According to You: What’s the one repair you couldn’t successfully overcome?

Your answers to our latest question prove one thing: the powerlessness felt by someone when working on a vehicle by themselves isn’t unique to you, dear reader. Plenty of us have been there. Perhaps we are there right now, trying to find a solution, a permanent fix, or just a quick repair to get us down the road.

No matter, let’s seek comfort from our fellow members of the Hagerty Community, as we learn about the one repair we couldn’t successfully overcome.

Cracks, sometimes with cranks

@Sunnyboy: My dad and I had to give up on our Nash Metropolitan. We had already successfully rebuilt the engine TWICE—once for pistons, then 200 miles later for a crankshaft—the cost of trying to save money by only doing “what’s necessary.”

But when we tried to fix this nasty clicking sound that happened in the front end on left turns, we discovered it was a large (2–3 inch) crack in the unibody where the upper A-frame was mounted. We could not weld, and no welder we knew (and we knew some really good ones in the O&G industry) would touch it. Plus we knew the weld would not pass safety inspection.

So we sold the car “as is.” This was long ago in the early 1970s when welding tech was somewhat more primitive, at least where we lived.

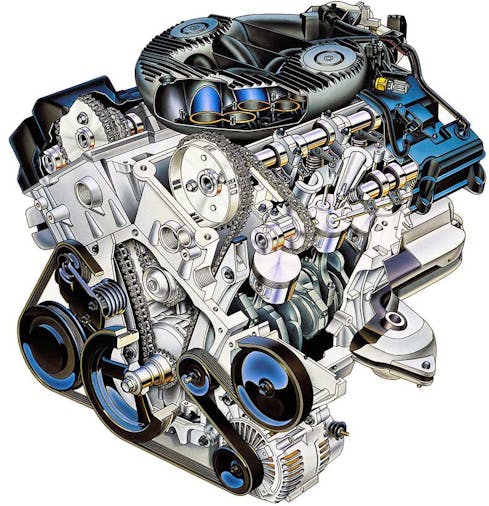

@DUB6: I welded a broken crankshaft from a Ford 8N tractor once, on the advice of a “tractor guy” and based on the assumption that rpm never got over 1500—therefore, little stress. I clamped, braced, measured, and remeasured about a hundred times for straightness, even welding three rods along and around the counterweights, then stick-welded and air-cooled in small increments, and really thought it would hold. Which it did, for about 2 weeks of mowing and light blade work, at which time the engine had to really torque down for a stump pull, and SNAP, clatter, clatter, thunk. The replacement (engine, not just crank, as the internal damage was pretty extensive) is still running fine, some 15 years later. Turns out it wasn’t rpm I should have been considering; it was workload.

@TG: I don’t know that I would try it on a crank, but my gas-less flux core wire welder does a remarkable job on cast for reasons I cannot explain

Timing belt

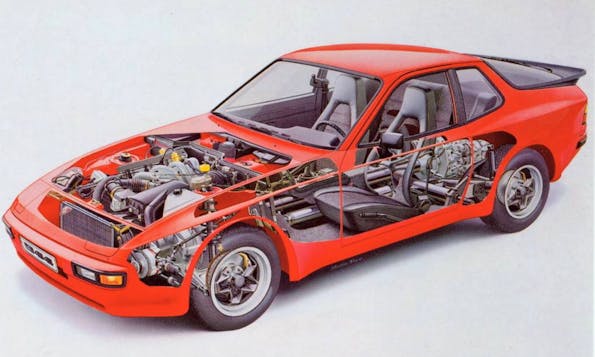

@TG: The timing belt on a 944 Porsche, but I did successfully complete the repair. I pulled the engine for other reasons that I don’t recall (I believe it was leaking balance-shaft housings), and the timing belt replacement on the mileage-unknown engine (estimated north of 200K) was a collateral repair. There is a timing-belt tensioning tool for the 944, but the repair cost was already pushing too close to the value of the car and I elected not to get a tool I would likely only use once. I tightened the timing belt using the sage wisdom of the internet (tighten until you can barely turn the long run of the belt 90 degrees).

