Media | Articles

Getting Hooked: A Tribute to Tow Trucks

When most people think of Tennessee they think of country music, Elvis, or whiskey. And with good reason. I mean, the state boasts Graceland, Dolly Parton and her theme park, the Country Music Hall of Fame, and, of course, Jack Daniels. Just to name a few. But next time you need a tow, tip your hat to Tennessee, because it’s also the home of the first tow truck.

Let’s be honest here, most people don’t think about tow trucks, not until the moment they need one, anyway. But tow trucks—and roadside assistance services like that offered through Hagerty Drivers Club—are more important than ever. Especially for those of us who choose to bear the financial burden of vintage car ownership. Because sometimes those joyous drives over winding backroads come to a grinding halt when some mechanical malady rears its ugly head. If you’re lucky it’s a simple fix, but even the most seasoned mechanic, or DIYer, has needed the dreaded hook of shame. The man to thank for the existence of that hook and the equipment it’s attached to is Earnest Holmes, Sr.

Now, we’ve all heard the old proverb, “Necessity is the mother of invention,” and the tow truck is no exception. See, Mr. Holmes was a mechanic, so broken-down cars were a regular occurrence for him. In the days before the tow truck, you either fixed the car where it broke down or you rigged some rope to pull it back to the shop. It certainly wasn’t the most convenient solution, but it worked, kind of.

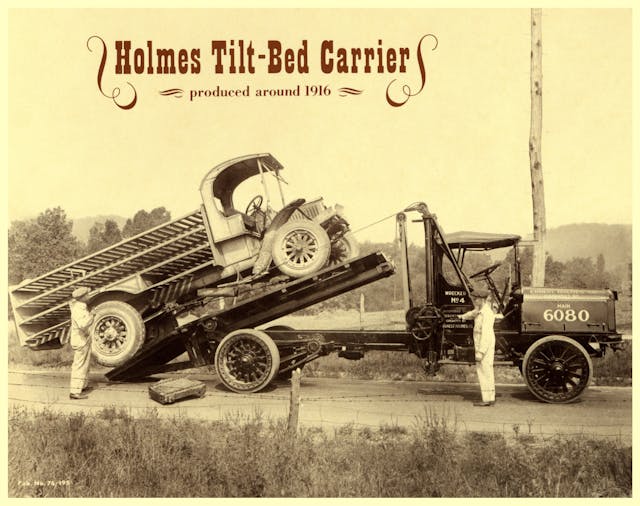

Everything came to a head in 1916, when Holmes’ friend, John Wiley, managed to get his Model T stuck in a creek bed. Wiley was reluctant to abandon the T, but he knew he couldn’t get it out on his own, so he called Holmes for some help. And help he did. The recovery of the T only took eight hours, 12 strong backs, and some creative and likely sketchy use of blocks of wood and rope. But the camel’s back was broken, and Holmes was determined to find a better way to deal with these precarious situations.

He immediately started work on what would eventually become the world’s first tow truck. The car of choice was a 1913 Cadillac Model 30. Luxury cars were more powerful, larger, and built to a higher standard than the average car, so this the Caddy the perfect place to start for home-built trucks. Now, according to tow truck lore, the first few attempts didn’t quite cut it. More modifications to the Caddy’s chassis were needed to support the added weight, and the wrecker wasn’t quite up to the job either. But, Holmes was resilient and didn’t let a few set-backs stop him.

Marketplace

Buy and sell classics with confidence

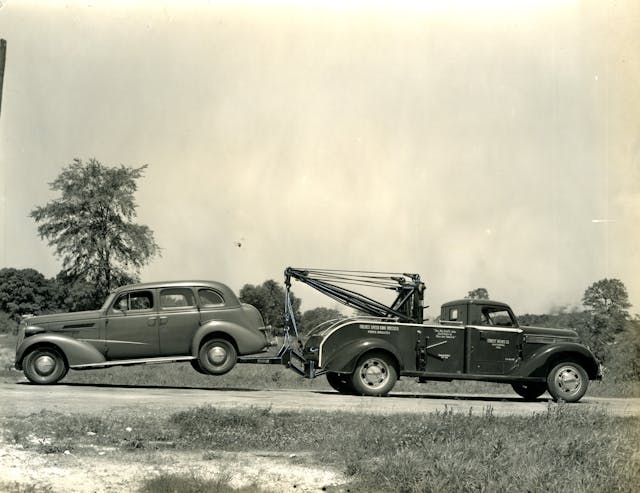

By 1917, he had finished and patented the split-boom mechanical wrecker. The body was made from heavy-duty metal tubes, cables, pulleys, and hand-operated winches. It consisted of two booms and an early form of outriggers, which lowered to help support and stabilize the truck. One boom could be used to anchor the tow truck while the other rescued a stuck vehicle. Of course, if a car simply needed a tow, the booms worked in conjunction to lift the car and take it wherever it needed to go.

