Media | Articles

Why your next project car should be built before Y2K

If you run down the typical roster of problems with modifying today’s machines—oppressive engine covers, wiring by Medusa, A-pillars so thick you could ram them through a redwood tree, and enough encryption to give the Russian hackers tuners a sweat—it’s no wonder we obsess over the honest, mechanical nature of vintage cars.

For a brief period, the unintended consequences of regulation allowed for a mix of simple engineering and ample technology. Lightweight, well-built machines gave us many of the modern features we enjoy without the challenges of today’s new cars. Somewhere between 1996’s OBDII mandate by the EPA and 2008’s CAN-Bus mandate by the SAE, hot rodders and tuners lived in a state of mechanical bliss. Consider the following:

Let’s start with the foundation

For better or worse, the 1990s were transitional years for chassis design. Body-on-frame platforms from the 1970s saw their final days (GM’s B-body along with Ford’s Panther), and, with the move to unibody construction and independent rear suspension well underway, chassis engineering departments flexed their muscles.

This was especially evident at Honda, Mazda, and Toyota. The Civic and Integra sported double-wishbone suspension on all four corners that set the standard for front-wheel-drive handling; the RX-7 and Miata defined the driver’s car model with taut, lightweight chassis; and Toyota was throwing the house at the Supra. And while the maritime handling characteristics of the aforementioned B-bodies and Panthers weren’t for everyone, they were still the last of their kind for the many who loved them. Each benefited from decades of development under the hood, inheriting the likes of the 5.7-liter LT1 and 4.6-liter Mod motor—hell, the Panther eventually saw rack-and-pinion steering and a Watts-link rear axle.

Marketplace

Buy and sell classics with confidence

Today, we’ve seen a reduction in these more focused products. Honda is back to using McPherson struts, since the RX-8 died Mazda’s sole dedicated sports car has been the Miata, and Toyota gave up development of its halo sports car, more or less, to BMW.

When it comes to your project car, one of most significant variables is its foundation—the car’s inherent traits that, without extensive modification, you essentially have to accept. No amount of stripping and cutting will make a BRZ as light as a first-generation Miata—and you’re still stuck with a cheap strut suspension in the nose, y’know?

And for those who enjoy traditional SUVs and sedans, this era was the peak of the old-school V-8, solid-axle tanks. Cars from just before the year 2000 offer incredible bones for not a lot of cash, and in some instances, they’re technically superior to some of their modern versions.

Streamlined

Speaking of built-in traits, a big advantage to machines from the ’90s is that automakers by this point had a decent handle on aerodynamics. No, they don’t look as striking as cars from the ’50s and ’60s, when styling was considerably more free from emissions regulations. Still, such restrictions did eventually yield a plethora of aerodynamically efficient canvases that undoubtedly advanced performance.

Lift and drag—undeniable forces that many classics struggle to reckon with at triple-digit speeds —were much better understood and accounted for by the tail end of the ’80s and into the ’90s. At this time, drag coefficient fell as low as 0.29 in the hottest performance cars of time (for example: FD RX-7, fourth-generation F-body, C4 and C5 Corvette, the DSM Eclipse, Laser, Talon, etc). The 1992 Crown Vic, with a drag coefficient of 0.34 was even as slippery as some of today’s supercars. In its low-drag mode, with the rear wing in position for high speed, the Koenigsegg Agera R has a drag coefficient of 0.33.

The drop in drag coefficients was largely driven by the computer-aided quest to meet CAFE regulations. When the policy was first enforced in 1978, the mandated goal was 18 mpg. By 1990 CAFE regulations demanded an average of 27.5 mpg, and manufacturers quickly found that optimizing aerodynamics was one of the easiest (and cheapest) ways to improve fuel economy during new car development. In motorsports, however, the profile and frontal area of a car body are among the two most difficult areas to modify when seeking to improve aerodynamics. You’re locked into certain dimensions that can’t be nipped-and-tucked away, and this can be a critical factor depending on the scope of a project.

