The Rhythm of Repair: Juggling time, space, and money

One of the near-constants in my life—and I suspect in the life of anyone who wrenches on his or her own cars—is a phenomenon I call “The Rhythm of Repair.” It refers to the little chess match of time, space, and money you almost always play whenever you engage mechanically with your car.

It begins with an estimation of the scope of the job, and along with it, the parts you think you’ll need to complete it. For something utterly trivial, like replacing wiper blades or changing your oil, it’s usually not even noticeable—you either run to Autozone or order the parts online, and when you have them, you install them; boom, done. But for anything more complicated, you almost invariably get sucked into some weird physical manifestation of Gödel’s incompleteness theorem, where no set of parts can be both complete and cost-efficient.

Here’s the issue. Even if you know for certain the cause of the problem you’re about to try and correct, the dynamics of “I didn’t know this part was broken too,” or “Gee, this other part doesn’t look so good either,” or a vaguer mission creep (while you’re in there …) can pull things off track. If the vehicle is a garaged project car, no problem; you simply roll the garage door down, submit yet another order to your favorite parts supplier, and re-engage the project when the parts arrive. But if the car is a daily driver, and you were counting on a quick repair to be able to use it the next day, your best-laid plans suddenly get scattered like leaves in the late autumn wind. You can go with it, Zen-like, or you can “rage, rage” against the dying of the done-by-the-end-of-the-day dream.

I just completed a long-delayed cooling system refresh in my 2003 BMW E39 530i, and to no one’s surprise, the old Rhythm of Repair issue bit me in the butt. In my case, although the E39 is ostensibly my daily driver, the issue was more that a) my three-car garage is stuffed full of must-keep-out-of-the-rain vehicles, and I really need a damned good reason to have the DD kick one of them outside into the elements for several days, and b) my middle son, Kyle, was visiting from out of town for a few days and I wanted to give him the car to use while he was here.

The cooling system is a weak point in any post-1990 BMW. The radiator’s side tanks, the expansion tank, the thermostat, and the hose ends are all plastic. With age and engine heat, they get brittle and crack, resulting in loss of coolant. Since the 530i has an inline six-cylinder engine, a single overheating episode can crack or warp its long straight head. When I bought the car five years ago, it had no repair records, so the state of its cooling system was unknown. In the past, I would have prophylactically replaced the whole thing, but since I work from home and have no regular commute, I tempted fate, figuring if I saw the temperature rise, I’d simply call AAA, have the car dragged home, and then refresh the cooling system. However, as the car is approaching 200,000 miles, and as I could see from the date codes on the radiator and the upper hoses that they were original, well, there’s tempting fate and there’s being an idiot. I really try not to be an idiot. As I wrote a few weeks ago, there’s no shame in a car dying from a bolt-from-the-blue failure, but there’s little sense in being inconvenienced and having your bank account drained by a tow-to-the-dealer repair for something you knew about. So, I ordered a cooling system refresh package for the E39.

The first potential issue is that “a cooling system refresh package” isn’t a unique, accurate, or a complete description. What I purchased was an OEM radiator, lower and upper hose, thermostat, expansion tank, two sensors that thread into plastic components, and a water pump. However, there’s more to the cooling system than that, including at least five other hoses, an auxiliary electric water pump, plastic hard coolant pipes that run beneath the intake manifold, the fan and viscous clutch, and the auxiliary electric fan in front of the condenser. The second issue is that the water pump is driven by the serpentine belt and thus has a tensioner and two idler pulleys. How much of this should you replace while you’re in there?

On previous daily drivers, back when I had an actual commute, I prophylactically replaced every one of the parts mentioned above, but it’s expensive and time-consuming. With this E39, I took a more moderate approach. In addition to the refresh package, I ordered a mechanical fan, as it’s plastic, moderately priced, and I have had old fans shatter. I also ordered a new serpentine belt, as it’s much easier to replace with the radiator out of the car. I elected to leave the tensioner and idler pulleys alone, as my experience has been that the pulleys give a lot of warning in the form of bearing rattle before they fail.

The day before my son arrived, two big boxes of parts showed up on my front porch. At first, I thought that maybe the repair was best done in the driveway so as not to kick my ’72 BMW 2002tii outside, but the garage’s shade and safe level concrete floor were irresistible. I quickly realized that, with the number of things that needed to be accessed or disconnected from beneath the car, it was the right call.

