According to You: What’s the one repair you couldn’t successfully overcome?

Your answers to our latest question prove one thing: the powerlessness felt by someone when working on a vehicle by themselves isn’t unique to you, dear reader. Plenty of us have been there. Perhaps we are there right now, trying to find a solution, a permanent fix, or just a quick repair to get us down the road.

No matter, let’s seek comfort from our fellow members of the Hagerty Community, as we learn about the one repair we couldn’t successfully overcome.

Cracks, sometimes with cranks

@Sunnyboy: My dad and I had to give up on our Nash Metropolitan. We had already successfully rebuilt the engine TWICE—once for pistons, then 200 miles later for a crankshaft—the cost of trying to save money by only doing “what’s necessary.”

But when we tried to fix this nasty clicking sound that happened in the front end on left turns, we discovered it was a large (2–3 inch) crack in the unibody where the upper A-frame was mounted. We could not weld, and no welder we knew (and we knew some really good ones in the O&G industry) would touch it. Plus we knew the weld would not pass safety inspection.

So we sold the car “as is.” This was long ago in the early 1970s when welding tech was somewhat more primitive, at least where we lived.

@DUB6: I welded a broken crankshaft from a Ford 8N tractor once, on the advice of a “tractor guy” and based on the assumption that rpm never got over 1500—therefore, little stress. I clamped, braced, measured, and remeasured about a hundred times for straightness, even welding three rods along and around the counterweights, then stick-welded and air-cooled in small increments, and really thought it would hold. Which it did, for about 2 weeks of mowing and light blade work, at which time the engine had to really torque down for a stump pull, and SNAP, clatter, clatter, thunk. The replacement (engine, not just crank, as the internal damage was pretty extensive) is still running fine, some 15 years later. Turns out it wasn’t rpm I should have been considering; it was workload.

@TG: I don’t know that I would try it on a crank, but my gas-less flux core wire welder does a remarkable job on cast for reasons I cannot explain

Timing belt

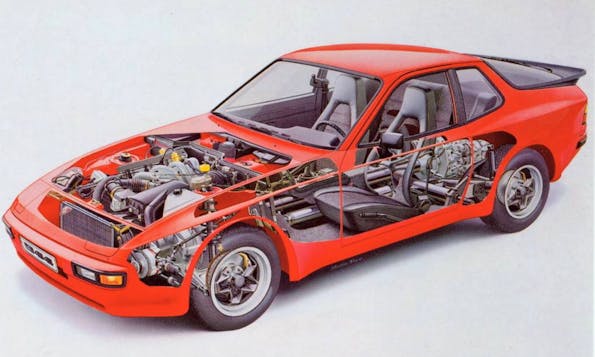

@TG: The timing belt on a 944 Porsche, but I did successfully complete the repair. I pulled the engine for other reasons that I don’t recall (I believe it was leaking balance-shaft housings), and the timing belt replacement on the mileage-unknown engine (estimated north of 200K) was a collateral repair. There is a timing-belt tensioning tool for the 944, but the repair cost was already pushing too close to the value of the car and I elected not to get a tool I would likely only use once. I tightened the timing belt using the sage wisdom of the internet (tighten until you can barely turn the long run of the belt 90 degrees).

I reassembled the car and had a fairly loud howl coming from the timing belt area. I backed off of the tension a little and the howl went away. I left the top of the cover off for inspection and eventually forgot about it. Now about two years later, the belt failed catastrophically and bent my valves into a literal S shape. I replaced the head, but damage had apparently been done in the lower end, and that is when I threw in the towel on the 944. Something I think about frequently as my replacement 1 Series approaches due for a timing belt. Wing it and ride with the original belt? Take it to the dealer and pay close to half the value of the car to get it replaced … ?

Rust

@Dean: Rust. No matter how hard I try to fix it, it always returns. Neil Young was right: it never sleeps.

