Media | Articles

Artemis: Rover heading back to the moon … and soon!

Never mind America’s crying need for road, bridge, and tunnel repairs, our tax billions are about to fund a return trip to the moon. NASA’s Artemis program, involving multiple domestic contractors and several international partners, hopes to deliver humans to the dark, frigid, rugged lunar south pole by 2025. Missions lasting up to two months are planned for completion by 2033. In case you napped through Greek mythology class, the lunar goddess Artemis was Apollo’s twin sister.

We bring this to your attention because, as part of its preparations, NASA is once again shrewdly tapping auto industry expertise. Long before SpaceX emerged as the prime contractor of choice, Chrysler constructed the Redstone missiles that rocketed Mercury astronauts into space. Ford-Philco built and operated Houston’s Mission Control Center. GM supplied inertial guidance and navigation systems for the Apollo program. GM was also Boeing’s mobility systems subcontractor for the Lunar Roving Vehicles (LRVs) that successfully explored the lunar surface half a century ago.

Early last year, GM and Lockheed Martin announced a collaborative agreement to design, develop, and manufacture exploration vehicles to visit the southern reaches of Mother Earth’s only child. Thanks in part to its Apollo experience, GM is a world leader in battery-electric propulsion systems and autonomous guidance technology. Three other partnerships are competing with GM and Lockheed Martin for Artemis funding, two of which list Michelin and Nissan North America as allies.

