This all-original, aluminum-bodied hot rod is a real Lulu

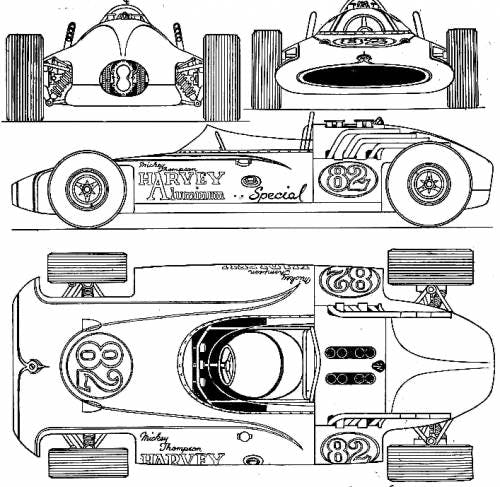

I was 10 years old when Mickey Thompson designed and built his Harvey Aluminum Special for the 1962 Indy 500. The V-8 sat low behind the driver in an all-aluminum chassis with aerodynamic skin. Ever since, I’d always wanted to build my own car from scratch.

In early 2019, at age 68, I had the tools, the time, and the garage space, so I tested my skills with this tribute.

The project started as a monocoque aircraft-fuselage design, with 12 sheets of 6061 aluminum set 10 inches apart on a simple jig. Each plate was shaped into bulk-heads to create a wedge-shaped oval exterior, sitting on a frame of four 1.25-inch box tubes with purlins to support a thin aluminum skin. Hundreds of cutouts were made throughout to “add lightness” prior to welding, and the entire platform weighed in at 125 pounds.

All Heliarc welding was done in my garage by a welding instructor at the University of New Mexico-Los Alamos. I did all the machining using my father’s lathe, milling machine, and hand tools, which he taught me to use when I was in the third grade.

For power, I mounted a 325-hp GM 2.0-liter turbo-charged four behind the cockpit and mated it to a six-speed transaxle. “Lulu” tips the scales at 1530 pounds, has 3.5 inches of clearance, and is 32 inches tall. Handling, acceleration, tracking, and braking are exceptional.

Even better, Lulu is street legal and fully VINed. She now has 4000 mostly reliable “get acquainted” miles, though I have broken six CV joints, now replaced with longer units after embarrassing pushes home.

Sure, Lulu is a bit unusual, even a tad impractical, but she will always be all-original, no matter how much modification she needs. If you have ever thought of building a car, get to it. It is the best use of your time, tools, and talent, and to finally drive it makes all the effort well worth it.