Media | Articles

Chevy small-block: The little engine that did

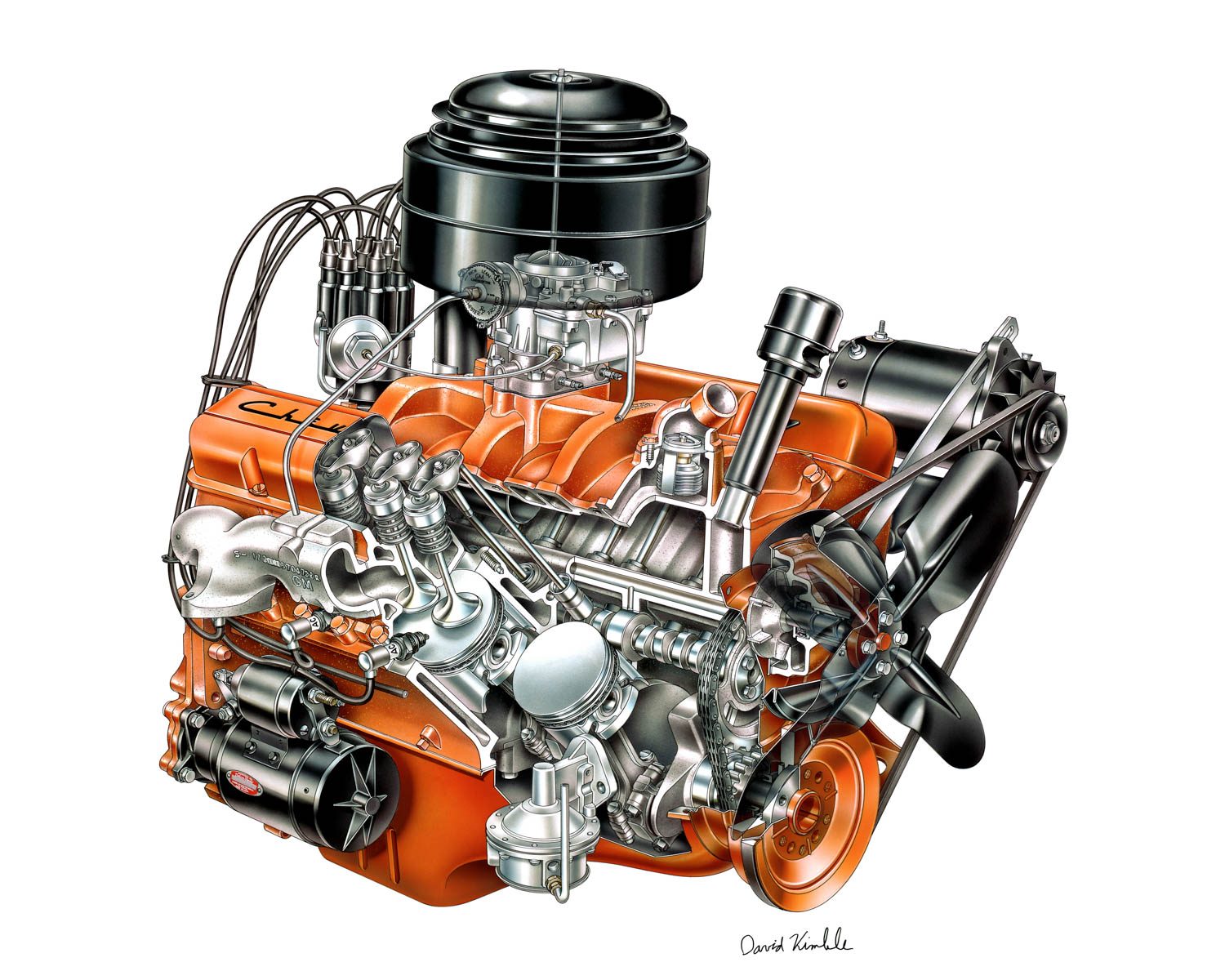

Mankind’s list of significant 20th century achievements includes space flight culminating in travel to the moon, personal computing and the Internet, and life-saving medicines such as antibiotics and vaccines. Add to that the small-block Chevrolet V-8 (SBC), the most prolific engine ever made. Since its 1955 introduction, more than 108 million have been sold. It may be the most beloved internal combustion engine of all time, thanks to its performance, durability, adaptability, and accessibility. Well into its fifth generation, the SBC is showing no hint of fatigue and is more than ready to power the eighth-generation Corvette to ambitious new heights.

Though not one small-block bolt or bobbin has made the trip from 1955 to 2020, every SBC shares these architectural threads: cylinder bores spaced 4.40 inches apart and a simple valvetrain with two overhead valves per cylinder operated by one camshaft and 16 pushrods. By the 1980s, when the Japanese were eating Detroit’s lunch, the lowly pushrod was the perfect exclamation point for skeptics convinced that U.S. engine tech was antiquated.

Conventional wisdom insists that pushrods are obsolete, that engines breathe better and produce more power when they’re topped by multiple camshafts operating four or more valves per cylinder. This notion began when Peugeot won a Grand Prix race with its seminal dual-overhead-cam (DOHC) engine in 1912, 40 years before Chevy chief engineer Ed Cole put his team to work designing an overhead-valve (OHV) small-block V-8 for the 1955 Chevrolet. (Side note: In 1917, Chevrolet introduced the Series D, which was powered by a 288-cubic-inch OHV V-8 producing 36 horsepower; it lasted but two model years.)

