Media | Articles

How the Zerk fitting changed the automobile forever

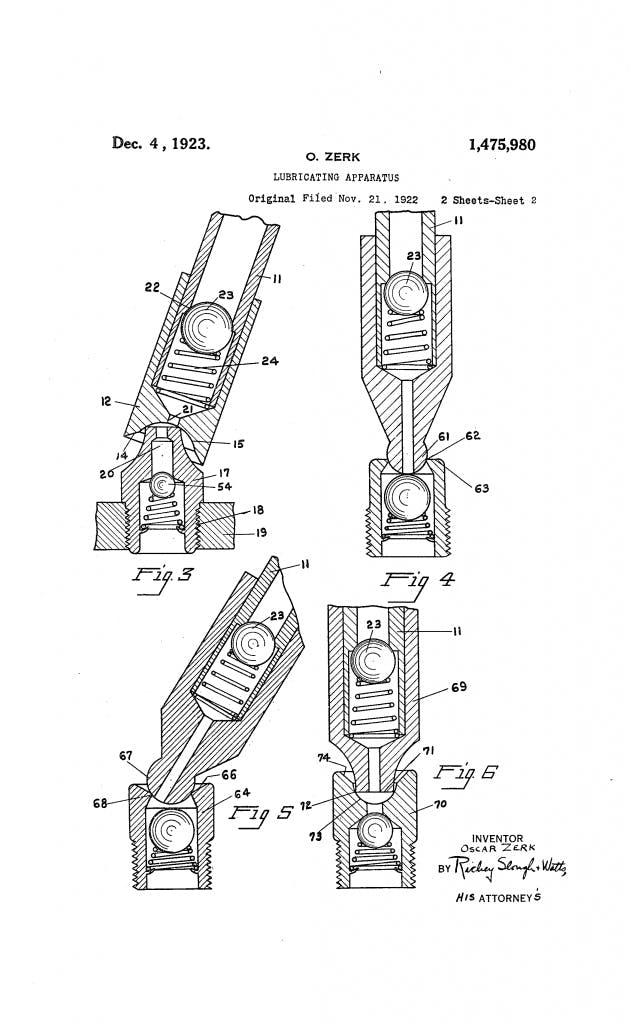

The advancement of the automobile has always been a steady stream of small, incremental improvements. Sure, there were revolutionary moments along the way, but the vast majority of what shifted the car from a novelty to this country’s primary form of transportation came in the form of steady progress. One such step was how to keep moving parts lubricated easy and clean. You can thank Oscar Zerk and his 1923 patent for a special fitting for that.

The process for maintaining such lubrication had advanced somewhat, but it was Zerk that created a design that made truly meaningful improvement. Early cars were lubricated like machines, by manually slathering grease where it was needed. Then came drilled-out oiling holes, requiring the operator to regularly circle the machine with an oil can and inject a dollop of oil to avoid the parts self-clearancing themselves into destruction. The next step in the evolution was to add spring-loaded caps that prevented dirt and debris from entering those oil holes.

Then, the grease cap. It was a threaded fitting that had two parts; one threaded into the piece that needed lubrication and had a hole that allowed the second piece to force grease into the part when the second piece was tightened down. The end user had to keep grease on hand to keep the cap full. This design made the task of keeping parts lubed much simpler and easier, but it required the large cap be placed on parts, forcing design changes in some cases.

Zerk took this idea to its next logical place. As early at 1919 he was marketing a fitting that allowed grease to be forced into a part using a simple nipple and a grease gun that sealed to the nipple, and the fitting also included a spring-loaded check ball which then retained the grease inside the part. He marketed and sold these fittings for 10 years before they were adopted by auto manufacturers.

It was a design that caught the eye of a big brand from Dearborn, but only after Zerk sold his Allyne-Zerk Company to Bassick Manufacturing Company. (The owner of the Bassick Manufacturing Company was also partner in the Stewart Company which produced the speedometers for Model T Fords.) Ford took a liking to the fitting and made it standard issue on the 1928 Model A.

Marketplace

Buy and sell classics with confidence

The next advancement came in 1934 when an engineer at Stewart-Warner modified Zerk’s design to have a slight bulb at the end of the fitting, which allowed a redesigned grease gun to seal to the fitting without requiring the operator to apply pressure. That change made the design more popular than ever, and it is estimated that 99 percent of vehicles produced in 1934 featured these new Zerk fittings.

Such humble parts, developed over time, are what that have allowed the advancement of the automobile to reach the high level of reliability, efficiency, and performance that we enjoy today. Zerk fittings can still be found in use on new cars, on the u-joints of a driveshaft for instance, with the same essential design of the 1934 piece. It’s quite something for a part to soldier on like that for nearly 90 years, so let us salute Oscar Zerk, the man who greased the gears of progress.