Media | Articles

4 things to consider when choosing a bench vise

There are lots of tools in any garage but only a handful are investments or generational purchases like a good bench vise. These chunks of metal are often literal fixtures on our workbenches and are something that can be used in a multitude of ways to solve all kinds of problems when tackling repair or restoration tasks.

A vise can be as simple as just something to clamp or hold workpieces or have additional features like an anvil for allowing hammer work. Regardless, having a sturdy vise that is secure and can be trusted is basically a safety feature in the workshop. The ability to properly hold material or parts is critical to any precision process or just generally working on things in a safe manner.

For something so important, it is best to know a little about what you are buying because a higher price tag does not always mean better—especially for those just working on home projects. Here are four things to consider when shopping for your bench vise.

Cast vs forged

Vises are metal, or at least 99% of vises are. That doesn’t make them equal though. How the body of the vise was formed matters for how strong it will be while in use. A cast vise is produced by pouring molten metal into a mold and then allowing it to cool in place before removing the mold and doing some cleanup on the part to remove rough edges or casting marks. This method leaves the possibility that there is an impurity or flaw inside the casting that you may never know is there until the vise fails.

The other option is a forged vise. This process starts with a solid chunk of material which is heated and hammered into the final shape. This helps ensure the material is solid and strong. The difference between a cast and a forged vise is huge in terms of durability and tolerance for misuse and abuse. Of course, pricing matches the functionality and durability since forged vises are more difficult to make.

Marketplace

Buy and sell classics with confidence

Jaw opening

This is simply how far apart the vise is able to open without falling apart. Most home DIY folks don’t need much more than five inches or so of clamping width, but vise shopping is a time to be thinking about the future and what types of projects or hobbies you might dive into at some point. Most hobbyists can get by with a vise that has 4-5 inches of opening, but having the option for larger pieces or using the vise as a small press is nice and that means scaling up. A larger jaw opening means that the vise will take up more bench space so it is still a trade-off between utility and space.