After World War II, GIs returned home anxious to own new cars with modern technology such as the muscular V-8s replacing prewar flathead and inline engines. This movement began with the 1949 Cadillacs and Oldsmobiles, quickly trickling down to Chryslers (1951), De Sotos (1952), and Dodges (1953). Cole’s mission was to beat Ford and Plymouth to market with an OHV V-8.

Kicking the hell out of the status quo

Born on a Michigan dairy farm, Ed Cole was not one to let muddy fields slow him down. During his teen years, he was a tractor field rep armed with knowledge gained rebuilding cars and farm machinery. Following a stint at community college, Cole attended the General Motors Institute of Technology (renamed Kettering University in 1998) with Cadillac’s sponsorship. Graduating early, he joined Cadillac in Detroit and quickly ascended the division’s engineering ladder.

Marketplace

Buy and sell classics with confidence

The war years provided Cole a sense of urgency that served him well throughout his career. The fact that Cadillac built no cars from 1942 to 1945 gave engineers an excellent opportunity to plan new models for sale when peace returned. Designed by Cole, Harry Barr, and Chris Bouvy, Cadillac’s first OHV V-8 was ready for introduction in 1949. At 34, Cole became Cadillac’s chief engineer responsible for manufacturing tanks in support of the Korean war effort.

The success of Cadillac’s first postwar models prompted Cole’s next promotion, in 1952, to head of Chevrolet manufacturing. While some would have grabbed that assignment, Cole held out for the role he really wanted—chief engineer—a position already occupied by Ed Kelley. Fortunately, Kelley was amicable to a job swap largely because the chief engineer and the manufacturing manager enjoyed equal ranking on Chevy’s organizational chart.

Cole’s oft-spouted motto was “kick the hell out of the status quo.” Upon moving over to Chevy in May 1952, he convinced GM’s upper management to expand his staff from 850 to 2900 people in support of the radically improved 1955 Bel Air and 210 models, which the company expected would top a million sales per annum. Cole became the employee who switched on the GM building’s lights every morning.

Kelley’s team had toiled for years over the 231-cubic-inch OHV V-8, imagining it might power what would hopefully be America’s bestselling car line. Unfortunately, the engine fell short of Cole’s expectations. It was for all intents a downsized Cadillac V-8, out of sync with the lighter, more agile cars Cole had in mind for Chevrolet. Kelley’s design was heavy, expensive to manufacture, and lacked growth potential. That prompted a clean-sheet restart in spite of the fact that barely two years remained until the ’55 Chevy’s launch.

No time for memos

The last thing Cole needed was an intricate, expensive, or finicky engine, so he made his priorities clear: Chevy’s new V-8 would be a breakthrough in terms of size, weight, and manufacturing cost while providing class-leading power. The only design feature carried over from Chevy’s successful Stovebolt inline-six and Cadillac’s V-8 was a conventional pushrod valvetrain.

Cole wasted no time on memos or paperwork. He seldom required more than a quick glance to recognize a clever design. Reviewing cylinder-head sketches offered by engineer Don McPherson, Cole exclaimed, “That’s it!” McPherson was less confident in what he’d drawn, but his design did pan out in development. What most impressed Cole was that this cylinder head featured wedge-shaped combustion chambers and required minimal machining after casting. Valves were supported in the heads without separate guides; placing the four intake valves and four exhaust valves per head in the same plane expedited machining.

Former Cadillac colleague Barr headed Chevrolet’s chassis and drivetrain development while Al Kolbe, who had previously worked on Packard’s V-12, oversaw engine design. Fourteen draftsmen worked 60 hours a week designing the new V-8 in a skunkworks across the street from GM headquarters. Cole made frequent visits and seldom skipped his Saturday morning stroll past the drawing tables.

In this era, each GM division proudly designed, developed, and manufactured its own engines. This longstanding tradition didn’t stop Cole from shopping throughout the divisions and the corporation’s Research Laboratories—responsible for longer-term development—for fruitful ideas. At Pontiac, he found an interesting valvetrain feature that engineer Clayton Leach had created in his home’s basement machine shop when he couldn’t convince his bosses that his idea was worth spending the corporation’s money to develop.

