Media | Articles

The Willock Swivel put a (literal) twist on Dodge’s Power Wagon

In the period immediately after the second World War, the vast forests and mountains of the Pacific Northwest were ripe for exploring. They are still so today, veined by thousands of miles of forest service roads and backwoods trails, filled with mountains, trees, deer, and the odd quizzical bear. In such an environment, the mighty Dodge Power Wagon proved the ideal tool for many a forester and frontiersman. However, some thought even its capable four-wheel-drive system needed a twist.

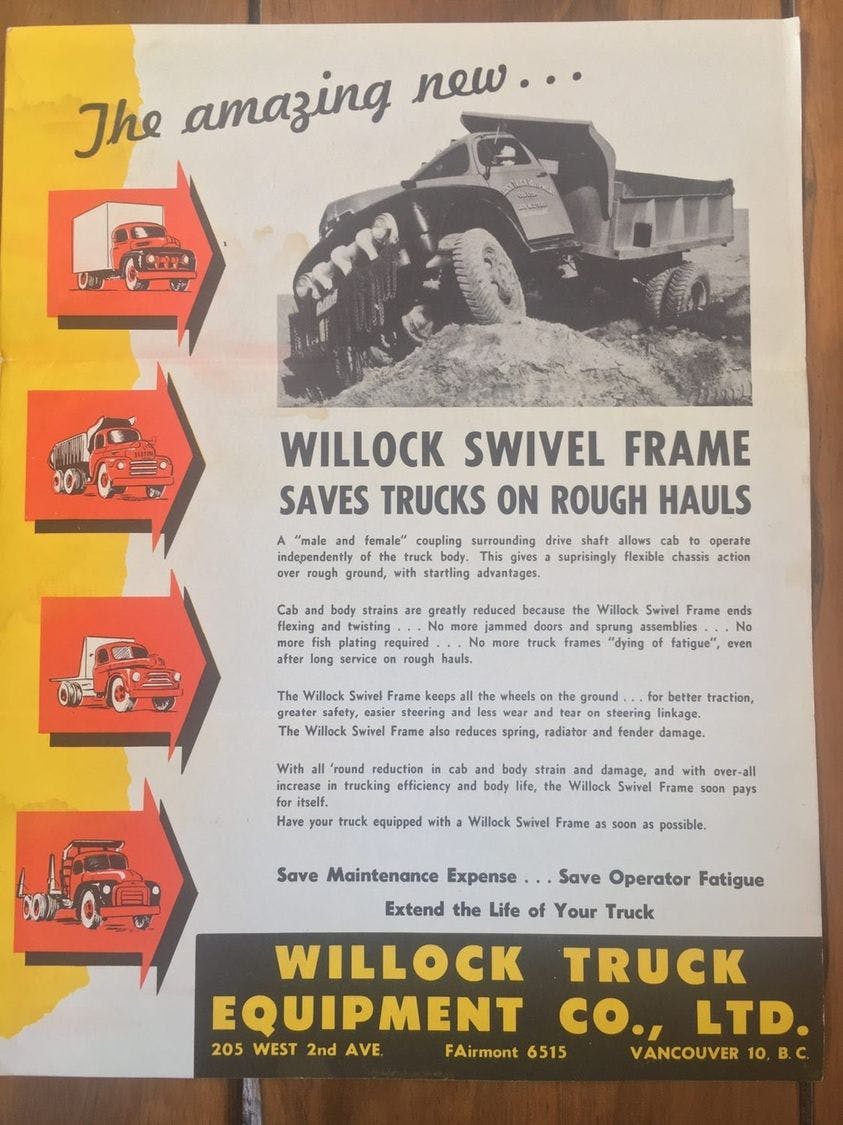

This big beast, still wearing the patina of a hard-working life, is that twist. Literally. Just aft of the cab, its frame has been bisected, the cut rejoined with a clever hinge called the Willock Swivel Frame. With Canadian patents dating back to 1944, the Willock was a simple yet ingenious idea that worked well enough to be fitted onto roughly forty Power Wagons (and an unknown number of heavier trucks) over the years. About a dozen survive.

This one, a 1953 model which you can see exhibited at Los Angeles’ Petersen Automotive Museum until late April, belongs to Jonas Smith, who lives in rural Washington. He uses it properly.

“When [The Petersen] called, I told them it was far from perfect and that I still had half a cord of firewood in the bed. They said that’s exactly what they were looking for—I told them, great, but you don’t get the firewood.”

Smith is currently the custodian of two Power Wagons and figures he’s owned about thirty over the years. Originally a fan of early Jeeps, he spotted one of the big Dodges while on an off-road expedition.

Marketplace

Buy and sell classics with confidence

“I was just done,” he said, later adding, “They’re like potato chips. You can’t just have one.”