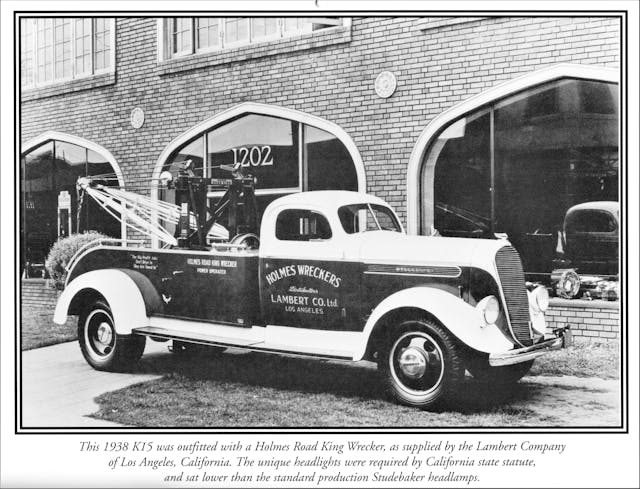

Word got around pretty quickly, and more and more people asked Holmes to build wreckers for their auto repair businesses. Eventually, he had so many orders for his wrecker, that he closed down the auto repair shop in 1919, formed the Earnest Holmes Company, and started selling the Model 485, so named because it sold for $485. This marked the beginning of the tow truck industry as we know it.

Holmes’ products weren’t the only game in town but they proved to be the most popular. Companies like Manly and Weaver built similar systems to the Model 485, but they were simpler and lacked the features that made the 485 so popular—things like the split boom and outriggers. Instead, they were more akin to a hand-operated crane than a traditional tow truck.

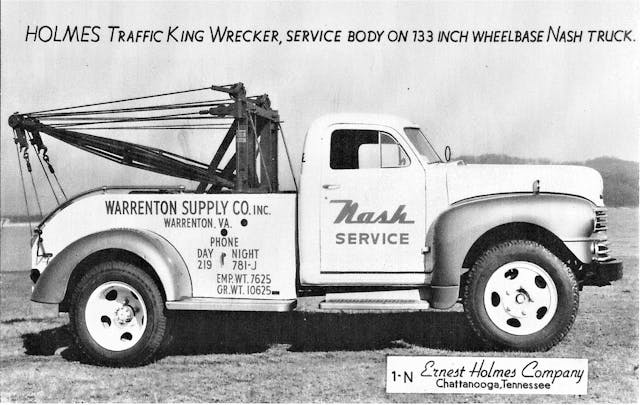

Holmes even supplied wreckers to the military, massive 6×6 monsters equipped with equally massive Model 45 wrecker bodies. A total of around 7000 were used by Allied forces during World War II and played an integral role in keeping things moving. After the war, as NASCAR started to gain traction (or in this case maybe lose traction …) the series used Holmes wreckers to remove dead cars from the track. Eventually even Indy Cars used them. By 1965, Holmes wreckers made up two-thirds of in-service tow trucks.

The split boom wreckers, Holmes or otherwise, were purely mechanical. This meant that when a vehicle was rescued or towed, the work was handled with pulleys and gear-driven winches. Even up through the 1970s, they were similar to the models from 1919. The winches evolved, however, and were driven off of a PTO (power take-off) engaged with a cable from inside the cab of the truck. The booms came together at a point, rather than being placed on opposite sides of the truck, and a pin was pulled to separate them. A seasoned operator could make quick work of a tow, but they were still tedious and difficult to operate, especially for a beginner.

The ’70s brought about a great deal of change for both the automotive and tow truck industries. For a long time, when a car was towed, the operator used something called a J-hook. Just picture a big metal “J.” The J-hook was attached to the frame of the vehicle, the control arms, or the rear differential. Chains would run up around the front of the bumper, and a sling made of thick rubber protected the car from damage as it was lifted. They were nicknamed “Slingbacks.” But as car design and safety regulations progressed throughout the decade, hooking to the frames and other components became increasingly difficult and proved more likely to damage the vehicle being towed. Especially as big chrome bumpers started to go out of fashion. Of course, this led to some innovative ideas from various companies.