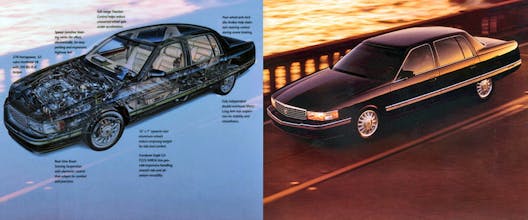

A Northstar buffet

@ap41563: An oil-pressure sensor for a 2003 Cadillac DeVille with the Northstar. The sensor had about half an inch of clearance between the end of the sensor and the subframe, oil-filter housing bracket, and the exhaust manifold; there was a bunch of stuff for me to curse at while I was trying to get it.

I got it out finally after a couple of hours and then when trying to screw the new one in, the wiring harness for the plug snapped in half. My dad, who was nearby heard me drop the wrench and said, “Troubles?” I said, “Nope, not anymore. I’m calling a tow truck I am done.”

Being of sage wisdom, he said, “Now it can’t be that bad,” and crawled under there with me, looked up at it, and said, “I think this engine was designed by Satan. Call the tow truck and pay them whatever they want.”

Best $500 I spent.

@Billy: So speaking about the “dreaded NORTHSTAR engine,” the starter started to make a grinding sound, [and I] crawled under the car: no starter! Well, I found out that the starter was under the intake manifold so I had to remove everything up top. Next I found out that the starter killed the flywheel [teeth] so the trans had to come away from the engine. It has been almost a year of five more simple things on this barge and now the blower for the heat/AC went out. I have to remove coil packs, wire harness, etc. everything between the engine and firewall, tilt the engine three inches forward … hey, do you know anyone who wants a 2001 DeVille with 77K miles?!?

@ap41563: (again) I feel your pain! I inherited a 2003 DeVille with 96K and kept it till 170K. In my time with it, I did regular maintenance and several repairs. Including:

- Oil level sensor

- Oil pressure Switch

- Coolant Reservoir tank

- Water pump

- Intake manifold gaskets

- Coolant crossover gaskets

- Fuel vent tubs

- All actuators for the HVAC system

- Blower motor (that was easy, less than 10 minutes): you can get to it from under the dash on the passenger side.

Things I didn’t fix:

- Transmission’s overdrive solenoid

- The head bolts began to stretch (nobody was willing to take on the job around my area)

- Oil leaks from every single gasket on the engine

I loved the car, and I’m not upset about the work I did to keep it as my daily driver for seven years, as all that was cheaper than a car payment. I got to the point, though, that the whole driveline really needed to be replaced, and I couldn’t find anyone willing to do the work. If I tried to do it myself, I was worried I’d have to haul it to the junkyard, which would break my heart. I replaced it with a Buick with the 3800 V-6. Repairs I’ve done to it in the past three years: NOTHING! When the time comes, I know on the Buick, I can work through any needs it has and remind myself at least I’m not working in the DeVille Engine bay.

@audiobycarmine: I’ve got a 2002 DeVille with the NorthStar. I don’t think I’ll be sleeping very well anymore.

Hatching a plan

@Brushmore: It took me years to fix the hatch on my ’82 Corvette Collector Edition so it doesn’t leak. After many attempts I may have done it but I am afraid to call it a victory just yet. I am always nervous when I wash it, but the true test will be if I ever get caught in a surprise heavy rainstorm. The problem is that there is only one source for the weatherstripping and it’s up to the OEM specs.

