5 Electrical Tools Every Toolbox Should Have

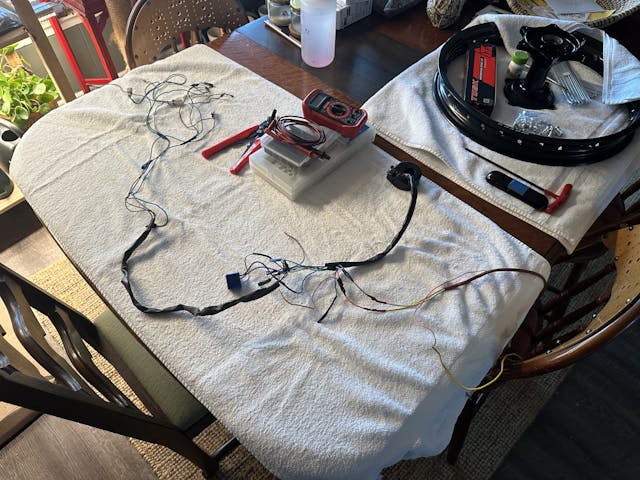

For some, it’s the work that they might make any excuse to avoid. Even if that’s how you feel about repair or fine-tuning of your car’s electrical systems, a case can be made for having at least some preparations to handle problems that may pop up. A personal instance was when a project motorcycle appeared in the garage with the wiring harness completely stripped off.

The electrical system is often one of the more easily explained systems of a project. It’s not any more difficult to understand than the oil path from the oil pump back to the pan. If you can understand where that oil goes and how it gets there you are most of the way to understanding a wiring harness. Electrons want to flow in one direction, so the absolute basics of a toolkit for the tasks you’ll address center around seeing where electricity is, where it’s not, and how to bridge the two properly, along with a few extras that just cannot be replaced and are great to have on hand.

Multimeter

Look, you might resist reaching for it, but multimeters have gotten downright cheap and are easier to use than ever. Getting familiar with even the basic functions can unlock diagnostic powers that will save time, money, and frustration compared to guess-and-check parts replacement. This allows testing most sensors also, which is how I found that the coil and main wiring harness were in serviceable condition on my project bike.

Test Light

The more durable but less educated brother to the multimeter is the test light. It’s basically a light bulb in a screwdriver, so it just can’t give the same amount of information as a multimeter. However, the ease of use is undeniable. I still reach for mine to quickly and easily test grounds on misbehaving vehicles. Vintage test lights are nice as they often feature an incandescent bulb rather than an LED. The filament in a traditional bulb is nothing but a resistor that gives a visual indication of power flowing through it, which means if you get tuned into your test light you can quickly spot a connection with more resistance than it should have, but that often requires a little luck and is really a job for a multimeter.

Wire strippers

So you found a frayed wire or damaged connection. Cutting most automotive wire is a trivial task, but stripping the end in preparation for a connection is best done by special tools. A properly stripped wire will still have all the strands of the core and a tidy square cut end to the insulation. It can be done with a pocket knife, so many of us have been there, but having a set of strippers makes the job easier and more enjoyable.

Soldering iron

Crimp connectors have their place in the electrical world, but aren’t practical in every application. The need to solder a joint or connection is relatively rare for most project cars once the bulk of electrical work is done so a soldering iron might spend more time in the back of a drawer, yet they are nice to have and occasionally can be used to solve other problems like adding heat to a delicate fastener or area to break corrosion.

Timing light

Your ignition system is an electrical system on your car, and while there are ways to dial in the distributor, a timing light is one of the easiest ways to get the job done. I’d put a dwell meter on this list except so many modern timing lights include that function and a handful of others. Vintage gauges are sweet, but calibration should be considered at some point.

Have something you would add because you find yourself reaching for it regularly? Add it in a comment down below. Tools kits are like fingerprints, except we get to change them based on our needs and wants and it’s always interesting to hear what other people are doing and why.

***

Check out the Hagerty Media homepage so you don’t miss a single story, or better yet, bookmark it. To get our best stories delivered right to your inbox, subscribe to our newsletters.

