5 Electrical Tools Every Toolbox Should Have

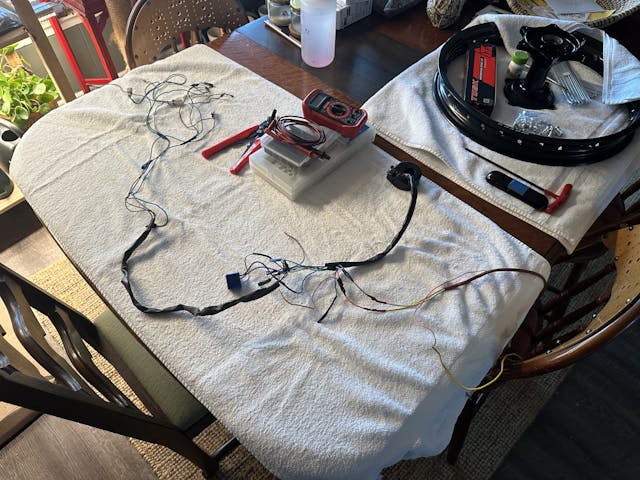

For some, it’s the work that they might make any excuse to avoid. Even if that’s how you feel about repair or fine-tuning of your car’s electrical systems, a case can be made for having at least some preparations to handle problems that may pop up. A personal instance was when a project motorcycle appeared in the garage with the wiring harness completely stripped off.

The electrical system is often one of the more easily explained systems of a project. It’s not any more difficult to understand than the oil path from the oil pump back to the pan. If you can understand where that oil goes and how it gets there you are most of the way to understanding a wiring harness. Electrons want to flow in one direction, so the absolute basics of a toolkit for the tasks you’ll address center around seeing where electricity is, where it’s not, and how to bridge the two properly, along with a few extras that just cannot be replaced and are great to have on hand.

Multimeter

Look, you might resist reaching for it, but multimeters have gotten downright cheap and are easier to use than ever. Getting familiar with even the basic functions can unlock diagnostic powers that will save time, money, and frustration compared to guess-and-check parts replacement. This allows testing most sensors also, which is how I found that the coil and main wiring harness were in serviceable condition on my project bike.

Test Light

The more durable but less educated brother to the multimeter is the test light. It’s basically a light bulb in a screwdriver, so it just can’t give the same amount of information as a multimeter. However, the ease of use is undeniable. I still reach for mine to quickly and easily test grounds on misbehaving vehicles. Vintage test lights are nice as they often feature an incandescent bulb rather than an LED. The filament in a traditional bulb is nothing but a resistor that gives a visual indication of power flowing through it, which means if you get tuned into your test light you can quickly spot a connection with more resistance than it should have, but that often requires a little luck and is really a job for a multimeter.

Wire strippers

So you found a frayed wire or damaged connection. Cutting most automotive wire is a trivial task, but stripping the end in preparation for a connection is best done by special tools. A properly stripped wire will still have all the strands of the core and a tidy square cut end to the insulation. It can be done with a pocket knife, so many of us have been there, but having a set of strippers makes the job easier and more enjoyable.

Soldering iron

Crimp connectors have their place in the electrical world, but aren’t practical in every application. The need to solder a joint or connection is relatively rare for most project cars once the bulk of electrical work is done so a soldering iron might spend more time in the back of a drawer, yet they are nice to have and occasionally can be used to solve other problems like adding heat to a delicate fastener or area to break corrosion.

Timing light

Your ignition system is an electrical system on your car, and while there are ways to dial in the distributor, a timing light is one of the easiest ways to get the job done. I’d put a dwell meter on this list except so many modern timing lights include that function and a handful of others. Vintage gauges are sweet, but calibration should be considered at some point.

Have something you would add because you find yourself reaching for it regularly? Add it in a comment down below. Tools kits are like fingerprints, except we get to change them based on our needs and wants and it’s always interesting to hear what other people are doing and why.

***

Check out the Hagerty Media homepage so you don’t miss a single story, or better yet, bookmark it. To get our best stories delivered right to your inbox, subscribe to our newsletters.

If you are working on anything in the electronic era, use a high impedance test light. The lamp in an incandescent light can over-draw some circuits.

And let the smoke out of your very expensive ECU!

Why is it when we install a fancy steering wheel, the horn will work for awhile then quit. Using the fancy tools checking for power seems to be a futile solution. Is it the Italian horn hating society that is against me. Wr can’t properly drive without proper hand gestures or a horn!!!!

Wiring terminal removal tools.

Insulation piercing probes for multimeter.

I enjoy doing electrical work, but I don’t like being called a ‘wire weenie’ !

Hard snicker.

What good is a timing light when the coil sits on top of the spark plug? And just how do you adjust the timing without a computer? Do you twist the coil or turn the spark plug? Just asking for a friend.

A battery load tester. Just because a battery shows 12 volts on your voltmeter doesn’t mean it has enough amps to turn the engine over. A load tester will tell you in a few seconds. And an inexpensive one works just fine.

Where would we be without our remote starter switch ?

I never use use solderless connectors – was in the aviation industry for years. Do it the right way, de-pin from the connector. I the wire needs repair, solder and use shrink wrap. I don’t care how good the convectors or tool are, soldering is much more durable. Yes there are very good solderless connectors that have water proof sealant that activates with heat. Show me 1 commercial aircraft flying with a solderless connector – there is a reason it not used! Yeah, I know your car does not fly 300mph at 35K but my point is I NEVER have to think twice about the repair and same failure.

I can’t believe no one mentioned a tube of dielectric grease!

A circuit tester isn’t all that bad a thing to have either especially when trying to find a short or break in a wiring harness.

It sure beats having to tear into a harness to find a problem and destroying the original look of a harness.

Ya, I’m that fussy , the Devil is in the details after all and when I do a repair I insist on making it as undetectable as possible and modern wire just does not “cut the mustard” in my book and makes for a sloppy looking job IMHO. Even if the repair is done in a place you won’t normally see it , like under a dash or something and man oh man have I ever seen some snake pit looking mess’s there ! As I’m sure we all have.

I keep several rolls of the old school cloth and rubber covered wire with the proper tracer colors on hand,which BTW was a real Bear to track down in any great quantities and getting even more difficult to find in good usable condition.