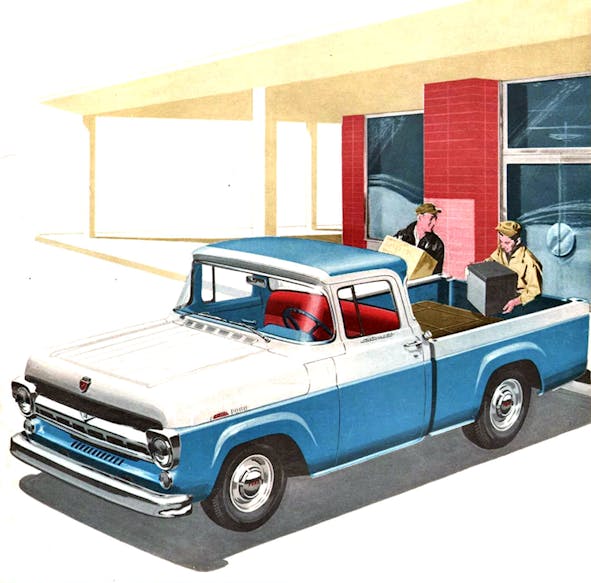

Pushed out by pushrods

@Mark: Oh, I have one for the conversation. I purchased a good-running 1957 F100 short wide a year ago. 272 Y-block, factory auto transmission. I drove it 250 miles home with no problems! Put another 100 miles around town and one day it had an issue starting. Well, I fired it up, drove home, and parked it. Next day, no fire. So, into the garage, and I start chasing ghosts. Starter, new solenoid, I yanked the points and installed Pertronix ignition and coil, changed carb, fuel lines, battery cables, cleaned the tank and sending unit. Nothing. I pulled the valve covers to discover three bent pushrods. So, a year later, still no fire. Hopefully I will solve this.

Getting ungrounded?

@jim: I’ve got a 2004 Silverado SS that’s been in the garage for two years. It goes into low-power mode, so you clear the code so you can get it home. I replaced the gas-pedal sensor (the box on the firewall) and the sensor on the throttle body twice. Ran grounds to everything, checked all the wiring. I work on it ’till I’m frustrated, then try to drive it somewhere close to home. It works for a couple of trips then screws up again. [The truck] is sentimental because my wife bought it for me new for my birthday, made the payments on her waitress money ’till it was paid off. Still nice to look at. The red rocket! Anyone got any ideas?

@SG: Double-check the ground wire that is on one of the bell-housing bolts. You can access this wire through the passenger-side wheel well with the inner liner removed.

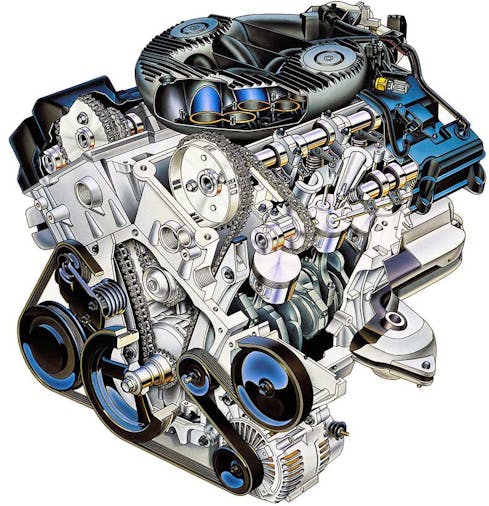

Hidden water pumps

@Ryan: Chrysler 2.7 V-6 water pump replacement. I actually didn’t have a problem changing the water pump itself—it was removing and installing the timing chain. Apparently there are tools to lock the cams in place, but neither online video I watched made any mention of this. The plastic chain guides seemed to disintegrate while installing a new chain, and even though all timing marks appeared to [be] correct, I could not rotate the crankshaft a full revolution by hand, and I didn’t dare attempt to crank it with the starter because I was afraid of bending valves. Car got towed to a shop that knew what to do, and it was OK after that.

I got beat by that engine, but I have since learned from my mistakes, and my daily driver is now a Chrysler Sebring with a 2.7—it’s a great engine that really only has a bad reputation because people don’t understand it.

Buried by time?

@Mark: Replacing the clock on my 1958 Imperial. When this car was assembled, the first thing down the line was said clock, and the car was assembled around it. You know you are in trouble when some enthusiast in France has put together a three-page website of tricks to get this done!

This is a cramped and complex panel, and the parking-brake release assembly has to be removed for access. Trouble is the release control shaft extends through the instrument panel (IP), and there is only one, narrow odd position angle where the assembly will clear the IP, the firewall/ floorboard, and steering column. That one component took a full day of trying to remove. Add in much blood offerings due to sharp raw edges inside the IP, and you have the job from hell.