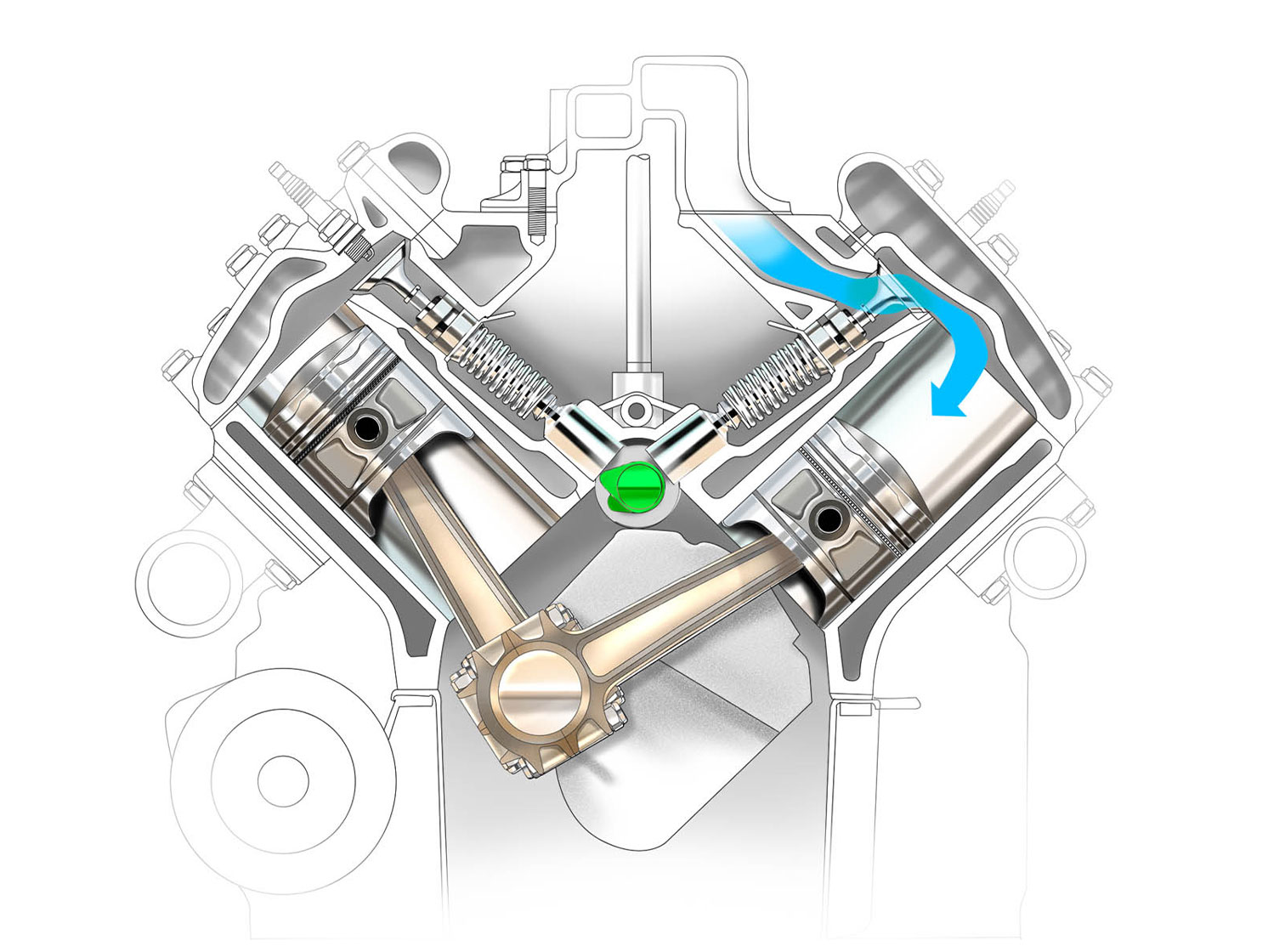

Instead of rocker arms pivoting on a tubular shaft that ran the length of the cylinder head (common practice in the 1950s), Leach’s design had a concave surface stamped into each rocker arm that engaged half a steel ball, which was secured in place by a stud pressed into the head. This arrangement was lighter, cheaper, self-aligning, and low in friction. Using slightly different radii for the ball and rocker surfaces allowed lubricating oil to readily enter their interface. Galleries in the cylinder head delivered oil to each fulcrum (pivot point).

Beginning with Leach’s patent, Chevy engineers refined the design in several areas. Hollow pushrods (not a new idea) delivered oil from the block-mounted valve lifters to the rocker arms. Oil bleeding out at the pushrod-to-rocker contact point flowed down to lubricate the fulcrum, then the valve stem. To regulate the amount of oil sent to the heads, there was a small disc in each lifter with a calibrated bleed hole. Another Chevy-exclusive feature (later adopted by Pontiac along with the hollow pushrods) was lock-nut retention of the pivot ball to facilitate valvetrain lash adjustment after the engine was assembled and running. Although none of these details were considered a monumental breakthrough, in combination they advanced the engine design art.

Creative casting

Cole tapped GM engineer John Dolza to create expeditious manufacturing methods. Working on a stillborn Pontiac V-6 in the late 1940s, Dolza had invented a means of simplifying how cylinder blocks were cast at GM’s foundries by using a creative mix of green (uncured) sand and fewer baked-sand cores. The green sand was simply poured then shaped in the bottom of the mold box, the way sand castles are built at the beach. The cores, which defined cooling passages and bore cavities, were locked together, then positioned upside down in the mold over the green sand. This methodology allowed reducing the 22 cores required for Cadillac’s V-8 block to only 12 in the SBC. The quantity of sand required and the assembly time were both significantly diminished. More significant, this new precise casting technology allowed halving the crankcase wall thickness to only 0.156 inch, yielding major weight and cost savings.

To minimize the block’s height, the team settled on a 3.00-inch stroke with 5.70-inch-long forged-steel connecting rods. Though some automakers, such as Ford, extended their block skirts several inches below the crankshaft centerline (a so-called Y-block design), the SBC’s corresponding dimension was 0.125 inch, just enough to securely register the main bearing caps. (Using the minimum material required to support the crankshaft was one of Cole’s smartest weight-saving moves.) A 4.40-inch separation between bore centerlines allowed ample space for a 3.75-inch bore and coolant passages between each cylinder, with room for larger bores in the future. Cole allegedly set initial (1955 model year) displacement at 265 cubic inches to duck under the existing 266-cubic-inch displacement limit for hydroplane racing so that the new Chevy engine could be used in that venue.

20200324141358)

The SBC’s intake manifold was a prime example of functional integration. One elaborate casting provided a mounting pad for the two-barrel carburetor, eight intake runners, an exhaust crossover to warm the carburetor after a cold start, a coolant passage containing the thermostat, a distributor mounting pad, an oil fill port, and the valley cavity cover.