I reassembled the car and had a fairly loud howl coming from the timing belt area. I backed off of the tension a little and the howl went away. I left the top of the cover off for inspection and eventually forgot about it. Now about two years later, the belt failed catastrophically and bent my valves into a literal S shape. I replaced the head, but damage had apparently been done in the lower end, and that is when I threw in the towel on the 944. Something I think about frequently as my replacement 1 Series approaches due for a timing belt. Wing it and ride with the original belt? Take it to the dealer and pay close to half the value of the car to get it replaced … ?

Rust

@Dean: Rust. No matter how hard I try to fix it, it always returns. Neil Young was right: it never sleeps.

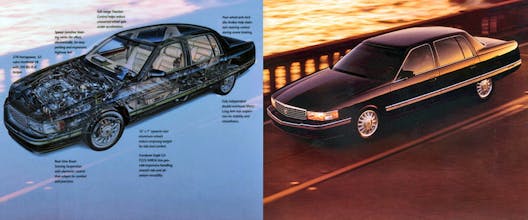

A Northstar buffet

@ap41563: An oil-pressure sensor for a 2003 Cadillac DeVille with the Northstar. The sensor had about half an inch of clearance between the end of the sensor and the subframe, oil-filter housing bracket, and the exhaust manifold; there was a bunch of stuff for me to curse at while I was trying to get it.

I got it out finally after a couple of hours and then when trying to screw the new one in, the wiring harness for the plug snapped in half. My dad, who was nearby heard me drop the wrench and said, “Troubles?” I said, “Nope, not anymore. I’m calling a tow truck I am done.”

Being of sage wisdom, he said, “Now it can’t be that bad,” and crawled under there with me, looked up at it, and said, “I think this engine was designed by Satan. Call the tow truck and pay them whatever they want.”

Best $500 I spent.

@Billy: So speaking about the “dreaded NORTHSTAR engine,” the starter started to make a grinding sound, [and I] crawled under the car: no starter! Well, I found out that the starter was under the intake manifold so I had to remove everything up top. Next I found out that the starter killed the flywheel [teeth] so the trans had to come away from the engine. It has been almost a year of five more simple things on this barge and now the blower for the heat/AC went out. I have to remove coil packs, wire harness, etc. everything between the engine and firewall, tilt the engine three inches forward … hey, do you know anyone who wants a 2001 DeVille with 77K miles?!?

@ap41563: (again) I feel your pain! I inherited a 2003 DeVille with 96K and kept it till 170K. In my time with it, I did regular maintenance and several repairs. Including:

- Oil level sensor

- Oil pressure Switch

- Coolant Reservoir tank

- Water pump

- Intake manifold gaskets

- Coolant crossover gaskets

- Fuel vent tubs

- All actuators for the HVAC system

- Blower motor (that was easy, less than 10 minutes): you can get to it from under the dash on the passenger side.

Things I didn’t fix:

- Transmission’s overdrive solenoid

- The head bolts began to stretch (nobody was willing to take on the job around my area)

- Oil leaks from every single gasket on the engine

I loved the car, and I’m not upset about the work I did to keep it as my daily driver for seven years, as all that was cheaper than a car payment. I got to the point, though, that the whole driveline really needed to be replaced, and I couldn’t find anyone willing to do the work. If I tried to do it myself, I was worried I’d have to haul it to the junkyard, which would break my heart. I replaced it with a Buick with the 3800 V-6. Repairs I’ve done to it in the past three years: NOTHING! When the time comes, I know on the Buick, I can work through any needs it has and remind myself at least I’m not working in the DeVille Engine bay.

@audiobycarmine: I’ve got a 2002 DeVille with the NorthStar. I don’t think I’ll be sleeping very well anymore.

