From acid rain to EVs: The march of progress in emissions

Many of us weren’t around for the true smog eras, where acid rain and grey-out conditions were sometimes the norm for congested metro areas. It’s novel now to enter a car show or a street cruise where a floating fragrance of gas hangs in the air as a bunch of huffing, carbureted machines belch raw gasoline, but it used to be an inescapable albatross prior to this era of clean air regulations. You see it in a first-time classic owner’s reaction to parking in a garage; they’re surprised to find that it’s normal for the vehicle to constantly give off a gas smell in confined spaces.

From 1967–75, heavy regulatory blows were thrown at the automotive market, especially at the domestic automakers who were injecting corporate cash into motorsports and trickle-down homologation specials in the pursuit of “race on Sunday, sell on Monday.” Up to this point, emissions had simply been a byproduct of the machine; there was little thought of what happened after gasses escaped the tailpipe.

However, in 1975, the California Air Resources Board (CARB) was created to battle pollution in the air-locked metropolis of Los Angeles, and the organization created a unique set of emissions requirements that automakers had to satisfy to sell products in California, in addition to the U.S. Clean Air Act, which went into effect in 1963. The following year, Congress’ National Emissions Standards Act demanded that automakers slash all 1968-model-year vehicles’ emissions by more than half 1963 levels. This was also the nail in the coffin for gas-turbine automobiles and heavy trucks, which struggled with high NOx emissions.

Throughout the ’70s, infamous fuel shortages were also so strenuous that gas stations rationed fuel based on license plate numbers, with odds and evens splitting the days. To top things off, gasoline lost a monumental amount of octane with the removal of tetraethyl lead from the fuel, which severely limited both performance and efficiency in showroom models and meant certain detonation for older, high-compression engines.

By 1975, as asphyxiated muscle cars began to fill dealer lots, the gavel came down: The EPA implemented the Corporate Average Fuel Economy standards, a moving-average target that punished fuel-thirsty OEMs with yearly fines. The Big Three—still chanting the traditional, pushrod-actuated, rear-wheel-drive mantra—couldn’t react fast enough. In just a few years, imported compacts from Germany, Britain, and Japan had taken root while the Malaise era sank in.

Malaise Era

The immediate consequences of the 1975 emissions crackdown were not kind to automakers or customers. Arguably, too much had been changed too quickly. Every variable was now under a new standard and the ever-watchful eye of The Man. Automakers scrambled to retool current engine programs to meet the looming changes as quickly and cheaply as possible, choosing to focus instead on next-generation platforms and drivetrains over dragging older tech through the mud. The late ’70s were an era of downsizing as drivetrains struggled: full-size sedans began to shrink while new compact platforms were the center focus.

Though catalytic converters were implemented to reduced CO and hydrocarbon emissions, the early catalyst materials were prone to failure, clogging, or eventual overheating. It wasn’t unheard of for one to go into thermal meltdown and cause a fire, leading a handful of OEMs to install warning lights for an overheated catalytic converter. Carburetors, capable of metering fuel with the finesse of a meat tenderizer, were also being stretched beyond their designs to meet the new emissions targets.

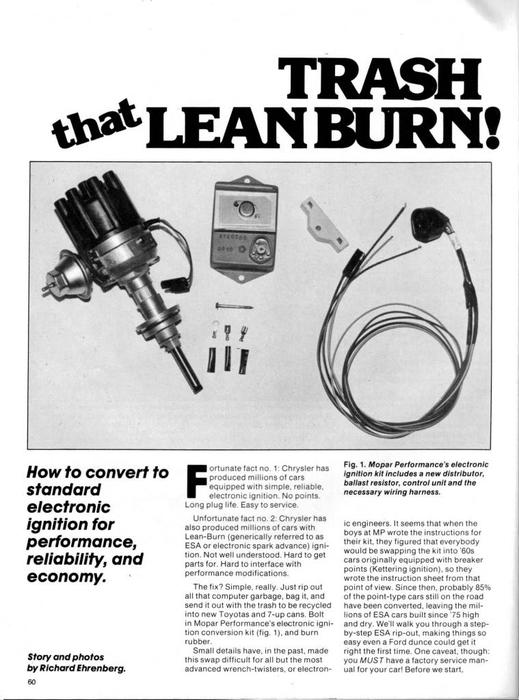

Chrysler was the first to introduce a computer-feedback emissions system in 1976 with its Electronic Lean-Burn system. The biggest change was the implementation of computer-controlled ignition timing, along with several modifications to the already-infamous Carter Thermoquad to (ideally) allow it to operate nearly 20-percent leaner than before. While traditional carburetors and distributors passively react to driver inputs, the Electronic Lean-Burn system proactively adjusted idle speeds, fuel ratio, and timing advance with a pre-programmed routine for different conditions, promising better cold starts as much as improved emissions.

