Media | Articles

Piston Slap: CFM Calculations the Easy Way and Hard Way

DUB6 writes:

Although I think I already know the answer, I’m going to throw out a question because, after having read previous posts, I know that not everyone knows everything. We can often help each other learn new things, and maybe I don’t REALLY know the answer. (Or at least, not all of it.)

So here’s my question for everyone: How should one determine what CFM (cubic feet per minute) carburetor to install for best fuel mileage/drivability and performance?

I assume that there is some sort of calculation that takes into account displacement, intake runner type and flow numbers, cam specs, combustion chamber size, compression ratio, exhaust port size, and actual exhaust design—all sorts of variables that could fill up a large blackboard with numbers and algebraic squiggles, etc., resulting in a number at the end that tells us exactly what size carb(s) to purchase, right?

Sajeev answers:

Marketplace

Buy and sell classics with confidence

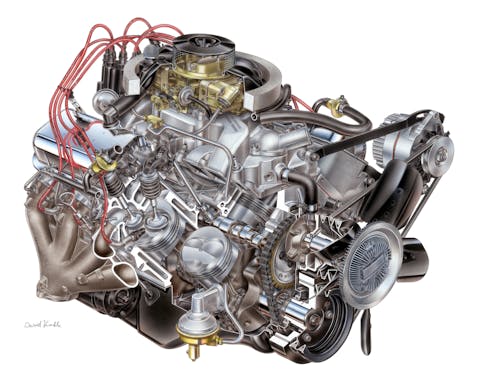

To the best of my knowledge there are two CFM calculations pertinent to carburetor selection, and I have used both recently. That’s because my recently resuscitated Continental Mark III needed a lot more work than originally anticipated. There’s a rebuilt engine, new cooling system, and a new fuel system in my future. But let’s get back to my Mark’s big-block engine and its need for a new carburetor:

CFM = (Engine CID × Max RPM) ÷ 3456

For my Mark’s 460-cubic-inch motor that redlines (around) 5800 rpm, I need a 772 CFM carburetor. But let’s consider a more accurate formula, even if it borders on being too pedantic for most folks:

CFM = ((Engine CID × RPM) × Volumetric Efficiency) ÷ 3456

What you see above is my manipulation of the Volumetric Efficiency (VE) formula, pushing the CFM on one side of the equation by itself. Hopefully I did the math correctly, but even if I got it wrong, VE is not an easily-sourced figure. (Finding it might require an engine dyno to know the truth.) The fine folks at Summit Racing offer a rough estimate of your engine’s VE, but save yourself the effort and use Summit’s handy CFM Calculator instead. It includes VE data into its formula, and it gave me a CFM requirement of 656 for my Mark III.

You can mull over your intake design, camshaft profile, compression ratio, combustion chamber size, boost from turbo/supercharging, etc., but the more generalized information from Summit Racing is good enough for most folks. Getting the right CFM is just the first step, because you then adjust it via jetting, mixture screws, etc. to get the right amount of fuel to go with all that air the engine will consume.

And no, you didn’t ask, but last week I bought an Edelbrock 750 CFM carburetor for the Mark’s new engine. Odds are it will need to be tuned down just a little by my mechanic, but I am looking forward to driving this one soon … sooner or later.

Have a question you’d like answered on Piston Slap? Send your queries to pistonslap@hagerty.com—give us as much detail as possible so we can help! Keep in mind this is a weekly column, so if you need an expedited answer, please tell me in your email.

***

Check out the Hagerty Media homepage so you don’t miss a single story, or better yet, bookmark it. To get our best stories delivered right to your inbox, subscribe to our newsletters.

As Dick O’Kane wrote in his marvelous book “How To Repair Your Foreign Car”: Carburetor is a French word meaning “leave it alone”.

Well you can do like most. They go out buy a 750 double pump because that is what their buddy has and they put it on a 305 Monte Carlo. The car smokes and fowls plugs. So they call the shop they bought it from and try to return it.

Now what I described here is too often the case that happens. Carbs are an art to themselves and while you may be an accomplished mechanic many just never get carburetors right. I have customers that can build a 1500 hp engine but sill never understand a carb.