Hatching a plan

@Brushmore: It took me years to fix the hatch on my ’82 Corvette Collector Edition so it doesn’t leak. After many attempts I may have done it but I am afraid to call it a victory just yet. I am always nervous when I wash it, but the true test will be if I ever get caught in a surprise heavy rainstorm. The problem is that there is only one source for the weatherstripping and it’s up to the OEM specs.

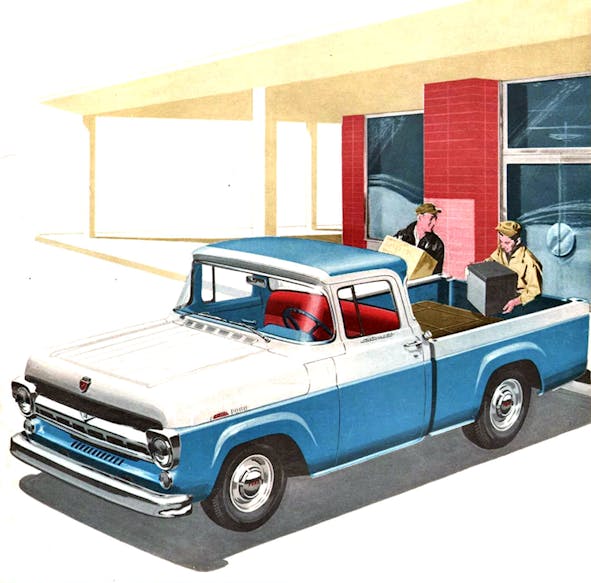

Pushed out by pushrods

@Mark: Oh, I have one for the conversation. I purchased a good-running 1957 F100 short wide a year ago. 272 Y-block, factory auto transmission. I drove it 250 miles home with no problems! Put another 100 miles around town and one day it had an issue starting. Well, I fired it up, drove home, and parked it. Next day, no fire. So, into the garage, and I start chasing ghosts. Starter, new solenoid, I yanked the points and installed Pertronix ignition and coil, changed carb, fuel lines, battery cables, cleaned the tank and sending unit. Nothing. I pulled the valve covers to discover three bent pushrods. So, a year later, still no fire. Hopefully I will solve this.

Getting ungrounded?

@jim: I’ve got a 2004 Silverado SS that’s been in the garage for two years. It goes into low-power mode, so you clear the code so you can get it home. I replaced the gas-pedal sensor (the box on the firewall) and the sensor on the throttle body twice. Ran grounds to everything, checked all the wiring. I work on it ’till I’m frustrated, then try to drive it somewhere close to home. It works for a couple of trips then screws up again. [The truck] is sentimental because my wife bought it for me new for my birthday, made the payments on her waitress money ’till it was paid off. Still nice to look at. The red rocket! Anyone got any ideas?

@SG: Double-check the ground wire that is on one of the bell-housing bolts. You can access this wire through the passenger-side wheel well with the inner liner removed.

Hidden water pumps

@Ryan: Chrysler 2.7 V-6 water pump replacement. I actually didn’t have a problem changing the water pump itself—it was removing and installing the timing chain. Apparently there are tools to lock the cams in place, but neither online video I watched made any mention of this. The plastic chain guides seemed to disintegrate while installing a new chain, and even though all timing marks appeared to [be] correct, I could not rotate the crankshaft a full revolution by hand, and I didn’t dare attempt to crank it with the starter because I was afraid of bending valves. Car got towed to a shop that knew what to do, and it was OK after that.

I got beat by that engine, but I have since learned from my mistakes, and my daily driver is now a Chrysler Sebring with a 2.7—it’s a great engine that really only has a bad reputation because people don’t understand it.

Buried by time?

@Mark: Replacing the clock on my 1958 Imperial. When this car was assembled, the first thing down the line was said clock, and the car was assembled around it. You know you are in trouble when some enthusiast in France has put together a three-page website of tricks to get this done!

