How SEMA Garage helps supercharge the automotive aftermarket

While lots of car buyers enjoy their vehicles as they were originally equipped, there are plenty of auto enthusiasts that see their car, truck, or 4×4 as a canvas upon which to create their ultimate track machine, desert explorer, or rock crawler. Those buyers that want to improve upon the factory performance of their vehicle typically rely on aftermarket companies to give their rides the added power and capability they’re looking for. The SEMA Garage is how many of those companies get a leg up on developing their parts.

We’ve often wondered how so many manufacturers have such a wide variety of aftermarket parts available for popular models seemingly as soon as said model goes on sale. The answer, for a lot of companies, is the SEMA Garage. We recently got invited to tour SEMA’s Diamond Bar, California, facility to see how SEMA members can get a head start on product development and also wade through all of the red tape involved in getting a California Air Resources Board (CARB) Executive Order (EO) that makes an engine performance part emissions-compliant.

Vehicles like the Ford F-150 and Bronco, the Jeep Wrangler, Chevrolet Corvette, and the Nissan Z are in high demand for aftermarket companies, as buyers will likely be ready to modify them right out of the gate. SEMA noted that a majority of those that modify their vehicle do so within the first 30 days after purchase. When a popular enthusiast vehicle is about to hit the market, SEMA does its best to get its hands on a production example for a measurement session.

Some vehicle manufacturers even work with SEMA and allow access to early production models before they’re on sale, and some OEMs even share 3D files of their own. Without those detailed models straight from the manufacturer, SEMA relies on measurement sessions that enable manufacturers to get an up-close look at the actual vehicle and get their own measurements in case they’re trying to fit a particular part.

