A Break-In That Could Have Broken Down

I held the black-and-white wire to the piece of scrap metal bolted to the cylinder head, and sudden quiet washed over the whole shop. As heat waves rose off the Honda XR250R engine, fresh from its first cycle of the break-in process, I took stock of the assembly of parts, which was now a functional object, with a sign of relief. Anyone who has experienced the first startup of an engine they rebuilt likely has felt something similar, and this little Honda holds a special little spot in my heart. It also forced me to think: Why did hearing it run for the first time bring such relief?

After all, I rebuilt the thing. Why wouldn’t it run, and run right? Did I really doubt my own work? Maybe I did—or maybe it was something else. The only way to prove my work was to make it run, and with two engines and no motorcycles in need of said engines, getting one running presented an interesting problem. After a night spent sitting and staring, I decided to fabri-cobble together a test stand with some steel stock and parts pulled from my spares pile. In an afternoon, the system took shape.

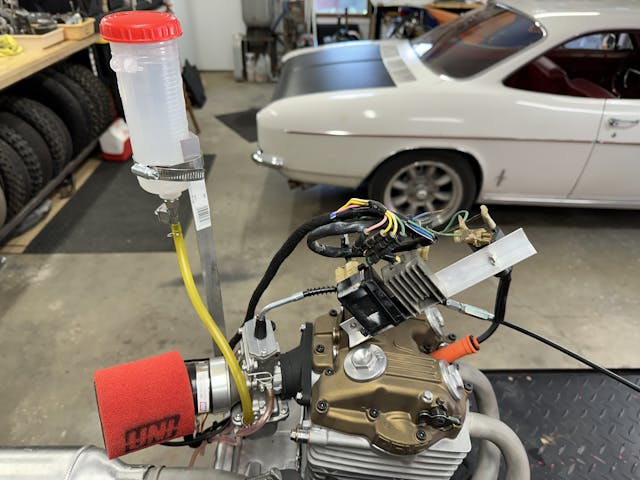

The steel frame that held the engine while I assembled it on the bench would be plenty sturdy to serve as the base. In the bins on the back wall of my garage were a full wire harness, CDI module, regulator rectifier, and coil. I mounted all of them to a piece of aluminum angle, which I then bolted to the top of the valve cover. A muffler clamped onto the header would keep things quiet enough to not annoy the neighbors. A small fuel bottle, an old camera tripod, and gravity-handled fuel delivery to the new carburetor. The final step was to bypass the oil cooler with a short length of rubber hose. Once I had attached all that to the motorcycle lift with a couple bolts, suddenly I had a mobile, modular break-in stand.

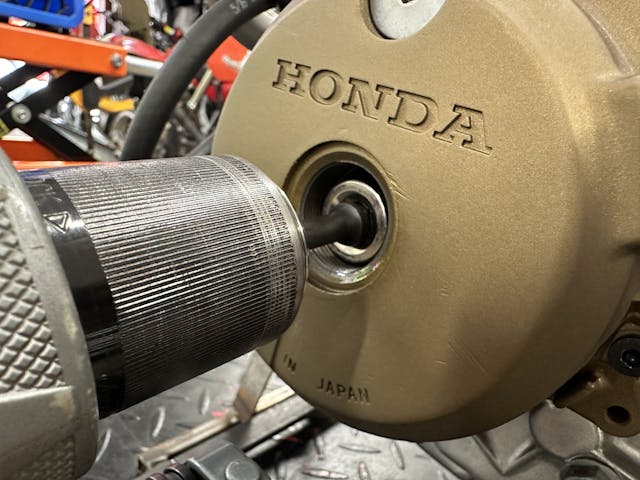

With a solidly mounted and wired engine, you can perform real inspections and prepare for starting. The cases held the proper amount of oil for running, but the entire oiling system was filled with air, so I used a cordless drill and a 17mm socket to turn over the engine until oil squeezed out from the banjo bolt that feeds oil to the cylinder head. This also enabled me to check the ignition system by grounding the spark plug outside the cylinder head. Good oil pressure and a strong spark are always great to see before even trying to start an engine. Since the cordless drill could turn this engine at a few hundred rpm pretty easily, I could also get a feel for any hitches or odd noises.