Five bolts per cylinder sealed the heads to the block. The head was designed to fit both sides of the block by simply rotating that part 180 degrees. (While this cost-saver was not brand new, it was not yet a universal practice.) The wedge-shaped combustion chamber produced high mixture turbulence in the vicinity of the spark plug.

Instead of the more common cast-iron material for the crankshaft, a stiffer, stronger forged-steel design minimized weight. Eliminating the usual oil groove from the bottom half of each main bearing insert doubled the bearing’s load capacity by reducing oil seepage out the side of the bearing. To prevent catastrophic failure, the crank must always be supported by an oil film between its journals and bearing caps. Perfecting this lubrication detail gave the SBC the extra bearing capacity it would exploit in the distant future when combustion pressures were doubled to deliver 755 horses in the 2019 Corvette ZR1.

The cast-aluminum slipper-type pistons were fitted with steel inserts, which helped maintain their round shape under severe heat loads. (With a slipper design, there are two narrow lower skirts wrapping less than halfway around the piston to minimize weight and friction.) Wrist pins were pressed into the connecting rods’ small end to eliminate the need for retaining clips.

Working long hours and most weekends, Dolza’s team of engineers completed the SBC’s design in three months. Three weeks later, the first prototype engine was assembled. Production tools were ordered straight from the drawing boards before the first engine had run. By early 1954, a mere 15 months after the design effort began, tools were in place and ready to commence pilot production. Dyno tests revealed a peak output of 162 horsepower at 4400 rpm with a two-barrel carburetor and single exhaust. Adding a four-barrel and dual exhaust pipes bumped that to 180 horsepower at 4600 rpm. The 1955 Corvette V-8 delivered 195 horsepower at 5000 rpm.

A canvas for hot rodders from the get-go

Ford ended up beating Chevy to the punch with its 239-cubic-inch OHV V-8 in 1954, followed by Plymouth with its 259-cubic-inch V-8 in ’55. In finished form, Chevy’s new V-8 engine weighed 531 pounds, 40 pounds less than the brand’s inline-six and 100–150 pounds less than other contemporary V-8s. The SBC was a design triumph, the lightest V-8 on the market when it arrived in 1955.

Across the street in the GM building, Cole directed the design of Chevy’s new car line, which consisted of 150, 210, and Bel Air series available in several body styles. Their shared frame had tubular-steel main members to reduce weight by 50 percent while increasing stiffness 18 percent over the ’54 design. Front suspension spindles pivoted on ball joints and were supported by unequal-length control arms. Rear semi-elliptic leaf springs were nine inches longer than those fitted in ’54 to improve the ride. Finished body weight was trimmed by 52 pounds. Overall height was reduced by six inches, the windshield was a wraparound design, and two-tone paint schemes were offered. Styling’s crowning touch was an egg-crate grille inspired by contemporary Ferraris. Start to finish, the design of the ’55 Chevrolet spanned but 28 months.

Zora Arkus-Duntov, who later became the Corvette’s spiritual father, admired Cole’s work. After he joined GM in 1953, the outspoken Arkus-Duntov circulated a memo titled “Thoughts Pertaining to Youth, Hot Rodders and Chevrolet.” Duly impressed, Cole willingly shared his pet V-8 with the 1955 Corvette. By 1957, Duntov and Dolza would develop a wilder camshaft along with mechanical fuel injection for Corvettes and other Chevy models.

To pique interest in the new SBC, three early engines were shipped to Southern California’s Vic Edelbrock, the leading prophet in the budding hot rod industry. Edelbrock’s three-two-barrel intake manifold hiked output by 20 horsepower. Exhaust headers fabricated by Bob Hedman added 20 more. A new, hotter ignition system from the Spalding brothers yielded another 10.

Several cam grinders were also invited to help tune the SBC. The best of the bunch was Ed Iskenderian, who upped the redline from 5000 to 6500 rpm. A long run of valve covers, aluminum heads, induction systems, and fully tuned crate engines ensued. One of the first three engines shipped west served in an Edelbrock test car for years. Another was shipped to Florida to power a hydroplane, and the third powered a sports car in road races. Paul Pfaff of Pfaff Engines was one of the first to graduate from Ford’s flathead V-8 to the Chevy small-block; he called it “the best thing to happen to hot rodding since the 1932 Ford roadster.”

Interviewed by author Tom Madigan for his 2012 book The Chevrolet Small-Block Bible, revered engine builder Ed Pink called the 302-cubic-inch SBC (created for drag and road racing) a “graceful deer at full speed.” In contrast, Pink deemed the supercharged, nitromethane-fueled Chrysler Hemi V-8s he built for Top Fuel and Funny Car drag racers “water buffalo charging through the brush.” Pink admired the SBC’s innovative rocker arms and called the engine’s overall balance “near perfect.” Bill “Grumpy” Jenkins advanced the cause on the East Coast with his screaming drag-racing SBCs.

To fan flames in the NASCAR camp, SBCs were dispatched to Smokey Yunick in Daytona Beach and leading car builder Junior Johnson. Driving a Chevy prepped by Yunick, driver Herb Thomas passed 67 cars to win the 1955 Southern 500 at Darlington.

The success of the ’55 Chevy—1.7 million were sold—and its revolutionary V-8 shot Cole up GM’s corporate ladder. He became Chevrolet general manager in 1956 and the company’s president in 1967. Not all of the causes he championed during his career panned out as well as the SBC. The rear-engine Corvair, the aluminum-block Vega, and GM’s rotary engine were Cole’s three problem children. They did not, however, hinder this genius from kicking the hell out of the status quo with his catalytic converter and airbag advancements.

