Media | Articles

Could this turbo engine have saved DeLorean?

Forty-two years ago, as rumors of strife and impropriety were only beginning to swirl around his fledgling car company, John Z. DeLorean entertained the idea of boosting his stainless steed. If ever a fast-looking slow car deserved more oomph, it was the DeLorean DMC-12 and its anemic 2.8-liter V-6. New York’s Legend Industries had just the thing—a twin-turbocharger upgrade that transformed the car from lamb to lion. For a tumultuous few minutes, engineer Chris Theodore and his colleagues thought they were on to something …

One day in mid-May 1980, I was sitting at my desk in Chrysler’s Highland Park Engineering Center when the phone rang. “My name is Fred Dellis,” said the voice on the other end. “I understand you’re an expert in turbocharging.”

“I have some experience,” I said. What can I do for you?”

Dellis told me he was president of Legend Industries, that they had several turbocharging programs in the works, and that Legend was looking for a vice president of engineering to lead them. I was gainfully employed at the time and told him I wasn’t interested. “You will be,” Dellis said.

He turned out to be quite persistent, and the calls continued. Finally, I decided it wouldn’t hurt to check out a potential opportunity, even if I was happy at Chrysler, so my wife and I flew to New York on a Friday evening to spend a weekend with Dellis. It was the beginning of a two-year saga I will never forget.

Marketplace

Buy and sell classics with confidence

The next morning, we were off to Long Island to visit Dellis’s Porsche/Fiat dealership in Amityville, where he introduced some of the Legend officers. In addition to his dealership, Dellis had successfully started an aftermarket turbocharging company called Windblown Systems. Emissions testing had already been completed and the kits could be dealer-installed; Windblown had even set up distribution throughout the country for Porsche 924 and VW Rabbit/Scirocco turbo kits that provided a full warranty. But Dellis wanted to take turbocharging to the OEM level. He already had a contract in hand from Fiat of North America to build a thousand Fiat Spider Turbos. He had also been in contact with John DeLorean, he said. Then he showed me the cryptic series of notes he had exchanged with John:

Dellis: “Are you interested in a turbocharged DeLorean?”

John: “Yes.”

Dellis: “Shall we meet?”

John: “Yes.”

Dellis: “When?”

John: “June 10.”

It was the John DeLorean part of the business that intrigued me. Every car guy dreams of designing his own car and starting his own car company. John looked like he might pull it off. Knowing that I would never fulfill my own dream, the next best thing would be to have a hand in helping someone else fulfill theirs.

“What will it take to bring you on board?” Dellis asked me. Before I’d even finished telling him I needed to think about it, my wife blurted out a figure. Dellis topped it, and now I was stuck. Joining Legend was a risky proposition, but I couldn’t resist the John DeLorean hook. Back in Detroit, I gave my notice at Chrysler and began preparing for the move. Then came another call from Dellis: “I need you to put together a proposal for John,” he said. “We’re meeting with him in two days.”

Proposal in hand, on June 10, 1980, I flew to New York. Dellis and I estimated the cost of the proposed twin-turbo, twin-intercooled package and headed to John’s office at 280 Park Avenue. Taking the elevator to the 43rd floor, we entered the magnificent lobby of DeLorean Motor Company.

John’s secretary, Marian Gibson, came out to escort us to his office (it was Marian who would later become a whistleblower to the British government). John was standing behind his desk as we walked in. “So you’re the guy who likes to write letters,” he said to Dellis. “Well, Mr. DeLorean,” Dellis said, “it got me in this office today.”

The whole discussion that day was very casual. I took John through the proposal, and Dellis closed the presentation with the price of the kit. Before the meeting was over, we all agreed to draw up a contract. I couldn’t believe how easy it had been, even though it was what I call a “something for nothing” deal that would be hard for an automaker to refuse: Legend would do all the engineering, development, and tooling up front, with those costs amortized into the piece price. Dellis was on cloud nine when we left DMC, and we went out on the town to celebrate.

A month later, the contract was signed, and on August 1, we received a purchase order for 5000 turbo systems, at a price of $3888 each. We had just sold a $20 million program. At the time, I thought we were the world’s greatest salesmen. It wasn’t until John’s drug bust and reports of his other dealings that I realized this was the way he did business. Legend had taken on all the risk, while John would be the recipient of the reward.

