Teacher to student in 60 seconds

Teaching is the best way to learn. I’m not sure that is universally true, but it is for me most of the time. That’s why my garage has an open-door policy. The slight slowdown of work to help another person better understand the systems of vintage cars and motorcycles is totally worth it to me. Fulfillment is a two-way street. I know this because in one day I was on either side of the fence, taking a turn being Tim Taylor, then Wilson.

I dropped by a friend’s shop on a Friday evening and found their son wrenching on a Honda XR80. When he had purchased the bike, it was not running; the seller and he believed it to be a carburetor issue. Aren’t they all? Given my knowledge of Honda XRs big and small, it was only a minute before we had tools in hand, tearing into the Keihin PC20 carb.

This 80 had a goofy running issue of stumbling and sputtering, along with the occasional hard start, symptoms which usually get filed under “carb needs to be cleaned.” It’s often not even worth further diagnosis: Regardless of where the junk is lodged in the carb, it will get evicted when everything comes out. This was the second time I had encountered this problem on this motorcycle; my friend’s son had purchased it from another of my friends who had taken the quick solution: Replace the factory carburetor with a knock-off. It worked for a bit, then ended up worse than the original. Time to sort out the correct carb and get this bike running again.

So there we were, a 32-year-old and a tweenager sitting on the ground asking each other questions about idle circuits and explaining how the throttle slide worked. No one so thoroughly troubleshoots a problem as someone who knows just enough to be dangerous. Each time he thought of a solution, he would bump up against his lack of understanding and ask another question or attempt to work around his lack of knowledge. Cleaning the carb took us a couple of hours; on my own, I would have finished the job over the course of a single beer, the last sips of which might be slightly warm.