The radiator, shroud, expansion tank, hoses, fan, and viscous clutch on the E39 are bit of an interlocked puzzle. What you need to do is slide the auxiliary electric water pump, with its hoses still connected, up and out of the U-shaped clip holding it to the bottom of the shroud, slide the two hoses out of their clips, undo the big nut holding the viscous clutch to the nose of the mechanical water pump, edge the shroud and fan upward together to reveal two small hose clamps holding a hidden thin hose passing through the shroud and connecting the top of the radiator to the expansion tank, and undo one end to disconnect the thin hose. However, despite watching several videos, I couldn’t even get to first base moving the electric pump. I finally figured out there’s a Torx-head screw holding it into the clip that you can’t see from under the car.

With that, I carefully withdrew the shroud and the fan/clutch, exposing the plastic snap-on hose connections beneath the expansion tank. Although I was replacing the larger snap-on hoses to the radiator itself, I was electing to re-use these smaller ones that plumb the expansion tank, so I had to pop the clips and very gently pry the hoses off the tank without damaging the ends.

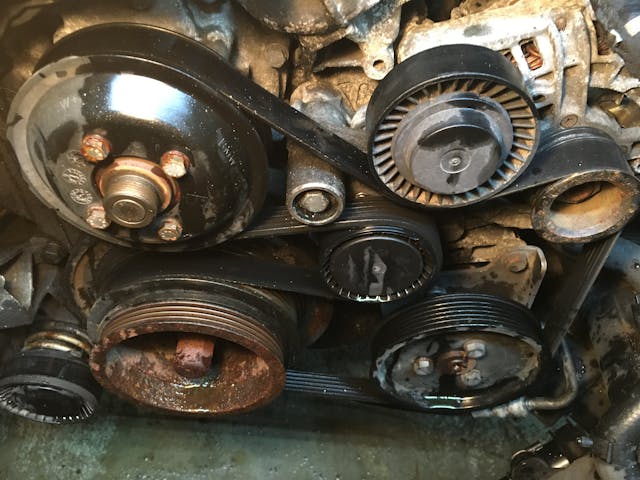

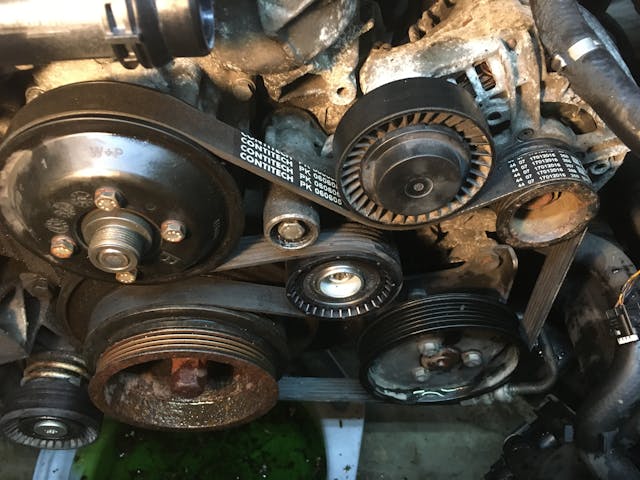

I then withdrew the radiator itself, fully exposing the belts and pulleys. Belt tensioners can be tricky, and there were several versions during the E39’s lifetime. One of my tensioners required a Torx bit, the other one an Allen bit—facts not revealed in any of the videos I watched. But off came the belts, allowing access to the water pump.

With all the components out, I performed the remaining forensics. Only the water pump had been changed, its replacement unbranded and of unknown origin. Every other part of the cooling system, including the often-failing plastic expansion tank and thermostat, appeared to be original, with 2002 or 2003 date codes. Yeesh. In a 200,000-mile E39 5 Series BMW, that’s not tempting fate. That’s not whistling past the graveyard. That’s trolling for a tow truck.

Although I loathe this plastic-laden cooling system configuration, I do admit that the design of the water pump and thermostat, with their o-ring gaskets, is kind of nice in that it eliminates the need to spend time with a single-edged razor blade cleaning off old gaskets and sealant. The old water pump and thermostat were removed and new ones installed in minutes.

With the belts still off, before buttoning things up, I tested the tensioners and gave all the idler pulleys a spin, and that’s when the RoR issue rose up to bite me. The bearing on the pulley on the main tensioner had obvious lateral play, didn’t spin smoothly, and exhibited a bit of a rattle. I was surprised that I hadn’t heard it with the engine running. It was in no danger of imminent failure, but it would be trivial to replace right now, and would be so much more of a pain after the belt, fan, radiator, and shroud were reinstalled. I thought I had a genius-level idea of swapping it for the A/C tensioner pulley, as they’re both the same size and the A/C pulley can be easily reached from under the car, but when I tried, I found that the center holes are different sizes.