Goldilocks’ fuel system

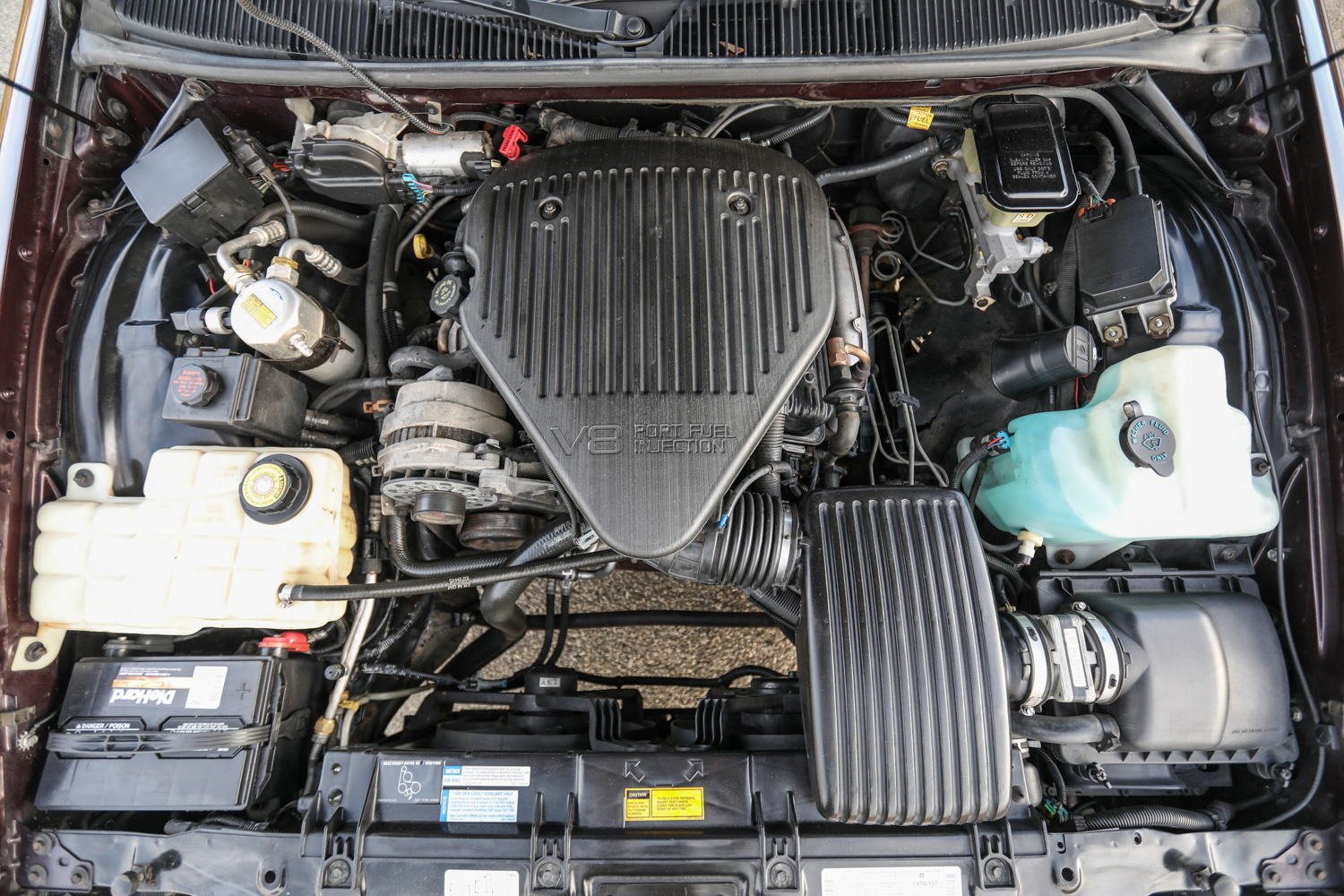

Here’s the real love affair hobby wrenchers have with this period of machinery—we had just enough niceties in electronic fuel injection with none of the labyrinthine electronics and engineering that’s gone into today’s ECUs. Carburetors are an interesting kink, no shame there; but there’s no arguing the performance and economy advantages that EFI represents.

The transition was slow, with computer-controlled carburetors (see GM’s CCC Quadrajet and Honda’s CVCC Keihin units) filling in the stopgap as the advent of electronic injection systems finally settled onto the standard port-injection systems we see today.