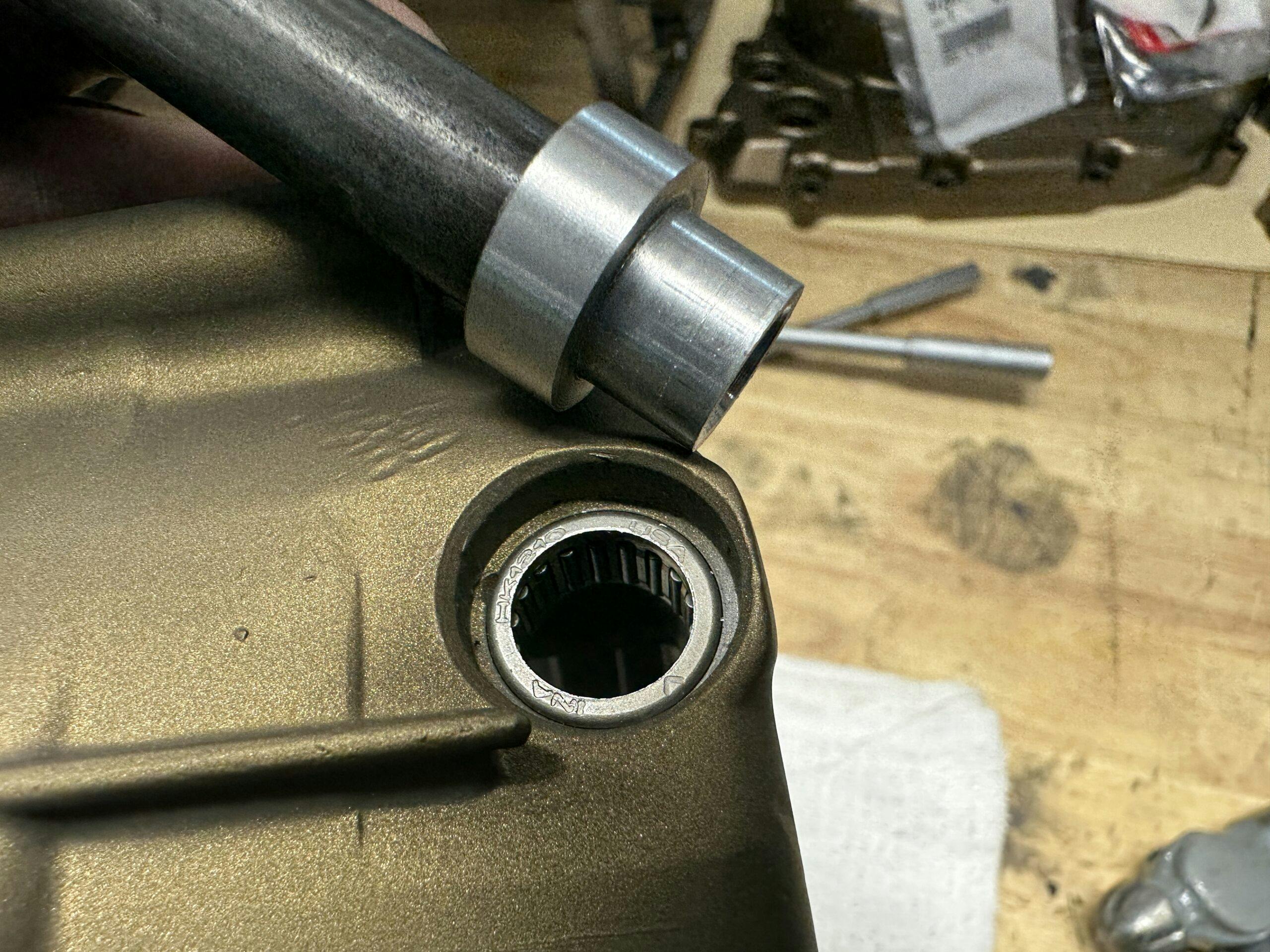

With the little Honda running, it was time to turn my attention to why I had first visited my friend’s shop: the lathe. I switched from teacher to student as my friend, a trained engineer, discussed with me the crude drawing of a special tool I had designed to help press delicate needle bearings into the side covers of a motorcycle. He confirmed my design was functional and that we could machine it with the materials we had on hand.

We chucked some 6061 aluminum into the lathe and turned a medium-sized chunk of metal into a custom driver for inserting bearings into the clutch cover of a 1986–95 Honda XR250R. (Hondas doesn’t even sell these fiddly little needle bearings—you have to source them from industrial supply houses.) Driving in needle-bearing shells has always been hit-and-miss for me; I always fold a lip over and cause the needles to bind. I wanted to make a tool that would hold all the needles in place and also drive the entire surface of the shell at once. Sound fancy? It’s very much not. Perfect for my first lathe project.

So we stood there and asked each other questions about speeds and feeds, process order, and the finer points of thick-cutting oil. I troubleshot it like someone who knows just enough to be dangerous: Each time I thought I had the solution I would bump up against my lack of understanding and ask another question or jump to attempt to work around the lack of knowledge.

Mentor and mentee, all in a couple hours. A kind reminder that the entire automotive community is just a circular motion of knowledge. The more freely we share, the more we gain and understand—even if only because we have to think of that perfect way to explain how a planetary gearbox works.

If you care about something so much that it becomes a part of your personality, you should be sharing that thing. Not just parking it in public for someone to see and appreciate, though that is a start. What I would really challenge you to do is to take the same time you would spend learning or enjoying our hobby and go out proselytizing. Your first time tackling a project might be best done alone, but the second time, invite someone who has never done that job. You’ll likely learn something new. Whether it’s listening to stories, telling stories, or sharing resources, make sure that the chain of mentorship does not go broken.

***

Check out the Hagerty Media homepage so you don’t miss a single story, or better yet, bookmark it. To get our best stories delivered right to your inbox, subscribe to our newsletters.

Nice work!

There is a grease that holds needle bearings, Assemblee Goo, no need to make a tool.

That was my first thought!

That is one option, and one I didn’t like. Different strokes for different folks is all.

If you haven’t already Kyle, stamp or engrave its purpose into it. Thirty years from now you’re going to have boxes of clever tools you’ve made, some of which you won’t have used for thirty years. I would’ve saved myself a lot of chin scratching asking myself “What in blazes did I make THIS for?” If I’d started labeling earlier.

Exactly, I have several crude tools I made decades ago for automatic transmissions that no one uses anymore! Think GM 200C, Ford AOD, 700R4, etc.

So true

Interesting. That thought crossed my mind and now I need to follow through! I keep all the “special tools” for rebuilding these Honda engines separate from everything else, but it’s still a nice reminder to keep track of what does what!

a lot of us make special tools for things. this week I made one to press in those little plastic t shaped pins for my door weatherstrips on my 55 bel air. And I get some good special tools from my dentist, he has a box of broken picks that can be used for many things. to clean the idle circuit in my 185 xl I had him send me some root canal files, they work great. keep those articles coming Kile, always good to get more tips n tricks. ive got a 1928 lathe surprising how much I use it. now I need a mill.

My tool story is just using what you already have to accomplish a task it wasn’t designed for. I’ve had an old Echo two stroke weed eater that had been very dependable for decades. Eventually the pull start recoil spring got so weak that it wouldn’t retract the cord so I tore into it. I spent a lot of time trying to fix it but couldn’t get it done. After several frustrating attempts I just gave up on it. Then, one day I got to thinking that there was a 12 mm nut on the end of the crank that was exposed from the removal of the pull start assembly. Light bulb went off and I got out my DeWalt cordless drill and found that the female end of a 1/4″ extension would fit into the chuck and with a 6 point socket on the other end I had the first electric start weed eater that I’m aware of. It works like a charm and is way easier to get it running than it every was with the pull start.

I love this story! I did a similar thing with an old riding lawn mower. I used my impact wrench as a starter motor.