My first day at Legend Industries was an eye-opener. The Hauppauge, New York, offices were unfinished, and there were there no final plans for the engineering facilities that were to be out back. The only staff were the sales, marketing, and service people from the Windblown operation. I had taken on quite a task, but Dellis essentially gave me carte blanche to put it all together.

I temporarily set up shop at the Amityville dealership, with a second office in Detroit, and began hiring some of the best engineers I knew. Meanwhile, Dellis and I went on a whirlwind tour to find a turbocharger supplier. Ultimately we selected Warner IHI, because the Japanese turbo was the smallest, lightest, and lowest-inertia unit on the market.

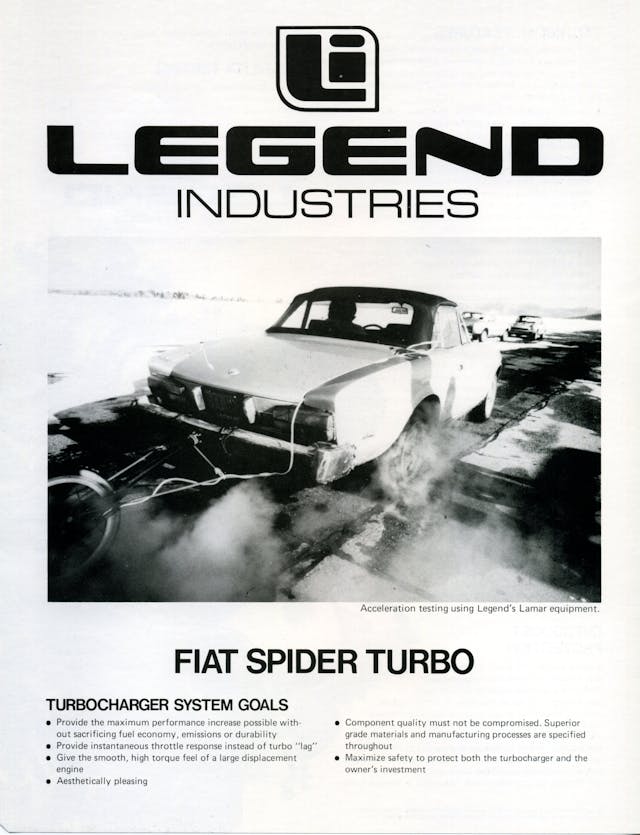

With no facilities in New York, we began design and development of the Fiat Spider Turbo in Detroit. Fabrication was done at Specialized Vehicles Inc., dyno-testing at McLaren Engineering (originally a spinoff from McLaren Racing but no relation today), and design engineering in our temporary offices in Troy, Michigan. Within a year, we put the Spider Turbo into production. We set up turbo-installation centers at the ports of entry in Jacksonville, Florida, and Long Beach, California, and we became the first non-OEM to receive EPA and CARB certification as a limited-volume manufacturer. More important, the automotive press raved, and Fiat dealers upped their orders.

With the Fiat program well underway, the Hauppauge test facility now under construction, and the engineering and purchasing staff in place, we turned our attention to the DeLorean project.

I made a few trips to the DeLorean plant in Dunmurry, Ireland, in 1980; my first visit showed me what we were up against. Michael Loasby, DMC engineering director and former chief engineer of the Aston Martin Lagonda, was my guide at the new facility. The plant shell had been erected and some of the heavy equipment was being installed, but the program was clearly behind schedule. Until then, all DMC engineering had been done by Lotus. But as they neared the production date, Loasby’s small engineering team struggled both to put together a durability plan and to keep test vehicles running, only coming up with fixes as failures occurred. It was also clear that the scope of the project was far larger than anything the team had handled before. Drawings and specifications available to Loasby were scarce, the bill-of-material incomplete. Loasby and I discussed the turbo program at length, and I outlined our needs for drawings, data, parts, and timing. Alarmingly, I also discovered that DeLorean’s managing director, Chuck Bennington, had absolutely no idea a turbo program was even in the works.

Disparate issues plagued the Dunmurry plant during this time, including its firebombing during the hunger strike of IRA officer Bobby Sands. The £14 million in damage it suffered was never recouped and only exacerbated DeLorean’s deteriorating financial condition.