The reality was that the early-generation circuit boards and programming logic were temperamental. Few mechanics, even dealership technicians, were adequately trained, equipped, or patient enough for the new labyrinth of wires and vacuum hoses, leaving many of these systems malfunctioning or disabled in the process. The lean fuel ratios, combined with the loss of octane during the earlier years of lead-free fuel, also meant that the Electronic Lean-Burn system was prone to detonation.

Another tactic to reduce carbon monoxide and unburned hydrocarbons was to retard the timing curve of the distributor, which fired the plugs later in the four-stroke cycle and caused the combustion cycle to end later. While it reduced power, igniting fuel later in the combustion cycle allowed for a better emissions at low engine speeds. The downside was increased coolant temperature as fuel continued to burn during the exhaust stroke and raised exhaust gas temperatures—it wasn’t uncommon to find that brand-new cars overheated until a simple timing adjustment was made.

Caption: Many of these vacuum-actuated emissions systems were problematic, but few were more infamous than Honda’s CVCC.

The problems weren’t unique to Chrysler. General Motors, Ford, Honda, and most others experienced similar issues with their own computer-feedback, lean-burn carburetor and ignition systems. Carburetors were simply never designed with this purpose in mind, and buyers endured several years of nearly-defective new cars. OEMs knew that the future wasn’t going to be based on Bernoulli’s principles, and thus the late-’70s and much of the ’80s served as an unfortunate stop-gap measure in engine technology.

Electronic Vapor Wave

While the history books record America’s Big Three as the biggest losers of the early emissions era, the truth was that few OEMs made it through the end of the ’70s unscathed. A notable exception was Honda, whose Compound Vortex Controlled Combustion (CVCC) cylinder-head design borrowed the pre-ignition cups of a diesel to well with incredibly lean fuel mixtures. It ran cleanly enough to avoid needing a catalytic converter, but soon became a Medusa-worthy nest of vacuum lines (over 50 individual vacuum hoses), pulling the strings on an over-complicated, computer-controlled carburetor.

Compounding the new emissions and fuel economy standards, the National Highway Traffic and Safety Administration (NHTSA) had simultaneously tacked new safety measures onto every new car sold starting in the ’70s, most notably the seemingly draconian requirement for 5-mph bumpers, which were often heavy beams mounted on shock-absorbers. Something had to give.

Electronic fuel injection (EFI) was hardly new. Bendix is credited with the first EFI systems on the mythical, one-year-only 1958 DeSoto Electrojector and later Bosch-designed D-Jetronic (introduced in 1967), but the technology was largely relegated to more expensive European imports. While fuel was passively sucked into the airstream in a carburetor, fuel-injection sprayed fuel at controlled intervals. Being able to precisely and proactively control the fuel ratio was the biggest leap forward in pollution control and fuel economy, and building a practical EFI system that could sneak under the noses of budget-conscious buyers was the goal of every OEM by the close of the ’80s.

Because it was familiar territory and cheap to retrofit, many early EFI systems were throttle-body-injected (TBI) units that effectively replaced a carburetor with a simple throttle body, maintaining the same general intake manifold design and poor fuel distribution carbs were known for at the time. But the solution was a big improvement over the bastardized powertrains buyers had dealt with and could be implemented with relatively little engine development. While TBI units stayed the stalwart of pick-up trucks and economy cars thanks to their simple design and low cost, multi-point fuel-injection quickly gained popularity. This method of fuel-injection moved the point of injection from the throat of the intake manifold down into the intake ports, just ahead of the valve, and thus could boast superior control over fuel.

Electronic Control Units (ECUs), benefiting from the rapid development of microprocessors, began to have a semblance of reliability, as both the engineers and repair technicians better understood what they were working with. Turbocharging, previously restrained by the difficulty of controlling boost and detonation through earlier carbureted engines, reaped the benefits of the feedback loop based on NOx and oxygen sensors. For the first time in a decade, horsepower began to climb above pre-1975 numbers.

The explosion of new EFI systems posed a new issue for both regulators and technicians, however. With each OEM down the wormhole of its own EFI protocols and components, commonality for diagnostics and testing was nowhere to be found. The diversity increased costs for dealerships, which had to routinely invest in new tools and training for their technicians, and severely limited independent repair shops’ ability to diagnose problems. With the myriad of new EFI systems, each with their own diagnostic connector shape and data protocols, the cost to support an array of OEM diagnostic systems became astronomical. Similarly, regulators struggled to keep up with the proliferation of EFI systems and methods for testing their functionality.

