Media | Articles

How Jeep made the Wrangler Rubicon 392, in nitty-gritty detail

Jeep recently introduced the Wrangler Rubicon 392. It is the first V-8-powered, open-top Jeep in four decades and, much like the diesel model, an answer to enthusiasts’ long pleas. Swapping an AMC 304 into a CJ-7, however, is a task that even a shade tree hack mechanic could do. Dropping a huge 6.4-liter V-8 into a modern Wrangler JL required significant changes compared to the conventional V-6 models. Let’s dig in and determine exactly, from a nuts-and-bolts perspective, how the 392 came together. It won’t surprise you, we’re sure, to hear that the aftermarket will likely make some adjustments of its own.

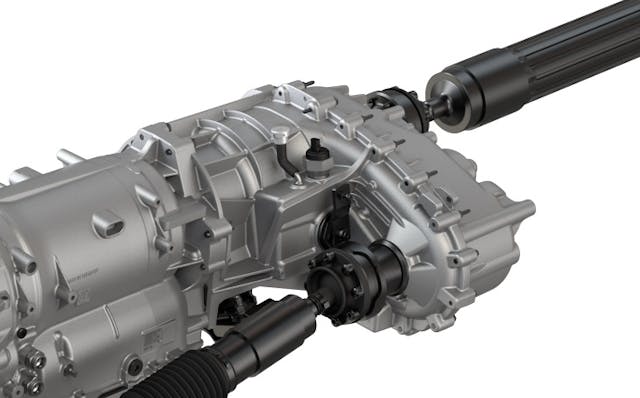

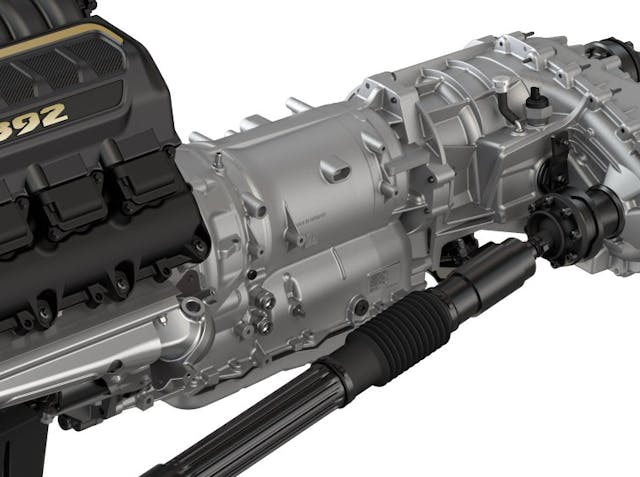

The transfer case

The MP3022 transfer case used in the Rubicon 392 is full-time unit previously used in the Jeep Liberty. As of 2018 it has been available in the Wrangler as the “Selec-Trac Full Time 4WD System,” becoming optional on 2021 Gladiator models, too. It should be noted that this transfer case is not available with the EcoDiesel engine.

The MP3022 does not have a center differential. Rather, it utilizes an electronically-controlled clutch pack. In 4WD Hi (1:1 ratio) that clutch pack automatically shifts power between a 50 percent front/rear split to 100 percent rear, based on wheel slip. In 4WD Low, the clutch pack is locked, sending 50 percent of the power to each differential, reduced by a ratio of 2.72:1. Conventional Rubicons have a low-range ratio of 4:1.

Non-392 Wranglers with this transfer case have settings for 2H (for use on dry pavement), 4H Auto (for when things can get slippery), 4H Part-time (typical 4WD setting with power going equally to both axles), Neutral, and 4L. In the Wrangler Rubicon 392, this transfer case has settings for 4WD Auto, 4WD High, Neutral, and 4WD Low. Notably absent is the selection for 2WD. One would guess that this is due to safety; the Dodge Challenger with this engine can catch an inexperienced driver by surprise. A taller vehicle that rides on much taller tires, with a significantly higher center of gravity, plus all of that power going to just the rear wheels? Probably not a good idea.

The same MP3022 transfer case however, operates in 2WD when it is packaged with four- and six-cylinder engines. It is therefore entirely possible that some lunatic will find a way of adding a 2WD mode to the Rubicon 392 for the sake of doing burnouts. Praise be!

Marketplace

Buy and sell classics with confidence

The transmission

The eight-speed ZF 8HP75 transmission is the same beefy piece of hardware used in the EcoDiesel-powered Jeeps. It is rated up to 553 lb-ft of torque. It is a vastly popular transmission used by many automakers for high-power applications. Each automaker, however, applies its own software and casings; despite having the same model designation, a transmission from a BMW 7 series won’t fit into an Alfa Romeo Giulia Quadrifoglio.

Rear differential

At first glance, the rear differential appears to be the identical Dana 44 found on the EcoDiesel Rubicon model, down to the 3.73:1 gearing. It uses an electronically-engaged locker, but that locker can only be engaged in non-392 Jeeps when the vehicle is in 4WD Low. Basically, it locks only under the most severe conditions.

When the differential is unlocked, it acts as if it is open. On modern vehicles, this really isn’t an issue, as traction control systems and braking do an excellent job mimicking the effects of a limited-slip differential. (One reason so few modern vehicles have mechanical limited-slip differentials.) Ultimately, when traction is an issue, tires are the most important factor.