By my last trip to Ireland, the assembly plant was up and running at full capacity. Bennington took me on a tour, highlighting the improvements that had been made with assembly worker participation. The vehicles still had issues, but the quality had improved since launch. It was encouraging to see Catholics and Protestants working side by side, but nerves were still frayed. Back in the engineering offices, for example, where things remained a bit tense after the bombing, a fire hose had been rolled out along the center aisle, just in case.

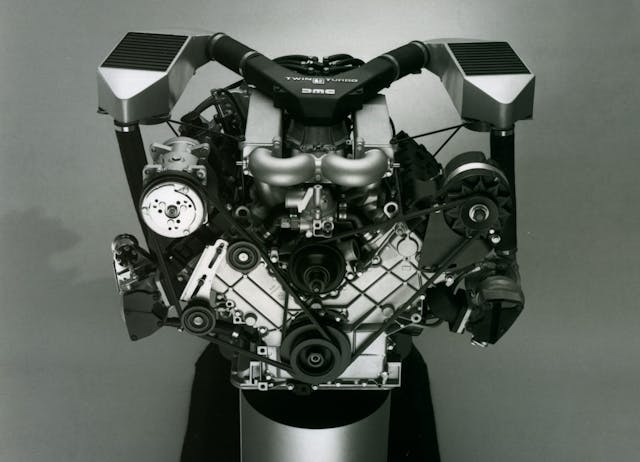

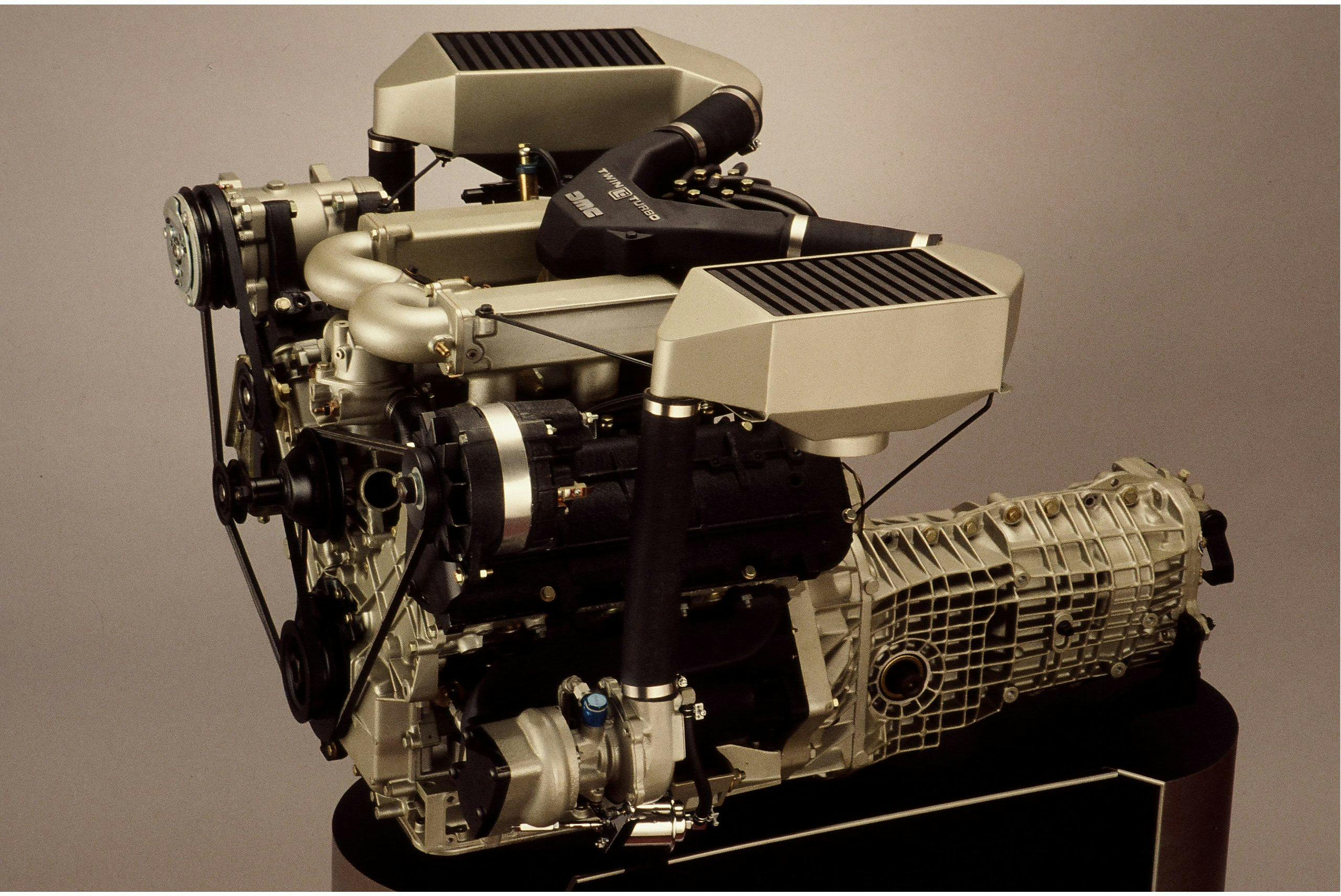

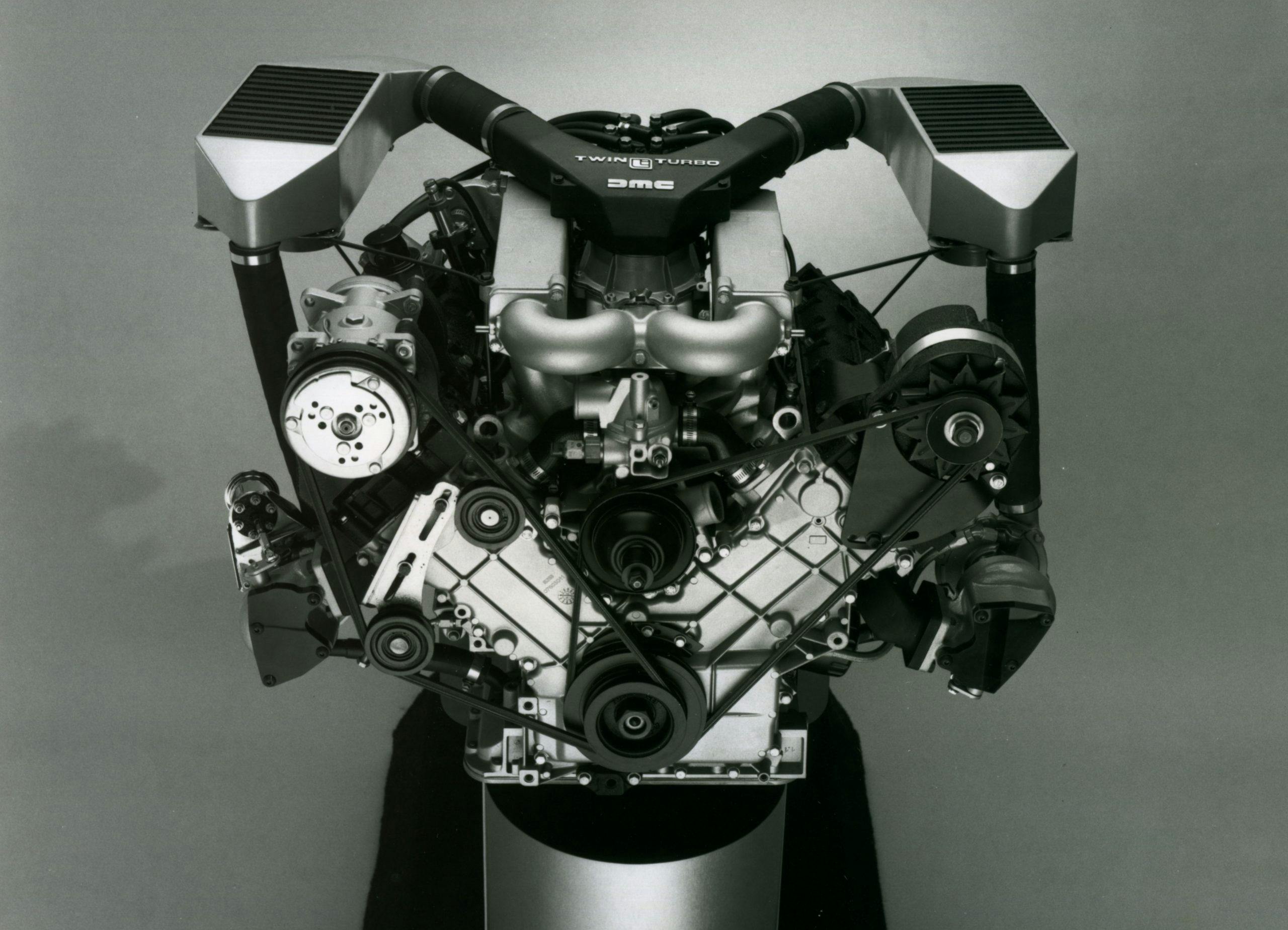

Because development of the DeLorean was behind schedule, it was difficult to make progress on the turbo program. However, by early 1981, we had received enough drawings and engines to begin development. Initial testing indicated that we could take the rather anemic 130-hp, 2.8-liter V-6 engine, a joint project of Peugeot, Renault, and Volvo, up to 175 horsepower and over 250 lb-ft of torque, even without intercoolers. We also discovered that the PRV engine was rather fragile and would need to be upgraded.