I did get it done, however. I am stubborn.

Starting something … or not

@Gil: My ’73 Lincoln starts erratically. I need to turn the key to start several times before it cranks. Not so bad, but when the engine is hot and I shut it off, when I try to start it again all I get is dead silence. What wire or connection, when hot, separates to cause this? I’m frustrated by driving the car to an event and waiting ’till it cools down before it may or may not restart to get me home. Anybody have recommendations? I thought it was the ignition switch, but it is on the steering column and should not be affected by engine heat.

@DUB6: I had a similar issue on my ’66 Pontiac. I suspected the old, rebuilt OEM starter was giving up due to age and constant heatsoaks. I decided to replace it with a mini-starter. When I was re-routing the battery cable/solenoid wire to the mini, I discovered that the ignition wire had a “cooked” spot in the insulation (it had been bundled with the battery cable and wrapped with silver heat tape, but the proximity to a header tube obviously overcame the protection). When stripped back, this revealed only two of the multiple strands of wire [were] connected. The ends of the others were in close proximity, and sometimes made enough contact to let the voltage/amperage through—sometimes not (likely due to heat deforming the insulation a bit which changed with cooling, or maybe me just not holding my mouth right). I replaced the wire and re-routed [it] to better clear the header and voilà! Issue solved. I now think I could have left the OEM started on, but I love the mini, so the old one is on the shelf as an emergency spare.

@TG: Ford solenoids are easy enough to check with a flathead screwdriver. Leaky valve covers put an early end to more starters than most folks realize. A lot of parts stores will not honor a warranty on a starter if there is any trace of oil on it.

Red mist from the red-block?

@Forty2: Volvo 240 red block crank-position sensor thoughtfully mounted on top of the bell-housing. I thought mine had gone bad. Ordered a new one. Not cheap!

- Buy multiple 1/4-inch-drive u-joints and extensions. 3/8-inch are too fat. You have maybe 3/8-inch of clearance between the back of the head and the firewall.

- Spend half a day figuring out the best mix ‘n’ match of above to reach the single 8mm bolt holding the sensor in place.

- Remove bolt. Aha!

- Be unable to pull the sensor out of the bellhousing because it’d become stuck after, oh, 30 years.

- Spend a few hours getting the little bolt back in.

- Give up on the bolt, because the sensor wasn’t the problem and it’s not going anywhere anyway.

Woulda been easier to remove the transmission!

Red mist from the Fireball?

@Malcolm: Many decades ago, I had a 1975 Buick Skyhawk with a 3.8-liter V-6 engine. For all of 11.5 months, the car’s transmission would jump out of first gear, especially if I was trying to cross a busy street. The car went back to the dealer to be fixed. It continued to jump out of first gear. The clutch was replaced; the transmission was replaced. It still jumped out of first gear, then it jumped out of second gear, then third gear. Long story short, after four new clutches and five new transmissions, the transmission still jumped out of gear. My patience was wearing out, so I decided to trade it in for a Plymouth Duster. I was fed up with GM.

As I was in the car wash getting [the Skyhawk] primped up to deal, I looked down at the transmission boot and pushed it all the way down the shift stick. As I drove out of the car wash and onto the highway shifting from first to second and so on, I drove for about 10 miles for one last drive, the darn thing never jumped out of gear! And it never did for the 10 years I owned it. The rubber transmission-boot material was too stiff and after a while the seams on the boot ripped and was “perfect” for the duration I owned the Skyhawk! I never went back to the dealership as I was embarrassed with the situation.

The relentless pursuit of electrical gremlins

@audiobycarmine: For me it was whatever accursed computer/sensor problem that killed my Lexus SC400. I chased down every error code, replacing part after part, while amassing a formidable library of information throughout. Finally, in desperation, I had it towed to my mechanic, who had sophisticated diagnostic equipment. Said equipment turned out to be “agnostic,” as nothing faulty could be detected. The Lexus went off to NPR as a donation. The whole ordeal still bugs me.

