild, so named for the coachwork firm that became a General Motors division in 1926, ran an annual nationwide talent search disguised as a model-building competition. The goal was to identify from among America’s teeming ranks of teenage youth the truly exceptional, the kids who had the artistic eye, the crafting skills, and the stick-to-itiveness to complete a phenomenally rigorous craft project.

Regional competitions fed winners to a national finale in Detroit, where a four-day pageant culminated in the awarding of scholarships that topped out at $5000 for the overall winners, a mighty sum in the era. The event also exposed the top echelon of young model builders to the wonders of the American auto industry at a time when it was at its imperial zenith. Naturally—and in accordance with the plan—many of those kids returned as college graduates to work in that industry.

Marketplace

Buy and sell classics with confidence

It’s hard to imagine in the modern age when most people spend their day tapping keyboards or swiping screens that at one time, there were enough boys aged 11 to 19 in America willing to create thousands of model cars every year entirely from scratch. “When I look at my model today, I think, ‘How the hell did I do this?!’” said 1961 junior national winner Tony Simone, now of Bartlett, New Hampshire. “I have to give the Guild credit for giving us skills to use in life. Even today, that attention to detail is still with me.”

“The people who won had mastered discipline before the age of 20,” said Robert Davids, who was a 19-year-old Venice, California, pinstriper and surfboard shaper when he won the 1963 senior national award and a $5000 scholarship by carving a dramatic three-seat bubble-top coupe out of yellow poplar wood. For a year, Davids said, there was no girls, no dates, not even haircuts, only work during the day and then the model at night, typically until 3 a.m. “Every single disciplined person who entered was going to do OK in life, but the winners excelled at an early age.”

Then, as now, there was free money around if you could throw a ball or converse in mathematical theorems. Sports and academic scholarships have long been familiar avenues for teenagers from disadvantaged backgrounds to access the realm of higher education. The Fisher Body Craftsman’s Guild stood apart by being a scholarship program based mainly on manual skills of the type one learned in the shop classes that were once commonplace in high schools.

“Here was a take-home, industrial arts aptitude test that identified teenagers with innate artistic ability, creativity, imagination, spatial relationship acuity, manual dexterity, aesthetic eye, good taste, a propensity for perfection, and high intellect,” wrote John Jacobus, a Guild member in the 1960s whose later historical research for the Smithsonian Institution resulted in a book on the subject, The Fisher Body Craftsman’s Guild: An Illustrated History (upon which our story is heavily dependent). The skills that the model competition prioritized, he added, “were all qualities sought after by the auto industry.”

The inspiration of William A. Fisher, one of the seven Fisher brothers who had transitioned the family carriage business into a hugely successful vehicle-body supplier, the Fisher Body Craftsman’s Guild launched on August 25, 1930, with radio and print ads and large posters plastered to the windows of Chevrolet, Buick, Viking, Oldsmobile, Cadillac-LaSalle, and Oakland-Pontiac dealerships. The posters as well as promotional booklets lured boys with the promise of a share in the unimaginable sum of $75,000 (about $1.3 million today). Nearly 150,000 signed up the first year, just over 400,000 the second, records Jacobus.

The need was great. The Great Depression was already beginning to grip the country following the October 1929 stock market crash. The ranks of the unemployed were swelling, and fewer and fewer families had the means to offer anything more to their children beyond a life of hardscrabble toil from the earliest age. Amid the bread lines and the whispers of worker revolt and communist revolution, big ideas floated around about the very nature of work and the role of individuals in societies that were rapidly urbanizing and industrializing. “It is the sincere desire of the builders of Bodies by Fisher,” extolled a 1930 ad for the Guild in The Saturday Evening Post, “that tomorrow shall see this country peopled by men to whom honor can be given for their ability to design well and build soundly whatever their generation may require.”