After leaving GM in 1974, Cole guided ambitious plans at Checker Motors and at a budding air freight company. He perished at age 67 when his aircraft crashed in severe weather. Cole’s legacy, the SBC, thrived more than three decades in millions of GM cars and trucks with relatively minor changes. Its successors have a bright future as noted below.

Secrets to success

The use of advanced digital analysis and development aids has eliminated most of the shortcomings associated with the pushrod, two-valves-per-cylinder valvetrain. Modern materials have shed unwanted pounds. The astute thinking that made this engine compact in 1955 still pays dividends.

Asked the secret to the SBC’s long-lasting success, Jordan Lee, the current global chief engineer for the engine, explains, “While engineers come and go, the team nurturing the small-block invariably loves this design and takes great pride in making each new version more modern, powerful, and fuel efficient than its predecessor.

“In the old days, engine development was ‘cut and try.’ You make a good guess, build prototype hardware, and strive to improve it. Now we have analytic tools that assure we extract every bit of energy from each drop of fuel. There’s finite element analysis to minimize weight while keeping the moving parts and the crankcase as stiff as possible. Computational fluid dynamics improves flow in and out of the combustion chamber. Other tools scrutinize the combustion process in remarkable detail. GM takes pride in developing proprietary analytic tools that are superior to what competitors have at their disposal.

“That said, we never pursue technology for technology’s sake. In keeping with Ed Cole’s original philosophies, we want the simplest design that meets or exceeds our performance targets. What matters more to customers than the number of valves or how they operate is the power, torque, and fuel efficiency we provide.

“We’re convinced that this engineering persistence will deliver new and better small-block V-8s in the future.”

Small Block, Big History

Generation I

1955 The small-block is the lightest V-8 on the market and makes 162 hp at 4400 rpm in base form.

1956 The three Corvette V-8 choices included a 210-hp version with a four-barrel carburetor, 225 hp from two four-barrels, and 240 hp with two four-barrels and a high-lift camshaft.

1957 A 1/8-inch-larger bore (to 3.875 inches) raised all small-blocks to 283 cubic inches. Outputs ranged from 185 to 283 hp. Fitted with new Rochester Ramjet mechanical fuel injection, the small-block yielded one horsepower per cubic inch, only the third American-made engine to do so.

1962 New block castings combining a 4.00-inch bore with a 3.25-inch stroke upped displacement to 327 cubic inches, with power outputs ranging from 210 to 375 hp.

1964 The 327-cubic-inch L76 (above) and L84 V-8s producing 365 and 375 hp, respectively, were the most potent naturally aspirated small-blocks until the LS6 arrived in 2001.

1967 To comply with the Sports Car Club of America’s Trans-Am road racing rules, Chevy combined a 4.00-inch bore with a 3.00-inch stroke in a 302-cubic-inch small-block for the Camaro Z/28. A special induction system, a wild camshaft, and tubular headers (shipped in the trunk) were included. The L48 350-cubic-inch V-8, also introduced for the Camaro, spread to the Nova in 1968 and throughout the Chevy lineup in ’69.

1968 A 3.875-inch bore with a 3.25-inch stroke yielded 307 cubic inches. Larger-diameter connecting rod and main bearings facilitated the change from forged-steel to less expensive cast-iron crankshafts.

1970 With the arrival of metric displacement designations, lower compression to use lead-free fuel, and net power ratings, the 5.7-liter LT1 (above) became the ultimate engine for Camaro Z/28s and Corvettes, with 360–370 hp. Chevrolet was able to cram a 4.12-inch bore with a 3.75-inch stroke in the small-block, increasing displacement to 400 cubic inches (6.6 liters).

1973 The L82 small-block produced 250 hp in the Corvette and Camaro, falling to 205 hp in 1975. The Corvette’s base ZQ3 engine fell to 190 hp with the added emissions controls.

1975 A new 262-cubic-inch small-block combined a 3.67-inch bore with a 3.10-inch stroke to produce 110 hp in the Chevy Monza and Nova and the Pontiac Ventura.

1976 The first energy crisis prompted the creation of a fuel-efficient 5.0-liter small-block fitted with a 3.74-inch bore and a 3.48-inch stroke, which shared many 5.7-liter parts. This “corporate” engine quickly spread throughout the GM lineup, with applications ranging from pickups to Cadillac Broughams to California Corvettes. The 5.0-liter, GM’s highest-volume V-8, lived until 2003. Bare blocks are still produced by GM for sprint car racing.

1982 New twin throttle-body fuel injection, called Cross-Fire, upped Corvette output to 200 hp in its L83 V-8. A similar 5.0-liter engine was labeled LU5 in the Pontiac Trans Am. Early service problems prompted the nickname “Cease-Fire” for these engines.

1983 The L69 high-output 5.0-liter V-8 for the Firebird Trans Am, Camaro Z/28, Camaro IROC-Z, and Monte Carlo Super Sport had an electronically controlled Rochester Quadrajet carburetor, low-restriction exhaust, higher compression, and an aluminum intake manifold. Output ranged from 180 to 190 hp.

1985 Tuned-port fuel injection inspired the 5.7-liter L98 Corvette engine to 230 hp. Top Camaros and Firebirds, powered by engines coded LB9, had 190–230 hp.