In 1988 came the biggest change to emissions regulations since the 1975 crackdown: the standardization of basic functions of EFI controls for diagnostics and regulatory testing. The Society of Automotive Engineers (SAE) pooled together a new standard for these emerging emissions systems, while California began its own efforts to require On-Board Diagnostics (OBD/OBDI). By 1996, a more formalized diagnostic standard, OBDII, rolled out with the cooperation of SAE and CARB. It essentially defined exactly which sensors an engine needed, which diagnostic and emissions checks the system needed to track, and (to the cheers of mechanics and DIYers) a standardized connection port—no more adapter plugs and cards. This also gave regulators a simple toolset for emissions testing regiments and regular field testing (for example, state emissions inspections).

The Reckoning

We often take for granted how convenient and clean-burning cars have become, and these bookmarks in automotive engineering history altered what ended up in showrooms. While the invisible hand of regulation has pushed emissions and fuel economy technology forward, it has not always come easily or even necessarily because of it. We’re on the horizon of another era of big changes in regulatory standards that will alter every segment we know and love. By 2025, the bar will be raised significantly, and with the all-EV pressure of some European markets, we could see a fundamental shift.

The two alphabet names that matter, moving forward, are CAFE and CARB. CARB no longer speaks just for California, as more than a dozen states now subscribe to those stricter emissions standards. Eloquently known as the “CARB States,” Connecticut, Delaware, Maine, Maryland, Massachusetts, New Jersey, New Mexico, New York, Oregon, Pennsylvania, Rhode Island, Vermont, Washington state, and good ol’ Washington D.C. follow in the footsteps of the Left Coast.

Look back far enough, and you’ll see “California Special” emissions and engine packages throughout the decades as OEMs answered to California’s stricter targets. Today, we see this in the form of varying degrees of Low Emissions Vehicle (LEV) certifications. This not only affects new-car sales (as states can restrict what level of LEV vehicles will be sold), but it also has a tangible effect on the classic car hobby as CARB continues to hammer classic owners in California with period emissions regulations and equipment going back to 1976. The aforementioned Chrysler Lean Burn was CARB’s stake in the history books, and utilizing modern engine swaps and ECU controls is difficult in current regulations without aftermarket support in the form of relatively expensive—though legally comprehensive—swap packages such as Chevrolet Performance’s E-Rod.

You can piece together your own swap, but be ready to reengineer the factory fuel system of your late-model donor to fit your classic ride, too. This is problematic since many classic emissions systems were faulty when new (much less with consequent decades of use) and can create reliability issues in an otherwise perfectly-good machine. Ultimately, problematic emissions systems lead to the loss of registration of an otherwise perfectly viable car, regardless of an owner’s personal attachment or livelihood.

The point here is not to debate the merits of CARB, but to point out that California speaks for nearly one-fourth of U.S. now. It is advised to watch local California developments; changes on the West Coast may bring change from thousands of miles away to the machine and hobby you’ve already built in your own garage.

These changes are not just accelerated by emissions concerns as a whole, but also by the ramping up of CAFE standards in the early 2000s. To be frank, the OEMs were already exceeding CAFE requirements, but political pressure, in part brought on by the “What are we saving you for?” attitude of the Troubled Asset Relief Program (TARP) bailouts, forced each of The Big Three, in one way or another, to promise to support increased fuel economy regulations in order to receive a quick injection of cash.

While CAFE regulations cars had flatlined to 27.5 mpg (truck requirements were still steadily pacing upwards), the automotive industry had been exceeding them for quite some time already. Starting in 2010, the CAFE bar began to quickly rise. Through the bailouts and presidential elections, the U.S. federal government finally settled on this: by 2025, the basic goal would be a fleet average of 54.5 mpg. While consumer buying habits have baffled regulators (why wouldn’t Americans give up their larger vehicles?), future changes won’t be where you expect.

Automakers will continue to lean on small cars to bring their fleet averages down, but as Americans continue to favor larger vehicles, you’ll see OEMs respond with ideas like an EV Mustang or hybrid/all-wheel-drive Corvette. Though many OEMs don’t mind paying off CAFE shortfalls through fines and carbon credits, increasing pressure from European countries to move into all-EV model lines will push hybrid and pure-EV projects through the pipeline. We’ve reached a point of diminishing returns in small cars, to a degree, but the lessons learned from the compact offerings are becoming more common in full size trucks, high-performance cars, and luxury offerings, which have stuck with traditional gasoline power, by and large (no pun intended).

Like Volkswagen and the Beetle, OEMs will eventually change the identity of the machines they build to mold with the era. In the meantime, while the petroleum party is still pounding, and the market continues to eat up products like the Dodge Demon and the Mercedes-Benz G-Class.

While bureaucrats figure out what to do with the situation, we can still expect a radical change under the hoods of our beloved nameplates in the coming decade. Like the plucky Volkswagen Golf, change can be uncomfortable and icky at first to the traditionalists (since many still espouse the gospel of air-cooling in 2019).

What we can take away from this is that things are gonna change, whether you like it or not—but at least you know where the invisible hand is pushing.