On the street most small block applications are 600 to 700 CFM. When racing you can move it up based on the rpm and expected HP. You can also go to a double pump with more instant throttle and need for gas.

Big blocks you start around 700 CFM and you can go you a dominator.

Often you can talk to guys with well sorted systems and they will share what CFM to start at.

Now here is where it really matters. Setting the carb up is where most fail. You need to set the float level. You then need to read the plugs to see if they are rich, lean or right. To adjust this you likely will need to rejet the carb.

Often even if you bought the wrong carb rejetting will bring it back. There are other tricks that good carb guys know.

When I did a dual quad tunnel ram for my Chevy. I used a small runner ram to restrict the air and keep velocity up since this was a street car. This helped the bottom end. I had a good to mid range cam.

I had two 600 CFM Holley carbs that were too large but. Rejetting and that they were vacuum secondary let me adjust them do they would not dump too much gas.

I also had to restrict the idle circuit. This was done by putting a wire in to cut it in half.

Now buying the right carb is always best but back then the 450 CFM was not available. But this is an example of what tuning can do.

Most carbs unless it is made for a specific vehicle it will need tunes. This means more than just an idle circuit screw turn.

So while the formulas above are a great help and where to start be aware there is more work to be done. Tuning is so very important.

Some folks bolt on a carb from the box and it may be a big improvement but with some tuning it would be even more of an improvement.

Edelbrock carbs are the easiest to tune for the street but Holley styles are the best for higher performance.

Or you can go Fuel Injection like many do today. You fail it in on your lap top or phone.

Your question is fuel mileage/drivability and performance.

You probably have two competing objectives here

There is a guy out there who put a lawnmower carb on a 351 Ford motor, drove it, and put it on a dyno. It drove fine, got excellent mileage, and made 60 HP on the dyno. 60 HP is generally a sad number, but remember… this is a 1BBL carb you usually put on a Briggs and Straton.

So here’s the point. For efficiency and drivability… use the smallest carb you can get away with… even down to a 2BBL

For performance, the stuff that Sajeev and the commenters have will get you down the right road, but even then I would err on the side of small.

Want the best of both worlds? Get a spreadbore (aka Quadrajet). The one thing about the Qjet is that if you go overboard on CFMs, the secondaries are variable venturi and will compensate… if tuned right

Right carburetor tuning… If it’s not tuned right, it doesn’t matter what you put on there, you won’t get what you are looking for. Find a local mechanic that knows how to tune carburetors. This will be the guy who has drag racing pictures and trophies all over his wall… Not the guy with ASE certifications all over the wall

The Rochester Quadrajet does NOT have “variable venturi” secondaries. It has a demand-dependent air valve that, as the air valve shaft rotates, lifts the secondary metering rods out of their discharge wells which in turn regulates the amount of fuel delivered through the discharge tubes. A variable venturi carburetor does just that; it changes the size of the venturi. The Q-jet secondary opening size does not change as it is part of the main body casting.

I hereby declare that you know more about Qjets than I… which is rare. Not because I know a lot, but because so many others know little of this mysterious beast. Sooo… does my analogy still stand that it will compensate for being oversized? That has been my general understanding, and I have been somewhat aware of controversy over the ‘variable venturi’ designation

The formulas typically compute what’s required at maximum throttle, but for normal driving, how often are you driving pedal to the floor for any length of time? But why not “Go big or go home”? Too big of a carb affects driveability because in a carb, fuel is pulled into the air, not injected. For a given engine size, a too large carb means much lower airflow at a given engine speed and more difficulty pulling fuel, especially on opening the throttle. Counterintuitively, this means you may need a bigger jet to pull the correct fuel. And everything else, accelerator pump, idle slots, will be more challenging to set up to achieve smooth throttle response. Carbs are not magic. If you have a reasonably sized carb match to your engine size (I won’t go into performance cams and overlap duration etc), all you need to set one up for efficient operation is an inline oxygen sensor, some various jet sizes ( carb kit), small tools, and a little time and you can equal or beat the performance of a $2,000 throttle body fuel injection system. 750 cfm is likely on the verge of overkill for 400 cu and smaller engines operating below 5000 rpm.

