Media | Articles

How a city painter curbed bad driving by inventing rubber safety cones

Safety cones are abused in so many odd ways. Everyone at all ages has run them over, kicked them a country mile, or bellowed animal noises out of them into the void. But as fun and silly as these antics are, what makes the safety cone such an ingenious invention is simply this: It’s a nearly indestructible item with a commonly understood message. How often do those come around?

For Charles D. Scanlon, managing the chaos of vehicle traffic was an everyday reality. You see, Scanlon worked as a city painter for Los Angeles in the Street Painting Department in the late 1930s. He was no stranger to the hell that would break loose when the stroke of a brush altered the status quo of traffic. Drivers’ unpredictable responses to the interruptions made the road repairs more dangerous than they ever should’ve been. The safety barriers, which were often made of wood, were common casualties on the job sites.

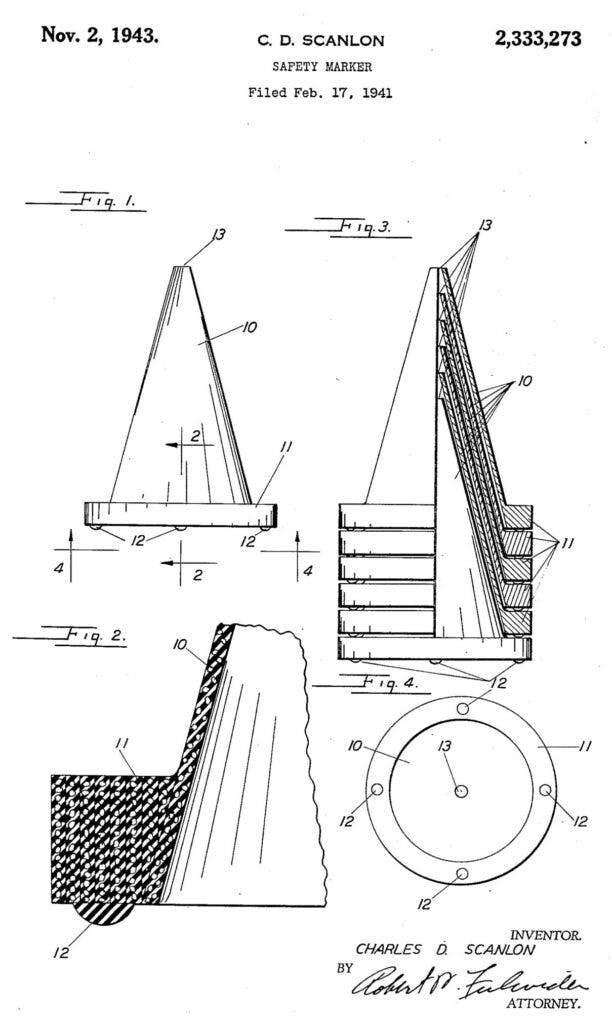

Whether lugged out to protect wet paint or city workers, wooden barrier designs were primitive and bulky. They were also easy for drivers to clip, and not very forgiving to vehicles that might impact them. (Heavy iron pedestals were also used to deviate traffic back then. Yikes.) As noted in Scanlon’s first patent application for the “Safety Marker,” filed February 17, 1941, he lays out the arguments—obvious, in hindsight—against using wood construction:

At present, it is customary to use small wooden tripods or larger wooden barriers to indicate the presence of dangerous spots in the highway such as those caused by repairs, etc. but the smaller tripods are not easily seen and are readily broken, while the larger barriers present a real hazard to an automobile which may accidentally strike them. Furthermore, the tripods must usually be made up for each job, while the barriers present considerable of a storage and transportation problem.

Scanlon’s reasoning worked from several angles. Firstly, it’s easy to agree that no driver needs a 2×6 penetrating their windshield, and that no pedestrian wants an impromptu projectile. The old markers raised durability concerns, as well. Unless you’re a craftsman working in fine furniture, wood is a bend-it-and-it-breaks material. Constant repairs—or, even worse, filling up landfills with splintered remains—aren’t practical for money-conscious city officials.