This is a cramped and complex panel, and the parking-brake release assembly has to be removed for access. Trouble is the release control shaft extends through the instrument panel (IP), and there is only one, narrow odd position angle where the assembly will clear the IP, the firewall/ floorboard, and steering column. That one component took a full day of trying to remove. Add in much blood offerings due to sharp raw edges inside the IP, and you have the job from hell.

I did get it done, however. I am stubborn.

Starting something … or not

@Gil: My ’73 Lincoln starts erratically. I need to turn the key to start several times before it cranks. Not so bad, but when the engine is hot and I shut it off, when I try to start it again all I get is dead silence. What wire or connection, when hot, separates to cause this? I’m frustrated by driving the car to an event and waiting ’till it cools down before it may or may not restart to get me home. Anybody have recommendations? I thought it was the ignition switch, but it is on the steering column and should not be affected by engine heat.

@DUB6: I had a similar issue on my ’66 Pontiac. I suspected the old, rebuilt OEM starter was giving up due to age and constant heatsoaks. I decided to replace it with a mini-starter. When I was re-routing the battery cable/solenoid wire to the mini, I discovered that the ignition wire had a “cooked” spot in the insulation (it had been bundled with the battery cable and wrapped with silver heat tape, but the proximity to a header tube obviously overcame the protection). When stripped back, this revealed only two of the multiple strands of wire [were] connected. The ends of the others were in close proximity, and sometimes made enough contact to let the voltage/amperage through—sometimes not (likely due to heat deforming the insulation a bit which changed with cooling, or maybe me just not holding my mouth right). I replaced the wire and re-routed [it] to better clear the header and voilà! Issue solved. I now think I could have left the OEM started on, but I love the mini, so the old one is on the shelf as an emergency spare.

@TG: Ford solenoids are easy enough to check with a flathead screwdriver. Leaky valve covers put an early end to more starters than most folks realize. A lot of parts stores will not honor a warranty on a starter if there is any trace of oil on it.

Red mist from the red-block?

@Forty2: Volvo 240 red block crank-position sensor thoughtfully mounted on top of the bell-housing. I thought mine had gone bad. Ordered a new one. Not cheap!

- Buy multiple 1/4-inch-drive u-joints and extensions. 3/8-inch are too fat. You have maybe 3/8-inch of clearance between the back of the head and the firewall.

- Spend half a day figuring out the best mix ‘n’ match of above to reach the single 8mm bolt holding the sensor in place.

- Remove bolt. Aha!

- Be unable to pull the sensor out of the bellhousing because it’d become stuck after, oh, 30 years.

- Spend a few hours getting the little bolt back in.

- Give up on the bolt, because the sensor wasn’t the problem and it’s not going anywhere anyway.

Woulda been easier to remove the transmission!

Red mist from the Fireball?

@Malcolm: Many decades ago, I had a 1975 Buick Skyhawk with a 3.8-liter V-6 engine. For all of 11.5 months, the car’s transmission would jump out of first gear, especially if I was trying to cross a busy street. The car went back to the dealer to be fixed. It continued to jump out of first gear. The clutch was replaced; the transmission was replaced. It still jumped out of first gear, then it jumped out of second gear, then third gear. Long story short, after four new clutches and five new transmissions, the transmission still jumped out of gear. My patience was wearing out, so I decided to trade it in for a Plymouth Duster. I was fed up with GM.

As I was in the car wash getting [the Skyhawk] primped up to deal, I looked down at the transmission boot and pushed it all the way down the shift stick. As I drove out of the car wash and onto the highway shifting from first to second and so on, I drove for about 10 miles for one last drive, the darn thing never jumped out of gear! And it never did for the 10 years I owned it. The rubber transmission-boot material was too stiff and after a while the seams on the boot ripped and was “perfect” for the duration I owned the Skyhawk! I never went back to the dealership as I was embarrassed with the situation.