One such outfit was NRC out of Quebec, which pioneered the first hydraulic under-lift system, called the NRC-500. Though not available in the U.S. at the time, it was still a huge accomplishment and solved the issues faced by slingback trucks in Canada. However, it was somewhat flawed. The design forced the vehicle to sit a long way from the rear of the truck, which meant almost all of the load was on the rear suspension. This led to increased wear on the tow truck’s chassis and suspension components. It certainly wasn’t ideal, but it was a step in the right direction.

In 1974, 1200 miles from NRC, a new company called Century Wreckers took shape in Ooltewah, Tennessee. At the helm was a familiar name: Gerry Holmes, the great-grandson of Earnest Holmes, Sr. Gerry decided to step away from the family business to develop the hydraulically operated tow truck, an idea that other companies in the U.S. thought was absurd—including the Earnest Holmes Co. But Gerry Holmes and his dedicated team knew it was the right move. The hydraulic trucks were quieter, simpler, and safer to operate than the old mechanical wreckers. Their bodies were also built on a subframe, so less modification was needed to install them on a cab and chassis truck. This meant the trucks could be assembled and sold at a faster rate.

Despite all those wonderful qualities, Century and its hydraulic trucks got off to a rocky start. It proved difficult to convince dedicated professionals that what they’d used their entire careers needed to be replaced. The higher price for a hydraulic unit didn’t help, either. But, just like his great-grandfather, Gerry and his team kept on going.

The development paid off in the early 1980s, with some massive game-changers in the industry. One of which came in 1983, when Century released the first commercially available hydraulic under-lift wrecker in the U.S., dubbed the Formula 1. The idea was similar to what NRC had built but with some much-needed improvements. The inspiration had come two years earlier at a trade show in England, in the form of lift gates mounted on box trucks. The hydraulic ram was mounted under the truck, not on the outside like you’d see in the States, and they could still lift the platform with ease. Holmes realized he could do the same thing with a hydraulic under-lift on his wreckers back home, and with the big rams out of the way, the vehicle could be pulled closer to the back of the truck and the weight distribution issue would be solved.

Progress didn’t stop with the hydraulics, either. The bed of the wrecker was sloped at the back, so the vehicle in tow could be pulled even closer to the rear of the truck, creating even better load distribution and further reducing the amount of stress put on the rear of the trucks to increase their service life.

Those new trucks were pricey, however, and smaller outfits weren’t always in a position to buy a whole new wrecker. So Century designed a retrofit kit that adapted the new under-lift technology to older tow truck models. The kits turned out to be a bigger hit than the Formula 1 itself. This ushered in a new era, and the old slingbacks started to disappear from the landscape.

The ’80s also saw the rise of the flatbed tow truck, which had begun to appear in the 1970s, with production by a variety of tow truck manufacturers. The car carriers were mounted to a standard one-ton truck chassis, just like the wreckers, but the heavy steel platform pushed the truck’s weight limit right to the edge. In 1977, Jerr-Dan launched the first car carrier to use an aluminum platform, the first of many improvements that would lead to the car carrier we see on the roads today.

The ideal load angle was around 10 degrees, but it proved troublesome for many builders—except for Landoll Corp. In the early ’80s, Landoll launched the Centerfold, which achieved a uniquely low load angle that set it apart from all competitors. From the outside, it appeared to be a standard car carrier, but it was called the centerfold for a reason: Just after the cab, the frame was severed and a large hydraulic hinge was welded in. When the driver activated the hinge, the hydraulic ram separated the two halves of the frame. And with the cab and the other half of the frame pointed toward the sky, the load angle was reduced to that magic number of 10 degrees. It was complicated, but it worked.

Century also managed a 10-degree load angle. Its design, released in 1986, was more conventional compared to the Landoll Centerfold and is pretty close to what you see on today’s trucks. Century improved reliability by employing the same innovations used on its wreckers. The carrier was mounted to a subframe, so the rear pivot point and hydraulic cylinder mounts weren’t welded to the truck frame. Not only did this solve the issue of cracked frames, but it meant Century could offer a 120-inch cab-to-axle carrier platform, something no one else offered.

This new longer platform and pivot point location all helped to get to the desired load angle. To test it out, Century took its new truck to a local Chevy dealer to try it with a new C4 Corvette. The long and low front end of the C4 made it onto the carrier without any damage. That was quite an achievement considering the C4 Corvette would scrape its front end on nearly every driveway in existence.

Today, car carriers still use some of the features found on those old Century models, like the subframe and the dual-sided hydraulic controls. To help with that pesky load angle, car carriers were eventually equipped with air suspension in the rear so the truck could drop, which made it even easier to load all sorts of low vehicles. They’ve also moved to a medium-duty truck chassis, rather than the old light-duty one-ton chassis of the past, and the addition of a hydraulic under-lift means they can tow two vehicles at a time. Some are even offered with special hinged platforms, so even the lowest car can be towed with ease.

