You (Nearly) Picked a Fine Time to Leave Me (Again), Loose Wheel

Part of my stock in trade in writing these columns is that, as your favorite automotive everyman, I’m willing to admit to doing things that most folks would deep-six, like the prom pic of you sporting a mullet, or the fact that you dug Night Ranger in the ’80s. I’ve never changed my oil and then backed over the catch basin, but if I had, I would write about it without hesitation, which then would give you folks cover to say “Okay, yeah, I did that too, but at my wife’s parents’ house, and the wave of oil hit my mother-in-law.”

I mention this because about four years ago, I wrote a piece titled “That time my wheel feel off and rolled past me on the street.” In it, I described how, nearly 40 years ago, after swapping my winter wheels onto a ratty BMW 1600, I was driving home at low speed on local roads, heard a rapidly-increasing whubba-whubba-whubba noise, and before I knew what was happening, BANG! the left rear brake drum was skidding on the snow-covered asphalt. The number of comments it received was astonishing. What I thought was weird negligent gonzo livin’-on-the-edge Hack Mechanic stuff was far more common than I ever imagined.

While I never again actually lost a wheel, I had two other ones loosen (one on local roads, the other on an interstate), and thus have become acutely aware that, when driving slowly, you may only have 20 or 30 seconds from that first whubba-whubba to chaos. On the highway, it may be more like only 10 seconds. Having lost one wheel and nearly losing two others, I became hyper-vigilant about always torqueing down lug nuts after swapping wheels.

So imagine my surprise and self-loathing when it nearly happened again.

Here’s the story. The day before Boston’s first predicted winter weather, it was delightfully mild outside. I set out to put the winter shoes on both of the daily drivers—my wife’s 2014 Honda Fit and my 2003 BMW 530i. Since the garage was fully occupied by my ’73 BMW 3.0CSi and both Lotuses (yeah, my life is hell), I did the swap on the sidewalk in front of the house. So, no mid-rise lift, no air tools, just a floor jack, a jack stand, a breaker bar and socket, a torque wrench, some Scotch Brite, and anti-seize compound. To make things quick and easy, I used the lightweight aluminum jack that I bring on road trips with me. The downside is that it doesn’t have enough reach to jack up the nose or the rear—you need to do one wheel at a time.

I did the Honda Fit first. Each wheel has one special keyed anti-theft lug nut, so I needed to dig through all my wife’s crap in the glove box to find the keyed socket. But the swap went quickly, as the car’s little 14-inch wheels are small and light and easy to throw around. One corner at a time, wheel off, Scotch Brite on the hub center, Scotch Brite on the center bore of the wheel that’s been sitting under the back porch for eight months, anti-seize on the bore, wheel on, torque it, second and third and fourth verses same as the first, boom, done.

Next was my E39 530i. I toyed with the idea of not swapping to the winter wheels, as a) the Craigslist Toyo snow tires have plenty of tread but the sidewalls have so much flex that it absolutely kills the car’s handling, b) I could probably leave the three-season low-profile rubber on it and just drive the Nissan Armada if it’s slippery out, and c) the alloys are not only cheesy aftermarket, but mismatched cheesy aftermarket. Every winter I imagine the car saying to me “Really? You say over and over that I’m the best daily driver you’ve ever owned and here it is, another winter, and you make me wear this crap again?” But then I remembered that my driveway slopes down, and when it snows, without proper snow tires, the E39 becomes immobile. Plus, my oldest son uses the car quite a bit, and I wouldn’t want him to be driving it on summer shoes if weather moves in. So onward with the swap.

The E39 has developed a steering wheel shudder on braking. I replaced the front rotors a few years ago, and that cured it, but it’s back. This could be due to either rotors or to a suspension component like lower control arms. One way to tell is to jack up the car and spin the front wheels. If there’s no rhythmic binding of the rotor against the pads, then the rotors are true, but if there is binding, then the rotor isn’t sitting flat against the hub, or has deposits on it, or in rare cases, is warped. While I had the E39’s front wheels in the air, I checked this. The right rotor ran true, but the left one did exhibit some oscillatory rubbing against the pads. I didn’t want to take the time to investigate further, as it would’ve meant pulling the rotor, but I made a mental note of it.

True to forecast, the following day brought cold temperatures and some morning flurries. I was glad the snows were on the E39, as my son borrowed it to go to the gym.

