Leifert Automotive Machine Shop: Small Footprint, Big Legacy

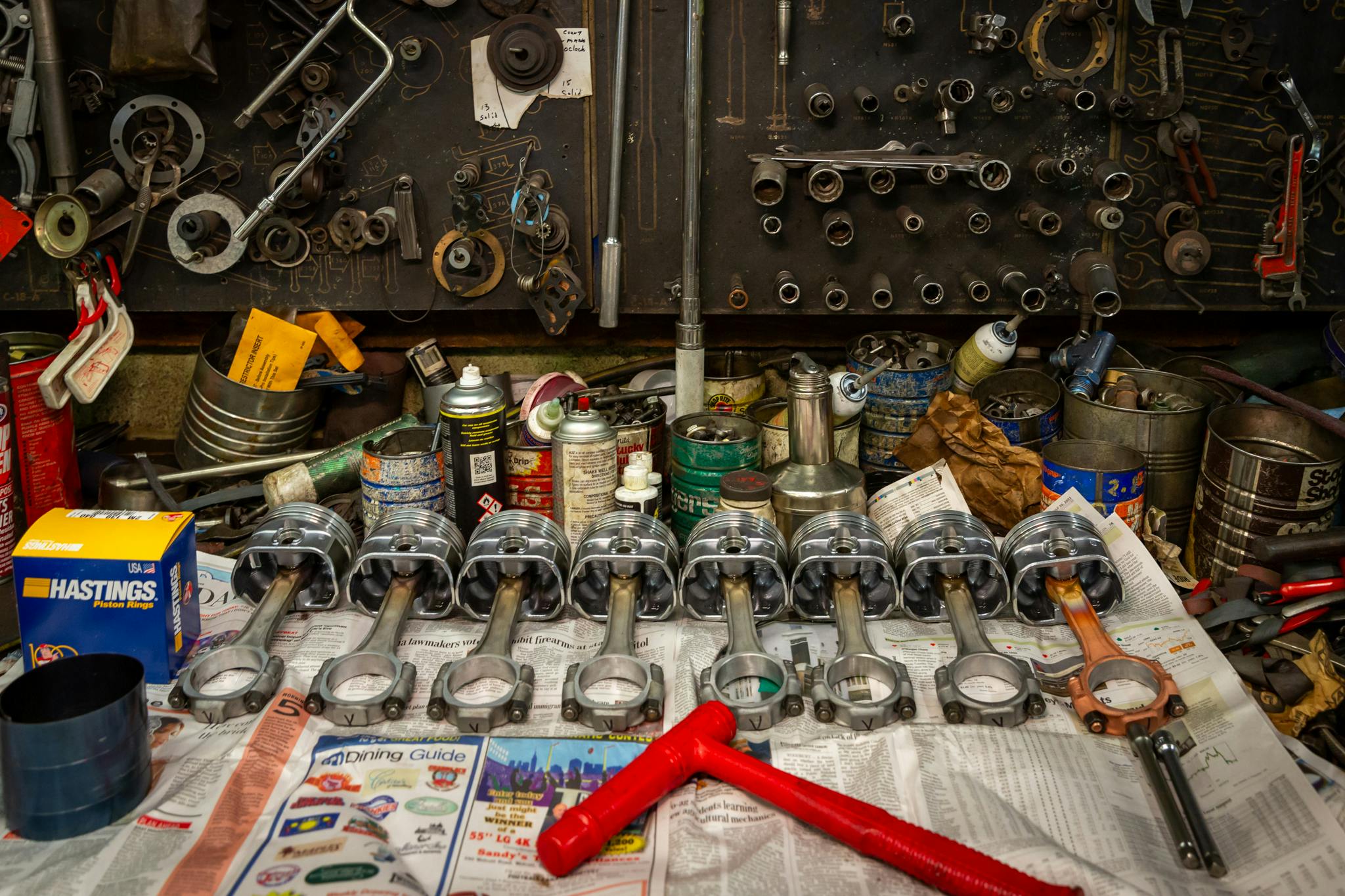

Step into the unassuming concrete building on quiet Brook Street in Torrington, Connecticut, and you’ll find yourself transported back at least fifty years. A few Chevy 350s and a “Hi Perf” 396 engine sit disassembled alongside a 1970 Ford Capri racing block that just came in the door. Deeper into the shop wait a dozen more motors in various states of repair—some heavily abused or neglected, others beloved and rare matching-numbers motors here for a routine refresh. The disarray of scattered parts looks frightening to the untrained eye, but the young machinist in charge, Trevor Riccardone, isn’t concerned. This has been the process at Leifert Automotive Machine Shop for more than a half-century, and it isn’t about to change. Nor will the quality of the finished products. Riccardone, 28, may have only recently taken over for founder Larry Leifert, but he takes responsibility for the shop’s legacy.

