Media | Articles

The slippery slope of cooling system repair

A few weeks back, I wrote about the alternator dying in the Winnebago Rialta (the little 1996 Volkswagen Eurovan-based RV my wife and I use for short beach stays). Normally I would’ve done exactly what I did earlier in the summer when the alternator died in my daily-driver 2003 BMW 530i—make sure the bearings aren’t crunchy, then simply replace the voltage regulator, which is a part that usually just screws onto the back of the alternator and can often be swapped with the alternator still in the car.

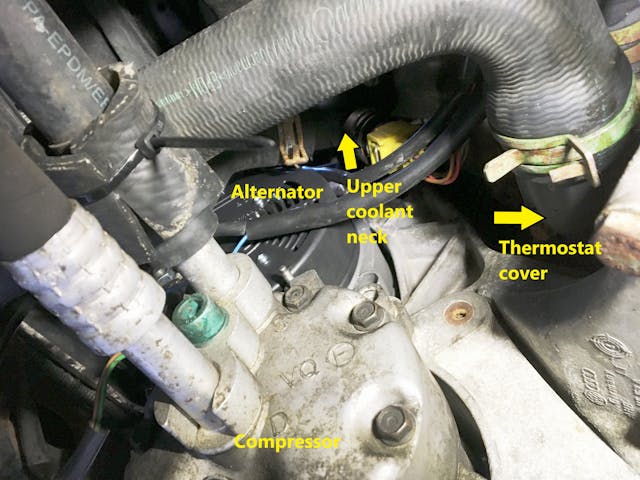

However, I’d already sussed all this out several years ago when the alternator first began showing signs of not charging the battery unless the RPMs were up. On the Eurovan, the voltage regulator is behind a cover on the back of the alternator that’s so close to a plastic coolant neck on the engine that there’s no way to get the cover off without removing the alternator. I didn’t know this, and when I tried pulling the cover in situ years back, I leaned the cover against the plastic coolant neck and was horrified when the neck began to drip coolant. Fortunately, it seemed to stop on its own accord. I figured that it was probably weeping from the rubber o-ring beneath the neck, but of course it could be a crack in the plastic part. Since we had a trip scheduled in a few days, I ordered the o-ring and the plastic coolant neck—a $5 Dorman part on Amazon—as well as its companion plastic part a few inches lower, a $5 Üro Parts plastic thermostat housing to have as spares in case something went sideways on the road, which it didn’t.

Fast-forward four years. I’m nursing a back injury that happened, coincidentally, during one of the trips in the RV in August. The RV is not an easy vehicle to work on, and shoving the big floor jack and the metal plates around to jack it up safely on my asphalt driveway was sure to anger up my back. Fortunately, there was just enough room to skooch my torso under it. Breaking it up into a series of 15-minute wrenching sessions, I managed to drop the A/C compressor, then pull out the dead alternator.

Unfortunately, the idea of just slapping a new regulator on it vanished when spinning the alternator revealed noisy bearings. And taking it to a local auto electrical rebuilder didn’t seem like a great idea either, as the alternator had no stamps or markings on it whatsoever, making it likely that it was some cheap Chinese-made clone. Reading on the Rialta forum, I learned that my Rialta is supposed to have an up-rated 120-amp Bosch alternator to keep the coach batteries charged while driving, but many repair shops don’t know that and throw in a 90-amp Eurovan alternator instead. Although Bosch-rebuilt alternators don’t have a great reputation, I ordered one from FCP Euro to take advantage of their lifetime warranty. When the alternator arrived, I planned to install it in the same back-friendly piecemeal sessions I used to remove it.

But then I remembered the weeping cooling system. I examined the underside of the engine and found coolant weeps coming from three places. The first was just a trace oozing down from the spot I’d noticed years back on the upper coolant flange when I tried to remove the back cover of the alternator. The second was a similar weep from the plastic thermostat cover. The third was more of an actual drip from a sensor/switch integrated into the lower radiator hose.

Marketplace

Buy and sell classics with confidence

The last of these—the switch in the hose—is an easily-accessible location, so I elected to simply replace its o-ring, since if I was wrong and the switch itself was leaking, there was no it’ll never-be-easier-than-it-is-now dynamic. However, the upper plastic neck is virtually inaccessible with the alternator installed. The thermostat cover is easier to get at with the compressor removed, but it’s still accessible. Normally I wouldn’t be installing Dorman / Üro Parts components, but I had already bought them as road spares four years ago, and I figured they had to be better than the 26-year-old original plastic parts.