That afternoon, I needed to run to the hardware store to buy some fasteners. On the way back, the E39’s steering vibrated noticeably when I hit the brakes. Initially I thought it was the less-than-true rotor I was already aware of. But as I continued to drive, the sound was no longer only on braking. And it was getting louder. I thought, “Well, it can’t be the lug nuts because I know I was out there with a torque wrench and checked them all on both cars.” I initially thought that I could make it the two-ish miles back home and look at it then, but even at my 20-mph pace on local roads, the sound got louder quickly enough that I realized I had no choice but to stop.

I pulled over on a small side street, turned on the hazards, got out, grabbed the wheel at 12:00, and rocked it back and forth. The lug nuts clearly were loose. Damn, how did I get this wrong?

Well, no matter. BMWs come with a tool kit. There’s a lug wrench in the trunk. Snug these errant puppies down and I’ll be on my…

No tool kit.

And then I remembered. For reasons unknown, this E39 is missing its trunk-mounted tool tray. I have no idea why. I bumped into this when the alternator died. I needed a rollback tow home, and I couldn’t find the towing eye that screws into the bumper. I had made a mental note to find a used factory tool tray, but forgot about it.

While this was hardly a dire situation—I could’ve called an Uber, or seen if my wife or one of the kids was home, or just walked to the house if necessary—it was inconvenient, and a little embarrassing.

Then I remembered. I was maybe a quarter of a mile from The Tool Shed, a delightfully old-school little store in a little strip mall where a guy sells used tools. His prices aren’t give-away, but they’re very fair. I hoofed it up there, went inside and said, “I’ve bought stuff from you many times over the years, I’m parked just around the corner with a wheel that’s about to fall off, can I borrow a breaker bar, a 17mm socket, and an extension? I’ll be right back with them.”

“Sure, he said. He grabbed the stuff off the shelves and handed them to me. The whole thing probably took 15 seconds.

“I’ll be right back,” I repeated.

“I know,” he said. “I trust you.”

I hoofed it back to the car and snockered down the renegade lug nuts. All five of them were completely loose. I checked the ones on the other three wheels. They all were fine.

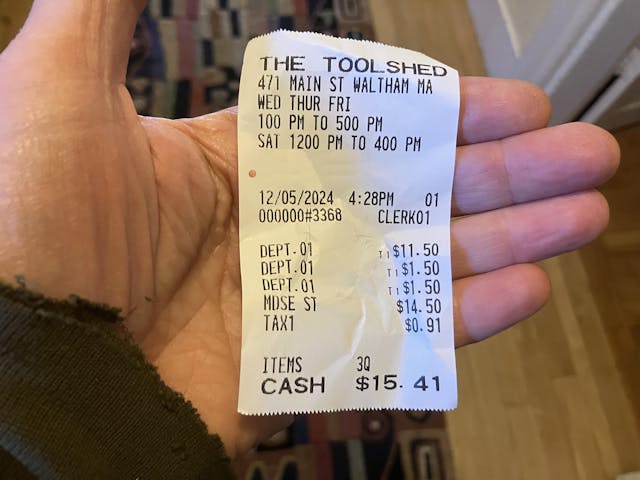

I walked back to The Tool Shed. The owner put out his hands to receive the breaker bar, but I said, “I’ll just buy it.”

“You don’t have to,” he said.

“I want to,” I said.

“Really,” he said, “You don’t have to. You probably have five at home.”

“Really,” I said, “I have two at home, but I want this one to live in this car.”

Fifteen bucks. You gotta love old school.

So, how did it happen? I’m not entirely certain. Since I was jacking and changing the wheels one corner of the car at a time, I believe that I was torqueing them one at a time as well. Some might think that’s a bad idea, and perhaps it is, but I’ve been working on the recently-purchased Lotus Elan +2 and doing things like shimming one tie rod or replacing the U-joint on one half-axle. These things have required removing one wheel, so when it goes back on, I torque it down. If two wheels are off, I put them both back on, then torque them both. On the E39, I don’t know if I got interrupted—a text, my wife coming out of the house—or whether I forgot to do the left front wheel because I was examining the runout of its brake rotor, but it’s likely that I was torqueing each wheel as I set it down, which may be a more fragile process than walking around the car and doing all four.

I posted this event to social media, and a number of people said that when they swap wheels, they leave a torque wrench on the driver’s seat. I’m not certain that alone would’ve saved me. I had a torque wrench on the front steps and somehow managed to miss a wheel. Plus, when I swap wheels on the sidewalk in front of my house, I need to move the car at least once in the process so I don’t step in my wife’s garden (one wheel at a time on the right side can be accessed from the cement in front of the steps to the porch). I think that the issue is more that I need to use a sequence where I swap all four wheels, then torque all four, instead of torquing them one or two at a time.

