Media | Articles

Matchbox launches carbon neutral toy cars

The news that Matchbox is introducing a new range of toy cars based on electric vehicles and made from recycled materials raises obvious questions. What sort of noise will children make when playing with them? Will there be a scale figure model of Elon Musk surrounded by a group of evangelists? And will this move prompt owners of classic Matchbox toys to convert their old models to electric spec?

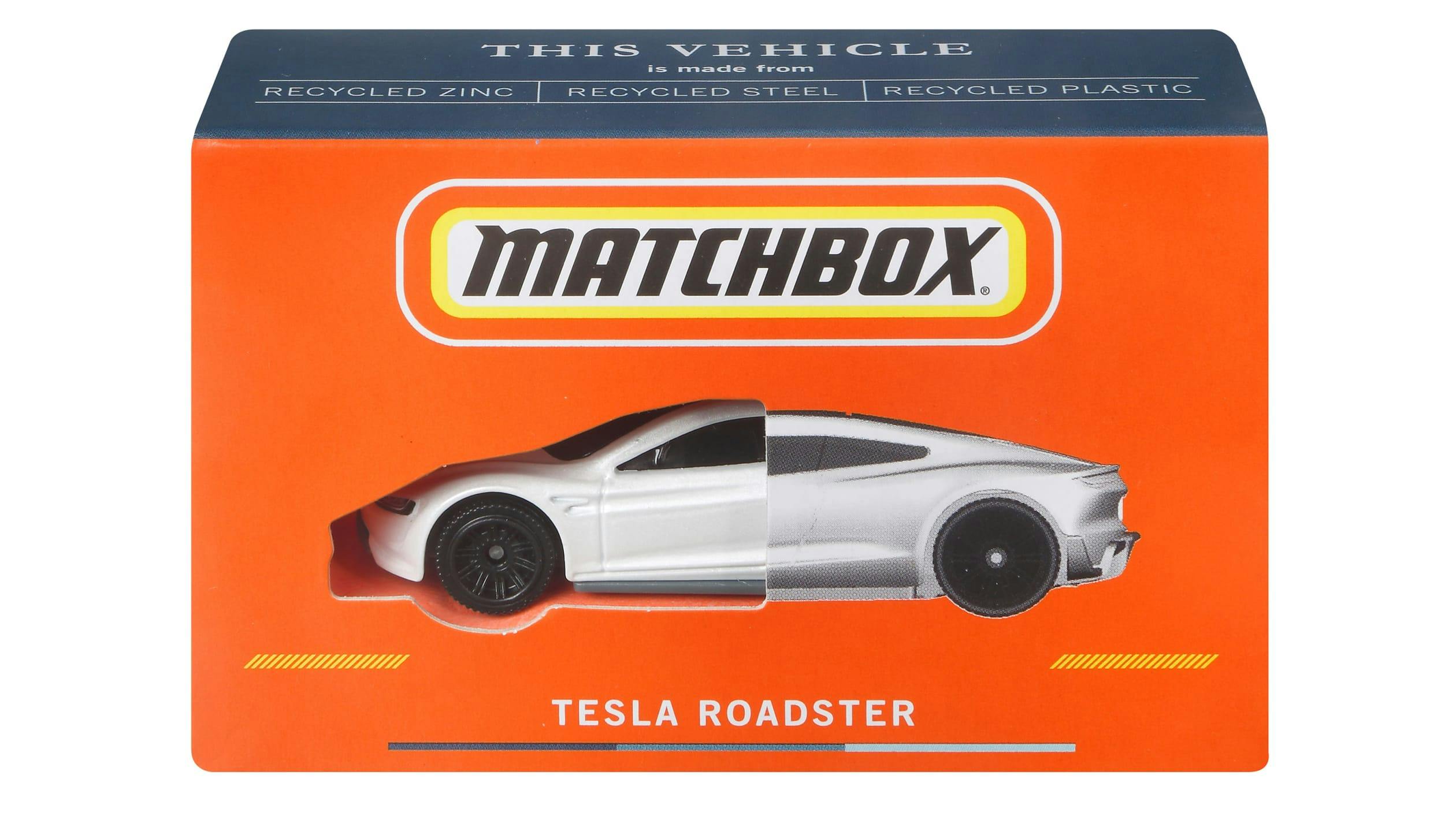

Launching its new range of environmentally aware toys, Matchbox chose the obvious brand to capture the public’s imagination, starting with a scale version of the Tesla Roadster. Like the Tesla, however, Matchbox’s toy is yet to go into production, with sales beginning across online outlets and toy shops (remember those?) next year.

The toy Tesla is claimed to be made from 62 percent recycled zinc and 37 percent recycled plastic, with just one percent of non-recycled stainless steel used in manufacturing. The company adds that the manufacturing process is carbon neutral, while associated packaging for the toy car will be made from paper and wood fiber.

