Media | Articles

Meet the “Pumpkin”, a Dodge snowplow truck looking for a second act in the sun

Unlike Charlie Brown, I didn’t have to hope to see the Great Pumpkin this past Halloween weekend. I knew exactly when it was coming.

My cousin Dave’s 1979 Dodge W150, in its perfect-for-the-1970’s orange hue, is a natural namesake for the legend from Charles Schulz’s cartoon special. Given its Sweptline long bed, slight lift from the factory to accommodate the full-time 4×4 drivetrain, running lights over the cab, and of course, that color, the Pumpkin has presence enough to shame any bro’d out modern truck.

The big orange Dodge arrived courtesy of a Hagerty-insured flatbed delivery for its second winter stay in my barn a few Saturdays ago. What started off as a barter deal has evolved into a long-term resto-improvement relationship with the Dodge and with Dave. that started something like this: I needed help. My wife and I have a horse barn behind our house, and over COVID we decided to better equip it to accommodate her (expanding) cut-flower garden hobby and my (expansive) automotive habits. We reached out to Dave, an electrician and generally very handy dude, seeking aid in projects that required adult supervision. He happily assented and asked if, in exchange, I would assist him with his ailing pickup.

The Pumpkin’s 360 had thrown a rod and was idly taking up space in Dave’s driveway, unable to fulfill its destiny as a weekend Home Depot hauler and cruiser for Dave and his son Jimmy. This could not stand. I’ve taken the engine out of my Miata race car more times than I can count, and I’ve replaced my Volvo 850 Turbo’s engine once (and then pulled it a second time to slap a manual transmission on it several years later), so pulling the front end off an old pickup and swapping in a replacement mill to get Dave and Jimmy back on the road was right up my alley.

Dave and I are about ten months apart in age, and though he grew up in Ohio and I in Virginia, we’d spend a portion of our summer breaks together, often at our grandparent’s house in Richmond Heights, Ohio. Our Grandpa John would take time to teach us how to tackle projects, whether it was fixing a flat tire on a bike or the way to sand furniture just so before staining it for a perfect finish. Whatever the task at hand, it usually involved a trip to Fatica Hardware, a long since closed little shop that had absolutely everything we could want despite being the size of a Starbucks. This version of summer school enabled from an early age our collective breadth of DIY know-how. Once we started adulting, Dave and I didn’t see much of each other besides the usual holiday gathering, much less work on something together. Thankfully, the Pumpkin would change that.

Marketplace

Buy and sell classics with confidence

The W150 was a fulltime 4×4 version of Dodge’s pickup line, and with that stout drivetrain many served as plow trucks across the North and Midwest. Dodge even had a trim called the Sno-Fiter, which came equipped from the factory with a Meyer plow frame and controls in the cab on the bottom left of the dash. The Pumpkin, while not a Sno Fiter, did spend the better part of its 40-plus years pushing snow. It also had the good fortune of being endowed with the second-most powerful engine offering, a 360-cubic inch LA V8 with a two barrel carb, making 155 horses and 270 lb-ft of torque.

How did a plow truck, once regularly soaked in the briny slush of Northeast Ohio winters, become a survivor intended to carry hay bales and usher a father and son across farm country just for fun? Oil. Lots and lots of it. Perhaps a proprietary blend—I’ve learned some old plow guys would mix linseed oil and automatic transmission fluid and mist it across the undercarriage and anywhere else that might see salt and moisture. Whatever the case, it worked—the only rust issues are minor and in the floor pans, giving us a project for the coming winter.

Last year, though, just to work on the Pumpkin without looking like I’d fallen into the La Brea Tar Pits, I went through about a pallet worth of degreaser to gently remove the years of goopy protectant from the frame and engine bay.

Disassembly is easy, but I impressed upon Dave that with any project, especially one that would likely span a few months, keeping track of what goes where is critical. I go with the not-so-attractive-but-functional blue painter’s tape with sharpie method to label the to-and-fro of wires and hoses. Ziploc bags for hardware help, too. I admit to semi-organized piles for larger parts, like laying aside the grill and front fascia with hardware adjacent—this was not operating room levels of organization by any stretch.

We painted the new-to-us engine I sourced from a racing contact and picked up a new mechanical fuel pump, plugs and wires, hoses, hardware, and a few other things to facilitate the replacement. With each part of the rebuild I’d take some time to share the why of what we were doing. On weekends that didn’t involve working on the Pumpkin, Dave would teach me how to bend conduit, proper wiring for switches and sockets, and help with carpentry. Years of lost time flowed easily over weekends of shared work.

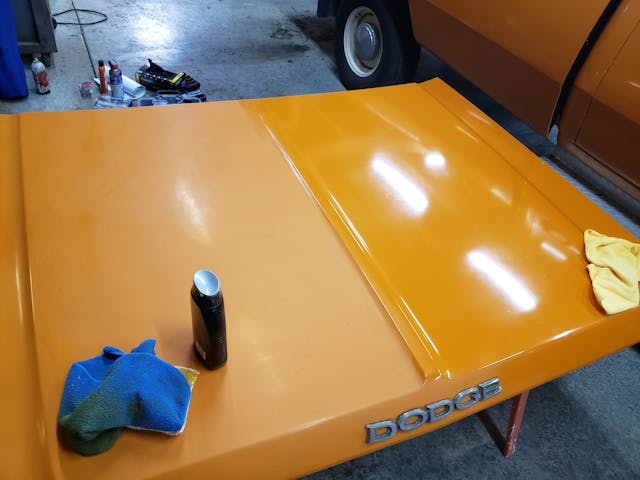

Whenever I read about car projects on forums, the snowball effect never takes long to appear. “Well, I noticed X, so I decided to Y …” It was no different with the Pumpkin. I ordered new shocks because they’re an easy job and the old ones had long since lost what dampening prowess they once had. I got sick of looking at the faded single stage paint so I buffed it to a nice shine. Pretty soon, Dave and I had quite a list of next steps to tackle—before we’d completed the original objective, of course.

Spring rolled around and we finally managed to get everything hooked up. With fuel, spark, and some starting fluid, the Pumpkin chugged to life. Even though I was able to make some adjustments to get it running smoothly, this was my first time playing with a carburetor (yeah, really, am I even a car guy?), and I wanted a more experienced hand to check my work. I’d have hated for Dave to be left on the side of the road by my doing, so we sent it off to another friend to make the final tweaks.

It turns out the electrical system on these old Dodges can be a bit … intermittent. Evidently owners often keep a spare ignition control module handy at all times, and it would appear that cut up harnesses from adding the plow rig those years ago aren’t helping the cause, either. Dave and Jimmy got a few hundred miles of use out of the truck this summer. That’s better than a dead truck in the driveway, but it’s not good enough. Among the first things on our list this winter is wiring and addressing electrical gremlins. Down-the-list items include swapping over to a round headlight grille from the original four rectangle setup, and replacing those rusty floor pans, along with several other odds and ends.

Even though the Pumpkin didn’t arrive under its own power this year, I was glad to see it. Around here, older Ford F100s or Chevy Square bodies wander around occasionally, but rarely does a ‘70s 4×4 Dodge cross your path. We get to be the stewards of this stand-out orange example. Besides, Dave and I have more catching up to do.