Evaporating will for the EVAP

@Justin: I have two currently, and both are fuel tank vapor recovery EVAP issues that are triggering a check engine light. One is on a ’16 Silverado and the other on a ’02 Jeep Liberty. Also I’ve a ’87 Chrysler Conquest that simply will not run right: replaced the injectors, TPS, pressure regulator, and plenty of other parts. But it still idles rough, but occasionally runs great for a day or two. Then it goes back to spitting and sputtering, so if we can’t get it figured out it’s gonna get a Toyota V-8 from a SC or LS 400.

But the real one that’s killing me is a Genie 34/19 towable boom lift. Apparently it has some issue with the computer board, and replacements are simply not available.

***

Marketplace

Buy and sell classics with confidence

Check out the Hagerty Media homepage so you don’t miss a single story, or better yet, bookmark it. To get our best stories delivered right to your inbox, subscribe to our newsletters.

A good list of some bad times.

My son bought a used 2006 Dodge Charger (auto trans). It ran great from the day we brought it home until one day on his way home from school it stalled. After a couple of attempts it started back up and he drove on home. This happened randomly over the course of a few months. We went through the electronics and replaced plugs, coil packs, plug wires, even the ECM. Finally I scoped the cylinders and saw that one cylinder was badly scratched. Pulled the head and saw that it had been a victim of the “dropped valve seat” issue that is fairly common with those engines. It had already been properly dealt with by a shop, but I cleaned up the scars on the head with a grinder and put a new head gasket on it, thinking that a random misfire was causing a stall. The problem returned. Frustrated, but also looking for a father-son project, we replaced the entire engine! And the problem came back! Ultimately I happened across a service bulletin the local dealership had failed to mention to me: That model car had a stall problem when the gas tank was freshly filled, triggering the rollover safety switch. Had to print out the service bulletin and hold it under the service manager’s face before they would replace the gas tank and valve as required by the bulletin. Sold the car as soon as we got it back and the person who bought it has never had a single problem.

I bought a 67 GTO with a spun rod bearing. Dropped a pan, measured the crank with the spun bearing use a little Emory put a new bearing in lasted about 500 miles. Took the engine out to Machine Shop had it line board, got a new used crank that somebody had laying around. I measured everything and it was all within specs. I put it in the car, all new bearings put in 20 W 50 engine oil. went to Delaware from New Jersey, I was in the Air Force at the time. On my way home at about 2500 RPMs, the oil gauge took a nose dive and then came back up and then the engine started to make a little bit of noise. Even though still having oil pressure I thought something was weird. Got to New Jersey, drop the oil pan, found another rod, bearing moving around too much. Went to my local auto recycling center and I found a 428, out of a 68 or 69 Bonneville. I put that engine in, went to Delaware. on the way home even though with oil pressure ok something started making noise. I drove the car to the garage where I was working at it at, kicked the quarter panel in threw the keys away and just left the car there. The old guy who owned the garage found the keys and he knocked some of the dent out of the quarter panel and sold the car for me and gave me the money. An old lady in town had a 59 Oldsmobile Super 88 with 23,000 original miles on it. I bought it for less money than I got for the GTO and drove that till I got out of the Air Force, more than 2 years with no issues. That was not my first, but that was my last Pontiac.

Strange, you must have gotten one built on a Monday morning. Buddy in HS bought a ’68 GTO that had a dealer replacement Ram Air IV motor and had been turned into a fake “Judge”- ’69 wing, decals, cold air system, and the ridiculous 12 bolt 4.33 posi axle.

Pontiac V8s of the era were torque motors, not high strung small blocks, why Pontiac offered a 4.33 axle seems a mystery.