And now comes the slippery slope. A 1996 Eurovan is far from a new car, but the construction of its cooling system is still quite modern, and I don’t really mean that in a good way.

Vintage cars have simple cooling systems. There are typically five hoses—upper radiator, lower radiator, thermostat/water pump, and two heater hoses. Maybe there’s a sixth for pre-heating the intake manifold. The components—radiator, coolant necks, expansion tank—are metal. There are no coolant sensors or switches, just a single temperature sensor connected to the gauge. It’s neither difficult nor terribly expensive to renew an entire cooling system if that’s what you feel you need to do to help ensure reliability. Radiator, hoses, water pump, thermostat, renewing the mechanical belt-driven cooling fan if you want to be thorough, done.

In contrast, on a modern car, there’s an explosion of hoses, a variety of sensors and switches, plastic coolant pipes or necks, electric cooling fans, the sensors, switches, and relays that control them, and frequently an auxiliary electric water pump to circulate coolant after the car is shut off. I have a particular loathing for these bolt-on plastic coolant necks, as I once had one snap on a BMW 318ti with only 42,000 miles on it and dump all its coolant. In addition, the five-cylinder engine in my Rialta has its water pump behind a not-easily-accessible cover, driven by a toothed belt. It’s very expensive to replace everything in the cooling system, and while it’s probably not necessary if you’re just trying to stanch a few small drips, it’s hard to know where to draw the line.

Over and over, I say that if I had to choose one word to describe myself, it’s pragmatic. I asked myself, “What’s the goal of this cooling system work? Is it to drive the RV up to Fairbanks in the winter and Yuma in the summer? Nope. Or is it instead it to be able to use it for maybe one more beach trip in the fall and not leave it in compromised condition over the winter? Yup.” Right then—so no full-on cooling system assault. If a part is leaking or obviously worn, replace it. If it involves a 26-year-old plastic coolant neck that might snap, replace it. If there’s an it’ll never-be-easier-than-now issue with a component, respect it. But other than that, don’t do more than necessary.

So, with that approach established, I ordered a few things. The Rialta has always run a bit hotter than I’d like, even in temperate weather, and the cooling system warning light (which is both a low-coolant warning and a high-temperature warning) comes on shortly after starting the engine, even though I’ve never found anything wrong. There are two coolant sensors—one for the dashboard gauge, the other for the ECU—that plug into the upper coolant neck. Like the neck, they’re difficult to reach with the alternator installed. They were inexpensive on RockAuto, so I bought them. I also ordered a new thermostat to go inside the new plastic thermostat cover. I selected one with a slightly lower opening temperature than the original thermostat.

When the parts arrived, I test-fit the new thermostat in the Üro Parts cover and immediately found an issue. Unlike the old cover, the new cover had a pair of prongs, presumably to hold the thermostat in position. But in addition, the cover didn’t seem to be deep enough—the back of the thermostat appeared to hit it. I tried the original Wahler thermostat that was in the car, and the clearance problem was so bad that I couldn’t see how the o-ring between the thermostat and the cover could seal.

Well, I said to myself, this is what I get for buying Üro Parts components. I sat down at the computer and searched for a genuine OE thermostat cover and learned that they are no longer available from Volkswagen. All of the covers from my usual parts sources appeared to be Üro Parts, Dorman, or other Chinese sources.

Then I looked on the website of a vendor for Eurovan parts in California that I use when I need expertise and I’m not shopping exclusively on price. It showed Meyle versions of both the upper coolant neck and the thermostat housing. Meyle is a generally well-regarded German aftermarket parts supplier. The cost was four times what I’d paid for the Dorman / Üro parts from RockAuto, but I figured the peace of mind would be worth it. I clicked and bought.

When the parts arrived and I unboxed them, I was disappointed. The upper neck came in a Febi box and was stamped Febi, not Meyle. That was OK, as I also regard Febi as a reputable manufacturer, but the thermostat housing was unboxed and had the logo scratched off. That in and of itself is also OK, as often the only difference between a dealer-purchased Original Equipment (OE) part and an Original Equipment Manufacture (OEM) part is that the OEM part says, for example, “Meyle” but has the VW logo scratched off. However, other than the scratched-off logo, the thermostat housing looked exactly like the Üro Parts one I already had, right down to the casting marks. And more to the point, it had the same clearance issue with the thermostat not fully seating.