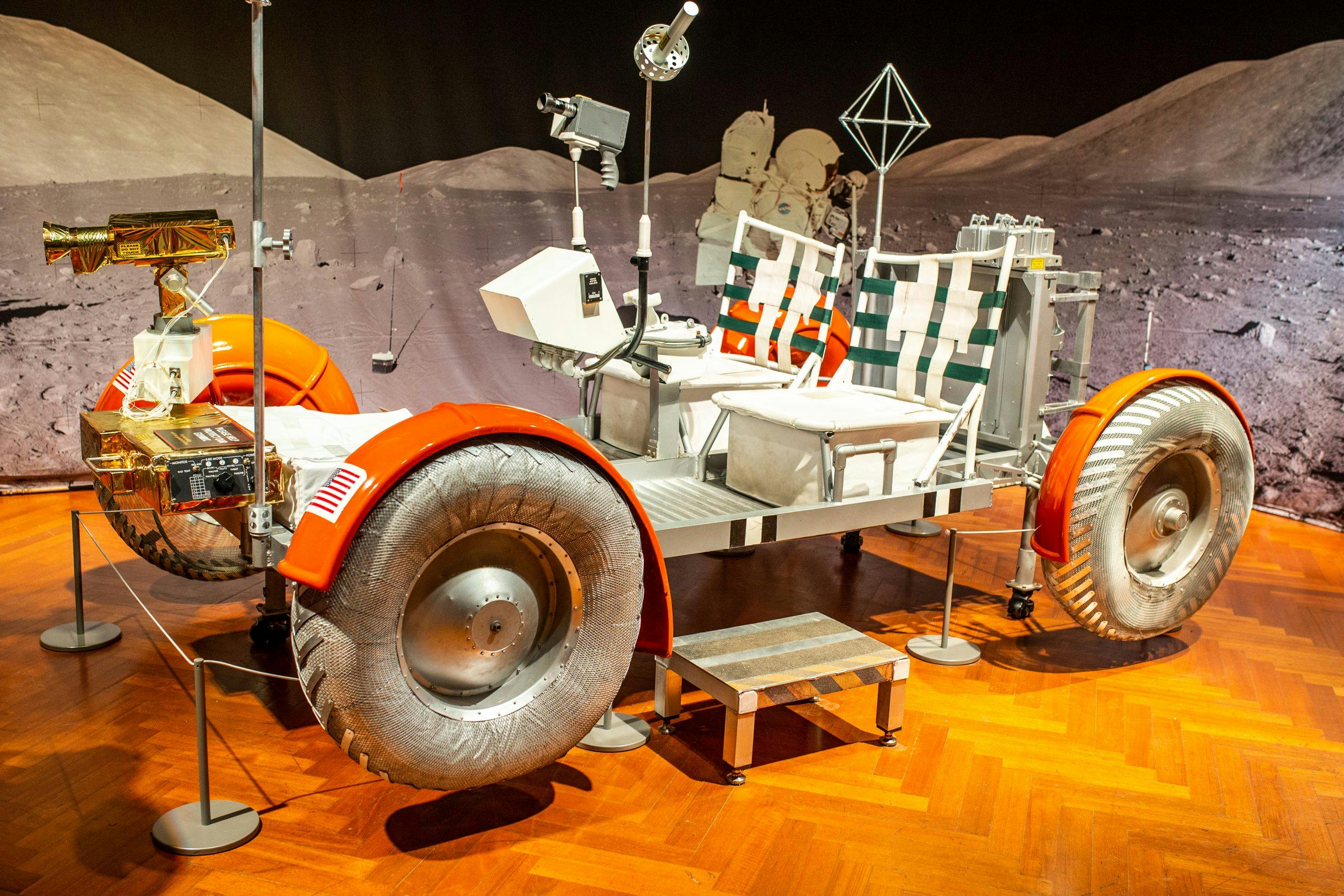

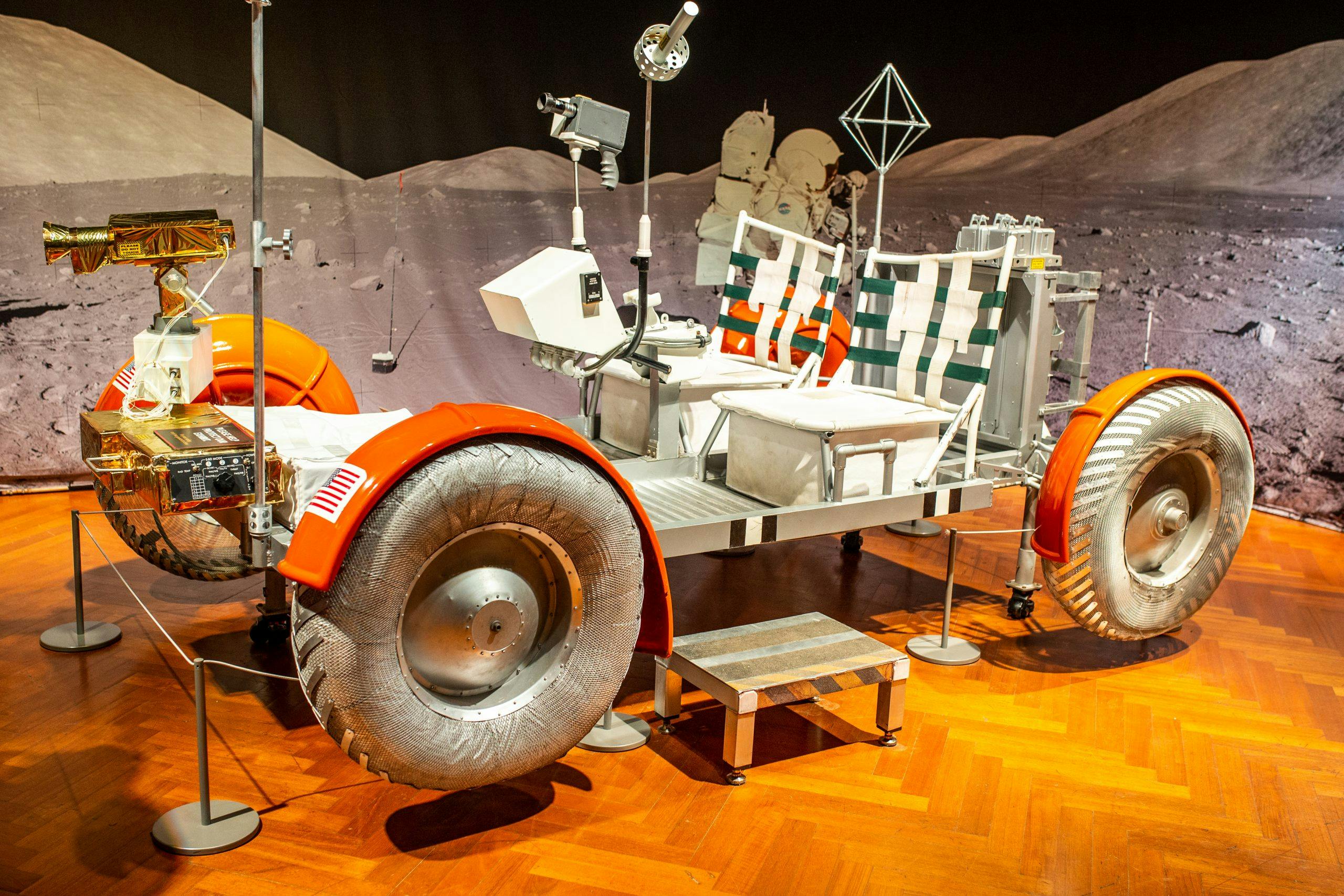

At this stage, little is known about the Artemis LRV beyond GM’s conceptual illustrations shown here. Insights as to what lies ahead can however be found in the 20th Century’s most advanced vehicles: the LRVs driven on the moon during Apollo 15, 16, and 17 missions in 1971 and ’72. In addition to the three buggies still parked there, several test prototypes and replicas remain as popular museum attractions, including the unit shown here photographed at the Henry Ford Museum in Dearborn, Michigan.

Developed and constructed in 17 months by 600 engineers, the LRVs were built by Boeing in Seattle. GM was the “mobility” supplier responsible for motors, wheels, and suspension systems. NASA’s cost for the 4-unit production run was $38 million when one million was still a major heap of cash.

Marketplace

Buy and sell classics with confidence

Boeing missed the LRV’s 400-pound design target by sixty pounds in spite of measures such as shaving metal from the aluminum alloy frame tubing in low-stress areas. The 1080-pound payload included two astronauts belted into what looked like lawn chairs, their tools, and material samples excavated from the moon’s surface. Given the moon’s gravity—only one-sixth as much as Earth’s—the half-ton payload was a bearable burden.