The relentless pursuit of electrical gremlins

@audiobycarmine: For me it was whatever accursed computer/sensor problem that killed my Lexus SC400. I chased down every error code, replacing part after part, while amassing a formidable library of information throughout. Finally, in desperation, I had it towed to my mechanic, who had sophisticated diagnostic equipment. Said equipment turned out to be “agnostic,” as nothing faulty could be detected. The Lexus went off to NPR as a donation. The whole ordeal still bugs me.

Evaporating will for the EVAP

@Justin: I have two currently, and both are fuel tank vapor recovery EVAP issues that are triggering a check engine light. One is on a ’16 Silverado and the other on a ’02 Jeep Liberty. Also I’ve a ’87 Chrysler Conquest that simply will not run right: replaced the injectors, TPS, pressure regulator, and plenty of other parts. But it still idles rough, but occasionally runs great for a day or two. Then it goes back to spitting and sputtering, so if we can’t get it figured out it’s gonna get a Toyota V-8 from a SC or LS 400.

But the real one that’s killing me is a Genie 34/19 towable boom lift. Apparently it has some issue with the computer board, and replacements are simply not available.

***

Check out the Hagerty Media homepage so you don’t miss a single story, or better yet, bookmark it. To get our best stories delivered right to your inbox, subscribe to our newsletters.

After discovering that the starter was under the intake on Northstars and their sibling Aurora engines (by following the red cable under the intake), I found that they are remarkably easy to change

I discovered that folks had the bright idea of putting water pumps under the timing cover when my mother’s Neon started leaking coolant out of the bottom of the timing cover. I managed to wrangle that timing belt without mishap… Getting the motor mount out of the center of the timing cover was the biggest challenge of that job

Agreed. The starter was an easy change. The only N Star issue I found was the head bolts on the later engines that would let the head gaskets leaking.

Same on the timing belts and chains.

I have had challenges but I got through most.

BMW was one of the worst cars to work on for me. Often simple things were major jobs.

I had one to change the oil filter the canister had to be removed from the block or the sway bar had to be removed.

On the other hand msny things on a Benz was like how can we best do this.

Agreed. The starter was an easy change. The only N Star issue I found was the head bolts on the later engines that would let the head gaskets leaking.

Same on the timing belts and chains.

I have had challenges but I got through most.

BMW was one of the worst cars to work on for me. Often simple things were major jobs.

I had one to change the oil filter the canister had to be removed from the block or the sway bar had to be removed.

On the other hand many things on a Benz was like how can we best do this.

Yes, but both my Caddy ETCs with North Stars were a blast to drive…

65 Mustang clutch/brake bracket under the dash above the steering column

The only one of any of these that aren’t repairable are the structural cracks in bad places and major rust. Everything else is fixable (assuming you can find the parts and afford them).

Also, if you notice almost all of these are on newer cars. That is why I prefer working on the 50s to 70s.

The thing that finally killed my ’96 Plymouth Breeze – after 320,000 miles – was an electronic gremlin located somewhere between the PCM and the cam & crank sensors. Chased that for a long time & several parts, including 3 different PCMs, but finally gave up on it. Still bummed out about it, actually: he was a fun little car with great MPG, and otherwise as reliable as sunrise.

Electrical gremlins. When no consistency to when it would misbehave. (Does not matter the brand or model vehicle.)

Another here for the Northstar. I had an ’02 DHS that head bolts went south on. I didn’t want to invest in doing the inserts for the block so I put a giant sign on it thoroughly explaining exactly what was wrong and sold it for pennies. The guy who bought it came back a week later and said that he put leak sealer in it and it didn’t work. I told him to go back and read the big sign again. I did feel bad for him but I think he thought I was ignorant and that he was stealing it from me. In defense of Northstars, I then bought an ’05 DTS that had the upgraded head bolts and that car was terrific. Sold it only when the AC compressor went bad but I’m pretty sure it is still on the road today.