I emailed the vendor describing this, and to his credit, he immediately refunded me for the thermostat housing, saying he’d bought them as “OEM-neutralized” and apologized that they clearly weren’t OEM. However, he said that he also sells the Üro Part thermostat housing and didn’t understand my clearance issue because he’d never had a complaint about the part.

Thinking that I must be missing something, I took another careful look at the fitment of the thermostat. I realized that what I thought was the thermostat hitting the back of the housing was in fact it touching the tops of the prongs in a very particular way—the prongs were pressing against the top of the inner thermostat plate. I theorized that this was probably by design to hold the thermostat partially open to help air bleed out during filling, as the plate would move when the housing was tightened down onto the o-ring.

So, with that newfound knowledge, I took the new Üro Parts housing and o-ring and the new, slightly cooler, aftermarket thermostat and installed them in the car. The original Wahler thermostat came with a small hole and a little ball check valve on it to aid in bleeding. Despite the pronged design of the new housing, I drilled a small hole in the new thermostat to be sure it would bleed. I also installed the new Febi coolant neck with the two new coolant sensors and o-rings.

I tightened everything down, filled the system with coolant, started the engine, bled the air out, and checked for leaks. I didn’t see any, but I did notice that the prongs on two of the non-worm-gear constant-tension-style clamps were poking directly into the hose beneath them. I squeezed the clamps and rotated them 90 degrees to remove the interference, and when I did, one of the hoses began dripping and wouldn’t stop no matter how I repositioned the clamp. I’ve had this once-removed-and-it-won’t-reseal problem with the coolant hoses with integrated plastic ends and internal o-rings that snap-fit onto plastic necks in my BMW, but this was different. I had no choice but to drain the coolant, clean the inside of the hose, and apply a thin coating of Permatex Aviation Form-A-Gasket. Well, of course, I did have a choice—I could’ve installed a worm-gear clamp, or I could’ve gone down the slippery slope of replacing more components. But this worked.

OK, all buttoned up. Let’s just heat it up to operating temperature, then run it around the block. I was more than a little bit alarmed when, just idling in my driveway, the temperature gauge headed straight for the top.

I crawled under the car and felt the hose coming from the thermostat, and it was cold. This is the classic symptom of a thermostat that isn’t opening. However, I’ve been fooled by this before, as it can also be a temperature gauge that’s malfunctioning and an engine that hasn’t been run long enough for the thermostat to open. And, after all, I had just replaced the sensor that feeds the gauge. Since replacing either the thermostat or the temperature sensor both required dumping the coolant (again), and since the thermostat was easier to reach, and since this was a new untested thermostat with this odd clearance issue, I elected to swap the thermostat out for the original one. I pulled the new thermostat and tested both it and the original one in boiling water. They both opened about when they were supposed to. Nonetheless, I put the original ’stat back in (still using the Üro Parts cover) and refilled the system. I can’t explain why, but it worked fine, creating a nice, hot, lower radiator hose. Maybe I hadn’t fully bled the air out the first time.

Unfortunately, the temperature gauge still rapidly pegged.

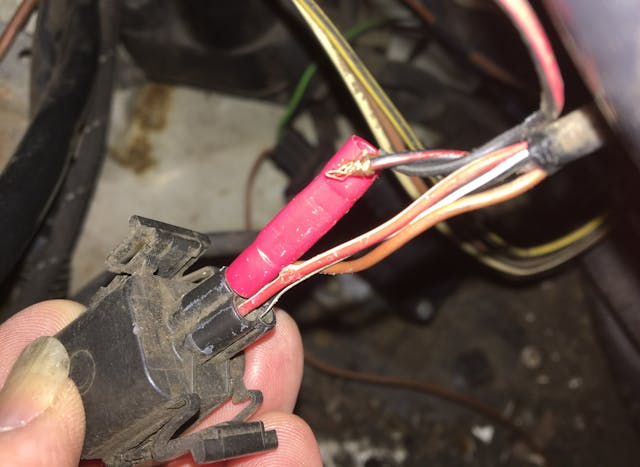

Then I noticed that neither the electric cooling fans nor the electric run-on water pump were coming on. I trouble-shot the two-speed fans, jumpering the connector on the temperature sensor that screws into the side of the radiator. The high speed came on, but the low speed did not. A-ha! It turned out that a splice I’d put in the wire four years ago to connect a switch to manually turn on the fans had come loose.

Unfortunately, even with the fan wired correctly, the temperature gauge still pegged, and the fan still didn’t come on. However, from a seat-of-the-pants standpoint, the engine didn’t seem all that hot. Did I really have a problem, or was the temperature gauge far off?