Another friend commented that sometimes, if a wheel is put on the hub slightly cocked, and if there’s corrosion on the hub and/or the center bore of the wheel, it may seem that the lug nuts are torqueing down, but the wheel isn’t properly seated, and won’t be until the car is driven and bounced around. I did experience this the first time I dismounted and mounted the wheels on the Armada, but I caught it, as one wheel was loud the moment I moved the car in the driveway. Others say that their routine is to torque all four wheels, drive the car around the block and hit the brakes a few times, then torque the wheels again. Even though I think that this was operator error on my part, not a cocked-and-therefore-unseated wheel, I am now vowing to adopt this torque-em-all, drive the car, torque-em-all-again procedure.

The whole Kenny Rogers song parody, “You picked a fine time to leave me, loose wheel” thing is funny, but this really wasn’t. It was jarring. My son was driving this car just a couple of hours before I was. This could’ve happened to him. It could’ve happened to my wife. I absolutely cannot let this happen again.

So when you see a person systematically walking around a car and torqueing all four wheels, then doing it again, it’s not a glitch in The Matrix. It’s me.

***

Rob’s latest book, The Best Of The Hack Mechanic™: 35 years of hacks, kluges, and assorted automotive mayhem, is available on Amazon here. His other seven books are available here on Amazon, or you can order personally inscribed copies from Rob’s website, www.robsiegel.com.

Luck was with ya this time, Hack (and with your son, apparently)! And as much as you’ve now stuck an earworm ditty in my head (for which I forgive you), I agree that it couldn’t been serious. I’m a proponent of torquing once, twice and yet a third time when it comes to wheels. In my lifetime I’ve driven school bus, raced in SCCA and 1/4-mile drags, driven 80,000 pound 18-wheelers, ridden big V-twin motorcycles, and done all sorts of 4WD off-roading, so the thought of losing a wheel while in motion is one of the most dire things I can imagine. I think the wrench-on-seat idea is akin to putting the oil filler cap where the hood latch goes, and should work – as long as one actually realizes what it’s there for and pays attention to it.

Yes, fifteen dollars well spent, sir!

I often do one or the other – torque wrench or critical part on the drivers seat, or over the hood latch receiver. This has only saved my bacon a few times, but even once makes it worth while.

oops, COULD’VE been serious, not couldn’t – lesson: check your lugs AND check your words before hitting SUBMIT 😉

Hub centric wheels make it critical to torque and retorque. Even cleaning the hub in the salt areas. We even carry heavy rubber mallets as sometimes the wheel will not come off with a little persuasion. .

Also it is OK to say you like Night Ranger. They are still putting out new music and still sound like they did back in the day.

“Also it is OK to say you like Night Ranger. They are still putting out new music and still sound like they did back in the day.”

Lousy?

Sorry, hyperV6. It was sitting out there like a Christmas goose and I have no self-control.

Could be worse. I took my car to an actual mechanic about 10 years ago for some suspension work. Come to find out they LEFT OFF 2 of the 5 lug nuts on my passenger rear wheel, and didn’t tighten the other three. Then took it for a test drive where it promptly lost one of the loose nuts. Lucky for them the wheel decided to play nice and stay on the car until they got back to the shop. Not entirely sure how with only 40% of the required lug nuts.

And I think the only reason they told me is because they had already told me the car was ready but them had to order a new lug nut that wouldn’t arrive until the next day.

Yikes. I’m generally for giving out second chances, but I hope you didn’t give that shop even a second thought!

Great story, Rob – from one Rob to another, and with this Rob being in and around the tire business my whole life, your story (this and the previous) isn’t uncommon. Many things can happen, such as being interrupted, etc. Although I am generalizing, we all do this at least once and then create a habit, like leaving the torque wrench next to the first tire or on the seat as one reader said.

I am glad this happened on a Thursday around 4:00, as I noticed the Toolshed may have been closed otherwise… 😉

Now THERE is a Rob with a sharp eye for detail. You made this story 100% more interesting for me, RobH!

Yup; nobody’s perfect. Been there/done that 45+ years ago, 5 miles from home, after a front brake job on my old K-G. Never again, though; learned my lesson.

Since then, I’m always double-checking, but not in an OCD way, and carry that mindset when I’m tightening drain plugs, oil filters, hose clamps, filler caps, etc.

If at all possible, I’ll try not to begin jobs if I’m too tired or if I know I’ll be interrupted.

