Media | Articles

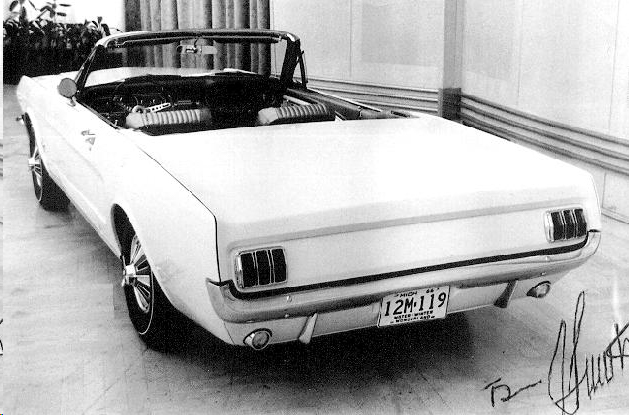

The folding-hardtop Mustang convertible that never was

In the mid-’60s Ford was on top of the world, still riding high on the Mustang’s 1964 introduction. In an attempt to keep the model fresh for 1966, Blue Oval top brass tasked Ben J. Smith, one of its designers who worked on the late-’50s Ford Skyliner’s power folding roof, to create a retractable hardtop for the Mustang.

Smith delivered a manual, split-roof design based off of a chopped Mustang coupe in early 1966. Thanks to a torsion-bar system involving two fiberglass panels that fold into the trunk, the prototype did not require power operation, saving weight, complication, and cost. In fact, lifting or lowering the top required just 11 pounds of force.

Still, Ford pushed for a power version, based on a survey of potential buyers that indicated it would sell better. Smith did not approve. The impasse between Ford and Smith prevented the project from moving forward, and his time at Ford was over by 1967, at the age of 48. Smith attempted to negotiate keeping the original ‘66 retractable hardtop conversion that was built as part of his exit from Ford, but the Blue Oval would have none of it. Smith researched for many years as to the whereabouts of the original prototype but was never successful.

The project never went further than the concept phase, according to Ted Ryan, Ford’s archivist.

Marketplace

Buy and sell classics with confidence

“It was interesting to look into because there was not a lot of information,” Ryan said. “Most of the documentation and archives pick up when a new design reaches the clay model phase, but from what I have found this design never got there.” Ryan was intrigued that a version of the Mustang, one of the most thoroughly documented Ford models in the archive, had something like the retractable hardtop so thinly documented in its history.

Smith, now 96 years old and still driving himself on road trips all over the country, never fully gave up on the hardtop Mustang concept. In 1993 he founded Retractables Unlimited, a startup company where he and his son David recreated the original retractable hardtop Mustang design and packaged it into kits. Owners could install the kits themselves, or, David’s body shop, Car Service Collision in New London, Connecticut, could handle it for them. The Smiths sold a total of 35 kits, in addition to three prototypes.

After selling the 35 kits that had been produced, Smith contacted a vendor in Mexico to create another batch of fiberglass tops. Instead, the vendor took the roof molds, plans, a stack of Smith’s money and disappeared. Smith sold the remaining parts and molds to Mustangs Plus, a Mustang parts supplier located in California. David Smith told us that he knew a few kits that were purchased but never installed, meaning if you can get a hold of them, there is still the option to build a folding-hardtop pony car of your own.

The first production kit the Smiths made is owned by Hagerty member John Duley, who purchased the car not only sight unseen, but without real knowledge of what it even was.

“I was at David’s collision shop after I hit a deer. David took a phone call, and in the middle of it looked at me and asked if I wanted to buy a retractable hardtop Mustang that was out in California,” Duley says. “Of course I said yes.”

Duley wasn’t familiar with the hardtop convertible Mustangs, but he got a crash course in untold pony car history right there, right from the source. It only reinforced his interest in buying the oddball Mustang.

Duly’s car had lived its entire life in Salton Sea, California until that point, and the previous owner self-installed the conversion kit. Shipping it to the east coast took some time, which only heightened the anticipation before Duly took delivery. Upon arrival, the car more than lived up to his expectations.

“It was dry as a bone.” John says. “If there was ever an example of rust-free, this is it.”

Still, the car was in rough shape, and the unique top had seen better days. Duley chose to have the car restored at David’s shop. The plan was to take the car down to bare metal and restore it with select, light modifications. The velour interior installed by a previous owner came out in favor of a correct Pony interior package, and Duley upgraded the 289 cubic-inch V-8 with a four-barrel carburetor and a mild camshaft. He left the stock automatic transmission alone.

Fortunately, thanks to Ben Smith’s design, the custom retractable hardtop required only minimal changes to the Mustang, so it wasn’t an obstacle during the restoration. The fiberglass trunk lid, top and mechanism are the obvious differences from stock, and on the underside of the chassis Smith added two braces to reduce flex and cowl shake. Even the side glass remains the same as an un-modified coupe model.

The restoration was finished in 2007, and since John has enjoyed showing the finished Mustang at events around the northeast, bringing home trophies and enjoying the compliments he gets. He loves sharing about the history behind it and explaining the story behind this uncommon ‘66 Mustang. The green drop-top is a living example of a what-could-have-been moment in Ford history. For Duley, though, it’s just his beloved Mustang.