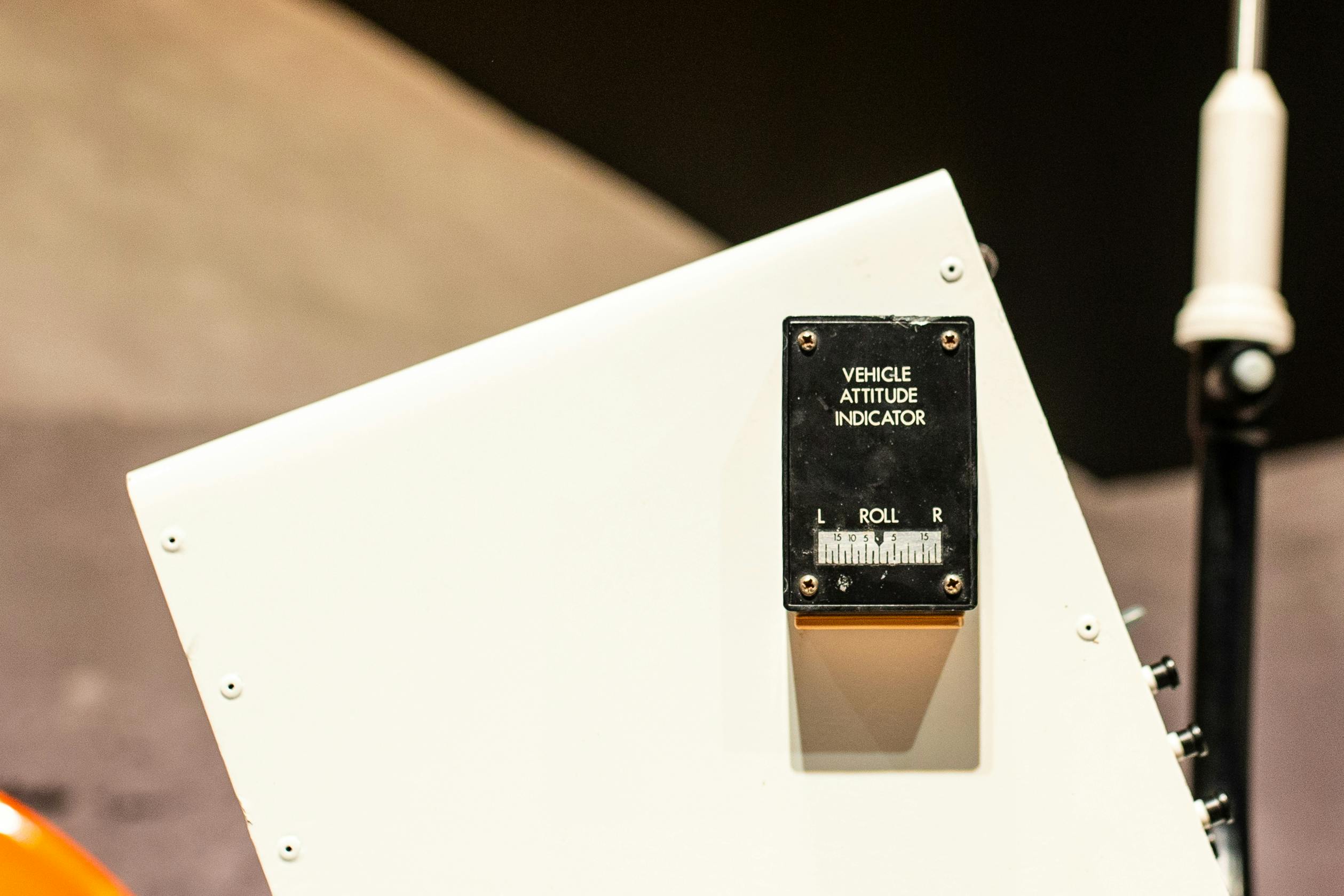

Each LRV had 90-inch wheelbase, a 72-inch track, and a 10-foot overall length. Unequal-length control arms fitted with torsion bar springs and tubular dampers supported each wheel. Four-wheel steering provided a 20.3-foot turn circle. To accelerate, brake, and steer, the mission commander operated a central T-handle.