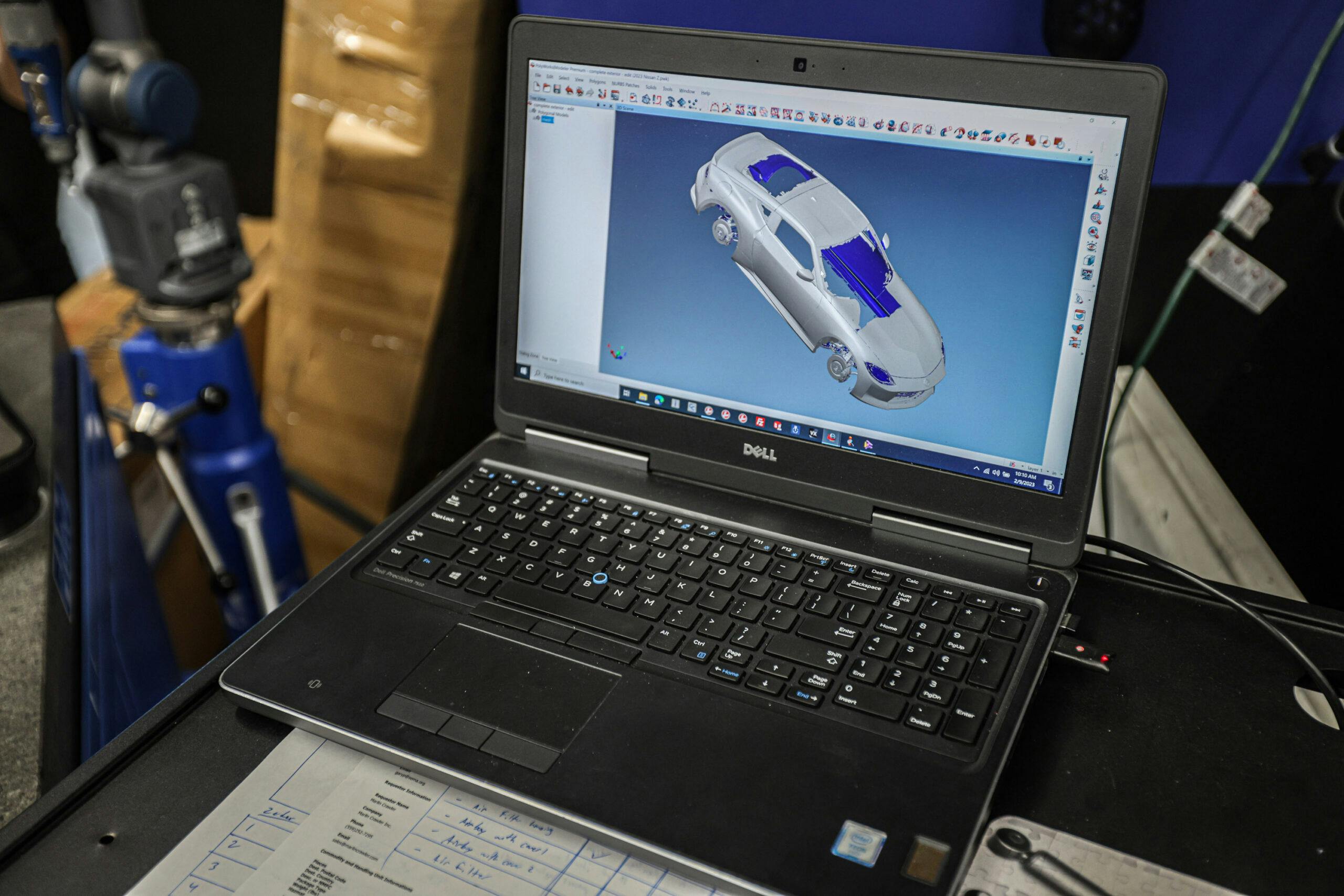

For example, a bumper manufacturer might be looking for the factory mounting location and any sensors that it may be required to incorporate into its products or an audio manufacturer might find a place to stash a subwoofer enclosure. Once the measurement session is over, those pre-production cars will get 3D scanned over the course of two to three days, and that data will be made available to all SEMA members. When we visited, SEMA Product Development Engineer Jared Calderone had a 3D scan he’d been working on of a Nissan Z that he showed us as an example.

Another service that’s available is the scanning of individual parts. This FARO Arm scanner (shown above on the right) can be used to make detailed and exact models of parts to ensure that mounting holes and linkages are in their proper places. The FARO Arm scanner can be repositioned and scans can be merged together to complete entire vehicle body scans. This is the same scanner that created the scan of the Nissan shown above. Once the scans are complete, manufacturers can begin the design process. SEMA Garage also offers companies assistance with rapid prototyping parts using various 3D printers to create a physical model to test fitment, like the 3D-printed throttle body that was standing in for the real thing.

Besides helping manufacturers design and build parts that fit vehicles properly, SEMA also assists aftermarket manufacturers in meeting emissions regulations when developing engine modifications. SEMA often rents cars for these tests, but they have also purchased vehicles just for testing. Due to the demand for performance parts, and the fact that cold starts require up to an entire day of cooling between sessions, SEMA bought a pair of 2.3-liter EcoBoost Mustangs just for these tests.

Some vehicles need to be broken in before the tests can take place. Diesel trucks in particular can require a few thousand miles before they’re suitable candidates. When we stopped by, a Ram pickup was strapped to the dyno for testing and Dan Ogden, the Emissions Lab Manager at SEMA Garage, showed us some of the equipment and methods used to measure vehicle emissions. We were particularly impressed by the room holding all of the sample gases that are used for comparing with the test samples. The perfectly plumbed lines run to bottles containing samples of gases found in emissions, including C02, and hydrocarbons.

“We collect everything that comes out of the tailpipe.” Ogden explained, highlighting the ducting that leads from the vehicle to a set of cabinets that capture exhaust samples. The exhaust is diluted and routed into the collection system, and each part of the three-phase test has its own filter that collects particulates as well as baseline samples from the ambient air. The results from those three phases are calculated and they have to meet the specifications of the manufacturer. “It’s probably the hardest test for manufacturers to pass because it’s a cold start. The first 50 or so seconds are crucial,” said Ogden. If a product doesn’t pass, the live emissions data collected from the vehicle can help pinpoint what conditions caused the emissions to spike so that the tune can be modified.

A typical session to validate an aftermarket part can include three days of testing, and the paperwork to get the CARB EO can take a few months. Access to the SEMA Garage can be the most efficient way to get the needed approval as SEMA has several employees on staff as part of a compliance team who are tasked exclusively with handling paperwork.

This impressive facility is certified by the California Air Resources Board (CARB) and is one of only a few dozen like it across the country, but SEMA’s bandwidth just expanded significantly. It recently opened a new facility in Detroit that has 14 emission testing bays like this one, which is a good sign for the future of the performance industry and those looking to get more performance from their late-model car or truck.

Baby it on the way to the test, give it hell on the way back! Nothing like R&D. BTW who drives down hot a$$ CA roads with the hood open and a fan in front of the truck… or any road for that matter? At least now they can just open a bay door in Detroit to keep tests optimized.