This is the deal. The big sins of performance work or restoration is too much carb, too much can, wrong converter and wrong gearing. These all need to work together and with the engine involved.

But to compound this few people actually have no idea how to adjust a carb. There is magic or knowledge to setting one up. Often the best carb for some is the one they have the most understanding or sucess.The truth is there are a number of great carbs out there less thess the Themoquad Lean Burn.

Too many think a carb just works right out of the box and that is rare. It may run better but it still needs work.

But in the long and short the FI systems out there are still better. They can be set and adjusted exact and not vary. This is why the automotive industry had gone to them as they measure the air and apply the proper amount of fuel no matter the tempter or altitude.

But working on and adjusting a carb is something you have to learn and really understand how each one works and how each one reacts. This is where many fail. They may get lucky to get the car to run better but they will leave you with watering eyes due to it still being too rich.

Then you can get into NOS and Turbo systems where if you do not get the fuel right you are fixing burned piston.

So I have a wonderful story every time the carb vs FI debate comes up. To start off with, I know enough about tuning carbs to be dangerous and to get myself to 90% of where I need to be. A buddy of mine was working on his non-factory engine about the same time I was working on my non-factory engine. I bought a Qjet from a swap meet. He spent a few grand on EFI. I have been riding for years… his is still tucked away in a garage somewhere. EFI is great, because a lot of time you can set them up with a few known inputs and let them autotune… but this does not always work which means you better know how to do real tuning… which most people don’t, which is why they bought EFI in the first place

hyperv6,

Aftermarket throttle body injection systems have not produced long term, trouble free performance. Do an internet search, but not for the glowing reviews on day one. Rather see stories from car people who have had them installed for over one year. They take relatively frequent adjusting , and the ones with integrated electronics that sit on top of the intake manifold are subject to electronics failures due to accelerated thermal ageing.

Retrofitted systems are not comparable to those in new cars today. The best modern day factory injection systems use multiple injection techniques, which are impractical to retrofit to a vintage car. They employ direct injection for overall performance plus throttle body injection simultaneously for economy and to negate valve carbonization issues caused by direct injection.

I calculated mine the easy way also. I calculated I would be better off with a 1995 C4 in lieu of a 1979 C3 Corvette.

Sajeev, how many project cars do you have? This isn’t “Valentino” is it? I’m forgetting now.

I have a lot of cars that sat around and went to absolute heck. This isn’t the Valentino, but its another reason why I don’t do enough to it.

Fuel injection on factory cars has been refined with thousands of dollars and time and on those cars, yes it is great!

if you take one of their f.i. units and put it onto another vehicle without the proper knowledge of computer tuning it, You Will Fail.

Hyper has great points, Bottom line fuel injection is not user friendly without computer skills and they are also prone to tuning problems just like carbs, but you are going to get a hell of a lot more money in a f.i. system than carb so you can experiment a bit more.

I have a friend that has a ’56 Chevy Gasser with a H****y f.i. setup that has not functioned properly and he has tried several times to get their tech help. He is not an idiot and has decided to go back to a carb. Could be because of the camshaft as f.i. dosen’t like low vacuum profiles.

The drivability of a carb is all about air velocity past the venturies. Too much carb size means same amount of air going slower past venturis. Growing up I loved the throttle response of the 2 barrel carbs on small block fords.

RE: Carb vs EFI — I have converted nearly all of my old iron to EFI. Done properly, it is awesome. But done IMproperly it is a nightmare. This is not for the weak of heart as it is a definite learning curve that most mechanics are not equipped for, either with knowledge, experience, or patience. Here’s what I have found. Any issue you have with your carbureted engine will be magnified tenfold with EFI. It is NOT a “fix” for a worn out powerplant. Much of an initial installation will be trial and error and you will likely need to become friends with a nerd or two to figure it out. I am fortunate in that my skillsets are computer oriented (yes, I am a nerd) and I also have been building/diagnosing/repairing automotive wiring and electronics for years. Even so, I am never above asking someone with a little more experience for their input. EFI isn’t for everyone, but it works for me and has brought a few of my anciently designed engines to life…