Tow trucks of all shapes and sizes continue to evolve thanks to companies like Miller Industries, which produces the majority of the tow trucks in the United States. Century, Holmes, Chevron, Vulcan, and a few others all fall under the MiIller umbrella these days. Light-duty car carriers and wreckers are all modular, built to spec at one of Miller’s factories, and then shipped to dealers so they can be installed on a chassis. The electronics are standalone, so there aren’t too many modifications to the truck’s factory wiring harness. This makes installation and troubleshooting a lot easier for owners and their mechanics. Even the OEMs have moved cross members at the request of wrecker builders so their chassis are more accommodating. And with more cars on the road than ever before, the industry certainly isn’t going anywhere anytime soon.

It’s been over a hundred years since Earnest Holmes, Sr. sold his first wrecker, and the goal of the tow truck is still the same: to get disabled vehicles and their drivers safely off the side of the road—or maybe to get your new project car back to your driveway. Either way, the humble tow truck will be there to save the day.

I like the classic tow trucks. They are fantastic point of automotive history.

I operated tow trucks as a kid in high school for a local company. Got my Class 5 at 18. We had a 1966 B61 Mack, 1940 something GI 6X, multiple Fords and Chevy 1 tons and a roll back. Pulled semis, cars off RR tracks, out of creeks in winter time, cars stolen stripped, on fire, DUIers and saw a few fatalities removed. Never a dull moment and learned some difficult lessons on physics.

Towing can teach geometry and physics faster than the “Teacher of the Year”. You know immediately when you have failed!

The true icon of the tow truck was the driver, and how emasculating the whole experience was. There you are, standing uselessly outside your disabled vehicle with a look of sheepish bewilderment, (maybe you have the hood up as you stare into the abyss of this mysterious mechanical thing) when up rumbles the tow truck driver in his hissing, clanking WWE version of a truck, all flashing lights and steel levers. He’s bigger than you, tougher than you, with grease-stained hands that have seen a wrench or two, and he knows his way around an eight cylinder powerplant; fearless and efficient. He’s not trying to make you feel like a putz, but yet you do. It can’t be helped.

Good article, however you skipped over the the greatest advance in conventional tow trucks, the “Self Loader” made by companies like Vulcan, and Dynamic. My towing business owned boom trucks, wheel lifts, flatbeds, but the self loaders, also known as Repo trucks were incredibly easy to use, and fast, being operated from inside the cab. Hydraulicly operated “L” arms swung out of the wheel lift to grab the wheels, and snatch the car. Fast to clear accidents, do hat moves in the lot, pull cars out of parallel parking spaces. Hook and book in a minute or two!

And there’s no shortage of repo videos on YouTube showing how slick they work!

Missing from this account are contemporary European tow trucks, which use a crane to hoist a car out of even the tightest parking spot, with four cables attached to frames under the wheels, and then onto a flatbed. In use in London since at least the first time I saw one, in 1998, and almost certainly well before that. Very slick, fast and easy to use, and much less likely to damage a vehicle than towing it.

Corgi made a Holmes twin boom wrecker on a Ford C Series with operating winches in the 70s. I still have mine. The closest I got to actually driving a tow truck was the Jerr-Dan rollback the rental yard I worked for used for equipment hauling. I borrowed it to move my Ford Ranger when the engine blew, plus I moved Bobcats and mini excavators a lot.

The history of Holmes Wreckers and model identification can be seen at holmeswreckers.com.The late John Gunnell was a tow truck enthusiast and wrote the book”Tow Trucks…a photographic history”

Back in the day (70’s) and maybe still Houston TX PD used private wreckers and would call “need 2 wreckers at (address)” over the radio. The first two got the hook and #3 didn’t. The result was the wreckers driving crazy and fast and often a fight on the accident scene.

A buddy of mine drove one and said that when business was slow, several of them would all stop somewhere on the freeway and turn on the lights and pretty soon they would have some wrecked rubberneckers to pull.

From what I see, HPD still contacts wreckers that way. If you want to learn how to become an aggressive driver, pilot a tow truck in Houston.