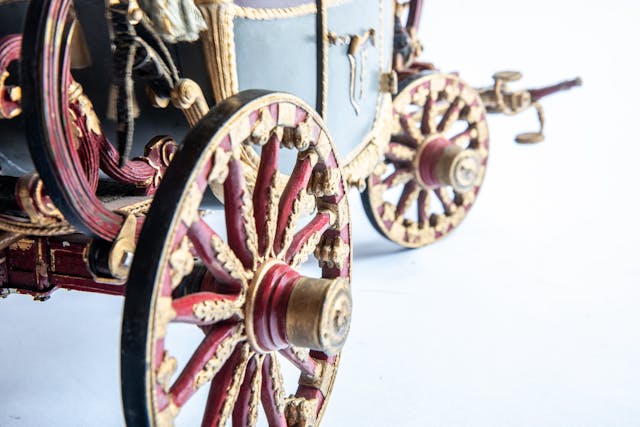

The competition’s challenge was as daunting as the prizes were lavish. Early competitions required entrants to produce a detailed wood-and-metal replica of the ornate Napoleonic carriage that appeared in the “Body by Fisher” logo (ubiquitous on GM cars produced from the 1920s through the 1980s). Builders had to construct an 18-inch-long, 10-inch-high scale model complete with metal filigree, opening doors, and upholstery-lined interior using only blueprints and a 25-page instruction booklet that the Guild provided. It’s believed that two master models were produced over six months by craftsmen at Fisher’s Pennsylvania-based Fleetwood Metal Body division and that their time estimate to make a copy from the plans was 1600 hours.

Which helps explain why out of the millions of boys who signed up to the Guild in those early years, receiving their free pamphlet, membership card, and diamond-shaped Fisher Body Craftsman’s Guild pin, only a few thousand coach models were ever actually produced. Enterprising model companies developed kits to speed the builds, but even those were crude by today’s standards—just a few blocks of unshaped wood and some metal—and they still required enormous skill and patience to turn into viable entries. By the time the coach idea was dispensed with entirely in 1948 (the Guild paused its activities during World War II), it’s thought that only around 7000 carriage models had been built.

As it happened, the contest that replaced it wasn’t much easier. It asked entrants to build a 1/12th-scale concept-car model entirely of their own design. Believed to have been heavily pushed by GM’s first and renowned styling chief, Harley J. Earl, the concept category debuted in 1937 and the Guild fully pivoted to it in 1948. According to the late Charles E. “Chuck” Jordan, who won the 1947 competition and went on to become vice president of design at General Motors, the coach project was handicapped by the fact that “no individualized characteristics or personal creativity were sought—the coach was in the strictest sense a craft project, with no variation sought or accepted, saving excellence in detail or finish.”

That was fine in 1930 when, as the author Jacobus notes, car bodies still employed lots of timber as well as hand-finishing. Originally, the Guild was created to ferret out promising pattern- and toolmakers. But as the industry evolved, stamped-steel mass production took over and styling rose in importance. The talent need shifted away from an increasingly low-skill and automated production floor and toward the newly created styling studios, where designers and clay modelers were tasked with envisioning tomorrow’s vehicles. It’s no mere coincidence that the Fisher Body Craftsman’s Guild turned its attention to futuristic concepts almost at the same time Earl unveiled the industry’s first concept car, the 1938 Buick Y-Job.

In an age before the time sucks of television and computers, when more families made their living doing manual labor in factories or on farms and college seemed like a faraway dream, plenty of kids were willing to gamble their free time and their sweat on a long shot like the Fisher Body Craftsman’s Guild. And it was indeed a long shot. Though the posters advertised the riches available to winners, fewer than 400 scholarships were awarded over the 34 years the Guild was active (though smaller prizes were distributed at the regional level). During that time, 10 million American boys signed up—girls were allowed only in similar programs run by GM’s European and Australian subsidiaries—from which about 33,000 models were produced.

Despite the odds, it was worth it to kids who saw little opportunity elsewhere. “My father was a machinist and a toolmaker during World War II,” said Tony Simone, the ’61 winner. “One night, he came home and told my brothers and me to come to the dinner table, and he said, ‘I can put a roof over your head and food on the table, but I can’t afford to send you to college.’ [The Guild] was a lifeline, and I’m just one story out of thousands and thousands.”