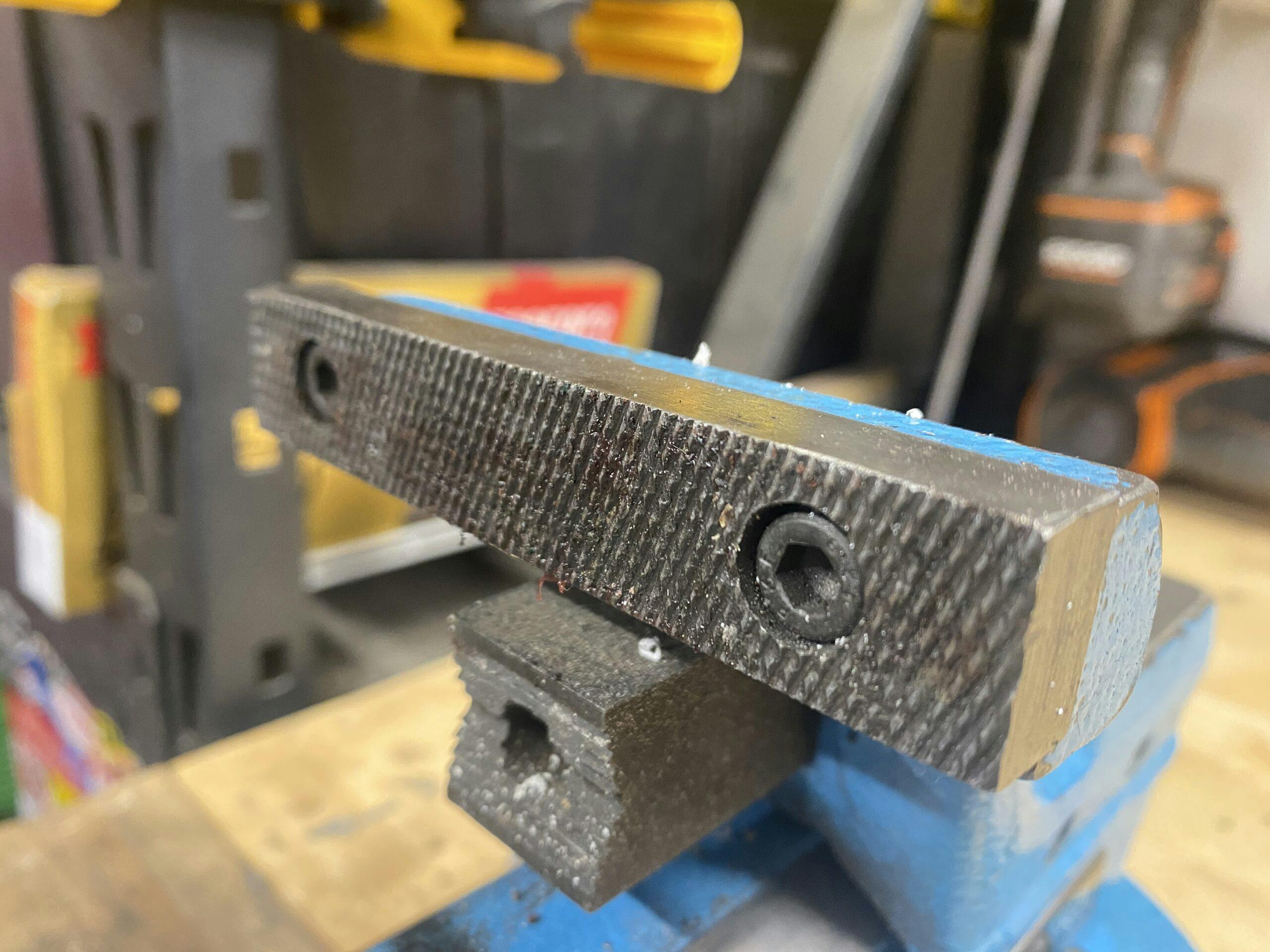

Jaw type and material

What material do you plan on working with most often? Delicate things? Pipes? Most vises have the option to change the jaw faces but it is not something most users do regularly. Serrated jaws are likely the most common, but can leave marks and impressions on soft materials like wood or aluminum. Soft jaws can often be purchased that will hold to the jaw face with a magnet and allow for more delicate holding, but can also be annoying to work with as they can fall off or shift when working, and also be damaged by heat.

The addition of pipe jaws can be nice if fabrication is something you expect to be doing, as the angled opening does a better job at holding round objects without distorting or damaging them.

Mounting and base

You can have the strongest vise in the world but if the mounting between those jaws and your bench is lacking your vise isn’t that strong after all. Take a look at your workspace and ensure that the vise you select fits the space you plan to put it. Affixing it to your workbench should be done with serious hardware, not just what you happen to have laying around.

Another item to consider is a fixed vs rotating base. Again, both have strengths and weaknesses but it all depends on how you plan to use the vise. A rotating base is often much easier to use and provides a lot of utility for regular use while a fixed base is much sturdier for hammering material or other heavy-duty tasks.

***

In short, there is no perfect vise for all tasks but with a little planning, you can find the perfect vise for your workshop needs. Do we all want a Wilton Bullet or some other total overkill vise? Well yeah, but there are likely some less pricey options that will fulfill your needs and last a long time. Also, don’t rule out buying a used vise at a swap meet, garage, or estate sale as this can be a great way to get a quality vise that might just need a little repair or love before serving valiantly for years. Just know you are likely best served shopping locally since shipping often gets expensive on bulky, heavy items like a vise.

My son purchased an very old, heavy duty bench vise for our shop at a out of business auction. It has a stationary front jaw and the back jaw that moves forward to clamp. Maybe think of it like a “backwards” vise.

Not sure if it has any advantages, but it does take getting used to from using a standard front jaw moving one.

I have one of those and it is great. Since we have to park cars in a tight garage the handle never sticks out any further when used, the back jaw does the moving. Also the back jaw rides on V ways, is strong and not all wobbly. I have owned it for 50 years now. I also have the miniature of this same vice on my small parts work bench. Found it at a garage sale for $5. Dang!

If I knew how to post a picture of it I would, but I don’t.

Pipe jaws won’t damage round objects? Maybe if the round object is made of titanium, but those jaws will definitely leave a mark on any softer materials…

1) Do I have a good bench

Real estate in my garage has always been at a premium, and no matter how big my garage is, this will always be true, so a good sturdy big bench has never made it into the garage.

The other consideration is that once that vice goes on that bench, it will impact how the rest of the bench is used.

I currently have a so-so bench with a small vice that can be removed if needed. I use the same (homemade) mounting plate for my shrinker-stretcher when needed, and have a clear unobstructed bench the rest of the time

Likewise, my garage has no real horizontal work area. My compromise solution was to mount a vise to a trailer hitch insert. Just pop it into the receiver on my truck when needed, and it provides a solid mount. Main drawback is that I have to be very careful not to scuff/dent or to throw sparks onto my tailgate when working at the vise.

My partner and I picked up a S/H garden workbench that had a Dawn Junior woodworking vice on it. Cleaning, painting, a touch of grease on the screw plus new wooden jaws put it back into service.

I had some real fun a few years back planning and creating “custom” jaws for one of my vises – made several sets from wood, plastic, aluminum, and mild steel also creating several different “contours” in sets to hold specific items that I often clamp into the vise. It was a good exercise in calculating angles and shapes and deciding how to work with the different mediums.

I chose a 6 inch Wilton because it was the only Made in U.S.A. vise remaining on the shelves at Northern Tools. (20 years ago)

A month ago I pulled a Wilton woodworking vise out of an ash heap. An evening of cleaning later and the screw is working again. Now to replace the handle, wood face, and add a coat of paint!