Media | Articles

Sixth-gen small-block on horizon as GM invests $918M in U.S. factories

GM announced hundreds of millions in investments in the production of the next generation of small-block V-8 engines for use in pickup trucks and SUVs. There is no information yet on the power, displacement, or efficiency of the upcoming V-8s, but GM did share that the investments will be spread over four facilities in the United States that will build V-8s.

The Flint Engine Operations plant will continue to produce the 3.0-liter inline-six turbodiesel used in full-size pickups and SUVs while the factory gets a $579 million upgrade to assemble the sixth generation of GM’s small-block V-8. The Michigan facility will also machine the block, crank, and cylinder heads.

Bay City Global Propulsion Systems, also located in Michigan, will receive $216 million to further support V-8 production with camshaft, connecting rod, block, and cylinder head machining. Defiance Operations in Ohio will see a $47 million investment to support casting V-8 engine blocks and components of EVs. Finally, Rochester Operation in New York will see a $12 million retooling for V-8 intake manifolds and fuel rails along with $56 million for producing battery-pack cooling lines for EVs.

“Today we are announcing significant investments to strengthen our industry-leading lineup of full-size pickups and SUVs by preparing four U.S. facilities to build GM’s sixth-generation small-block V-8 engine,” said Gerald Johnson, GM executive vice president of global manufacturing and sustainability. “These investments, coupled with the hard work and dedication of our team members in Flint, Bay City, Rochester and Defiance, enable us to build world-class products for our customers and provide job security at these plants for years to come.”

For those that need a refresher, the previous and current generations of the Chevrolet/GM small-block V-8 are:

Marketplace

Buy and sell classics with confidence

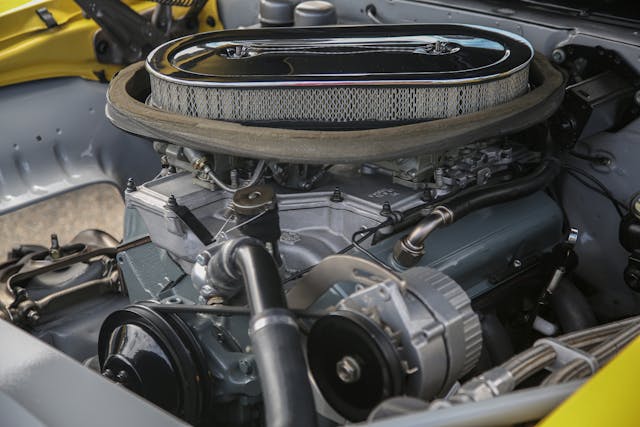

Gen 1: 1955–2003

This is the classic small-block, that includes everything from the original 265-cubic-inch V-8 launched in the 1955 model year through the rowdy 327 and 302 as well as the ubiquitous 350. The last of these engines were the Vortec variants, that lasted until 2003 in vans and commercial vehicles.

Gen 2: 1992–1997

Built in 4.3- and 5.7-liter displacements for rear-drive cars, GM’s second-gen small-blocks were best known as the LT1 and LT4 used in Camaros and Corvettes. Reverse-flow cooling and front-mounted distributors set these apart.

Gen 3: 1997–2007

First seen in 1997 in the all-new C5 Corvette, this was the biggest change to the small-block architecture yet. While it still used the familiar 4.4-inch bore spacing, the intake and exhaust ports were evenly spaced and the block was a deep-skirt design.

Gen 4: 2005–2020

Just a minor update to the Gen 3, the Gen 4 brought improvements to the block as well as more powerful ECUs, also introducing displacement on demand.