Davids, the ’63 winner, was born the son of a soybean sharecropper in Franklin, Missouri. “My mother told me, ‘You don’t have a chance. People like us don’t win things like that.’”

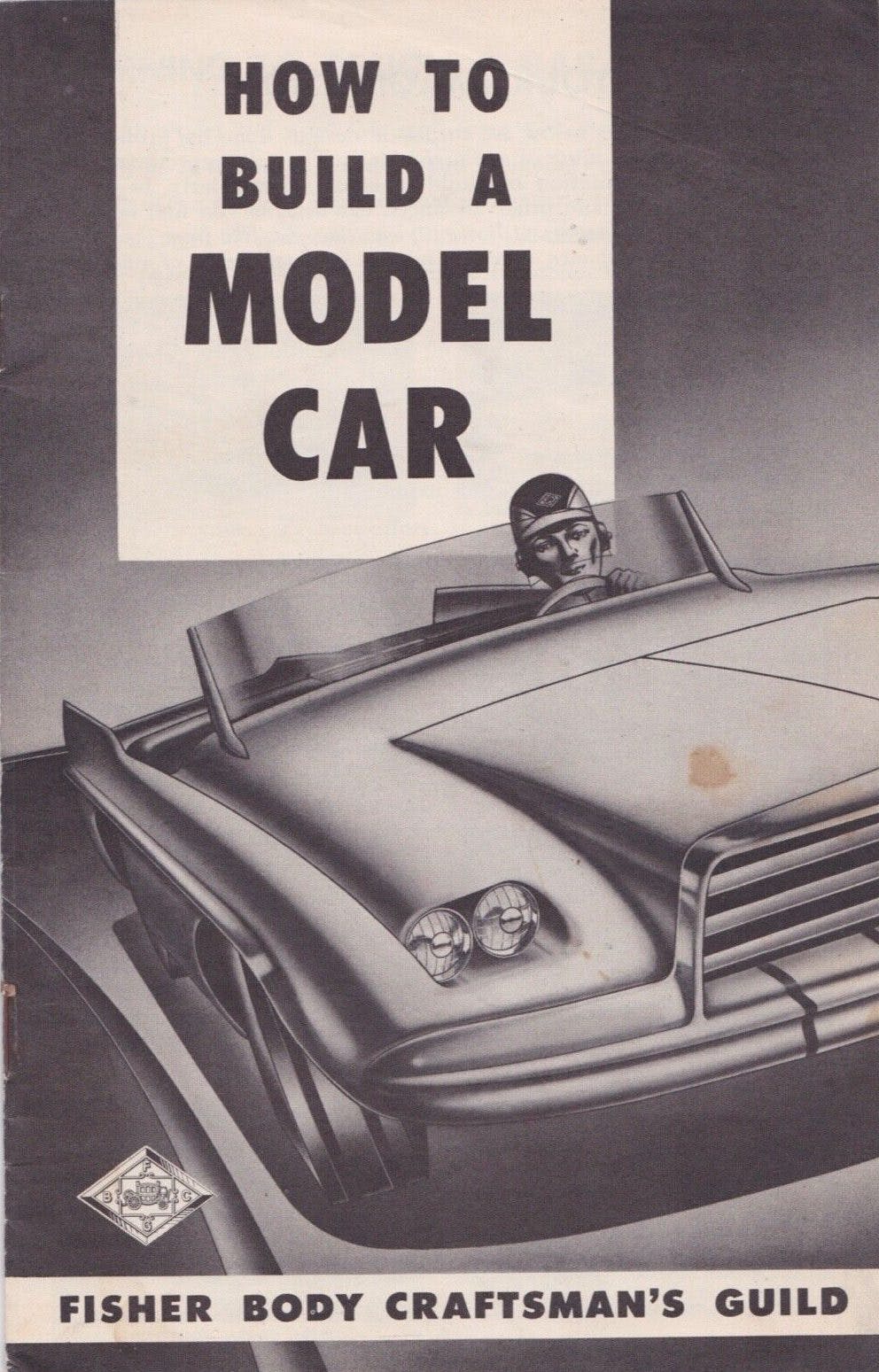

Keenly aware of the challenges facing its members, the Guild produced a booklet called “How to Build a Model Car” with illustrated step-by-step instructions, starting with the basics of vehicle design. Cartoons showed readers how a low, curved roof and a long wheel-base was more aesthetically pleasing than a short wheelbase under a tall, boxy roof. It encouraged doodling of headlights and taillights, of fins and windshields and different types of exterior decoration such as hood ornaments and faux jet exhausts. It gave instructions on how to make a clay model, a wood model, or a plaster model from your drawings, how to get the wheel-to-fender clearances right, how to curve a piece of translucent plastic to make a windshield, and the best ways to apply paint. It included plan drawings of coupe and sedan/wagon cockpits, giving builders an accurate size template to sketch around.

In addition, a bimonthly newsletter, called the Guildsman, was full of tips as well as profiles of working designers and interviews with past winners. Typical headlines: “Four Hundred Pleasant Hours of Work: How Ken Kaiser built a $2000 Winner.” And, “Use Proper Plaster—Avoid Breakage; Hydrocal and Dental Plaster Good.”

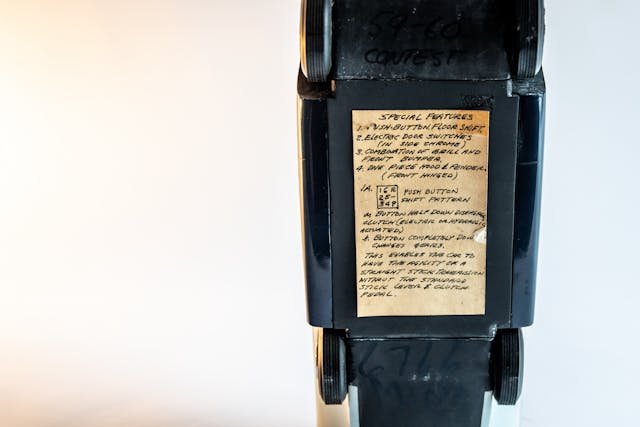

“Headlights can be made from the ends of small, inexpensive screwdrivers,” read one how-to column from 1959. “The end of the handle is sawed off, filed, and mounted. The parabolic shape of the end looks much like an actual headlight.” To make things easier, aspiring builders could send to the Guild for a free set of prefinished wheels (sans hubcaps, of course, as those were up to the builder). The newsletter reminded builders not to forget rule No. 7 of the 13 compulsory rules, which required the models to have provisions for license plates front and rear.