Yeah, in Houston, tow trucks run red lights, stop signs, cut you off, speed, ride the berm, etc. CRAZY! Get out of their way..,

My paternal Grandfather operated the Blue Ribbon Garage in Putnam, CN. He had a 35 Ford, probably a 1 1/2 ton chassis with a second transmission that he fabricated and a Holmes Twin Boom wrecker operated by a PTO. He also had an extra cable reel that he could splice in as he often had to retrieve cars that ran off the road and down into a ditch or canyon. I have some old 8mm movie footage of my Grandfather removing a car that was partially imbedded into the front porch of a house when the driver somehow lost control. When he retired in the late 50’s, I heard that the Buick dealer bought the wrecker just for the Holmes Twin Boom.

I’ve done much with wreckers including repos and motorcycles, which there is a special technique for. Not often considered is the vastly superior maneuverability of a wrecker over a ramp truck. A wrecker can place a disabled car right into a parking space between two others with no drama. And what of the short lived “cradle snatcher”? The intermediate vehicle between sling and ramp.

Used to drive a tow truck and flatbed back in late 70’s early eighties. Sling trucks. One time towing a car on the freeway I was entering a construction zone doing about 50 mph. Knucklehead in front of me got confused at a split in the barrels and didn’t know which way to go so they stopped dead. I jammed on the brakes and the sling raised straight up to the sky with the car on it then fell back down. One J hook came off but was able to get inside the barrels to re hook. No damage just a oh crap moment. Another time went to pickup a cutlass at a tow lot with the flatbed. Dead of winter. The car was a theft recovery the boss bought at auction. No tires and the rear axle was frozen in a big puddle. Usually I’d hook up the cable and chains , put the truck in neutral and winch away so the flatbed would work its way under the frozen in car. 99 percent of the time the suspension would pop out of the frozen ground. This time it didn’t and the rear quarters buckled. Had to go put a couple bags of salt around the axle and come back a few days later. Boss wasn’t upset, luckily the car was being parted out at their junk yard. Also towed hundreds if not thousands of cars with rubber bumpers using a sling. Lot of wood blocks on the frame and always had a think of shag carpet to go between the sling and rubber bumpers. Usually ok unless bumper was repainted without the flex additive. If I remember correctly the boss had a disclaimer about paint cracking on receipt if the bumper wasn’t factory paint

When I was young and dumb boss sent me to tow a semi trailer. Always up for a challenge I accepted. The trailer was short. I believe only around 20’ or so. But still an old big hunk of metal. I used F-350 with a 460 in it. Had to tow it across town about 10+ miles. Short chained the sling and skipped across town. Literally. There was no weight on the front of the truck and every stop you could hear and feel the front tires skipping along. It was a long ride 20-25 mph. Probably be a good ticket nowadays

Robert…when the marketing team reached out to me and put us together, I knew that your task of learning the history and understanding the market would be challenging, but you did your homework great job. Couple of side notes:

Yes, the towing museum, now located at the foot of Lookout Mountain in Chattanooga, started in a 48 ft van trailer that was converter as a rolling history of the industry. It now also commemorates the “Wall of the Fallen” for those that lost their lives while serving the public. And yes, it is a must see, when visiting the “Scenic City”.

The towing industry, is made up today of mainly 2nd – 3rd or 4th generation “family” business. It’s a tough business, who’s needs are 24/7…rain-shine-snow-day-night. But, these families are dedicated to servicing the motoring public and keeping our highways and lives moving forward. It’s great when business like Hagerty take the time and effort to recognize, the industry and people that make it all happen. Thanks Robert PS in 2024 Century celebrates their 50th years of service, if you google that you’ll find a U Tube video with Gerald Holmes (now 91 years of age) and how like Henry Ford pioneered the industry into the “hydraulic era” Thanks John L Hawkins

I towed lots of vehicles in the eighties at the service station where I worked. Sling trucks. Amazing what you could do with them.

The fun part of the story: I was a skinny little suburban boy. I regularly towed cars from the depths of the inner city, the kind of place we suburbanites were afraid to go without an armed escort. Yet I never had a moment’s trouble. Later in life, I learned why: in the city, the tow drivers were all armed, and not afraid to use it. Bad news travels fast, no matter where you are. After an encounter or two, the locals all moved on to easier pickings than tow drivers.

As a very young apprentice mechanic in a truck shop I had the opportunity to be involved in a heavy tow truck custom build. 24 k lb steer axle three axles all driven and a 600 to 1 Scagitt logging wench with huge wire rope on reel. The telescopic boom was special built by Lockheed with a fantastic weight to full extension ratio and I had the job of marrying a 13 speed box with a 10 speed box plus a browny and a 2 speed final drive. The number of gear selection just to get rolling was a masterful feat of over and under browny and two speed stick slapping with no clutch work only matching road speed. When the big Centuries came to town the days of the old rig were numbered, no one knew or wanted learn how to handle the old Autocar.