There’s a saying: If you’re going to shoot the messenger, you’d better make damn sure he’s full of crap. OK. It’s my saying. But it’s the truth. I don’t lightly ignore a temperature gauge. I needed independent confirmation of the actual cooling system temperature.

So I pulled out the infrared temperature gun. I don’t regard these as the panacea that other folks do, as they’re very sensitive to what they’re aimed at, and unless you have a baseline that correlates their readings with that of a properly functioning temperature gauge, it’s dangerous to rely on them. However, everywhere I aimed the IR gun, the temperature read under 180 °F. So I let the engine run a bit longer. The fan came on in the 169- to 192-degree range that it’s supposed to. Conclusion: Something is clearly amiss with one of the new senders, or there’s another more subtle long-standing problem with the gauge, the warning light, and the electronics that drive them.

So, I’ve stopped it from leaking and made it drivable again, but the gauge-accuracy issue is worse. When I’m not so back-hobbled, I’ll try putting the original coolant temp sensors back in. Either that or cut a hole in the hood so I can lean out the window and shine the IR temperature gun in there while I’m driving.

Ah, the never-ending joys of vehicles that are too new to be simple and too old to simply work properly.

***

Rob Siegel’s latest book, The Best of the Hack MechanicTM: 35 years of hacks, kluges, and assorted automotive mayhem, is available on Amazon. His other seven books are available here, or you can order personally inscribed copies through his website, www.robsiegel.com.

I enjoy Rob’s Hack articles, as they are not only entertaining and informative, but they often hit VERY close to home. It is reassuring to know that there is someone else out there who has a raw spot on their head (from scratching while trying to figure out a damnable issue with a vehicle). Best of luck with the cooling problem and with the back recovery, Rob!

Rob, you have the patience of a saint and the masochism of a De Sade.

But without those, we wouldn’t get these vicarious experiences. Thanks!

Side-note to the Hagerty web-page folks: What happened to our Community?

The pages, with the wealth of info, are gone.

So too the Comments features, such as Like and Reply.

Without an actual Community, we might just as well be reading a magazine — no interaction.

Please bring it back.

The community is gone for now, but it might come back in the future. While I understand the frustration, I am both reading your comment and replying back, which makes this nothing like reading a magazine.

Not that there’s anything wrong with reading a magazine in solitude…

“Not that there’s anything wrong with reading a magazine in solitude…”

You mean, like the latest issue of Hagerty Drivers Club mag? 😋

Or any back issue!

Except there is no way to know if someone comments or liked, etc. on something you said without researching everything you posted on.

Also the new one will say you are posting comments to quickly when I have literally posted one thing and nothing else. Hmmmm???

Sadly you are correct, these blog comments are not as feature-packed as a traditional forum. Only thing I can promise is that we are looking into other alternatives or additions to add such functionality back. At some point.

Clear your browser cache and tell me if that same message shows up. I remove stuff from spam ASAP but that’s only tangentially connected to what you are dealing with.

Ah, I do see a Reply feature…

And Tinkerah figured out a “like” function: you just click on “reply” and write that you like a certain comment. Okay, that’s sorta lame, I know. Yeah, it’s a bit substandard compared to the old Community package, for sure. But it’s what we’ve got for now, so guess we’ll just have to make the most of it. And knowing that Sajeev is reading and responding back is kinda satisfying, no? 🤗

While we’re on it, I miss getting the email whenever anyone “Liked” any of my comments, it triggered me to go back and often they had replied as well, and we would occasionally have lengthy exchanges. Also, no more photo capability. Also, we can’t edit our comments after a cooling off period to tone down the vicious personal attacks that get banged out in the heat of the moment. Now I have to use restraint in the first draft! I’m not just a cranky old man, The Old Way really was better.

Tinkerah, I agree with you 100% about how this new format sucks! I liked the “heat of the moment” comment, too.

Rob, I know you have a ton of cars to keep up, but sometimes when I read these articles I have the thought of “penny wise and pound foolish”….and maybe that’s the point you’re making on occasion.

I still enjoy the read and thanks for being a part of the Larz Museum.

I would have set fire to the Rialta about halfway through this endeavor.