I had a ’99 F150 for 19 years, and spent about 5 of those years chasing an intermittent run problem, bucking, missing, low power, especially in colder temps. No faults ever showed up in the computer, but multiple parts were replaced at several repair shops, including it spending 2 weeks (and me spending ~$1500) at a dealer trying to solve it, with no success. Finally the fuel pump gave out. The (non-dealer) mechanic dropped the gas tank to replace it, and found cracked EGR hoses in the space above it. After the hoses were replaced, no further issues.

EGR hoses are not anywhere near the gas tank. Perhaps you are thinking of evaporative emission control hoses.

You are exactly correct – senior moment for me! Thanks for the note.

I believe you mean Evaporative emissions hoses.

Yes, you are right – senior moment for me! Thanks for the note.

I had to chuckle at the 240 crank position sensor as I’ve removed transmissions from 240s a number of times.

The one that really flummoxed me at least also flummoxed the professional as well. This was my ’79 Volvo 245 which was misfiring to the point of failing emissions. But it was also a bottle of his choice to the to the fine & honest mechanic. He said that the diagnoses were pointing to replace the the ECU, which he could get for a jaw dropping number of dollars. But he also said that his gut was telling him that wasn’t the culprit. I offered a junkyard ECU, but he opined that one couldn’t absolutely trust used parts. Long and short of it was when I offered a live, living parts donor car car his eyes lit up and said that would do it. As I recall he had some Saturday hours, so I said I thought I could find a donor car and we scheduled the following Saturday.

Went to work the next day and asked my technician if he wanted to drive the ’88 740 Turbo wagon with stick (the rare option) and his eyes lit up – as I was offering it for the whole weekend!

Turned out that the distributor of that model had a trigger system that was actually working in my car, but wasn’t getting the signal levels high enough for the ECU to acknowledge. IIRC I got a call quite early and hit the pick & pull for a distributor and had the car before noon.

Turned out that both the tech & his girlfriend really liked the Turbo so much so that she actually found one to purchase!

I had a customer with a Volvo 164E – first generation Electronic Fuel Injection. He would make an appointment for an FI-related issue, then cancel, saying it had ‘fixed itself’. After months of this the car was towed in, dead as a door-nail. After an embarrassing amount of time spent, I discovered mice had chewed the FI wiring harness under the carpet, behind the heater. 28 parallel White wires with chewed-up insulation.

I just drowned a 164E EFI, unbeknown to me the floor had rusted out so a deep puddle flooded the footwells.

I had six months of trouble with a 1972 Volvo 142 with early fuel injection as well. ECU under the passenger seat. It would run fine for a while then sputter and cough for miles, then fix itself again. After changing out injectors and multiple sensors, I had it idling in the driveway. I touched the cold start sensor wire and it went into it’s usual act, running extremely rich. I had already replaced the cold start sensor, so that wasn’t the problem. Seems when they crimped the wire connecting to the sensor, they cut off most of the strands. I clipped the wire and installed a new connector. It ran beautifully for several more years before I traded it for a BMW Z4 along with a bunch of Benjamins.

Suggestion for @Jim w/ the 2004 Silverado SS stuck in “Limp Mode”. I have a 2006 GTO w/ LS2. Was cruising down the freeway at 80 MPH when suddenly the power door locks unlocked, the speedometer went to “0”, the tach jumped 1000 RPM’s – and the digital display starts beeping and says “check engine”. (Not the normal check engine light) The problem went away before I could pull off the freeway – but it returned intermittently. 5 trips to the dealer – they were diligent – once keeping it for a week with different techs taking it home each night – no solution and they couldn’t duplicate the problem. Then – finally it broke and stayed broke. It was a faulty AT control module that was randomly putting the car into “Limp Mode”. Replaced AT Control Module – no problems since.