A quality pair of wire crimpers. Those off-the-shelf parts store crimpers probably turn a lot of people off of crimp-on terminals.

Mulitmeters are great, but they will show proper voltage on a high resistance circuit because they draw (next to) no current. If you are troubleshooting in the 12V world, you definitely need a test light to actually put a load on the circuit. I used to use an 1156 in a socket.

Yes, proper rapid wire strippers and ratcheting crimpers are essential for quality connections. Spend a little more $$$$’s and enjoy greatly enhanced ease of use and reliability. The cheapies are indeed an abomination.

I’m with you two. About 10 years ago I got a set of ratcheting crimpers with jaws made to fit non-insulated terminals. I can now put a 1/4″ spade terminal on a 50 year old car and it looks like it came from the factory. It was such a life-changing event I wonder why I didn’t get them 40 years ago!

Nobody yet has mentioned using a scanner. Hmm. . .

A good pair of spark plug wire crimpers. Summit racing or MSD are the best I have used.

I would add marine grade heat shrink, especially if your connection may be exposed to weather. Also, good quality electrical tape. I’m partial to 3M Super 33.

or aviation grade heat shrink.

Given my history with electrical work, I’m looking for a Magical Electronics Genie who will live in my toolbox and grant me three electrical trouble-shoots and repairs each time I open his drawer. Anyone know where I can get one of those?

When you find that genie, can I borrow them for a day or two?

Sure thing!

Why is it when we install a fancy steering wheel, the horn will work for awhile then quit. Using the fancy tools checking for power seems to be a futile solution. Is it the Italian horn hating society that is against me. Wr can’t properly drive without proper hand gestures or a horn!!!!

Yes me, but only one wish

Would that be sort of like having a Trunk Monkey? 🙂

the trunk monkey is for when your daughter is on her 1st date. Hahaha

Or pulled over by the police. A few years ago, the whole series was on YouTube. Should have seen the face on one of my Black friends when I mentioned the name of that ad series.

Elf on the rear window shelf.

A heat gun is nice to have as well.

For sure. Good for more than just electrical work!

That solves the third hand I want to add. Maybe a fourth to rub the lamp or bottle.

A clamp on AC/DC ammeter is an extravagance I have gone for. I also believe in test lights; a bad connection can show full voltage on a meter, due to the very low load, whereas a light will load the connection closer to real world.

As far as a multimeter (DVOM or Digital Volt/Ohm Meter to be more precise) is concerned, the comments regarding current or voltage readings not reflecting actual conditions, try using the ohm feature and read the amount of resistance. A faulty connection on the affected circuit will show relatively high resistance due to inadequate load carrying ability stemming from that broken wire or corroded connection.

And in our many years of automotive and construction electrical experience, ninety-nine percent of electrical problems arise from a poor ground. Always check for continuity to ground!

Finally, use the proper size wire for the intended load. We always totaled the entire amp load plus twenty percent on any added or repaired circuit to arrive at the proper sized wire to be used.

Anthony is right on the money with this suggestion. I chased charging problems on my Thunderbird for over a year before I had sense enough to measure the resistance of the battery cables. They looked perfectly fine, but the positive cable had enough resistance that it dropped the voltage actually reaching the battery. I threw that cable half way down the driveway. Problem solved!

Why is it when we install a fancy steering wheel, the horn will work for awhile then quit. Using the fancy tools checking for power seems to be a futile solution. Is it the Italian horn hating society that is against me. Wr can’t properly drive without proper hand gestures or a horn!!!!

I used to work in auto parts and once a customer came in with battery charging issues. They brought the cable, which looked perfect on the outside, but when I flexed it I could hear crunching sounds. I sliced it open and it looked like green shredded wheat throughout!

Amen to bad grounds. Always the last place folks look and incredibly common!

To determine if you have voltage as determined by multimeter but possibly not enough current to make things work, set up a test light using a sealed beam headlight (I use one from a motorcycle.)