Larry Leifert opened his namesake machine shop in January 1969, after working at Lee-Mar Auto, where he gained a wealth of knowledge under the supervision of shop head George Varga, and then at Grinold Auto. At the time, Leifert wanted a raise but didn’t consider it likely, so decided he’d try to beat his $2.50 an-hour wage by opening up his own shop. He borrowed $60,000 to get his business up and running, purchased the building, outfitted the facility with mostly brand-new machining equipment, and hired two employees. He charged a $9 per hour shop fee for building engines, which today translates to $77.

In short order, Leifert built a reputation around the area as an expert designing, building, and tuning all kinds of engines. “I did a lot of work for guys off the street,” he says, but a significant portion of his time was also devoted to commercial fleet contracts. Leifert often refreshed and rebuilt motors for the phone and light companies, fleet vehicles for the City of Torrington, and truckers in the Connecticut Milk Producers Association. He even rebuilt the engines for ski lifts and snow-making machines for a local ski area. “I’ve worked on almost every kind of motor you can think of,” says Leifert.

Leifert is a big, affable guy with an authoritative presence. A recent back surgery has him walking with a cane, but once he’s got a comfortable seat, he’ll talk to you for hours. Conversation with him moves freely, from discussing the ins and outs of a disassembled motor, troubleshooting an issue, or sharing a colorful story or two from his mental vault. One thing is clear: Entire shop manuals could be written based on his lifetime of knowledge.

In the early days of his business, Leifert’s larger accounts took a notoriously long time to pay their bills, often on a minimum net-90 payment schedule. “In 1969 I owed everybody, everywhere. I was just about bankrupt,” recalled Leifert. When big accounts took months to pay up, it all compounded and took the business many, many years to get above water.

“Money was so tight back then. One time the phone company shut my phone off when I couldn’t pay them $50, even though they owed me 900 bucks for an engine.” Leifert wasn’t happy, and through his lawyer, conveyed that the company wouldn’t be getting their engine back without paying the $900 they owed him. The phone people threatened to never work with him again. “Well that didn’t last long,” he laughs, “they kept on bringing me stuff.”

It pays to be the most skilled guy around.

Still, getting square on all of his loans and running his business was a decades-long endeavor. “It took about 30 or 35 years until I began to be comfortable,” Leifert explains. Running a machine shop is expensive; he estimates that he spent “hundreds of thousands of dollars on tools,” over the years. “I used to say Thanksgiving was the best day of the year—a day off and people wouldn’t call me for money!”

Not long after opening his shop, Leifert entered the motorsports industry, working first with Trans Am driver Paul Pettey of Litchfield County, Connecticut. He was a regular in pit crews at Lime Rock Park and served as a crew chief and mechanic for about ten drivers in Sports Car Club of America (SCCA) road racing, A-Sedan, and drag racing over the next five decades.

Leifert was known around town and on the track circuit as a serious engine builder. He accumulated countless track wins all over the U.S. and Canada, and served in the pits at the 24 Hours of Daytona four times.

Leifert spent most of his career working with three main guys: Peter Andrighetti, Jack Busch, and Academy Award-winning actor (and founder of the Newman’s Own food nonprofit) Paul Newman. The latter hired Leifert to run his team after the actor decided to get back into racing in the last few years of his life.

Bruce Deming, Vice President of the East Coast Gassers car club, is a longtime customer as well as a personal friend to Leifert. Deming started riding to the machine shop on his bicycle in the summer of 1969, when he was 11 years old. “At that time he [Leifert] just finished a 327 for my brother Clayton’s Nova,” explains Deming. “I thought I was cool hanging around with those guys who were teenagers,” he laughs.