David Courtney, now of Lomita, California, remembers as an aspiring car designer in small-town Illinois reading in the Guildsman a tip that taillights could be cut from the ends of toothbrushes there were made out of transparent red plastic. “I had those red toothbrushes for years,” he said. But like a lot of aspiring entrants, Courtney never completed the two models he began, one of which, an attractive Camaro-like roadster crafted from wood, he still has. “I had a handsaw, a file, a drill, and a 4-inch vise. That was it. As a result, my designs were pretty limited, and how to go about making it, I had no idea.”

Davids, the ’63 winner, attributes at least part of his success to knowing some past winners personally, and to obtaining a mailing list of others so that he could write them. Thus, he learned before starting the high standards that were expected. “One of the things you heard was detail, detail, detail. And you had to be authentic; you can’t polish aluminum until it looks like chrome. It has to be chrome.”

Most kids didn’t have ready access to chrome shops or much else that was needed to build a winning model from scratch, so the Guild encouraged its teenage members to be resourceful. Davids knew he wanted to put a fully enclosed bubble-top roof formed from 1/16th-inch-thick plastic over a fully finished interior, a feat that had never successfully been attempted in the competition. Not only that, but in his design, the car’s rear had a dramatic duct-like channel molded into the roof that carried through the rear glass into the trunk, an absolute showstopper—if he could pull it off.