Through the late ’70s and into the ’80s, EFI was fraught with archaic ECUs and throttle-body-injection systems that barely outperformed their venturi-fed pasts, but the standardization of emissions reporting—locked down in 1996 with OBDII—resulted in a rapid development in the formula we see today in EFI. OEMs dumped pet project ECU platforms to meet more advanced, standardized controls. No more rudimentary cold-start injectors and swing-door airflow meters, or bizarro scan tools that used obsolete connectors. Hardware advances allowed user-reflashable calibrations, so no more burning physical calibration chips. In addition, most companies had figured out coil pack ignition by this point.

These advances not only laid a better groundwork for projects, but it also made ownership more practical—then, and now. EFI starts easily, every single day, no matter the ambient conditions—and there’s no denying the reduced operating costs from the improved fuel economy. This means more money in your pocket for fuel, parts, and the general maintenance that these machines (now decades old) will periodically need. Don’t get us wrong, the bullfrog wail of a Quadrajet’s secondaries is still one of the most addicting sounds out there; but we don’t mind the 20-plus-mpg that the 1990s LT1 V-8 returned with absolute ease, despite the era of laptop tuning it presaged. (The same can be said for every other OEM in this period, not just GM.)

Why are things so different today? Modern cars are nightmares for tuners and hobbyists, thanks to the march of progress in fuel economy and the concern with hardware and software security that accompanies always-on internet-connections. While these same concerns led to some of the most advanced and capable engine platforms we’ve ever seen, an obsession with chasing diminishing returns in efficiency underlies this progress more than anything else. Fuel and spark tables (the equivalent of tweaking the carb and distributor in days of yore) have grown from a single layer of adjustments to complex reverse-engineering complex algorithm strategies across what seems like an endless source of reference calibrations—and that’s if you get past the increasingly difficult encryption protocols that keep hot rodders at bay as much as hackers.

In this sweet spot of the 1990s and early 2000s, you have all the hardware necessary to manipulate electronic fuel injection to your heart’s desire with delightfully exploitable ECUs, and a robust suite of sensors and controls. While many inherent advantages followed the rise of CAN-Bus integration seen after the 2008 mandate, the same advances brought in a new layer of complexity with a considerable learning curve. Routine modifications—such as replacing a factory wheel with a quick-release unit required by many racing rulesets—became network engineering challenges. Progress isn’t inherently bad, but the scope of OEM controls over the engine and chassis in today’s cars slants towards locking out the tinkerer and innovator.

Swap ’til you drop

Cars of this period are entering the 20- to 30-year cutoff for emissions testing in some regions. As these cars come of age, so arrives my most cherished aspects of a “true” classic: the freedom to tinker with the engine. It means no longer having to listen to The Man. Engine swaps are on the table. Thinking of swapping that turbo-ready LS or JDM-spec 2JZ you’ve been eyeing on eBay? Now might finally be the time.

It’s no secret that the EPA and CARB have begun to crack down on the aftermarket industry, and an increasing number of states have hopped onto California’s emissions standards by accepting CARB’s tighter regulations over the federal standard. If you live in a stringent region, you understand how much weight is lifted off your shoulders by eliminating the need to retain (often defunct) factory emissions systems.

“Yeah, I read that on the forums!”

We didn’t have comprehensive, easily accessible car-enthusiast forums and far-reaching search engines until the ’90s, and thanks to sheer luck in timing, tuners and hobbyists of today can access an incredible treasury of resources with ease. In addition to the younger demographic that naturally flocked while these cars were still new, more enthusiasts over the past two decades have been chronicling and recording just about every modification that you can imagine.

There isn’t just user-generated brain trust, but entire archives of factory information—the kind of stuff that dealerships used to guard close with $150/hour labor rates. Almost everything from this era is now obsolete, and OEM support is gone in many instances. For DIY hands, the factory wiring diagrams, parts breakdowns, and diagnostic trees are invaluable tools that are often even provided for free.

Any number of new projects never get off the ground just because of the sheer lack of how-to knowledge for the home mechanic. Thanks to the democratization of information, the barrier to entry has dropped and allowed folks to take on new projects without those subconscious doubts. Knowledge is power. So fire up your web browser and find a pre-2000 classic.