At age 15, Deming bought a ‘66 Chevelle with a blown motor from his brother. The Chevy was Deming’s first car, and Leifert rebuilt a replacement motor for him. “When I got my license, that’s the car I drove to school,” he says.

Deming calculates that over the years Leifert must have built or rebuilt a dozen engines for him, powering many cars, trucks, and tractors, “including one tractor that I pulled and won with many [times] back in the early 2000s.” To this day, Deming races a Leifert motor in his 1941 Willys drag car. “He’s just a super guy, there aren’t many like him,” says Deming.

The shop is dimly lit and cluttered. Photos of it from the ‘70s, taped to the walls, confirm that this condition is standard, rather than a decline from some previous state of shine. An ad for J&S Hydraulics, hanging from a nail on the back of the wood-paneled bathroom door, is attached to a tear-sheet calendar turned to January 1969, the month the shop opened. On the floor sits a concocted homemade toilet paper dispenser: a crankshaft mounted vertically on a flywheel, with a connecting rod protruding from the side.

Leifert’s is about as far from the dentist-office, polished-floor modern facility as one could imagine. In fact, I’m told, it’s actually a novelty that the floor is even visible in most areas. As I look around, thin curls of metal spit off the top of a cylinder head that’s clamped to an old Kwik Way planer. A compressor cycles on and off every 15 minutes or so, keeping up the constant demand for pressurized air needed to power tools throughout the shop. A recently retired rotary phone sits next to an original drill press at the former workstation of longtime employee and gearhead, the late Barry Lundon, who specialized in refurbishing cylinder heads.

Under Lundon’s bench are hidden gems: engine paint stalactites, accumulated over 20 years from his practice of turning the spray cans upside down to clear the nozzle after use. Just to the right of Lundon’s station worked Leifert’s brother, Eddie, who had the critical role of assembling motors during his 45-year tenure at the shop. “He did most of the same things I did and was a big part of the place. He took care of a lot … for me there,” says Larry.

A unique, distinctly chemical smell wafts in the air, an imprecise mixture of carb cleaner, engine paint, burnt motor oil, and ground iron. The scent bonds itself deep into the fabric of my clothes, clinging long after I’ve left the shop. Rumor has it that, years ago, some local guys would hang around the shop before returning home, in hopes of masking the smell of another woman’s perfume.

Leifert Automotive celebrated fifty-five years in January 2024. The sight of it enriches the picture I had of it in my mind, weaved from my father’s countless mentions and memories of happenings “down Leifert’s” over the years. This is the machine shop he trusted to void his dealer warranty and properly fix a known issue with big-block Chevy heads. It was 1971, and my father was racing weekly at Lebanon Valley Dragway, and decided to have Leifert bore the cylinders and add a more aggressive cam. The shop is doing the same work now as it was then, say the longtime customers around Torrington, and the new owner is similarly dedicated to quality.

Leifert was 79 when he sold the business in 2022 to Trevor Riccardone, then 25, who’s been running the shop full-time since. Trevor bought the shop with his brother, Alex Riccardone. The duo graduated from Oliver Wolcott Technical School, which is less than a mile from the machine shop. (Leifert graduated from the same high school, where he won an award, and a toolbox, for “Auto Mechanic of the Year” in 1960.)

Before taking over, both Riccardones worked for Leifert at the business. While in high school, Alex put in a couple of years of work that impressed Leifert, and Trevor worked there part-time on top of his tool and die position in a neighboring town.

Trevor has an approachable and friendly demeanor. He moves around the machine shop with a casual ease, as if he’s spent decades in one. He wipes the grease from his hands with a red shop rag while leaning on an old iron machine that is likely three times his age. He acknowledges that issues are sure to come up now and again, but he seems unfazed by them, sure that he can fix whatever mess comes in the door.

“Before coming to this shop,” Trevor tells me, “the first engines I did were my 1970 427 Chevelle, and then the first of many Subaru engines, but I was just a hobbyist then.”

With his machine tool background, Trevor seemed to Leifert like a great fit. “There weren’t many people you could find to take over this kind of shop,” the veteran points out. “He was already a machinist, so he knew how to run the machines. I’m still teaching him a lot about the business, but [the brothers] are just perfect. Boy I’m glad I found them.”