Meanwhile, the National Auto Dealers Association Show was coming up in February, and DeLorean asked us to prepare a mock-up of the turbo package for the show. Working around the clock, we barely finished the display in time to get it to Los Angeles.

The DeLorean’s unveiling at NADA on opening night was surreal. Rather than putting up a display at the convention center, DeLorean rented out the ballroom of the Biltmore Hotel in downtown L.A., no expense spared. With the cars on show, a string quartet played as guests strolled through displays of violin makers, glass blowers, and countless other high-end crafters, intended to signify the car’s high-quality bona fides. The ballroom was packed with celebrities and dealers, and I presented the turbo to investors like Buddy Hackett and Johnny Carson. The party didn’t end until 2 in the morning.

Legend received its first vehicles in March—two Renault Alpines and two early DeLorean prototypes that were in rough shape. We installed a twin-turbo, twin-intercooled engine in the Alpine first, since both DeLoreans needed serious debugging. The lightweight Alpine was incredibly fast—0-to-60 in five seconds. This indicated that the heavier DeLorean would be good for 0-to-60 in well under seven seconds, a serious upgrade over the unremarkable 10.5 seconds of the naturally aspirated car.

As the delays continued and it became apparent that internal-engine upgrades would be required, Dellis and I knew we needed to revisit the “something for nothing” contract with John. We met at his New York office in August to hammer out the details, which would include progress payments for achieving development milestones and royalties for production units. The meeting was cordial, but what struck me that day was John’s candidness. At one point, he strolled behind his desk, pulled out a file, and said that they were about to take DMC public. John said he had secured the rights to Smokey Yunick’s “vapor engine,” with its outrageous claims of fuel efficiency. To spike the stock price, John planned to make a public announcement at the appropriate time. I couldn’t fathom why he was telling us this, and I can’t imagine how many SEC rules were being violated. Upon reflection, I suspect it was this openness that made John DeLorean the perfect con man.