1986 After years of development effort to ensure durability, the first cast-aluminum cylinder heads were fitted to some Corvettes, Chevy Camaros, and Pontiac Firebirds powered by L98 small-blocks. LG4 V-8s now came with aluminum intake manifolds (replacing cast-iron).

1990 Though not really a member of the GM small-block family, the Lotus-engineered DOHC 32-valve LT5 V-8 introduced for the Corvette ZR-1 with an initial 375 hp is worth mentioning because it shared certain dimensions, such as a 5.7-liter displacement, with the mainstream GM design. Nearly 7000 Corvettes powered by this engine were produced over six model years.

1996 The 5.7-liter L31 truck engine was the final first-generation small-block V-8 design. It lasted through the 2002 model year powering trucks, vans, SUVs, Isuzus, and the Oscar Mayer Wienermobile. Gen II cylinder heads with improved ports and combustion chambers were added during the L31’s life.

Generation II

1992 Though Gen I V-8s persisted as Vortec truck engines through 2003, Chevrolet revived the LT1 (below) small-block code in a new small-block design for the 1992 C4 Corvette. Reversing the direction of the coolant flow—first to the heads, then the block, then back to the radiator—allowed higher compression, more spark advance, diminished piston-ring friction, and greater output. The block, heads, and intake manifold were new while the crank, rods, pistons, and flywheel carried over. The 4.40-inch bore-center spacing and the two-valve pushrod valvetrain also carried over. Corvettes, Camaros, and Firebirds received aluminum heads while Buick, Cadillac, and other Chevy models powered by this engine were equipped with iron heads. Corvettes also received four-bolt main bearings. Multi-port fuel injection and an ignition system mounted to the front of the block were standard across the board. LT1 Corvettes were rated at 300 hp.

1996 A new LT4 engine upped the ante, with wilder valve timing, aluminum roller rocker arms, larger fuel injectors, higher compression, and a more efficient intake manifold. With 330 hp, it was optional in manual-equipped Corvettes and standard in Grand Sports.

Generation III

1997 The fifth-generation Corvette’s LS1 small-block was essentially a clean-sheet design that kept the 4.40-inch bore spacing and pushrod valvetrain. The new aluminum block was a deep-skirt design with two vertical and two horizontal bolts per main bearing. Iron cylinder liners were cast in place. The camshaft was positioned higher above the crank to shorten the pushrods while clearing room for larger bores and longer strokes. In lieu of a distributor, eight ignition coils were triggered by the engine control computer, and the firing order was altered for improved smoothness. A 3.90-inch bore and a 3.62-inch stroke retained the 5.7-liter displacement. Output began at 345 horsepower, rising slightly with the addition of more efficient intake and exhaust manifolds.

1998 Chevy’s Camaro and Pontiac’s Firebird received LS1s rated 305 hp. Holden in Australia followed a year later, tuning the engine during its seven-year production run to 400 hp.

1999 A smaller (4.8-liter) LR4 V-8 for truck use produced 255 hp, climbing later to 285 hp. Various 5.3-liter versions were also produced for Chevrolet, Cadillac, and GMC trucks with 270–310 hp. LQ4/LQ9/Vortec 6000 truck engines with iron blocks displaced 6.0 liters and produced 300–370 hp.

2001 The Corvette Z06 introduced a hotter Gen III V-8 coded LS6 with 385 hp, subsequently upped to 405 hp, with higher compression, improved lubrication, and wilder valve timing.