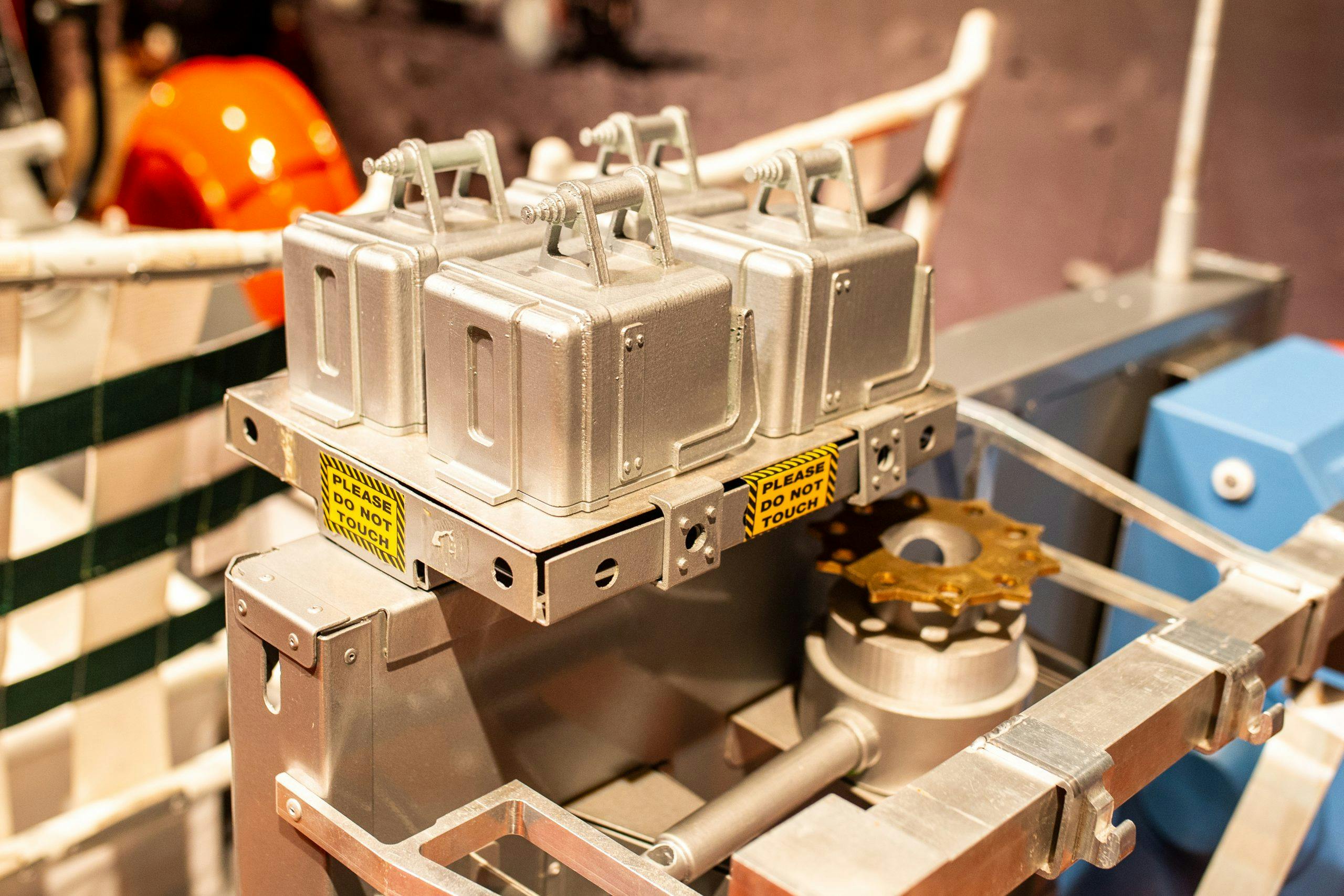

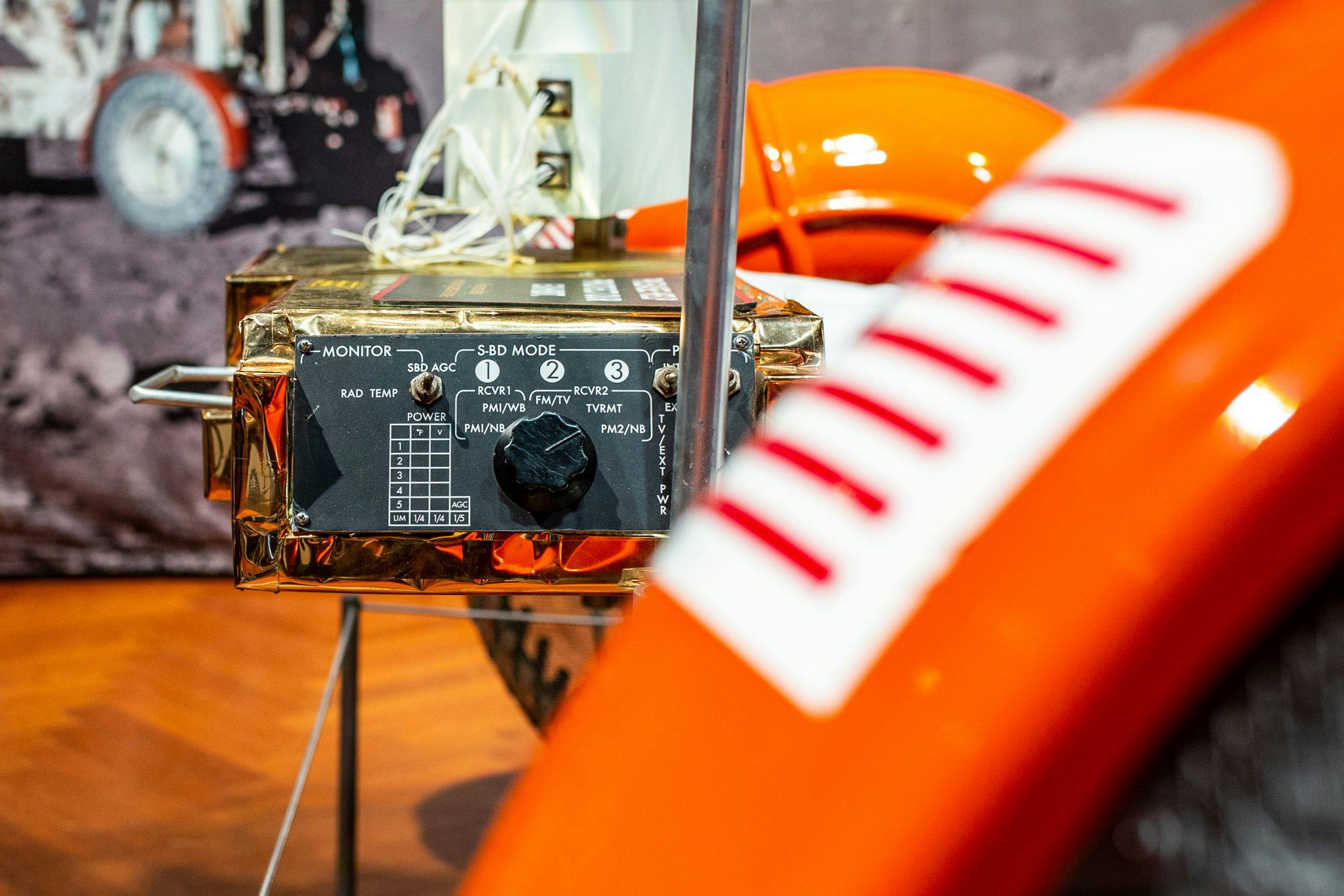

A quarter-horsepower DC motor, a small drum brake, and a harmonic gear drive multiplying torque 80 times were built within each wheel hub. Tight seals were essential to avoid dust intrusion. Twin 36-volt silver-zinc potassium-hydroxide batteries stored 8.7 kWh of energy, about 10-percent of a Chevy Bolt’s capacity. The batteries and all control electronics were secured beneath thermal blankets at the front of the LRV.

For the journey to the moon, front and rear sections of the LRV jackknifed together. Wheels, seats, and other gear folded to fit the LRV into the landing module’s storage bay. Upon landing, deployment and start up took but 15 minutes.

Six astronauts rode three LRVs 56 miles during 11 hours of lunar surface exploration. While the rated top speed was 8 mph, Gene Cernan topped 11 mph during a downhill sprint on the final Apollo mission in December 1972. Trips varied between 2.8 and 4.7 miles from the landing module, what was dubbed the “walk-back” limit. If their LRV broke down, the astronauts’ only option was returning to their Lunar Module on foot.