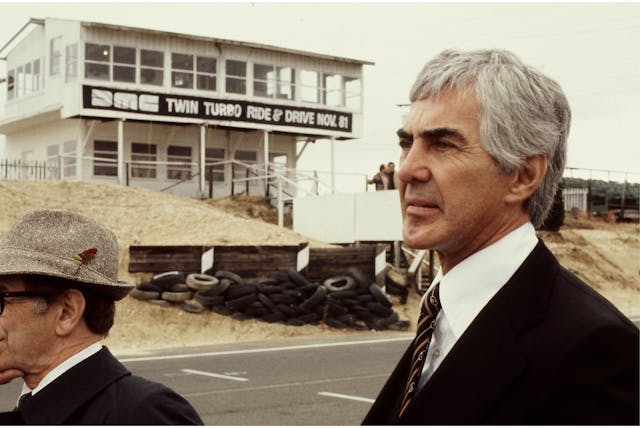

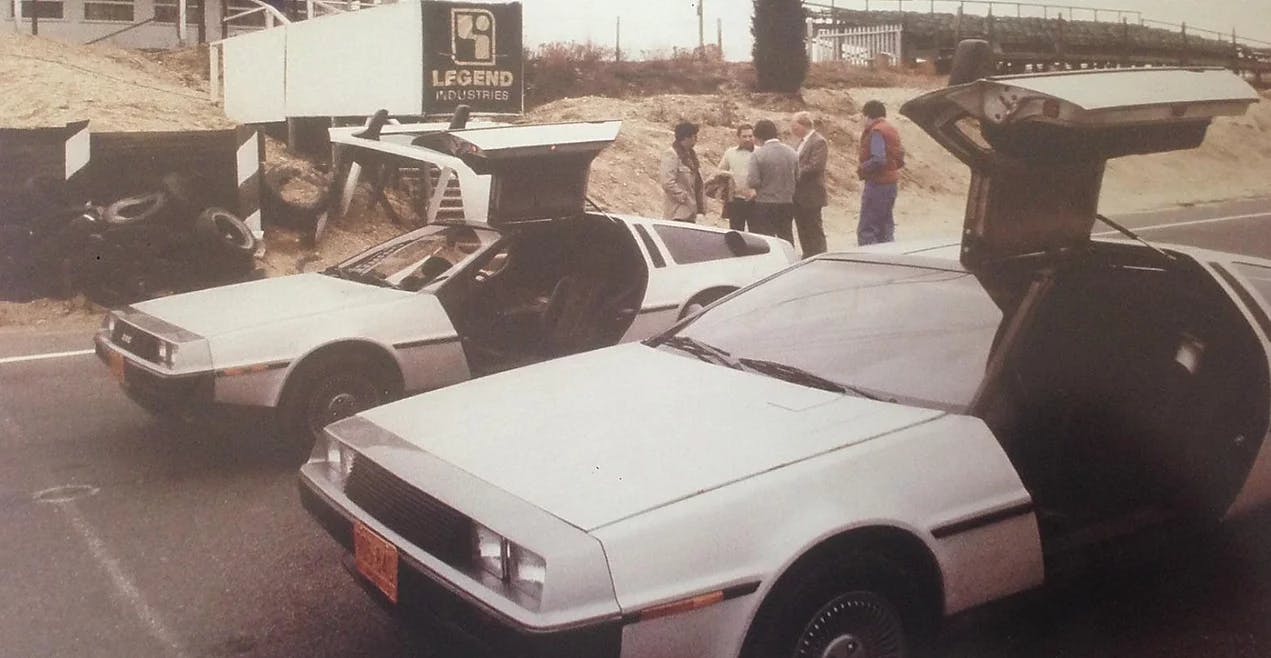

By late 1981, with early setbacks in the rearview, things were looking good for Legend Industries. The Fiat Spider Turbo was in production and receiving great reviews, and the DeLorean program was proceeding with the promise of a pay-as-you-go contract to keep the cash flowing. The high point of the entire endeavor came on November 16, 1981, at Bridgehampton Race Circuit, on the east end of Long Island, when we scheduled a ride-and-drive of the twin-turbo DeLorean prototypes for a handful of industry people—including the father of the Corvette, Zora Arkus-Duntov.

We spent the morning going over program status and providing a competitive drive on the public roads surrounding Bridgehampton. At lunch, Dellis and I did a dog and pony technical presentation, complete with storyboards showing all the affected parts. Then the fun began. We first conducted instrumented quarter-mile performance runs of the naturally aspirated and turbocharged DeLoreans, then demonstrated rolling side-by-side comparison tests before turning everyone loose on the track. John and Dellis jumped in the turbo DeLorean, while I got in the naturally aspirated car with Arkus-Duntov. Everyone was impressed with the turbo DeLorean’s performance, and even Arkus-Duntov had plans for it: He took me up to the timing stand where he unrolled some blueprints and showed me his proposal for an all-wheel-drive DeLorean, which he thought would be perfect for the turbo package. At the end of the day, Dellis and I celebrated another successful event, and, subsequently, the initial DMC turbo purchase order was increased to 7000 units.

The PRV V-6 used by DeLorean was technically interesting but disappointing in execution, the perfect example of too many chefs in the kitchen. What started out as a V-8–engine program had morphed into an unbalanced 90-degree V-6 because of the fuel crisis. Moreover, the block was an aluminum die casting. Rather than inserting or casting around iron cylinder liners, the PRV utilized “free-standing” liners. This meant that the cylinders were held in place solely by compression from the cylinder head. This worked reasonably well for the naturally aspirated PRV engines, but the addition of boost meant the head gaskets would likely fail. To make the twin-turbo engine reliable, we designed new head gaskets, head bolts, pistons with new ring packs and free-floating piston pins, along with revised rods and bearings. The only financially efficient way to accomplish these upgrades was to have the PRV engine plant install the new components. And the only way to make that happen was to persuade all of the chefs, firstly those on the PRV technical committee and then those at the PRV assembly plant.