2004 Cadillac’s hot CTS-V received LS6 engines rated at 400 hp.

Generation IV

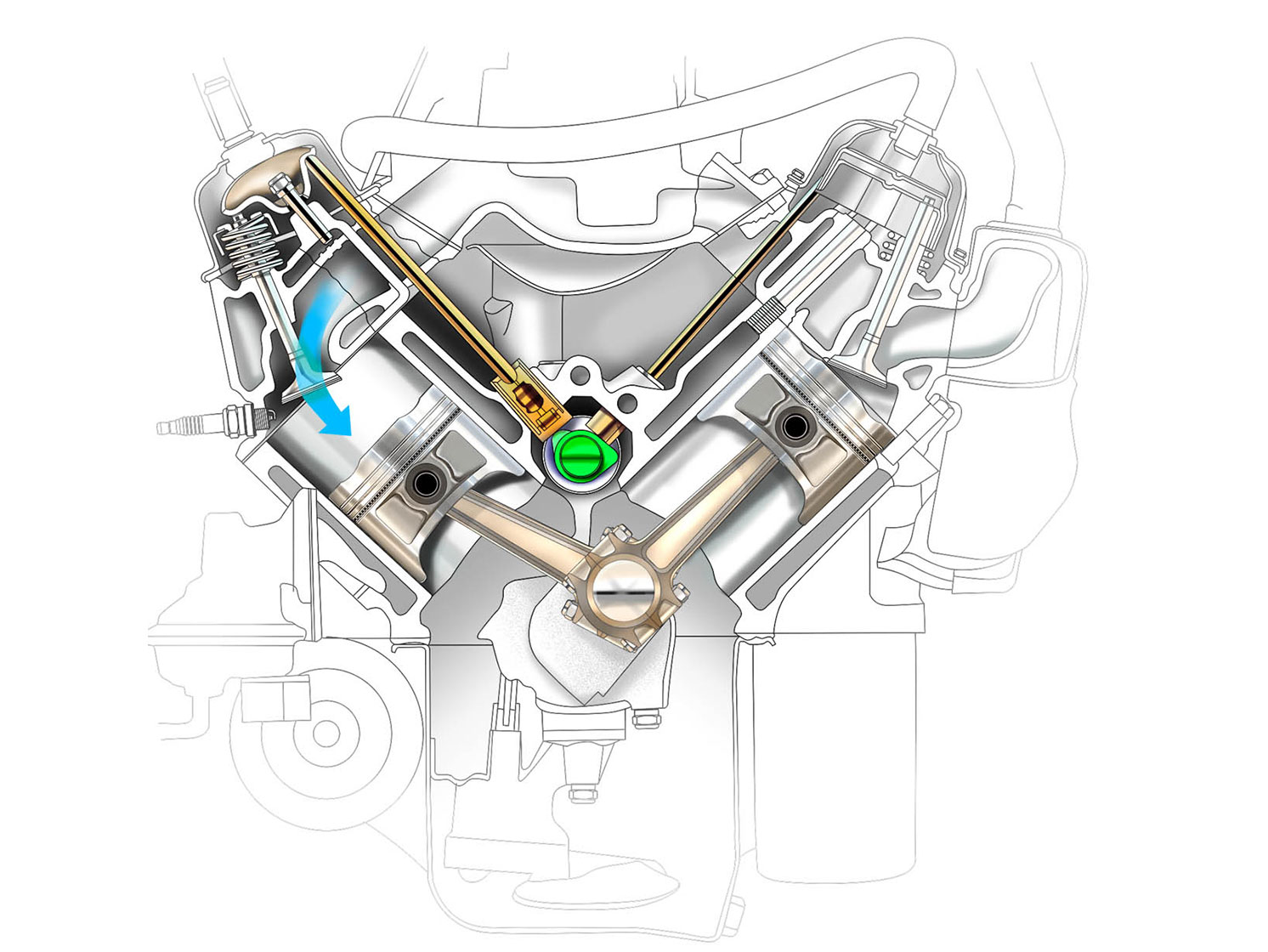

2005 For the sixth-generation Corvette, GM launched a fourth-generation small-block V-8 with the potential of growing to 7.4 liters. New features included displacement on demand (the ability to shut down half the cylinders at will for improved mileage) and variable valve timing (achieved by changing the crank-to-cam phase relationship on the run). The 6.0-liter LS2 (below) featured a 4.00-inch bore and 3.62-inch stroke inside an aluminum block topped with aluminum cylinder heads, yielding 400 hp. The LH6 truck version displaced 5.3 liters and produced 300–315 hp. The LS4 5.3-liter V-8 developed for transverse-engine front-wheel-drive cars produced 303 hp.

2006 Built for Corvette Z06, Camaro Z/28 (later), and aftermarket use, the racing-inspired 7.0-liter LS7 featured a 4.125-inch bore and a 4.00-inch stroke. The LS7 featured siamesed cylinders, pressed-in steel bore liners, titanium connecting rods, and a forged-steel crankshaft. Intake and exhaust ports and combustion chambers were CNC-machined for optimum flow and to achieve an 11.0:1 compression ratio. A standard dry sump sustained lubrication during 7000-rpm track driving. The LS7’s 505 hp at 6300 rpm made it one of the world’s most powerful naturally aspirated engines.

2007 The 6.2-liter L92 V-8 for full-size pickup and SUV applications delivered 403 hp. The L76 6.0-liter truck V-8 produced 367 hp. The LY2 4.8-liter V-8 for trucks delivered 260–295 hp. The 5.3-liter LY5 produced 315–320 hp.

2008 The Gen IV LS3 V-8 introduced as the Corvette’s new base engine brought improved cylinder heads, more aggressive valve timing, higher compression, and a freer-flowing intake manifold to produce 436 hp with the optional dual-mode exhaust system.

2009 The new Corvette ZR1 came with a 6.2-liter LS9 (above) equipped with an Eaton Roots-type supercharger, good for an impressive 638 hp. A similar LSA engine for Cadillac’s CTS-V and later the Camaro ZL1 delivered 556–580 hp. Jets squirting oil onto the bottom sides of the pistons for cooling were used on both engines

2011 GM assembled its 100 millionth small-block V-8 in LS9 trim. This heirloom is on display at the company’s powertrain museum in Pontiac, Michigan. (Side note: Your humble writer loaded the no. 6 piston and connecting rod assembly into this engine.)