After I tightened the spark plug back into place and connected the plug wire, it was time to Pelé this little ball of fun. Given the whole no-motorcycle-to-brace-onto aspect of this test stand, that meant me stabbing awkwardly at the kickstand. The engine popped right to life at a nice, smooth idle. I set it a little higher than normal and turned on the small Air Mover fan in front of the engine. Next, I inspected for oil leak and checked temperatures to see how everything was coming to life.

The simple stand gave me easy access to all the parts of the engine, making it easy to tune and check various systems. Surprisingly, the minimal exhaust setup was quieter than some of the other exhausts currently in my stable. The 15-minute heat cycles were about as loud as a small generator running outside on a Saturday afternoon. An afternoon of running in a new engine? That calls for celebration.

But why? And why was I relieved when this engine started and ran with no problem? Again, I knew I had built it right and had measured and checked every single part. My feeling of spotless preparation tempts Murphy’s law: Having removed every predictable opportunity for the What Can Go Wrongs, I am left only with the What Will Go Wrongs, things due to luck or chance. My feeling of relief wasn’t due to my fear of having done something wrong or missed a part. Rather, it was because I knew something outside of my control could have gone wrong—and didn’t.

More than anything, I’ve come to realize it doesn’t matter why I’m excited about having a restored and running engine. What matters is the machine the engine will power and where they will take me.

***

Check out the Hagerty Media homepage so you don’t miss a single story, or better yet, bookmark it. To get our best stories delivered right to your inbox, subscribe to our newsletters.

Nothing like firing up a newly built engine for the first time! And the stand looked like an ingenious way to do it.

Yes Kyle, it is somewhat irrational, but I know exactly how you felt when it came to life! I always feel the same thrill and satisfaction – not sure why, either.

I pulled wrenches professionally for 18 years and I STILL get anxiety starting an engine after any work done to it.

It’s part & parcel to the process, which makes the relief and victory all that much sweeter.

Is that a Yenko Stinger I see in the background? You dog!

If only! It’s “just” a ’65 Corsa. I’ve done some Yenko-inspired things but it’s really meant to be a fun to drive street car. A Stinger is a dream for now.

Funny but gratifying all at the same time, I hear ya. Doing the same thing to a V8 engine on a makeshift wooden stand was fun also.

Congratulations we have liftoff! The setup looks really good to me.

Congratulations, Kyle!

That has to be the easiest starting 4 stroke this side of electric. Having experience swapping with riding buddies and their 4 strokes down thru the years I swore I would never own one. When the starter button appeared on a friends KTM I tried it and the next season I was on a 450. Good job on the test rig.

Well-tuned 4-strokes are not tough to start. The Honda XRs also have a starting procedure that if followed makes them very easy to live with. Don’t follow it and, well, they are real bears.

Great article Kyle. I have felt the same anguish when starting a newly rebuilt engine, Ha d a CR250R for a while, what an animal….

Something akin to hearing a baby’s first cry, though of course on a different scale….And shorts and sandals in the shop: taking fashion cues from Frieburger? Or did he get them from YOU?

He’s got 10 times more foot protection than Freiburger would have – which, admittedly, ain’t saying much…. 🙄

Are your safety glasses smudged? Those are closed-shoes in the video…

I kid, but I hear you. Safety is a personal thing and I could see how some feel shorts and sneakers for the break in on that engine was inadequate. If that is how you feel be sure to wear long pants and boots when starting your engine for the first time. No different than how once the engine started and I confirmed no bad noises I put on hearing protection for the remainder of the break in. Probably should have worn it from the first kick, but I like to hear everything unmuffled for a bit to have a reference just in case noises develop.