After the Riccardones took over the business, Trevor spent some time moving a few machines around, decluttering, and organizing. “I’m still using most of the same equipment and made very few actual changes. It’s the same shop and still producing the same work,” he explains, though the tidying was crucial. “I’m particular about the clean work I do and take pride in meticulous details that customers may not even notice, down to making sure the freeze plugs are installed straight and upright.”

Cleaning out many of the old magazines and paperwork revealed a workbench along with dozens of near-empty spray cans that had rolled away over the years. “The bench was completely invisible,” he half-jokes, “I didn’t know it was there when I bought the shop!”

Patience, for Riccardone, is another major ingredient for success. “You can’t rush with this kind of work,” he says. “I can always figure it out, which is probably why Larry speaks so highly of me, and being mechanically minded and a problem solver helps. If I’m worried about something, the first step is to figure out how to do it properly since it’s not worth trying to save money or time to half-ass something—that never works out well. You just have to do it right the first time.”

It’s this determination and know-how that are earning Riccardone such a strong reputation and trust with customers. “He’ll do great, he’s really the only shop around that does more than just performance motors,” says Deming, “so I’ll definitely bring another motor down to him.”

Ricciardone is going to continue working, day in and day out, for that rewarding feeling of seeing the finished product bagged and set by the door for pickup. “A lot of people underestimate the value of a good, fresh, tight engine. If an engine cylinder is leaking then you’re losing power right there. It’s literally not going to be as efficient as it can be.” He also wants customers to have assurance that he’s personally there to help if questions arise after they pick up their cherished motors. “They’re getting my best work as well as my assistance moving forward. They basically have built-in technical support. If it’s work I did, I stand by it.”

Throughout the process of transferring his business to the new owners, Leifert has often been by his successor’s side or no more than a phone call away. Riccardone often seeks advice from him and Eddie when specific questions arise mid-project. “I still experience some [customers] that are a little reluctant with me working on their engines, which I understand,” says Riccardone, who admits he doesn’t know everything.

He nevertheless has the shop founder’s full confidence: “Everybody loves the guy, he’s a really smart kid,” Leifert adds, “you’ve got to love this kind of work and he does. He’s going to be good at it, he’s really going to be good at it.”

Courtesy Leifert Automotive

***

Check out the Hagerty Media homepage so you don’t miss a single story, or better yet, bookmark it. To get our best stories delivered right to your inbox, subscribe to our newsletters.

Reminds me of the shop where we used to get our stock car engines machined and built. We used to go in and do our work after hours since we were sponsored. I remember the guy who pretty much did the main work would have me put the tools back as his father owned the shop and had an out line for every tool on the wall. Rick was in his late 30’s and said make sure they are all back or dad will kill me. They closed not long ago and retired. The shop remained the same as it was for decades.

We lose so many of these anymore as family went two gens and stopped.

Nice article about three great guys. Larry is one of the most knowledgeable men that I have ever encountered. Whether it’s gas, LP or diesel, old or new, Leifert’s will make it run, and run reliably.

I’m glad Larry found a talented young man like Trevor to take over, which is not an easy thing to do nowadays. Trevor is great to work with and is very knowledgeable. Also, keeping an experienced guy like Eddie will insure that Leifert’s reputation for quality work will continue.

Scott Goff, Goff’s Equipment Service, Inc., Litchfield, CT

Great photos and beautifully written. Reading the story of this man, his business and the future of the business puts you right in the middle of the shop. With the smells and sights as you look through the photos, brings you to a time of growing interest in fast motors, close friendships and rivalry. We are grateful to have been part of this thrilling era.

I agree it’s a great story. I love the blue straight six in the background looking good and all the other great photos.

Great article – good to hear the shop is in good hands, with a future. When I first started wrenching I was taught that anybody can build an engine – IF – they have the backing of a good machinist. I was fortunate to have three great ones to guide me along.

This is a great story, heartwarming and it raises my spirits to see this shop continuing in business in this way. These guys are the spirit of hard work and the true American way.

Great story! Paul Newman starting racing in his 40’s.

Great legacy I’m glad it’s being carried on. We will support the shop moving forward with any of our needs. Trevor is a very meticulous person so I know the quality of his work and highly recommend him.