To make a roof from his hand-carved molds, Davids needed a vacuum former, but having no money, he hit the scrapyards and salvaged an electric motor from an old refrigerator and a surplus vacuum pump from a B-52 bomber, kluging a working machine together. “I made 20 to 24 attempts to make the roof, from which I got two, one that was perfect and one that was almost perfect. I put the perfect one on the shelf and used the almost perfect one to build the model around. When I was ready, I finished the model with the perfect one.”

Ron Pellman, who entered four competitions from 1956 to 1960, the final year taking second place and a $4000 scholarship, remembers scouring his native Buffalo, New York, for materials. A local lumberyard was willing to plane him some 7/16th-inch-thick poplar boards into which he cut, piece by piece, the rough outline of his car in sections. He then glued the sections into a multilayered sandwich, dripping india ink into the glue so that the seams would help act as guides as he began chiseling, planing, and sanding the model to its final form.

Finding a chrome shop willing to finish Pellman’s tiny bumpers to competition standard proved fruitless. Finally, a tradesman in a shop down by the Niagara River that did hard-chroming of engine parts for Great Lakes freighters was willing to give it a try—and spent a solid week chroming, filing, filling, and re-chroming the parts until they gleamed with smooth perfection. Recalled Pellman with a chuckle, “I asked him what I owed him, and he put his hand on my shoulder and said, ‘Son, you could never afford it.’”

The Guild had a few family dynasties, including Simone’s who, with his two brothers, entered a total of 15 models, winning a combined $10,000 in scholarship money. He credits part of his win to getting insider intelligence from his older brother, who was treated to a tour of GM’s design studio while attending the 1959 awards. “He came home from Detroit and said, ‘Forget the tailfins—they’re gone.’”

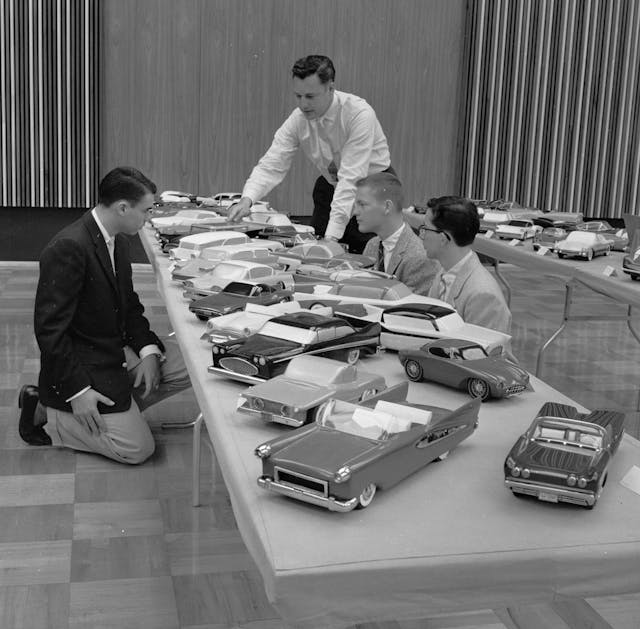

In order to ensure a geographic and age distribution of winners, the Guild divided the nation into regions and its entries into junior (11–14) and senior (15–19) divisions. In order to be eligible for the national scholarship competition, you had to do well in the region, then box up and mail your model to Detroit—instructions were included in the newsletters on the best way to safely crate it for shipping—to be judged for the national competition on a points system that split the criteria between the quality of the design and the workmanship of the execution.

Special telegrams notified the 40 finalists for the scholarships—20 each in the junior and senior divisions—who were invited on an all-expenses-paid trip to the Fisher Body Craftsman’s Guild National Convention and Banquet. Parents were not allowed; the Guild members traveled from the far-flung corners of America on their own, with GM personnel detailed as escorts to help the kids transit at layover airports and train stations.

