Media | Articles

Homegrown: Ex–GM designer’s “Voo Doo” magic

Welcome to Homegrown—a limited series about homebuilt cars and the ingenuity, diligence, and craftsmanship of their visionary creators. Know of a killer Homegrown car that fits the bill? Send us an email at tips@hagerty.com with the subject line HOMEGROWN: in all caps. Enjoy, fellow tinkerers! —Eric Weiner

Brian Booth, 57, has devoted 24 years, over 20,000 hours, and unmentionable dollars constructing the homebuilt he dubbed “Voo Doo.”

Booth is an artist and designer who spent 19 years at GM before becoming the chief designer at the L.A.-based firm Flyer Defense, which supplies rugged ATV personnel carriers to the U.S. Army. He’s also an instructor at the Los Angeles Art Center College of Design. His portfolio includes Chevy and Olds exteriors, Pontiac interiors, Chevy and GMC light trucks, various Opels, and the MV-1 taxicab.

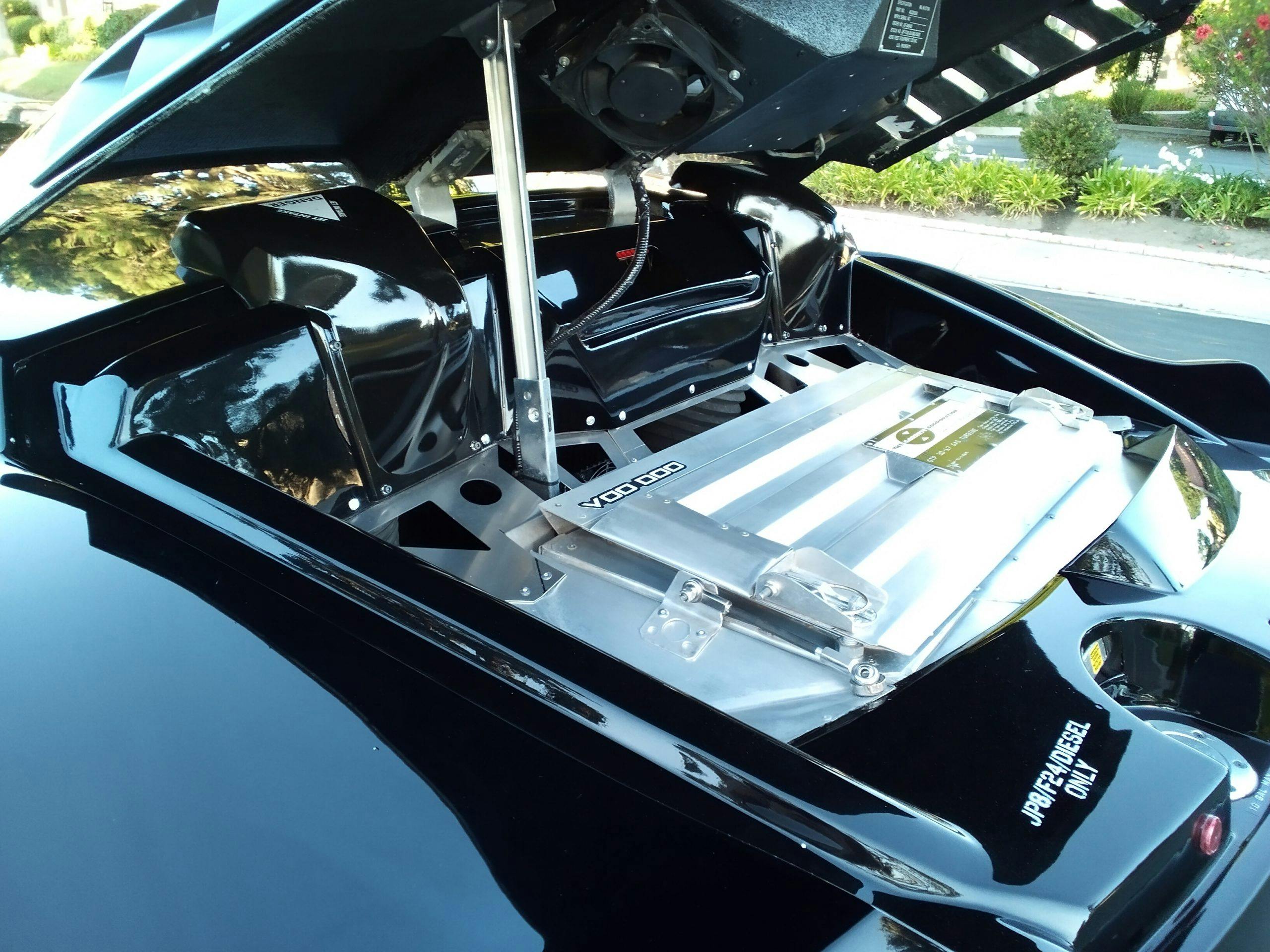

Voo Doo’s propulsion system resembles something NASA might dream up. Seeking immunity from environmental/geo-political disruptions, Booth engineered his driveline to run on a wide variety of fuels, yielding what amounts to a science fair on wheels.