Coolant issues are not fun. Took out my 81 Z28, good and bad news it has less than 19,000 miles on it. Always starts and everything works. Was driving down the road feeling all full of myself and looked out the back to see billowing smoke. Joy rotates to embarrassment. Turned out to be coolant. Thought it was the water pump. turns out to be the aluminum thermostat housing had disintegrated and looked like swiss cheese. Cars that sit get all kinds of other problems. Coolant, brake fluid, rear end oil, do not last forever. Will have a top flite radiator shop do a flush and fill, afraid the heater core will go.

When I read Rob’s stories, I realize, I’m not the only one who encounters these sometimes confounding and maddening vehicular challenges. It’s nice to know I am in good company. Thank you, Rob.

I am here to serve.

I use nothing but screw clamps on anything important. Spring clamps are for small engines.

Rob, I love the stories, always informative and thought provoking. I must say however, I have a friend who is fond of working on cars, and much of the time he will take a toke break. As soon as the green smoke lifts, the stuff that happens to you happens to him – it is like a never ending parade of bad luck, tough breaks, and half-remembered prior service records lol I am not saying that you do this, but I sure hope that only 1 out of 7 repairs turns into these usual story-worthy adventures. I guess if the repair went well then there would be no story….

Rob:

You have my empathy & admiration. I have been chasing a coolant leak on the in-line 6 in my ’87 BMW 325is. For two years, I have been trying to find the source of the leak. The front of the M20 engine is so congested with hoses, wires and the timing belt cover that it’s impossible to see anything. The radiator is jammed so close to the front of the engine and the fan blows the coolant everywhere.

I have torn down the front of my engine seven times this summer in a determined effort to find the leak. A Stant coolant pressure tester led me to believe that the leak was coming from between the block and my water pump. I replaced the pump and gasket three times to no avail. While removing the timing belt and cam pulley, I noticed a freeze plug in the front of the head, but it looked good, so I ignored it for a while. The plug is directly above the water pump, but hidden behind the timing belt pulley for the cam, which is under the upper timing belt cover. Not easy to find.

For a while, I believed the problem might be a blown head gasket and I performed a number of tests, including leak down and a NAPA/Balcamp test to identify combustion gases in the cooling system. To my great relief, the tests indicated that the head gasket was okay.

One morning at about 3 a.m., I decided to try removing my upper timing belt cover without draining my cooling system or removing the radiator or hoses. I pressure tested the system to 10 pounds using the Stant pressure testing tool. I was able to reach behind the cam timing belt pulley and could feel coolant in the expansion plug in the front of the head.

Getting the steel expansion plug out of the aluminum head almost gave me a heart attack. I had to strip the front of the engine and pull the pulley on the cam shaft. The space between the front of the head and the A/C condenser didn’t provide enough room to see what I was doing without a mirror. I drilled multiple holes in the old plug using an angle drill and attempted to pull the plug out with a small pry bar with no success. The plug was tightly in the head. I ultimately drifted the plug into the head and pulled it out.

I lightly polished the seat for the plug in the head and used aviation sealant. The plug didn’t want to drift back into the head and there was little room for the hammer. But it finally went in. I hope that my A/C works next year.

After reassembly, I still had a small leak from the plug,but I wasn’t about to pull it out again. I dumped a can of stop leak into the system and said that enough was enough. I’ve gone a few hundred miles without a problem. But what a nightmare.

Stephen, ugh, what a pain. I’ve only had to do that to a freeze plug on a BMW once. Fortunately it was one of the well-exposed ones, not the one you’re describing.

Boy did this hit home this time. I experienced something similar with my recently LS swapped car. I had all running good was happy, wanted to clean and flush the cooling system (on an engine that had been fine) so I drained, filled with cleaner/water, ran till hot / fans on drained, flushed with clean de-ionized water. Ran till hot/fans, drained and refilled with 50/50 mix. That’s when things went sideways, I filled as the last two times, burped the system, and proceeded to watch the radiator belch coolant, and the engine temp climb above normal. Freaked out, I let it cool, did a compression test on all 8, perfect! Yikes now what? I disconnected the steam line from radiator pressurized the rad until only coolant. Topped off the overflow, put the cap on and walked away. Next day, said a prayer, fired it up and no problem, ran perfect. Crazy.

Seems vehicular maintenance challenges are common to us all. New cars are nice and all, but to many things to go wrong. Old cars are, in most cases, easier to work on (but don’t get me started on Honda products), but a model with a short production run can be quite the challenge to find parts for. I would be forever indebted to the soul who can find me a new, unused clutch slave cylinder for a ’92 Acura Vigor…

As an aside, I am also not a fan of this new comment format.