Also in the pipeline is a fuel station playset that will include electric car charging stations, as Matchbox seeks to raise environmental consciousness among children—although some might argue that it is adults that are in greater need of reminding.

Roberto Stanichi, global head of vehicles at Mattel, said the move would “empower the next generation of Matchbox fans to help steer us towards a sustainable future”.

Marketplace

Buy and sell classics with confidence

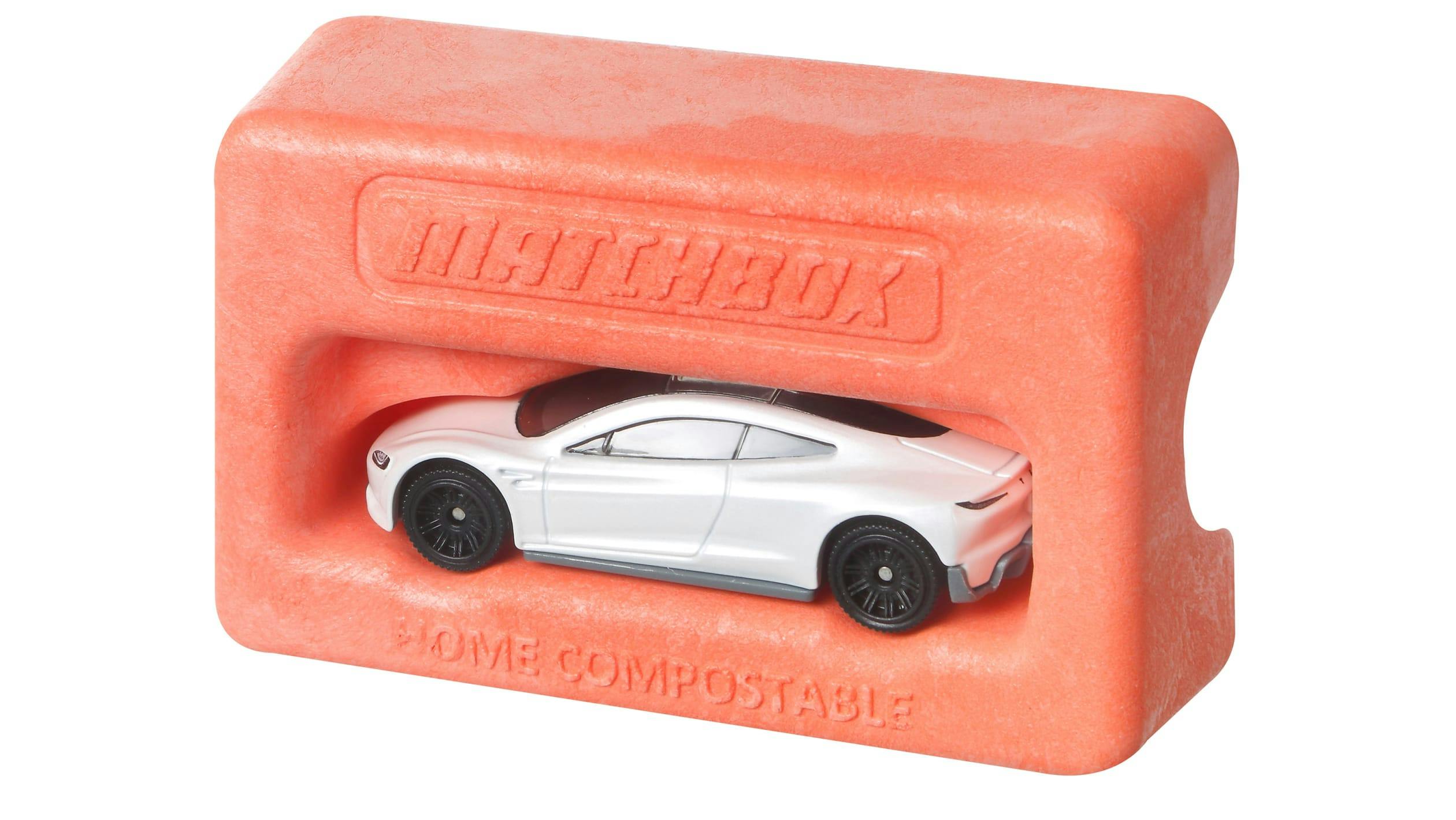

Before the mini Tesla reaches toy chests around the world, Matchbox will introduce die-cast electric and hybrid models. The pack will include toy models of the Nissan Leaf and Toyota Prius, as well as the BMW i3 and i8 sports car—the latter which failed to excite many drivers—and the packaging will feature a paper foam inner tray. Prices are still to be announced, so young car enthusiasts still don’t know whether switching to environmentally-friendly models will cost them more.

Matchbox’s parent company Mattel plans to use 100 percent recycled, recyclable, or bio-based plastic materials in the manufacturing of all its products and packaging by 2030.