To top it all off, the larger, sawhorse-styled barriers were inefficient to set up, store, and haul around. While safety concerns may attract bureaucratic interest, improving the budget’s bottom line always grabs serious attention. Scanlon’s design wisely addressed both.

Marketplace

Buy and sell classics with confidence

Scanlon focused on using rubber and fabric from old tires. Since the early 20th century, rubber had taken the automotive world by storm. Tires, seals, valves, wiring, and all sorts of components utilized the material. By the 1940s, rubber was an understood medium, and the perfect realization of Scanlon’s concept: a tough-as-nails, cone-shaped marker that was lightweight, stackable, and difficult to topple. Even better, Scanlon knew a local tire-shop operator—Rodney B. Taylor, who would eventually become his business partner—who could help make prototypes.

Scanlon initially thought that, for the cones’ bodies, layering lightly rubbered fabric (like papier-mâché) was the way to go. The cones’ bases were to be heavier, to ensure a low center of gravity, and could be built from more rigid layers of fabric. The cone could then be vulcanized together—one solid form of reused scrap. However, Scanlon kept an open mind to the possibility of new materials and from-scratch manufacturing methods.

While I prefer, for reasons of economy and convenience, to form both the body and the base in the manner just described, it will be apparent that new materials instead of reclaimed materials may be used throughout if that is desired. In either event, however, I prefer to employ a relatively large amount of fabric in the base, both to decrease the expense and also to prevent the base from being too “live.”

Scanlon went so far as to make considerations for his fellow painters, the guys toiling over crisp roadway lines.

On the underside of the base, I provide a plurality of pads or feet which hold the base above the surface of the highway and permit the marker to be placed on freshly painted surfaces without danger of smearing.

The hole in the top of the cone had another important function. As Scanlon explains, it prevented suction and allowed air to escape more easily when cones were stacked or separated quickly. He also suggested that it could provide an opening for a flag, with the cone serving as a holder of sorts.

Scanlon’s first patent was finally approved on November 2, 1943, during the throes of the Second World War, which caused material shortages and stunted his progress.

Four years later, the California-based Interstate Rubber Products Corporation, led by Charles Terry, teamed up with Scanlon to finally begin manufacturing his design professionally in 1947. Leaving behind Scanlon’s original recipe of tire scraps, Interstate Rubber used heat-pressed rubber sheets to make cones in abundance, and the City of Los Angeles soon became Scanlon’s inaugural big-fish client.

The cones were an irrefutable hit.

But what’s a great success story without an adversary?

One day, a fellow by the name of Isador D. Blumenthal, president of the Radiator Specialty Company, Inc. in North Carolina, took a shine to the traffic cone after seeing it during his travels out West. He wanted in. Repeatedly, he tried to court Scanlon and Interstate Rubber into a transcontinental partnership by securing a license to the patent. Again and again, Blumenthal was rebuffed.

He couldn’t let go of the cone. Blumenthal eventually realized that because Scanlon’s safety marker was a cone-shaped derivative of other historical objects, he could legally argue that the cone wasn’t a novel invention but merely a replication, and thus under less-ironclad copyright protections.

What did Blumenthal do? He began making strikingly similar traffic cones en masse, tweaking the shape of the base (a square vs. Scanlon’s circle) in a transparent attempt to skirt infringement claims.

Safety Cone Traffic Corporation, an offshoot of Interstate Rubber, had already begun to try square-based designs in tandem with the round-footed originals. Blumenthal’s square “Safe-T-Cone” began sprouting up in 1951 anyway. Mr. Sour Grapes even went so far as to pursue his own patents in Canada and the United States.

And so began: The Cone Wars.

Not really. But a legal battle did ensue. Interstate Rubber and Scanlon couldn’t keep control of their intellectual property. Rival cones soon flowed from both American coasts, and in 1958, rubber and plastic safety cones started gaining international appeal, spreading to the United Kingdom.