To my surprise, I met little resistance from the PRV technical committee, to which I presented our case at their gathering at Volvo’s technical center in Gothenburg, Sweden. Shortly after, at the PRV factory in the northern French city of Douvrin, the plant manager took me around the facility. The place was impressive and highly automated, and the most interesting station was the installation of the free-standing cylinder liners. To achieve sufficient “crush” of the head gasket, individual shims were automatically selected and fit under the cylinder liners to accommodate manufacturing tolerances. The complexity was unbelievable and accounted for five different displacements and nearly two dozen engine variations. In this consortium, it seemed there was no compromise; everyone got what they wanted.

Still, I was worried that the plant manager would reject additional complexity, the very enemy of manufacturing efficiency. Instead, he was eager to accommodate the new components. With manufacturing issues out of the way, I was confident that we would be ready to put the DMC turbo into production.

Although the Fiat and DeLorean programs were progressing, Dellis and I knew we needed to garner additional business from other manufacturers. We were in discussions with Volkswagen of America for turbo Rabbits and Sciroccos; with Ford for a turbo Escort, Lynx, LN7, and EXP; and with Pininfarina for an intercooled version of the Fiat Spider for Europe. The future looked bright indeed.

If November 1981 had been the high point for Legend, it certainly didn’t take long for the business to go south. By year’s end, Fiat withdrew from the North American market, and DeLorean sales, which had started off with such promise, slowed to a trickle as the U.S. moved into recession. Of the 7681 DeLoreans manufactured in 1981, only 4756 had been sold to dealers, and just 3085 of those had been retailed by January 1982.

We scrambled to get new business, but it was too late. By March of ’82, Ford had decided to give its turbo program to a new joint venture made up of ex-Ford engineers and Jack Roush. VW wouldn’t commit to anything. Malcolm Bricklin, of all people, was negotiating with Fiat and Pininfarina to import the Spider, which Legend could continue to turbocharge, but talks dragged on. Out of sheer desperation, we proposed to John a single-turbo conversion package to help move some of the vehicles stored at the ports. Adopting Bricklin’s idea, I even suggested importing the Lancia Montecarlo/Scorpion built by Pininfarina, as it bore a striking resemblance to the DeLorean, used the same 2.0-liter four as the Fiat Spider, and could be marketed as a lower-priced DeLorean model. But time ran out when the British government closed the Dunmurry plant, and Bank of America got an injunction on the sale of DeLoreans in the states. Any potential source of income for Legend had vanished.

To try to keep things going, Dellis sold his Porsche dealership, but it was too late. One Friday, we called everyone together to give them the bad news. I felt responsible for bringing all these talented people on board, letting them down, and disrupting their lives. Fortunately, in time, they all landed on their feet and went on to bigger and better careers.

I stayed on for several months with Dellis, trying to revive the business. John kept telling us he had new backers, and we tried to follow up on other leads. Finally, my wife reminded me that, without a paycheck, we would not be able to make the next house payment. It was time to find a new job.

Legend Industries declared bankruptcy before John DeLorean’s infamous arrest, on October 19, 1982. Although we were DeLorean’s second-largest creditor next to Renault, having spent millions on engineering, tooling, and facilities on the turbo project, Legend never received a penny from DMC.

As a coda before Legend’s bankruptcy liquidation, Dellis arranged a fitting end to the turbo DeLorean saga by inviting Road & Track editor John Dinkel to take the prototype for a test drive, where he recorded a 0-to-60-mph run in 5.8 seconds and hit the quarter-mile mark in 14.7 seconds. Dinkel reminisced about his drive in the December 1984 issue of R&T, a bittersweet taste of what might have been: “The DeLorean is an amazingly responsive car to drive … The boost is so perfectly matched to engine characteristics and gear ratios that it’s difficult finding a condition where the V-6 isn’t immediately ready to spring into action. It’s the sort of all-around drivability the DeLorean should have had right from the start.”

i understand that one deloran with twin turbo,s was taken by the president of finland and what became of it and could it still be out there

Here’s some more information about the Legend Industries DeLoreans: https://www.pjgrady.co.uk/legend-turbos