Simone vividly remembers his trip in 1961 from his home in Rhode Island. “I have to admit, I was in shock. I didn’t know nothin’, I was 15 and had never been out of Providence before.” He flew in a small plane to the old Idlewild Airport in New York, where a GM representative met the wide-eyed teen and walked him to his next flight. “The Boeing 707 had just come out, and they put me on a brand-new 707 jetliner—and here’s the kicker: We went first class.”

Following a dinner of filet mignon, they flew to Detroit, where Simone was directed to a Cadillac Fleetwood limousine that whisked him and some other arriving Guild members to the downtown Book-Cadillac Hotel. There, the group was intercepted by a team of tailors that measured the kids with military efficiency. “Overnight,” remembered Simone, “they made me a whole suit with the Fisher Body Craftsman’s Guild logo on the jacket.”

The next day, after a sightseeing trip around Detroit, the finalists were ushered to the banquet hall where Fisher Body gathered around 800 managers from GM’s vast design, engineering, and manufacturing organizations as well as top scientists, newspaper writers, politicians, and celebrities. Guild members in their matching new jackets sat in rows on a long, terraced dais while the event was presided over by emcees who were luminaries of the day, including Father Knows Best actor Robert Young, broadcaster Lowell Thomas, and TV newsman Walter Cronkite.

Seated in the crowd were typically some of the towering figures in GM history, including Alfred P. Sloan and Charles F. “Boss” Kettering. Judges included Harley Earl, his successor Bill Mitchell, Chrysler design director and tailfin czar Virgil M. Exner (a Guild winner himself), and rising young design star Chuck Jordan. The evening culminated in the scholarship awards for the top three models in the junior and senior divisions plus five honorable mentions each, usually announced by the president of GM or his second-in-command to uproarious cheers from the audience.

For the next few days (as GM photographers quietly snapped detail photos of every model to be studied later for possible inspiration), the young Guild members were squired around the region, visiting GM’s gleaming Technical Center, touring its design studios, and seeing and touching the dream concepts they had only read about in magazines. Dinners were lavish affairs at local country clubs. Pellman remembers going to a furniture factory and taking a Detroit River cruise to the Boblo Island Amusement Park. There were informational presentations by officials from the FBI, visits to Fisher Body assembly plants, and trips to the nearby Selfridge Air Force Base to sit in jet fighters and meet their pilots.

“If you won, you were on a roller coaster ride for a week,” said Davids. Winners were interviewed in newspapers and on the radio, and even appeared on TV talk shows. Their high schools received their own towering trophy, and their models went on a national victory lap of dealerships, corporate offices, and exhibitions, at times aboard GM Futurliners that once roamed the country touting the corporation’s industrial exploits. Many builders didn’t see them again for two years.

“It opened up a lot of doors for me,” said Davids, who went on to live a number of lifetimes, including fabricating body panels for Craig Breedlove’s 526-mph Spirit of America land-speed car, earning several college degrees, doing a stint running GM’s experimental design studio, operating a casino, launching a company in the late 1970s to design and manufacture some of the first hand-held electronic games sold in toy stores, and starting a winery specializing in pinot noir.

Other Guild alumni, like Jordan, Exner, Richard Arbib, who worked for years at GM as Harley Earl’s right-hand man, and Pontiac, GMC, and Hummer design chief Terry Henline, forged long and successful careers in the auto industry, often after Guild-funded degrees from the famous ArtCenter College of Design in Los Angeles. Still others went to work in aerospace, academia, product and packaging design, and varied pursuits in engineering and manufacturing. William A. Fisher’s plan to seed the American economy with capable, tenacious, hands-on thinkers had worked brilliantly.

However, even in 1963, the end of the Guild could be predicted. “It was a happy moment,” said Davids, “but the Beatles came out the year after I won, everything was changing, and kids were getting kind of crazy. There just weren’t enough who were disciplined.” Entries dropped precipitously through the 1960s, records Jacobus, from more than 4000 in ’63 to fewer than 2000 in 1967. Model quality also declined. Besides the social changes, which included more distractions and time demands on young people, GM was eyeing the multimillion-dollar costs of the program as new safety and emissions regulations threatened to squeeze Detroit in a financial vise.