Scanlon never rested on his laurels. Preferring his inventor’s cap on, he constantly looked to improve his original safety marker, amongst a handful of other traffic safety innovations.

On February 14, 1955, he applied for yet another patent that advanced his life-changing cone design: little kickstands for the bottom of the cones. When crews hucked cones into place, perhaps tossing them from the bed of a moving truck, the rubber additions meant the cones were more likely to stay upright, thus saving the crew time. The nubs also prevented the round-based cones from rolling when tipped over—crucially, without impeding their stackability.

These nuances were a sort of cherry on top of an amazing contribution, even if circular bases were ultimately inferior to square ones. Scanlon’s unrelenting attention to detail, and his consideration for the worker’s experience, show that he never forgot himself, where he came from, or the problems he sought to resolve.

Today, hundreds of safety cone designs (comprised of PVC polymer, mainly) have taken over the traffic landscape all over the world, speaking with an unanimous voice in a language everyone can understand: go this way, not that way. Do they keep every conehead driver in line? Of course not. But they do a darn good job, and in a much more forgiving manner than what preceded them. We can all thank Scanlon for that.

Now, if only autonomous vehicles could understand their brilliance the way that we humans do …

***

Check out the Hagerty Media homepage so you don’t miss a single story, or better yet, bookmark it. To get our best stories delivered right to your inbox, subscribe to our newsletters.

Thanks, Mr. Scanlon!

Interesting history of something I’ve seen nearly all my life, but never really considered the origins of…

Dub6, Bryan Gerould wrote the well-done story about things we take for granted which were devised by Charles D. Scanlon.

Follow up story is about how drunken teenagers curbed traffic cones by playing pac-man

Great article! It’s those seemingly mundane objects that are so important.

I’m old enough to remember “Smudgepots”.

Anything BUT mundane, they looked exactly like the archetypal bombs you’d see being handed to cartoon characters. Round and cast iron, they burned oil through a capped wick.

Placed along roadsides, they lent a gloomy will-o’-the-wisp air of caution.

I have a couple of old smudgpots and I fill them with skeeter repellent and burn them around the yard during Wisconsin summers evenings.

My father used smudgepots in the orchard to protect buds from a late frost

Wow. I’d completely forgotten about those. Thanks for the reminder… and making me feel old.

Ah, smudgepots!. We put them out on the macadam road leading up the hill to the post office in Rector, Pa., to warn off cars when we were sledding on winter nights back in the ‘40s and ‘50s. I forget who’s dad had them stacked away in his garage. The did indeed look like the classic anarchist’s bomb. I can still see them flickering, leaving an orange/yellow glow in a circle around them in the snow.

I worked for a highway department for several years. We had a cone truck (van) with a platform on the back. The driver would mash the go pedal in reverse and if the guy on the back missed picking up a cone he bought the crew a beer. Not for the faint of heart. You reaching over to grab a cone off the dotted line while traffic wizzed by at 60 plus mph couple feet away

Very neat story of something we take for granted.

I’ve killed many of those cones while participating in Solo II. That was as far as my driving career went.

Back 60 years or so, I lived in Northern Illinois, and my neighbor worked on a highway crew. He said that a guy that drove a beat-up old pickup delighted in sending the first few cones flying every morning. The crew got tired of picking up the cones, so they filled a few with concrete. Solved the problem in just one morning!

In PA orange barrels are the unofficial state flower.

And they bloom year round…

I can add a little humor to this story. In my days as a longhaul trucker the were known as “Schneider Hats” after the orange trucks of the trucking company from Wi. They were known at that time to mainly hire drivers fresh out of driving school that were not very knowledgeable yet about the the amount of skill and experience it takes to pilot a big rig through the various conditions they would encounter. The big orange barrels that are also used in construction zones were known as “Schneider Eggs”.

I wonder how much the inventor made of the cones? Even at 10 cents a piece, he would have made a fortune.