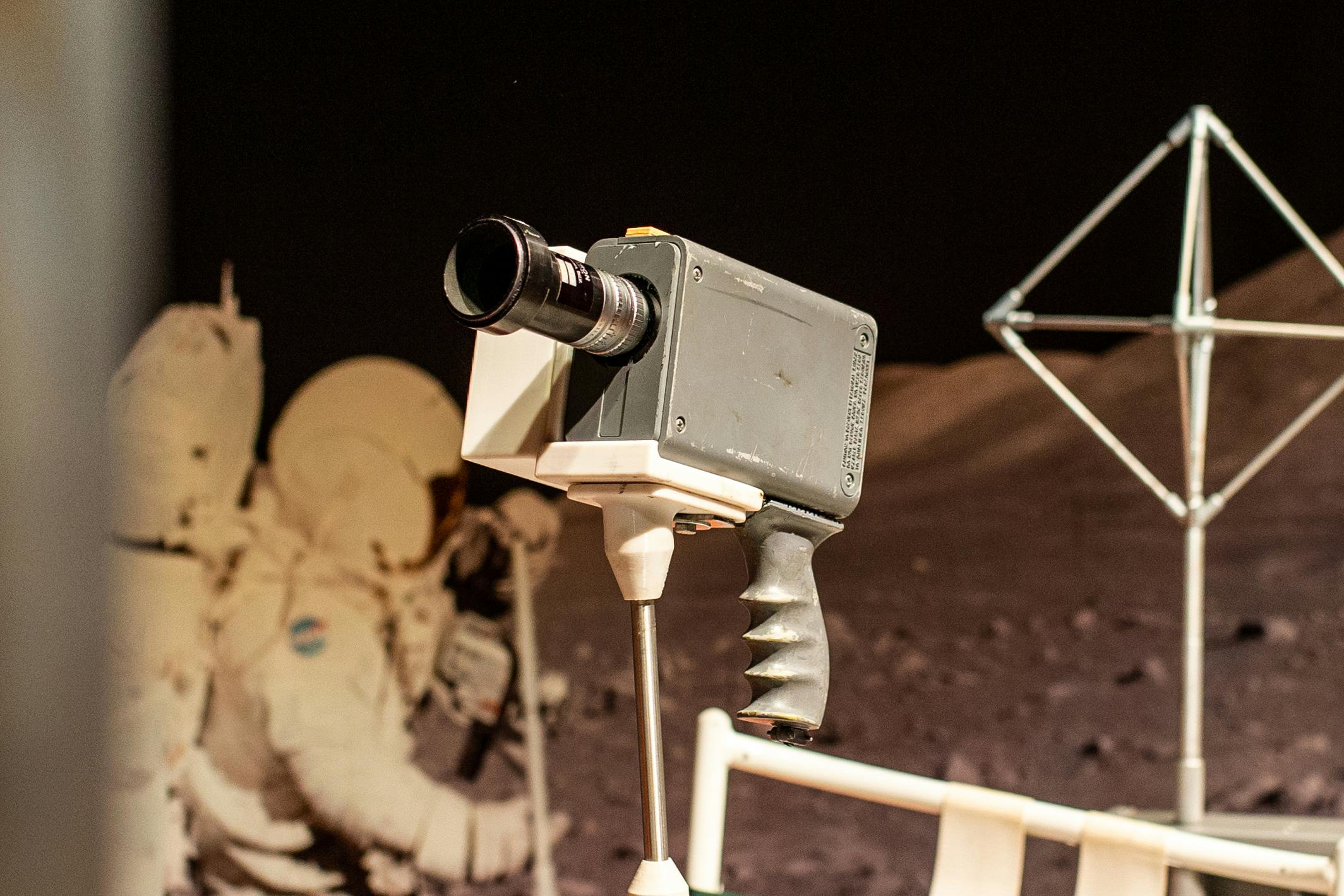

Navigation was supported by wheel-driven odometers, a directional gyroscope, and a signal processor calculating speed, heading, and distance. Range and bearing to the Lunar Module were displayed to guide each return leg. Throughout the three Apollo missions, this rudimentary nav system never missed a beat.

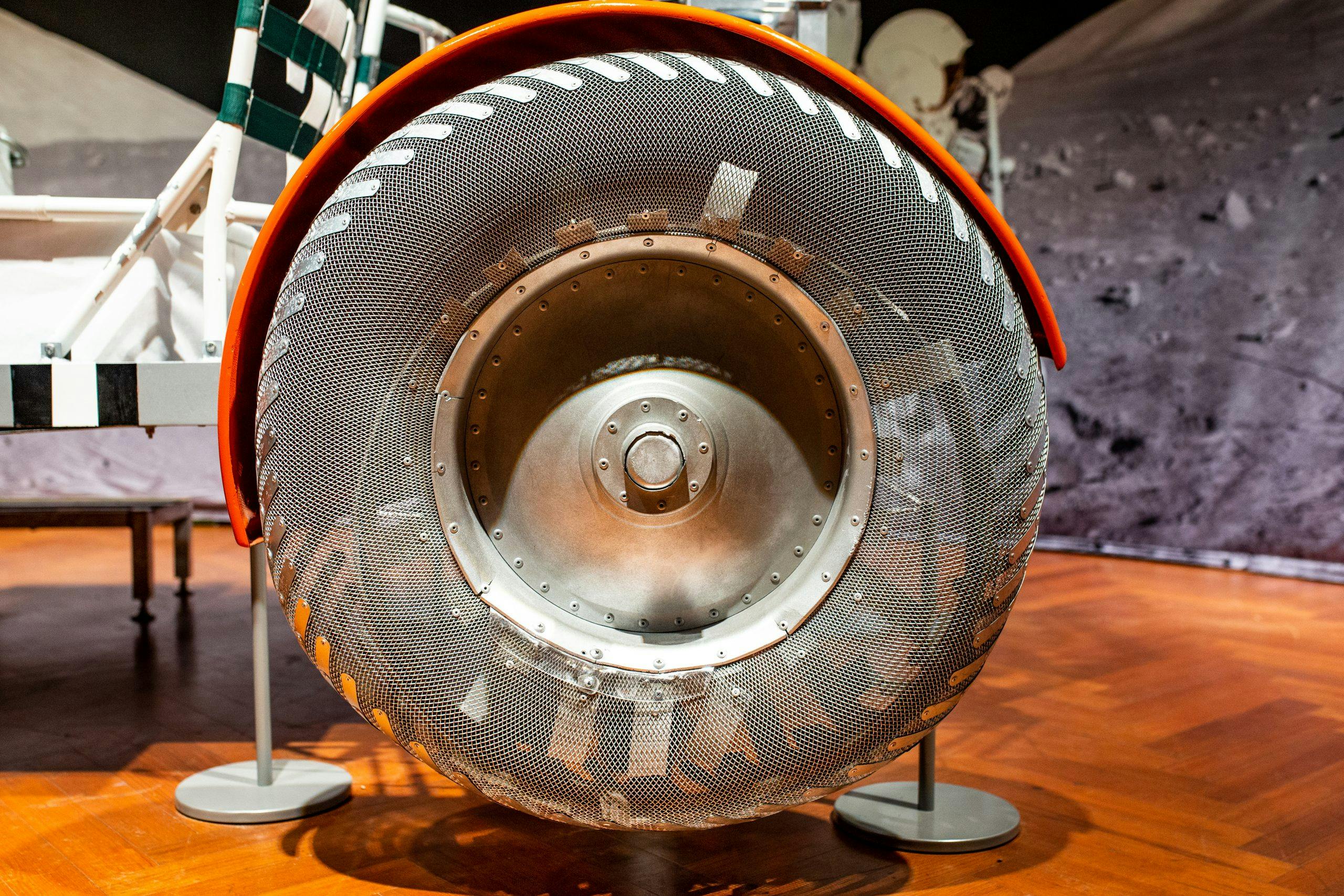

The single LRV component most crucial to mission success was the space buggy’s innovative wheel and tire system. In 1969, Apollo 11 and 12 astronauts—the first to walk on the moon—brought home samples, photographs, and vivid descriptions of the dust and rubble “regolith” blanketing the moon. In fact, studies aimed at optimizing traction and mobility actually commenced two decades before those missions, just after the Russians beat us into space in 1957 with Sputnik 1.