And so, along with the fading of the program’s originator and patron, William A. Fisher, who died in 1969, the Fisher Body Craftsman’s Guild expired as well. A reunion of Guild members at the ArtCenter College in Pasadena in 2016 led to an effort by former members to conserve as many models as possible, and there are now permanent displays in several museums around the country (see below).

As time thins the ranks of the Guild’s surviving members, it’s worth remembering an era when so many teenagers dreamed of a career designing cars. And when the auto industry was clever enough to devise a productive scheme to harness and focus that youthful energy, simply because it recognized that its future, as well as the nation’s, depended on it.

***

On Display: Where to See a Fisher Body Craftsman’s Guild Model

Petersen Automotive Museum

30 models, 1 coach

Los Angeles, CA | petersen.org

***

Gilmore Car Museum

50 models, 1 coach

Hickory Corners, MI | gilmorecarmuseum.org

***

AACA Library & Research Center

26 models, 1 coach

Hershey, PA | aaca.org/library

***

Piston Palace

20-plus models, 1 coach

Warwick, RI | pistonpalace.com

***

National Route 66 Museum

8 models, 1 coach

Elk City, OK | elkcity.com

***

National Automotive & Truck Museum

5 models, 1 coach

Auburn, IN | natmus.org

***

National Museum of Transportation (Coming Soon)

10-plus models, 2 coaches

St. Louis, MO | tnmot.org

Check out the Hagerty Media homepage so you don’t miss a single story, or better yet, bookmark it. To get our best stories delivered right to your inbox, subscribe to our newsletters.

I participated in 1965 during my 8th grade year. They sent an envelope containing 4 hard rubber tires and instructions. I made my car from Bondo coated basswood and was painted sapphire blue with an aluminum colored painted windshield. My “masterpiece” looked like a combo of a Corvette, Olds Tornado and a Honda Insight. The cockpit area had a deep retracted roof-line area with raised continuous vent that extended the width of the windshield. The car model was returned to me with a mere participation certificate. Really, what were they thinking? I’m holding out, 59 years later, that I’ll receive a letter soon from GM telling me there had been a mistake and that I had actually won. Matter of fact, believe I’ll just get me a lawn chair and go sit out there by the mailbox. Wow. Maybe a Pontiac Aztec will go by, too.

Two history books about GM’s famous Fisher Body Craftsman’s Guild design competition for young men are available online from McFarland & Co., Publishers, Jefferson NC. (Title #1) The Fisher Body Craftsman’s Guild: An Illustrated History (2005) by John L. Jacobus and (Title #2) “Inside the Fisher Body Craftsman’s: Contestants Recall the Great General Motors Talent Search,” (2012) Edited by John L. Jacobus.

I was a FBCG national award winner in 1956.

Winning this award allowed me, a student in the Chicago public schools, to attend college at Harvard University. My guild scholarship not only paid the tuition but was (in retrospect) unique enough to improve my chances of admission?

Like many other “Guildsmen“, I pursued a career in medicine-we all became surgeons. The skills required to build a model car and to pursue a surgical career are not dissimilar.

To this day, the car hobby remains my a source of great enjoyment to me.

I Just found this article and found it very interesting, since I (not my father) won 1st. Junior Scholarship ($4000)

in 1946 when my father was the Chief Designer at Studebaker in South Bend. I was 13 and believed to be the youngest ever winner. My father had been the chief designer of Pontiac styling when he worked for Harly Earl

at G.M. and was sent to Dallas Texas to be that area’s judge of the first F.B.C.G. to include car models.I used the scholarship to be able to go to Cranbrook School for my Junior and Senior years, then on to Notre Dame

where I earned my Masters Degree, won a model car gold medal, taught there, and the rest is design history.

My 5 cars are on display at the Buena Regional Middle School, Weymouth Road, Buena NJ 08310. Onwe was a regional winner and another was in Motor Trend magazine