Yes; I had the exact same issue with a GM (Oldsmobile) minivan that went into ‘limp-home mode’ at 65 mph on the freeway. Long story short: it was an automatic transmission module. Reputable mechanic replaced the module with a used one ($70) and never had an issue with it again. Success…!!

Chris- love your car, I gots a ’04 TorRed 40th Anniversary GTO with the Tremec crunch box. Street action, Sabin/Brainerd legit drag racing & some sports car/autocross stuff, burned up multiple clutches and a fortune in tires with no problems… at 76,xxx the accursed engine light comes on. And goes off every time I park the car. Comes on if I back down on the motor, goes off when I refuel.

Drove me & mechanicing buds nuts until I broke the key to my aftermarket locking gas cap and replaced it… Yeah. The emissions sensors didn’t like the first gascap. Been over 30k miles, no more engine light. Effing gas cap, who would have thunk?

1967 brand new Pontiac Tempest, in line 6 w/ overhead cam. Hurst 3 on the floor. Quick. The O rings kept failing under warranty and it was a time when they did not provide loaners. They kept replacing the O rings, like 5 times in a year and could not solve the issue. I knew of other owners with the same issue. I had to give up and traded it. I should have sued!

Had an Air Force bud in the late ’70s that had a short, windowless ’66 Chevy van (shaggin’ wagon custom, of course) with a Pontiac Sprint6 SOHC engine and 3 on the tree.

Everything about that custom van was a nightmare of failure and intermittent faults- save for the SOHC 6. Van went away, motor went into a ’67 Firebird convertible. Dude was still driving it six years later when I got transferred to the Middle East. Good motor, poor custom work.

Boy do I love (actually hate) electrical stuff! Yes that and fuel are the lifeblood of any car but really, like most of us, I have a hard time visualizing those streams of electrons doing their business. My latest, go to hook of my car trailer and find that the electric tongue jack is not “jacking”. The trailer sits a lot- go inside and try the interior lights- no lumens- so charge the battery- still nothing. Then I notice a trace of a spark when hitting the light switch- but not on the power side (I had already checked the battery posts to be sure they were clean and tight) but from the ground to the frame of the trailer. Put in a new bigger self-tapper for the ground leg and miracle of miracles- let there be light! My suggestion (as a mechanic buddy of mine is found of saying)- check the grounds first- the most likely culprit for your lack of juice.

The attempts to repair several different GM vehicles, (mostly from the malaise era and late ‘80’s) left me with a strong dislike for GM and their ambition to make even the simplest task impossible.

I’ve got a beauty. My father-in-law bought a new Edsel V-8 in 1958. After driving it a few years, it began to overheat on highway trips. Nobody could fix it in the small town where he lived. They replaced the obvious thermostat several times, water pump, radiator, even rad hoses, thinking one might be collapsing. Finally he gave up, stored it in a friend’s barn, and bought a new 66 Chrysler New Yorker. We rescued it in the 1990’s and I restored it for him. In the process, I rebuilt the engine. Low and behold, behind a coolant manifold that runs across the front of the engine were hidden to thermostats designed to make the heads heat faster and give you quicker cabin heat in the winter. This is in addition to the ordinary thermostat on top of the engine. Both were failed closed. Cure — throw them away.

The Edsels came with a Ford motor or a Lincoln motor. Obviously you had the 410 Lincoln motor. Those thermostats were put there so in the winter the car would get immediate heat for the heater core. Those thermostats were quickly discontinued.

Mine was minor. The electric sunroof on an ’89 Saab 900 hatch. As the sunroof was an adaptation of a 1973 design, the motor was located behind the rear bumper, and ran cables through the C-pillar and along the inside of the roof. Found the appropriate motor and gears (listed as Jaguar parts) but could never fix it. As the sunroof was closed, and the car had 200,000 miles, I just left it that way. Too much trouble, not enough reward.