That year, Ferenc (later Frank) Pavlics arrived in America penniless. Luckily, GM hired the 29-year-old engineer fleeing the Hungarian Revolution to study how tire design could improve the traction of off-road trucks and military vehicles.

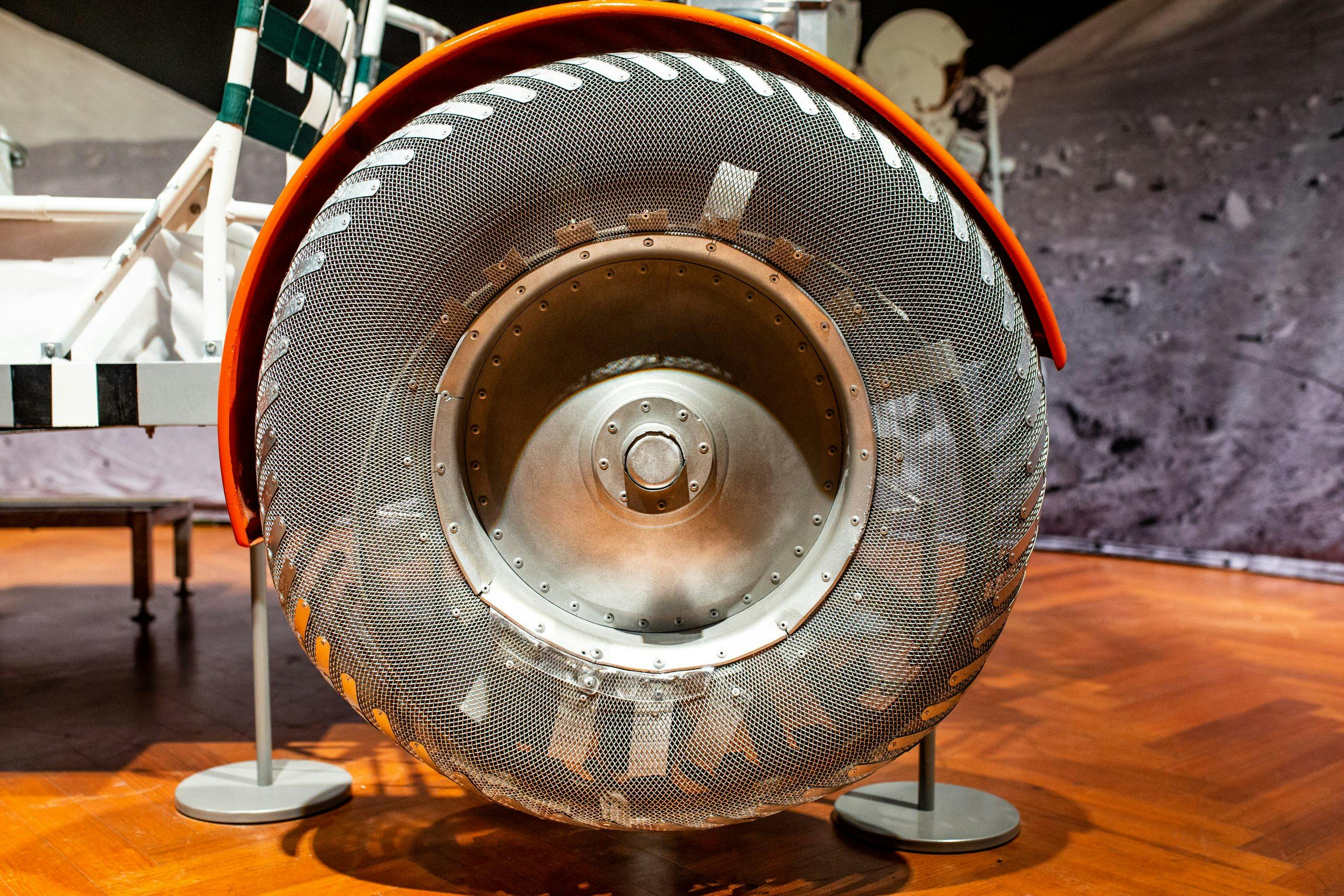

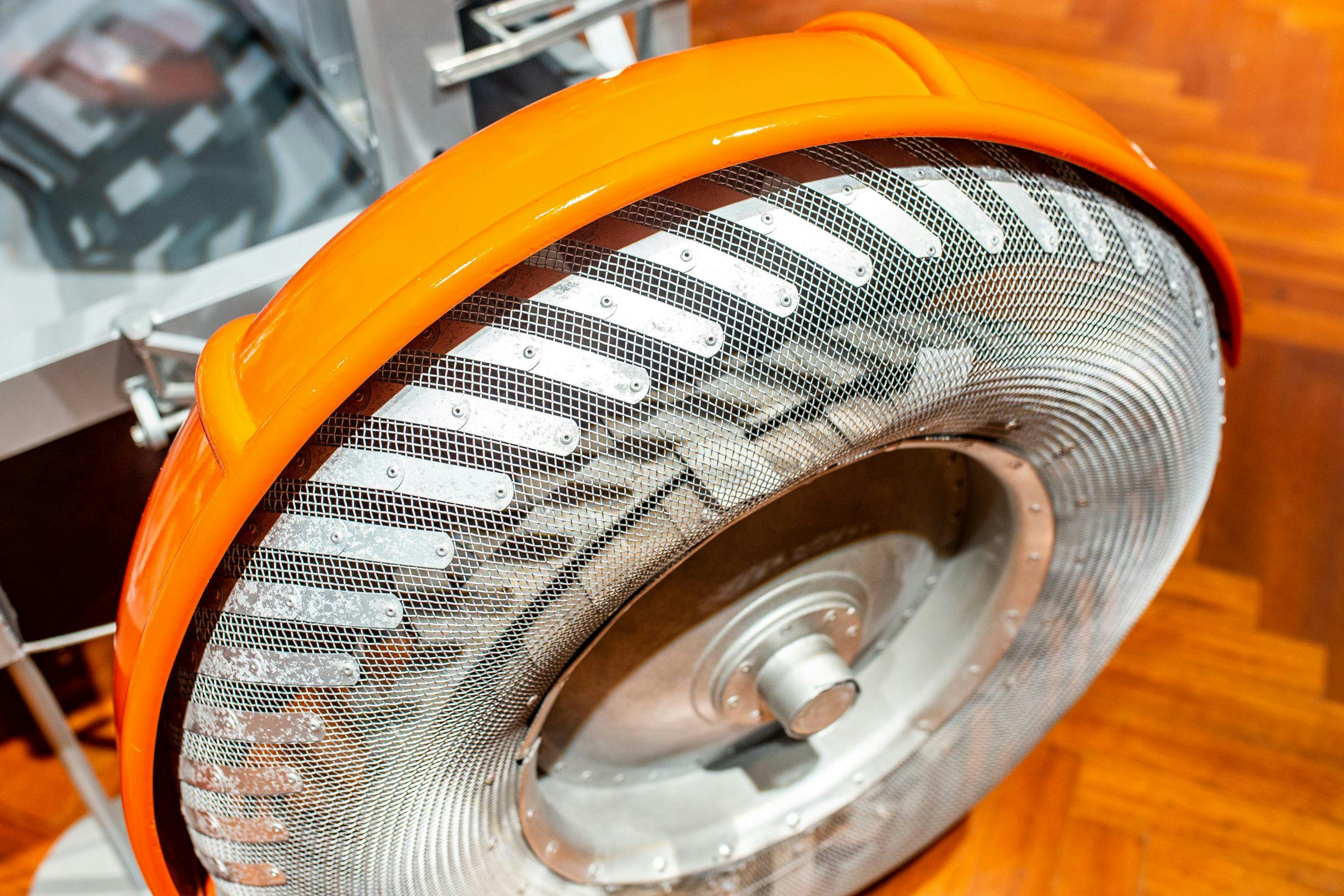

A decade later, Pavlics was tapped to create wheels and tires for the Apollo program. His all-metal system consisted of an aluminum hub surrounded by a titanium inner wheel serving as the tire’s bump stop. Each 32-inch-diameter tire was woven out of zinc-plated piano wire. Treads consisted of narrow titanium strips riveted to the tire in a chevron pattern. The wheel-tire assembly weighed 12 pounds.

Extensive R&D was conducted for years. To ascertain how much dust these tires would whip up, they were tested in flight conditions replicating moon’s gravity. To contain dust and debris, each tire was surrounded by a fiberglass fender fitted with flexible end flaps.

On the moon, Pavlics’ tires and the LRV’s suspension provided excellent traction and a resilient ride. Astronauts praised the LRV’s hill-climbing ability, responsive steering, and excellent maneuverability. Their gripe list mentioned excessive body roll and bounciness over irregular surfaces. Action photos captured several short four-wheels-in-the-air flights over hillocks.

The most notable LRV failure was fender breakage caused by accidental bumps by astronauts. Their bubble-faced helmets unfortunately limited close-by visibility. Repairs were mandatory, especially at the rear, to avoid clouds of lunar dust enveloping the LRV while underway. On the final mission, Gene Cernan effected a repair using a plastic map and duct tape carried aboard the LRV. Brought home as a souvenir, his fix is now on display at the National Air & Space Museum.

Tougher fenders for the Artemis LRVs are inevitable but don’t expect significant changes to the brilliant tires developed half a century ago. Still kicking at 94, Pavlics will surely cheerlead the coming mission to the moon.