A 181-horsepower UQM Power Phase 135 DC electric motor drives the rear wheels through a Ford Mustang 9-inch, 5.14:1 differential. Ten LG Chem lithium-ion batteries provide 60 miles of emissions-free range for daily commuting. A Thunderstruck control unit keeps the electric propulsion system happy while an Elcon 240-volt charger sits onboard to replenish the batteries during stops.

Marketplace

Buy and sell classics with confidence

When plugging in isn’t practical and charge is running low, a Garrett GTP 60-67 gas turbine spins a pair of ultra-light Auragen generators to energize the battery pack on the roll. “Believe it or else,” Booth explains, “I found this 60,000-rpm whistler—normally used as an auxiliary power unit—installed in a John Deere Gator side-by-side off-roader.”

“In my teen years I was inspired by the McDonnell F-101 Voodoo supersonic interceptor my father flew in the Air Force,” says Booth. “My priority here was more how I conserve energy than outrageous power and speed.”

Operating in its series-hybrid mode, Voo Doo’s range is extensive. The Garrett turbine is happy to swill gasoline, alcohol, diesel, bio fuel, or CNG.

“Thanks to my final drive ratio, low-end electric torque, and light weight, Voo Doo’s initial acceleration should be impressive. But even with an unlimited budget, I’d never want more than 500 hp in this homebuilt. I think the new generation of road-going performance must include responsible fuel consumption.”

Booth’s homebuilt mimics a C8 Corvette’s overall length and height. However, the wheelbase is longer by a foot while track and width dimensions are 4-5 inches greater, all to provide seating space for two adults plus two lucky kids. While he was timely employing an electric driveline, fitting four doors to this sports car must be considered a radical innovation.

The Voo Doo’s ten lithium-ion prismatic batteries are stacked two high inside a tubular stainless steel backbone. “A friend of mine designed the independent suspension systems employing unequal-length control arms at each corner,” Booth explains. The disc brake hardware is a mix of GM and Wilwood components. The unassisted rack-and-pinion steering gear was purchased from Unisteer Performance. Forgiato forged-aluminum wheels, 21×9.6- in front, 22×10.0-in back are fitted with ultra-low-profile Pirelli radials (245/35R-21 in front, 245/30R-22 in back).

Booth employed Alias CAD software to shape his exterior. A friend of his on the east coast milled stiff foam to create the main body mold. Booth helped lay up the fiberglass skin in the finished mold before designing and constructing his seats, instrument panel, center console, and door trim at home. The Aircraft Windshield Company helped shape the crystal clear polycarbonate windshield. Voo Doo’s side glass was custom made by Booth in his garage. In lieu of a back window, three cameras provide a comprehensive rear view.

‘The greatest challenge was a commitment to build my own fiberglass body, which cost ample time and money due to the need to mill the stiff foam used to make the mold,” says Booth. “That phase was done some twenty years ago before the advent of 3D printing. Once that technology became available, I was able to employ it to save cost and time constructing the interior components such as the roof pillar covers.

“Voo Doo has a true four-passenger interior with jump seats in back large enough to accommodate my 6-ft 1-in height. The front seat headrests came from an actual Voodoo aircraft and I installed a working AC system to maintain long-distance comfort.”

As for the weight, Booth hasn’t had a chance to put his homebuilt machine on the scale, but he’d “estimate the curb weight is about 3000 pounds.”

“Near the beginning of design and construction, a close friend counseled against trying to build a car at home. I learned so much collaborating with friends that I’m glad I ignored that advice. California assigned my VIN this August, long after I had enjoyed a few shake-down runs around the block.”

Check out the Hagerty Media homepage so you don’t miss a single story, or better yet, bookmark it.

Beautiful, but I quit reading when I saw electric powertrain. It cries for an LSX. The world has more than enough golf carts as it is.

It takes more than skill, it takes determination and the will to keep going until it is completed.

Great job!