So at the time, 15 years ago, I was an accident investigator. Guy in a Jeep Cherokee goes to a small shop operating out of an old gas station for a tire rotation and oil change. Picks up the car and drives 30 miles up the interstate, and hears a noise. Stops, looks at all the wheels, can’t see anything wrong. Continues 10 miles more, and the left rear wheel leaves home, jumps the center median, and hits another Jeep Cherokee in the middle of the driver’s windshield. That was the driver’s last day. When I checked all the other lug nuts, all were loose. I believe this is a story of the interrupted mechanic. Phone call, boss talk, lunch break, pee break, something. Never know, I went back to the shop, closed, everything gone. My recommendation, never even begin to really tighten the nuts. Make it so that driving 20 feet, will make the driver notice something is wrong, really wrong. Then go back with the torque wrench. Cheers, safe driving

Wow. Your post reminds of the scene in “Zen And the Art Of…” where Pirsig is in the motorcycle shop and the radios are blaring and there is general mayhem going on around him. I think one of the young mechanics punches a hole in some type of cover on Pirsig’s bike.

When I put tires on, I always snug down two lugs by hand while rocking the wheel a little to make sure I send them home. Only two – so visually I know that wheel isn’t tight yet

Interesting related story – Many years ago, I was in a work truck with duals going up one of our local high grade river bridges when I noted reduced speed, increased RPMs… and a grinding noise. I assumed I blew a rear, pulled over to the side of the bridge, and hopped over onto the sidewalk. This was before cellphones (well maybe not bag phones). I started footing it over the bridge and didn’t get too far before a bridge cop called me back to my truck. He asked what was wrong, I said I think it has a blown rear, and he told me to try to get it to the other side. What was really wrong was that all of the wheel studs had sheared (most likely due to being loose) and the hub was turning inside the rims. I crested the bridge and started picking up speed on the downside when my truck tipped to the right and two tires started bouncing across five lanes of bridge. Fortunately traffic was light. I don’t think that bridge cop made that particular call a second time.

I’ve done this twice over the years, thankfully with only shame and embarrassment as the outcomes.

Now, I use a ⅜” cordless impact wrench to install the lug nuts with the wheel still in the air. Hold the trigger down until the third whacka, which gets nearly to the spec 90 lb-ft (your whackas may vary).

Hub is seated, and bolts are tight enough that even if I do forget the rest of the job, they won’t come loose.

And I leave the torque wrench on the seat.

Once when I was young and inexperienced, I torqued down the alloy wheels on my ‘68 GTO after removing the jack, putting all the wait on the wheels before tightening them securely. Bad move. Wound up borrowing a socket and breaker bar from my future father in law after finding one of the wheels loose at his place. Now when I do my winter/summer wheel/tire swaps, I snug up all the bolts with the tires off the ground, then lower the jack just enough to get rubber contact with the ground. Then I torque the bolts to spec before dropping the car off the jack. Then after 50-75 miles, I retorque all the bolts. I can usually get a tiny bit of movement out of one or two of them before my digital torque wrench beeps. Never had a loose wheel since the old GTO incident.

Rob, Maybe printing a sign off sheet you tape to steering wheel before each tire swap. A separate sign off for each wheel. Sometimes the extra step helps.

Perfect timing, just came in from the garage after putting snow tires on my Audi. I torque them to full spec after all wheels are on, take the car for a short drive, then re-torque them when I return. Learned THAT lesson many years ago.

Thank you for sharing your stories Rob.

How many people are going out to the garage right now to recheck the torque on their winter wheels?

(Hand raised)

Experienced a flat tire. Called my auto club and they came and changed out the tire for me.

Drove about 30 kms at a low speed (congestion) and got off the freeway to go and get a new tire.

Driving at about 30 mph on a side street, found myself running on the left rear caliper. Yup, the tire and wheel came loose, bounded across a busy highway and I dragged my car off onto a side street.

I no longer trust anyone tightening my lug nuts except me!

Crewing for more than a few amateur and Vintage racers, usually with volunteer crews, I learned not to ask if something critical – like torquing wheels – has been done. Grab the wrench and check it yourself

It’s interesting how the loose lug nuts actually can allow the wheel to come off the rim, at least in the case when it happened to me. It was an ordinary steel rim, the lugs were apparently loose, and the wheel wobbled while driving. It came off before I could find a good place to pull over. When I retrieved the wheel and tried to put it back on, I saw that the lug nuts were still on the studs! Then I saw that the stud holes on the wheels were much larger than normal, so large that they let the lug nuts pass right through them! So what happened was the threads on the studs acted like a round metal file, and as the wheel wobbled back and forth the holes got “filed” larger and larger until the nuts went right through them. I don’t think this was a hub-centric rim, and that’s probably why it happened so quickly.