A Power Wagon makes for a thickly sliced, kettle-cooked crisp. Descended from the military-spec trucks that Dodge built to support the Allied armies, the enclosed-cab, 1-ton civilian version was one of the first four-wheel-drive trucks available to the public. It wasn’t exactly quick, but its 94-hp, 230 cubic-inch straight-six was durable. The Power Wagon had earned a reputation for toughness in the field, and ex-servicemen who knew its virtues well helped convince Dodge to bring it to market.

Equipped with a deep-sided, eight-foot box, the Power Wagon could carry pretty much anything to pretty much anywhere. However, these were the days before locking differentials became commonplace, and Power Wagons could find themselves teetering over uneven terrain with a couple of wheels in the air, spinning uselessly.

The Willock solution looks crazy, but it works. There’s little documentation on its original inventor, Harry Edward Willock, but if you wanted the company’s swivel technology installed in your truck in the 1950s, you could head down to West 2nd Avenue in North Vancouver. The Willock Truck Company claimed that its device extended the life of a working truck and “saved operator fatigue.”

The technology was originally applied to heavy two-wheel-drive trucks used in tropical sugar cane fields of the Philippines. Over time, constant flexing combined with the warm, wet climate opened cracks in the frame, sending a truck to the scrapyard prematurely. A Willock swivel made such flexing friction-free and preserved the trucks’ working lives.

Back in the equally damp but more chilly Pacific Northwest, the Willock swivel suited the Power Wagon well, giving it the chance to put down power no matter how broken the terrain. The B.C. Forestry Service used these articulated beasts, and some made way south of the border. Energy companies used the customized Power Wagons as refueling vehicles when cutting paths for power lines, since they were one of the few designs that could keep up with the Caterpillar excavators.

The swiveling design is brutally simple. The truck frame is cut in half, and then two enormous crossmembers are welded in. The bushings for the swivel are bronze, with brass sleeves and clever lubrication to resist corrosion. Because the swivel was designed for trucks larger than the 1-ton segment, it looks like it could hold two halves of a container ship together. In a Power Wagon application, the rebuilt spine was reportedly very reliable. The modification would set you back $350.

Why can’t you get a Willock Swivel in your 2022 Ford Raptor? The march of technology, for one, and a few pesky safety concerns. Smith reports that the swivel has an unlimited range of motion, and the driver has little seat-of-the-pants feel of where the load sits in the bed. With a heavy enough burden, on uneven ground, the whole thing might flip.

Further, the Willock doesn’t come with any way to lock the center joint in place once you trundle onto more civilized roads. Smith added some limiting chains for safety and has tested out his Power Wagon in Hollister, California. It’s the same venue used to host the Top Truck Challenge, and it’s also where Smith discovered the Willock swivel’s Achilles’ heel.

Smith often tests out various off-roading upgrades. One of his Power Wagons is basically a rolling laboratory for modern solutions on a vintage truck. He had fitted locking differentials to the Willock truck for the test and reports that the two technologies didn’t mesh—the rear end of the truck developed some disturbing behavior.

As locking differentials became more common in four-wheel-drive trucks, customers found that it was far easier to lock their trucks’ axles than make an appointment to have their vehicles cut in half. Even so, there are reports of swivel-equipped Fords being used into the 1970s, and the last filings of the Willock company itself end sometime in the mid-1980s.

Despite his familiarity with the Power Wagon breed, Smith had never seen a Willock-equipped truck before he stumbled across this yellow 1953 model. The swivel had been welded closed at some point in its life, and the current owner was unfamiliar with what its function, assuming the joint was simply a botched repair to an old truck.

Since restoring the swivel’s range of motion, Smith says he’s seen two other Willock-converted trucks in person. The Power Wagon community guesses about a dozen survive. There are also a handful of other swivel-equipped trucks from other manufacturers lurking in the stranger corners of the pickup world, but the Willock company appears to be the earliest producer of the heaviest-duty design, and the percentage of Willock-modified trucks that remain today is testament to its robust build quality. The aftermarket—and manufacturers—have since found better and safer ways to improve off-road performance, but, decades later, they’re tapping into the same creative spirit that birthed the wild, center-hinged Power Wagon.

my name is James Minnis and i lived in fayetteville nc and i am having trouble finding auto parts for my 1981 toyota celica Gt. i have had my car since Jun 1983 and it only has 83000 miles. I need help becuase i donot want to sale my car.

My friend Thomas Strand of Victoria B.C. Canada has one of these but unfortunately the swivel mechanism got damaged and does not function any longer, but i still love the truck. It was our saving grace in 18 inches of snow that another friends Chevy Blazer couldn’t get through

Wish I had that dodge power wagon at 72 years old my days are number

Harry Willock was my grandfather. I would love to see that yellow truck🥰