But that 400 RAIV lasted all through our highschool shenanigans and never a problem. Oh, u-joints broke, the N50-15s grabbed enough to twist the body so the transmission crossmember fell out sucking my hand on the Hurst T-handle down to the carpeted consoleless tunnel, the aftermarket TriPower fuel lines leaked and caused a dramatic fire in the staging lanes at Indianapolis Raceway Park; the basic Pontiac V8 ran well and was highschool bulletproof, however. And through the Hookers and Cyclone Purple Hornies (remember them, fellow boomers?) it sounded all the business.

In the days before the internet made even odd older parts fairly easily available, I scrapped a sweet-running Studebaker Lark because the all four brake drums were cracked… well, the body was kinda shabby too, as was the interior. No-one wanted such a car then, not even for a few hundred. Such a shame.

Similar story on a 1986 Saab 900 turbo sedan, a slightly odd duck but a great car nonetheless. It was such a bomb on the highway (once ran it at 180 km/h for hours on end through Montana), but the steering rack it needed would have cost (in those days, in Alberta) more than the car was worth — never mind the labour… and it was rusty after 15 years of hard winters.

I have the same symptoms in my ls1 Typhoon as @jim except mine won’t run smooth enough to drive it. Also I can’t seem to bleed the brakes after installing wilwood discs on the front, new mc, prop valve, remove ABS, etc. It has been in the garage for 3+ years now…

Fun read and feel all the pain. My response: anything and everything on a Jaguar XJS V12. What was I thinking!

I sure would like to see an article about when to get rid of a car I’ve had my Porsche Cayenne S for 12 years and cannot remember any time during that period when there was not something wrong with it. The cost of repairs so far this year has equaled the value of the car. As they did last year. A new, or even decent used one is out of the question due to my wife’s medical issues. The Cayenne was paid for at the start and I really enjoy it and it does serve it’s purpose as a very useful fun SUV. Does one keep patching it or does one get rid of it? Or, does one wait for the day when it can no longer be fixed? And of course I wouldn’t be in this dilemma if it wasn’t costing Porsche prices for repairs. Independent garages are pretty close to dealership prices and at the dealership I don’t have to bring it back. I do realize that buying a pricey car brings pricey repairs and I have to live with the unforeseen consequences. I suppose the answer is to keep patching it while I can and get rid of it right before the catastrophic failure. The buy a used Honda or Toyota. I need a fortune teller!

I’m sorry for your pain. This seems odd, for a manufacturer that prides itself on quality. In the mid 1980s, in Indianapolis, I had a roomie that had a Saturn yellow 914 2.7. It was as reliable as an anvil, drove like Satan’s own go cart, got great mileage, and everyone (including the ladies, rrowrrr!) except the Porschenazis loved it; I had a built ’77 TransAm and I loved it, it was just a perfect combination of engineering and fun. And it was as easy to maintain as a VW, although the parts were spendy. I’d post your Cayenne on Porsche sites and see what it would bring. Sounds like you have a lemon too old for the lemon laws. Wish you well.

@Mark with the ’57 F100, I have a feeling that you have a timing chain problem. Don’t know if that unit had a timing gear with plastic teeth or not but the symptoms, no start and bent pushrods, sound like the timing chain has slipped.

The Y block Ford motors were some of the worst motors made for their time. The pushrods would bend for no reason. The rocker shaft was starved for oil. The tappets were inserted from the bottom with the crankshaft removed. The timing chain wasn’t dot to dot but you had to count the number of links dot to dot. The worst was a 312 with ECZ heads. Every one was cracked in the exhaust seat.. I had to put on 292 ECD heads. The 312 had different journal sizes than all other Y blocks and the bearings were hard to get 40 years ago. The Y blocks burnt and consumed oil. The oil filters were hard to changed because the canister gasket always leaked. I worked on 100’s of these engines. Compared to a small block Chevy or Chrysler staggered valve semi hemi engines they were slow. The cylinder heads were mirror images of one another. So the left and right head weren’t interchangeable. What were they thinking. The FE motor 352 that followed it was the best motors ever made in my opinion. Ran like a Swiss watch.