The rear differential on the Wrangler Rubicon 392, unlike in other Jeep applications, can be locked in 4WD Hi. Doing so allows higher speeds with sustained maximum traction. Jeep did not specify if this differential unlocks itself at a particular speed as Ford units do, or if traction control and stability control systems are disabled when the differential is locked. Why would these systems be disabled when the differential is locked? Because they apply brake pressure to individual wheels to help control the movement of the vehicle. Doing that while the differentials are locked may add stress to the drivetrain.

Being able to move at speed with a locked rear diff is desirable for those who spend their weekends mudding, for instance. In fact, the aftermarket has developed a solution that allows rear differentials to be locked in late-model Jeep Rubicons in 2WD and 4WD Hi. This activity may void the vehicle’s warranty, however.

Front axle disconnect (FAD)

The JL Wrangler and JT Gladiator have a different front axle than older Wranglers. Similar only to early models of the Cherokee XJ and Wrangler YJ, mounted on the axle is an electronic front-axle disconnect module (FAD). Its purpose is to completely disconnect the half shafts from each other when the vehicle is in 2WD. This reduces the drag that a connected axle would create by spinning the differential gears and the front driveshaft while the vehicle is moving. The FAD essentially performs the same function that manual locking hubs did in the past.

Jeep forum regulars are no fans of the FAD. They say that the axle housing is weaker because of the FAD’s opening and that because the passenger side half axle is split into two parts—with a movable collar-like connector—it too is weaker. Such forum wisdom and the subsequent hysteria resulted in aftermarket FAD delete kits.

Hemi-powered Wrangler buyers need not worry about the FAD; the Wrangler Rubicon 392 has a full-time 4WD setup. It is therefore never in 2WD, so the front axles don’t need to disconnect. Engine power is always sent to the front wheels.

Constant velocity joints

Like other Jeeps with the Selec-Trac Full Time 4WD System, the Rubicon 392 has particular axle shafts. Typically, in part-time 4WD setups, the axle shafts are connected to the wheel bearings with a universal joint. They’re simple, strong, and proven, but these U-joints have a fundamental downside: steering is greatly affected when 4WD is engaged. The wheel becomes harder to turn, the turning radius may be increased, and there are occasional vibrations and funky noises.

Constant velocity (CV) joints wrapped in rubber boots at the ends of axles are typical for front-wheel-drive vehicles. They don’t possess the drawbacks of U-joints, but they are typically weaker. All Wrangler models with Selec-Trac Full Time 4WD System have CV joints, properly sized for tall tires and the demands of off-roading.

Frame, suspension, and tires

FCA says that the frame rails of the Rubicon 392 have been reinforced, but they don’t say if the frame was originally designed with the V-8 in mind. Whatever the case, developing a Wrangler frame capable of accommodating V-8, two flavors of V-6, four-cylinder, and plug-in hybrid four-cylinder engines in mind must have required some serious foresight. In addition to the frame, the front upper control arms and steering knuckles have been beefed up.

The suspension geometry on the Rubicon 392 appears to be similar to that of any other JL. Jeep uses several springs of varying heights in the Wrangler, depending on the model. Until now, the Rubicon rode on the tallest of them. The Rubicon 392 changes that, apparently utilizing a modified version of Mopar’s 2-inch lift kit. These springs are another half-inch taller, for a total lift of 2.5 inches over a conventional Rubicon. Spring rates and the accompanying Fox shocks have surely been adjusted for the extra weight of the V-8.

Oddly, despite the raised suspension height, the Rubicon 392 rides on the same 33-inch BFGoodrich K02 tires as the conventional Rubicon. The raised ride height and unchanged tire size give the 392 a slightly weird stance. It’s likely that Jeep had very specific, probably safety-related or legal- and compliance-driven reasons for not including the 37-inch tire it showed on the concept model. Given the possibility, it’s almost unimaginable that a Jeep connoisseur that buys the 392 would not install 35s or 37s shortly after rolling their new toy out of the showroom.

Ordinary oil pan

Jeep’s press release states that “the Wrangler Rubicon 392 engine is fitted with a rear-sump oil pan,” which sounds kind of exotic. Dry-sump oil systems are used in serious sports cars to ensure proper lubrication during prolonged high cornering speeds, but this is different. Here, the oil pan from FCA’s 6.4-liter engine was flipped around; the lower portion of the oil pan, where the drain plug is, is now closer to the transmission side than to the fan side. This design required the oil pump to be relocated, and the change was probably necessary to clear a frame cross-member.

Engine air intake

Another interesting bit: the Tri-level Hydro-Guide air intake system. Jeep proudly states that it can channel up to 15 gallons of water a minute away from the engine. What it doesn’t tell you is that all air intake systems are designed to channel water away from the engine. It’s just that never before has an automaker stated how much water an air intake system can prevent from entering the engine.

This air intake utilizes both the new 392 hood air intake—which is based on the Gladiator Mojave hood—and a secondary system, should the primary intake become obstructed. It also negates the need for an aftermarket snorkel (no matter how cool they look) or a cold-air system.

Conclusion

The Jeep Wrangler Rubicon 392 is a fascinating beast, to say the least. We would love to know how much convincing it took within the various corners of FCA bureaucracy to get this latest bit of insanity approved. On the surface, it doesn’t appear that product development was overly complex or difficult, given that most of the parts utilized already existed in Jeep’s bins. In the end, however, this tough-looking V-8 Jeep fails to claim dominance as the Wrangler with the most torque. The 392 simply matches the peak 470-lb-ft combined torque of the new Wrangler 4xe, gasoline-electric plug-in hybrid. Perhaps there should be a Wrangler Hellcat?