This is the familiar dynamic of the Rhythm of Repair. Instantly your best-laid plans are derailed, and you switch into a mode where you’re willing to do whatever’s necessary to get them back on track, but you also hate to pay stupid money for parts if you don’t have to. I looked online at FCP Euro, where I’d purchased the rest of the parts. The OEM German Ina pulley was cheap ($14), but it was Saturday, so anything ordered that day wouldn’t arrive until probably Wednesday. I called a BMW dealer in Boston, and it wanted $75 for the pulley. That felt pretty stiff. I did some quick online searching of the local Autozone, Advanced Auto Parts, and O’Reilly’s, and the latter offered a Gates pulley for $42. I regard Gates as a decent brand, so I phoned the O’Reilly’s in a nearby town, verified that it had the part, and 40 minutes later had it installed. Ha! Take that, Rhythm of Repair! On went the new serpentine belt. The old one actually looked fine (it was probably replaced with the previous water pump), so I kept it as a spare.

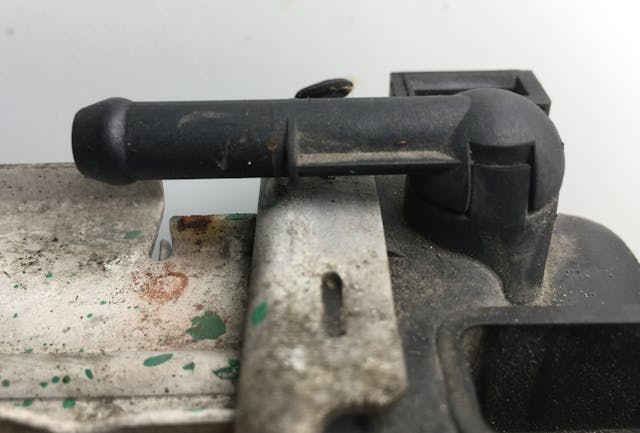

I then installed the new radiator and began to put the puzzle of the shroud, expansion tank, and hoses together when I found another problem: The thin hose connecting the top of the radiator to the expansion tank had a deep linear mark in it, more than an indentation but less than a gash. For all these years, it had apparently been trapped between the edge at the top of the radiator and the fan shroud. Squeezing the hose at that point, I could feel that the mark was more than just superficial.

Back online I went. The skinny little hose was nearly $60 at the dealer. It was only $3.59 ($9.80 shipped) online, but of course ordering it online meant I wouldn’t have it today. Although the hose has some bends engineered into it, it’s really just an 18-inch pinkie-diameter rubber hose—that is, it didn’t have the molded plastic snap-on ends that the bigger coolant hoses had. I felt certain that I could simply replace it, at least temporarily, with a length of fuel hose, but I found that all of my fuel hoses had a slightly smaller inner diameter. The plastic fitting on the radiator that the hose slides onto is integral with the plastic side tank and looks notoriously easy to snap off. It’s the same on the expansion tank end. The thought of doing that on my brand-new, just-installed parts stopped me in my tracks.

It was now 4:30 p.m. on Saturday. The parts counter at the dealer in Boston closed in 30 minutes. Maybe I could make it if I left immediately and burned rubber. Decision time. Dash to the dealer and pay nearly 60 bucks for a four-dollar rubber hose, or order one online and leave the car “down” in my garage and my 2002tii in the driveway, jury-rig something, or reinstall the original hose, which was weak but not actually leaking?

Damn you, Rhythm of Repair!

I again carefully examined the hose, but this time I also thought about its function. It’s a small overflow hose at the top of the radiator, so, hypothetically, even if it began to leak, it wouldn’t cause catastrophic loss of coolant. I then fit the hose back in its original location, and carefully examined the odd puzzle-like design where the hose was hidden under the fan shroud, requiring the shroud to be raised to change it, which in turn likely required the fan and clutch to be unbolted. I determined that, although it was tight, I could probably lift things up, access the small hose clamps, and change the thin overflow hose without having to pull the entire puzzle back apart and dump a lot of coolant.

I finished buttoning things up, filled the system with fresh coolant, backed the car into the driveway, hosed the front of the engine down, drove it a few miles, and checked for leaks and found none. The car was ready for my son Kyle to access while he was in town for the next four days.

He never used it once.

So, was it foolish of me to force this repair to be rapid? Partially. But by doing it in a day, I didn’t have to leave any of my rust-prone cars out in the rain. And, while I nibbled at the RoR’s bait by paying more for an idler pulley than I should have, at least I didn’t swallow the hook on going to the dealer for that thin rubber overflow hose, because that would’ve really stuck in my craw. The replacement hose arrived four days later. I changed it. It wasn’t a big deal.

In the case of Rob versus the Rhythm of Repair, I’d call this one a draw.

***

Rob Siegel’s new book, The Best Of The Hack MechanicTM: 35 years of hacks, kluges, and assorted automotive mayhem, is available on Amazon. His other seven books are available here, or you can order personally-inscribed copies through his website, www.robsiegel.com.