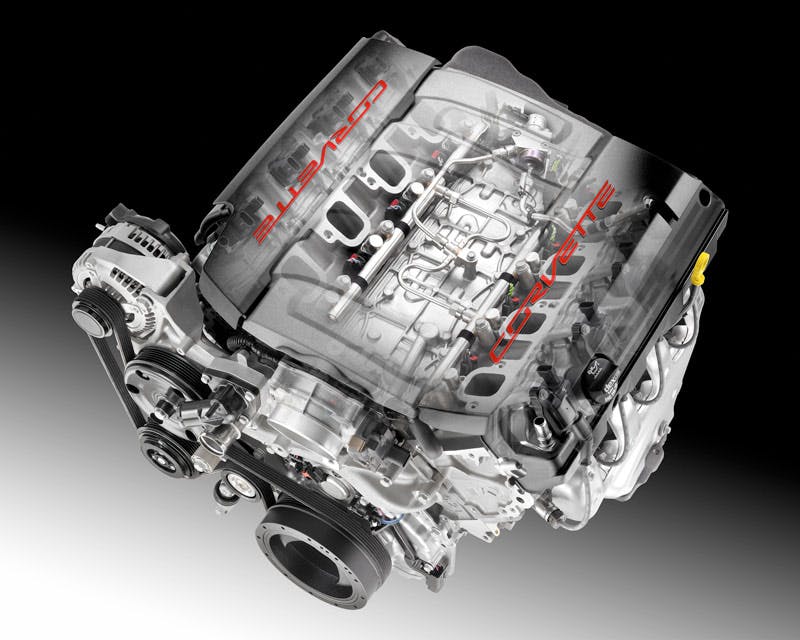

Gen 5: 2014–present

The fifth-gen V-8 debuted with the C7 Corvette and rolled out to the sixth-gen Camaro and full-size SUVs and pickups shortly after. It is still used in the C8 Corvette. The major changes are direct injection and a reordering of the valve arrangement that places the intake valve at the forward-most position on the driver side, as opposed to every other small-block before it.

We’re not sure how the sixth-gen V-8 will differ, but GM commented that the sixth-gen small-block will be for pickup and SUV use, thus notably ignore the Corvette. We’ll be paying close attention as the details emerge and will be keen to learn about the engine that future hot-rodders will be scooping up from wrecking yards in decades to come.

Check out the Hagerty Media homepage so you don’t miss a single story, or better yet, bookmark it.

Oops. Virginia booted Ford’s battery plant idea, but according to this, they won’t be replacing it with a GM engine facility. VA loses out altogether – but at least they won’t have any commie spies with jobs!

It’s likely that this new gen small block will be the most fuel efficient one that GM has ever produced. While everyone else is going all in on electrics, it seems that the General is looking to keep some powerplant diversity and try to please the hard-core ICE folks as well as producing EVs. Given the infrastructure and related difficulties associated with going total EV, it kind of seems prudent to me to consider both avenues – at least for the foreseeable future. The only thing I don’t see – which I kind of wish we would – is more research in hydrogen-powered technology.

That Ford deal was really shady if you look into it. It tells me the problems at Ford may be deeper than they appear. Stock is nearing $10 again.

When it comes to GM you see all the EV marketing but you need to watch how they are building two lines of product in most cases. We already have two Blazers and Equinox along with both EV and ICE Silverado.

I expect GM to leverage both as long as possible. This is why they skipped the Hybrids. Hybrids will be a very limited mode as they are still subjected to emissions and CAFE and the added cost of both.

I have driven a Hydrogen prototype. I also have experience with gasses from a past line of work. The real limiting factors are still #1 the Cells are not cheap. #2 refueling is not easy to find and can take time to do. -400 plus Degrees below zero and the flammability factors lead to many safety measures.

I do see Hydrogen as a factor that could be well used to start in fleets and trucks.

I was impressed with the performance of the Hydrogen but the infrastructure is much more complex than even the EV.

I recall the one I drove was in LA before I drove it and there was only 3 places they could fill in the southern part of the state.

There are definitely challenges to hydrogen, but my hope is the auto industry doesn’t give up on the technology.

HyperV6, did you get a chance to fill up with that hydrogen prototype you drove? Just curious how that went, if so.

Current EV technology cannot be scaled fleet wide; it’s too cumbersome, consumes too many resources. Woe to the company that doesn’t grasp this.

The MEDIA gets all excited about a slight rise in EV sales (concentrated heavily around commute heavy blue cities) but the accountants point out that gas guzzling, rip snorting V8 powered full size trucks are both (A) selling like gangbusters and (B) making up most (maybe all?) of their net profit… so like Ford, they’ll do the EV thing, but keeping most of their eggs in the full size ICE truck basket.

In a few years, after EV sales plateau and Congress (thankfully) fails to ban ICE trucks — maybe around the same time everyone realizes child slave labor in Africa is used for the majority of battery material sourcing? — we’ll all laugh, the same way we all laughed about leisure suits once disco died. The only ones not laughing (Stelantis, Cadillac, maybe a couple virtue-signaling European brands) will try to convince the rest of us their 3-ton paperweights are superior… but we’ll just add 400 miles of range in 3 minutes (i.e. fill up the gas tank), laugh, and drive away.

Great articles – thanks!

If GM is smart it will keep some ICE motor development funding going, not just the V8. I’ll take a V8 over their ultimatum toasters.