I have a 72 Jensen Interceptor with the 440. To replace the starter, you have to pull the driver-side head. I saw anti-freeze on the windshield on the drive from San Diego to Yosemite for the national meet-up. Pulled into Fresno, dropped the car at a shop on Saturday, and went to check on it on Monday. Never knew the head bolts went into the water gallows. Thank god it was only that. Missed the meet-up but drove though the Searris to Reno and back to SD. Great evnture.

Not one heater core nightmare story? I’m stunned.

I feel robbed by this omission!

Ok, Sajeev. My single parent two job working to support my five years younger lil bro & myself in the Indianapolis housing projects Mom knew I was into cars way deeper than school. When I was 14, and working hard on a homework project, she came home and told me her (’70 Buick Skylark 350) car smelled bad and didn’t have any heat, and a “red light was on”. And that there was water all over the passenger side floor.

You know exactly what that meant.

I called my crew for car people help.

My older (high school had licences) car friends diagnosed, then replaced the heater core/hoses and taught me, we shop vacced the carpet til dry, and likely saved my Mom enough money so my brother and I could eat lunch at school for the next week or two. My beloved all still a crew car buds wouldn’t accept any payment, did take some Mom brownies and milk to ease those ’70s munchies; it was the era, donchakno. We’ve been doing cars since 1973, don’t see it stopping soon. Mom passed 6 years ago, my car guys all showed at the wake with their latest whips, looked like a car show cuz we all gots $$$ now and can afford real cars; and we remembered. Mom was remembered.

I teared up remembering how my long haired loud music loud car friends turned my Mom into an honorary hotrod Mom. And she never forgot. Loud pipes, Led Zeppelin, squealing tires might have upset our neighbors, but Mom was always our shield.

All because of a rusted Buick heater core.

Not a nightmare.

But good enough, I think, yes?

More than good enough. What a fantastic story! Thank you for sharing!

Ryan; thanks for the great “Moms & Cars” story.

So many of us have those same connections with our Moms and our early driving years.

My Mother had a P.O.C. AMC Ambassador (nicknamed “The Ambastardor” by myself and friends.)

Still, it was “the (only) vehicle” for all of us friends for at least a year.

AM radio only — WKBW from Buffalo NY at night way down here on Long Island.

Mixed memories of that car.

My best regards to you & yours.

Well, I had a ‘92 GMC jimmy that went through two heater cores in a couple of years. I often wished for another elbow while doing that job.

Mark, the only vehicle I ever regretted selling was my 1957 F-100 shortbed. Good or bad engine, I am a buyer if it is a short bed fleetside.

Let me add one: spark plugs on a Subaru Outback 3.6R. Flat 6 between the frame rails. An inch or so of space from top of plug hole to the frame. Figure an hour or more per plug, using multiple ratchets, universals and extensions to get each half turn of the plug. Have done it on a lift and on the ground. Not sure which is worse. Doable, but the next time this is needed the new owner will do it.

Thank you for all the stories! I feel blessed that the issues I have run across maintaining two Honda products, two Toyota products, and three Chrysler products among my family members seem relatively minor by comparison. Although I will say that Honda, IMO, does not make their vehicles easy to work on, when they do need it.

Not impossible but epically difficult is removing and replacing cylinder heads on a 97-03 Ford F150 or Expedition with a 5.4 Triton. The engine is basically shrink wrapped in there and the OHC heads are big and heavy. I rigged up a ratchet strap on 2×4 to lift and lower the heads when I replaced them to fix the notorious ejecting spark plug problem because a previous owner had installed four of the abominable Dorman “repair kits” and rebuilt heads with solid inserts were the permanent fix. It could be worse, later 3 valve and DOHC heads require either engine out or cab off.

I feel this- my ’04 GTO with the LS1 seems as if they put the engine, trans, and rear axle into a mold, then poured the rest of the car around them. Worst was replacing the limp factory shifter with the B&M Ripshifter- there’s two bolts up under the firewall that required dropping the trans… which meant monkeying with the two piece driveshaft, clutch & rig up, and it was still tight getting the bolts to clear. Never. Again.