Battery post cleaner/brush is a must. Too many times, a simple cleaning fixed the problem.

tried to edit, but did repost below, sorry folks….

A can of smoke so when it leaks out of an electrical component you can refill it promptly.

You are looking for Lucas Replacement Part 530433 – Replacement Wiring Harness Smoke

That’s funny right there! 🙂

Electricity is smoke, when you see smoke, you know the electricity is gone. And why you use lots of electric tape, to keep the smoke in.

Even though not an “electrical tool”, a battery post cleaner/brush is a must to make sure those electrical tools work properly. Too many times, a simple cleaning fixed the problem.

This is probably the best electrical tool on the list.

Maybe it’s not a tool, but I really need an led light that straps around my head, above my eyes, to make wiring easier to follow and to bring out colors better. Long, skinny fingers that are strong and can pinch in different directions would be nice, too, but that’s asking a lot. And I end up using a jeweler’s flip down magnifying glass that clips on to eyeglass frames (you don’t have to have lenses in the frames if you don’t need them).

Many people use timing lights but I gave up on them several years ago. I’ve had better luck adjusting based on how the car performs rather than how close I am to TDC.

I’ve seen ads for connectors that look like crimp-ons but have some sort of solder inside. Anyone here used those?

yup. there’s a few different types. i’ve found them at the big box hardware stores and i’m sure they’re available from auto parts stores & the like. although i prefer soldering and heat shrinking wiring overall, a quicker repair is a crimp connector with heat shrink sleeve. crimp the wires at each end, and then use a proper source of heat to shrink the sleeve to the wire & insulation. it’s water tight and the connections is as good as the crimps are.

Mopar sends heat shrink and crimp sleeves with every component that needs to have wires spliced. I like using OEM recommended procedure.

Good point. There are advocates for soldering and advocates for crimping. I prefer crimps, but only really good ones. The proper terminals and crimpers are paramount, and very few people have the right ones.

I use this type of connection and they work well. I also use an adjustable temp heat gun as they due take plenty of heat to efficiently flow the solder. Don’t buy the cheapest ones they are much harder to make the solder flow without melting the shrink tubing.

Thanks.

Yes. You apply heat yo the connection. Very easy

This may be another item that “depends on the quality”, but I got a box of those and the heat required to melt the solder makes the shrink ends turn black. Like BBQ black. They seem to work but I always wonder when I use them. They are great in tight situations. I just had to repair a damaged bit of wiring that my one time pet squirrel made in a car parked in the driveway and used everyday.

This was funny looking back as the car was running fine and six hours later wouldn’t restart. I opened the hood and the little peckerhead raced right by me. I’ve read and heard of rodents loving wire, but in 65 years of automotive insanity never experienced it. Those solder connectors slid into the harness and the car now works. I soaked the area with fluid film after rewrapping the harness. He and his tribe don’t like the taste of that, although he has a taste for Double Reserve.

Solder is not recommended for crimp connectors. A proper crimp will form an airtight connection. Solder prevents that from happening.

I solder them anyway, sometimes a crimp is not as good as you think it is.

kyle, i like your list of electrical tools. this should handle 90+% of everything that can go wrong or needs attention electrically. and i like your analogy of comparing wiring & harnesses to an engine’s lubrication system. very similarly, i compare an electrical system to plumbing. like current, water flows. like voltage, there’s pressure. like resistance or voltage drop, there’s clogged pipes or leaky valves. yes, good article!

the tool i think to be added when stepping up the diagnosis agenda is a brake bulb i.e., an 1157 series brake bulb or similar. although a multi meter can check for voltage drop, sometimes the circuit needs to be loaded up more than the electrical component does. sometimes the drop can be detected by a dim bulb (pun intended, if you like), or checking the difference in voltage values while the bulb is lit up on that given circuit.

now, about that genie – that’s cheating! but then, when it comes to love & cars…

Spend a little more and get a wire stripper that grips the insulation next to where the wire end will be stripped. Seems like a small thing but makes the task so much easier.