Generation V

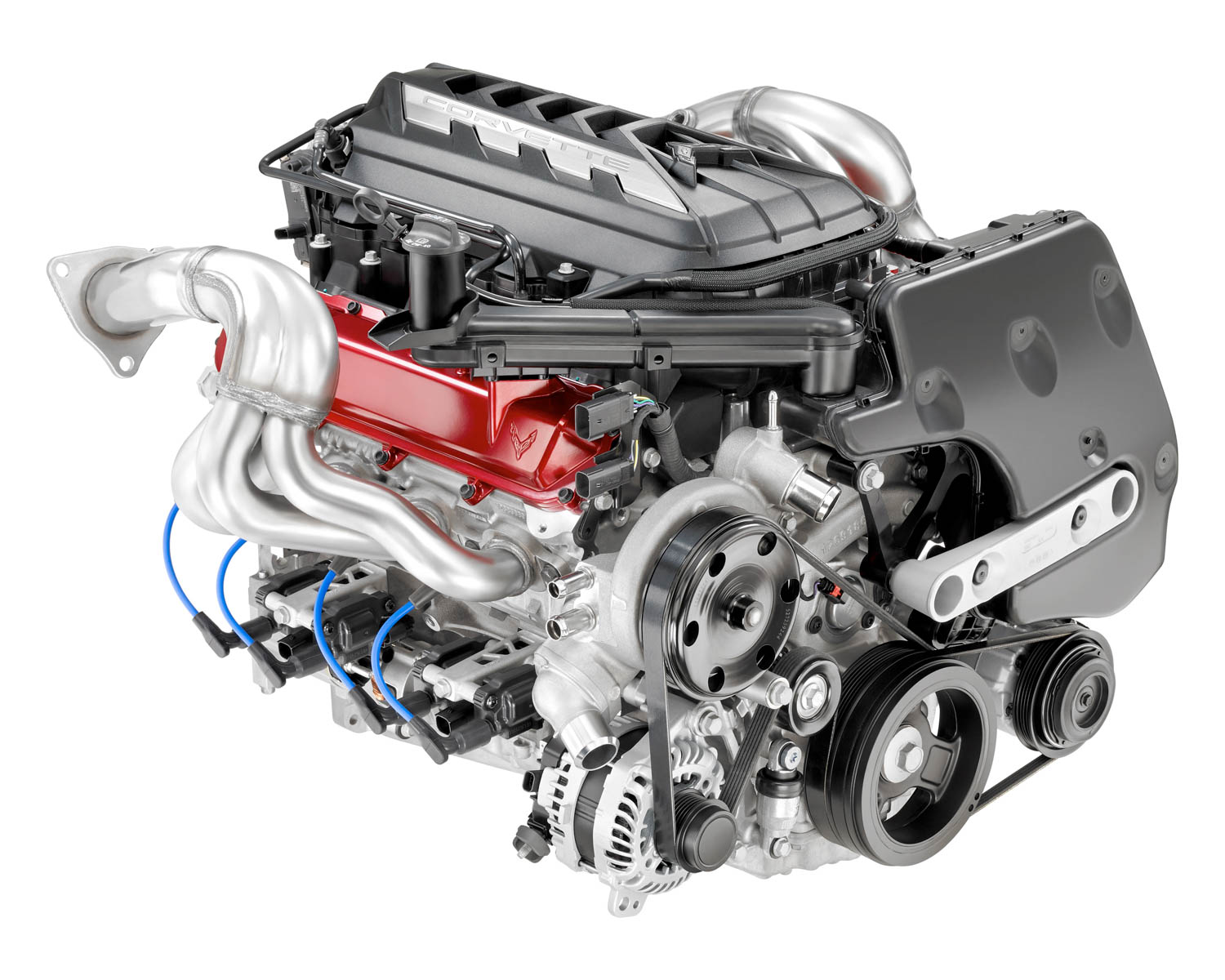

2014 To power its new seventh-generation Corvette, GM created a fifth-generation small-block coded LT1, which retained the sacred 4.40-inch bore spacing and simplistic single-cam valvetrain. New cylinder heads incorporated direct fuel injection. A variable-displacement oil pump minimized parasitic losses. Active fuel management and variable valve timing both carried over and piston oil squirters made their naturally-aspirated debut. The 6.2-liter LT1 engine delivered 455 hp as the base Corvette engine. The 6.2-liter L86 engine for trucks and SUVs delivered 420 hp while the 5.3-liter L83 version provided 355–376 hp.

2015 GM introduced a more potent 6.2-liter LT4 Corvette V-8 with an Eaton TVS supercharger (smaller but spinning faster than in 2009), specially cast aluminum cylinder heads, titanium intake valves, forged pistons with an ambitious 10.0:1 compression ratio, stainless-steel exhaust manifolds, and dry-sump lubrication. This new blower motor delivered a nice round 650 hp in the Z06 and the 2017 Camaro ZL1, with 10 fewer ponies in the 2016 Cadillac CTS-V.

2016 Chevy put the Corvette’s LT1 V-8, still producing 455 hp, into the Camaro SS.

2019 Reviving the revered LT5 production code previously used for the 32-valve DOHC Lotus V-8, a new supercharged Corvette ZR1 engine had an improved intercooler force fed by an Eaton TVS supercharger. It also combined port and direct fuel injection systems to produce an earth-rattling 755 hp at 6400 rpm.

2020 The C8 Corvette’s base engine (below), called the LT2—a code from a stillborn 1970 aluminum big-block V-8—is a 6.2-liter powerhouse delivering 490–495 horsepower (exhaust-dependent). It features dry-sump (and valley) lubrication with a storage reservoir bolted directly to the block, free-flowing intake and exhaust systems, heads passed down from the LT1, and gorgeous red-painted valve covers. A 6.6-liter iron-block pickup engine coded L8T makes 401 hp.

My greatest engines are the 327-365HP in my 65 Vette & now the LS-7 in my 2013 427 Vette. Bullet Proof.

Awesome SBC story,

Since 1961 I’ve owned a 265ci 56 Chevy Bel-Air, a 283ci, Dual Quad 60 Corvette, a 327ci, 300 hp 66 El Camino, LT1, 1997 Gen 2, 350 ZZ3, 66 El Camino, LS1 5.7L 2000 Corvette, LT1, 6.2L 2017 Camaro SS. I loved every small block I had, they all were very durable & quite fast in there the day. I Built a BBC Merlin 454ci LS6 Big Block roller everything which was just insane in a little 56 Chevy 3100 PU, sounded amazing, but blew in up consistently in 16 years.

The most american of engines and with a long history! One of the all time greats.

Why is it everything we buy has to have a metric equivelent, but apparently engines in liters are exempt and don’t have to tell you the cubic inch. The liter number means nothing to me.