According To You: Least Favorite Automotive Projects

There are some tasks that we just need to get done, without joy or relish in any moment of the activity. Last week we asked what automotive projects meet this criteria, and the good people in the Hagerty Community rose to the occasion. Perhaps while making a grunt, sigh, or groan with the thought of each dreaded task. These restorative efforts are not for everyone, and those who tackle them earn a well-deserved break after their completion.

So let’s see what made the cut—you will likely be surprised by some of the winners!

Anything on Anyone Else’s Car

Jeepcj5: Anything on another person’s vehicle.

ParaboTech: Definitely! Anything regarding working on another person’s vehicle. I try to be nice and helpful, but sometimes I really dread this.

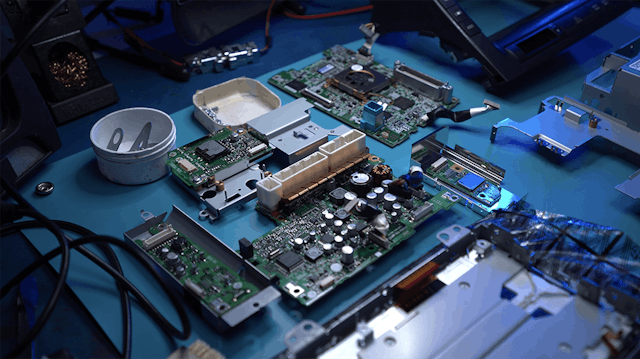

Disdain for Electronics

hyperv6: I agree with Sajeev’s comment from last week, because electrical is the bane of the auto repair or restoration process.

With mechanical bits you can often look and find a worn or broken part. It is clear when you find the problem as you hold the part or pieces of the problem.

With electrical, you may have things like a broken wire if lucky but often it is a bad ground that looks good or is one ground of 10 in the car in various spots that can make things work or not work randomly.

Worse yet are the sealed units that you can not see or find damage. The Service book will say replace with known good unit as the test to see if it was bad. In other words, throw parts at it.

Don: My brother and I have 5 VW Beetles and we have fought more with the carburetors than anything else except for figuring out the wiring that previous owners worked on.

TG: Black boxes… the worst part of electrical. A bunch of stuff goes in, a bunch of stuff goes out, but only a handful of people know what goes on inside.

Roberto: Yeah, under-dash wiring is the worst! Except maybe for trying to get the windows to work smoothly and seal properly on my ’65 Impala.

Mark: Check engine lights. Not the idiot lights, but ones on cars with a low-speed canbus, a high-speed canbus and a diagnostic bus. You get the code, then the description, and then have to “figure out what the code means.” Then replace what you think caused the ‘puter to be unhappy and then wait for the light to come back!

Trekker: Yes, anything electrical can be a challenge. Plus, trying to find good replacement parts for a 47-year-old Datsun can be next to impossible!

Steve: Working behind the dashboard, and inscrutable computerized “black boxes” have been a personal Hell for me. I think the bane of many projects is parts support, with faulty replacement parts a close second.

DBDixon: As long as I had access to electrical schematics diagnosing electrical issues were not an issue. Sealing electrical fixtures like headlights on a truck and finding out OEM replacements were $1000+ versus replacing a bulb did give me a pain in the back pocket. Integration of electronics and electrics are also a challenge now.

Or Electrical Is Okay?

ParaboTech: Actually, I kinda like the challenge of electrical. Admittedly, OEM schematics make the project much, much easier. The real anxiety comes into play when you decide that an expensive component needs to be replaced and you really hope that your diagnosis is correct before spending money on a non-refundable purchase.

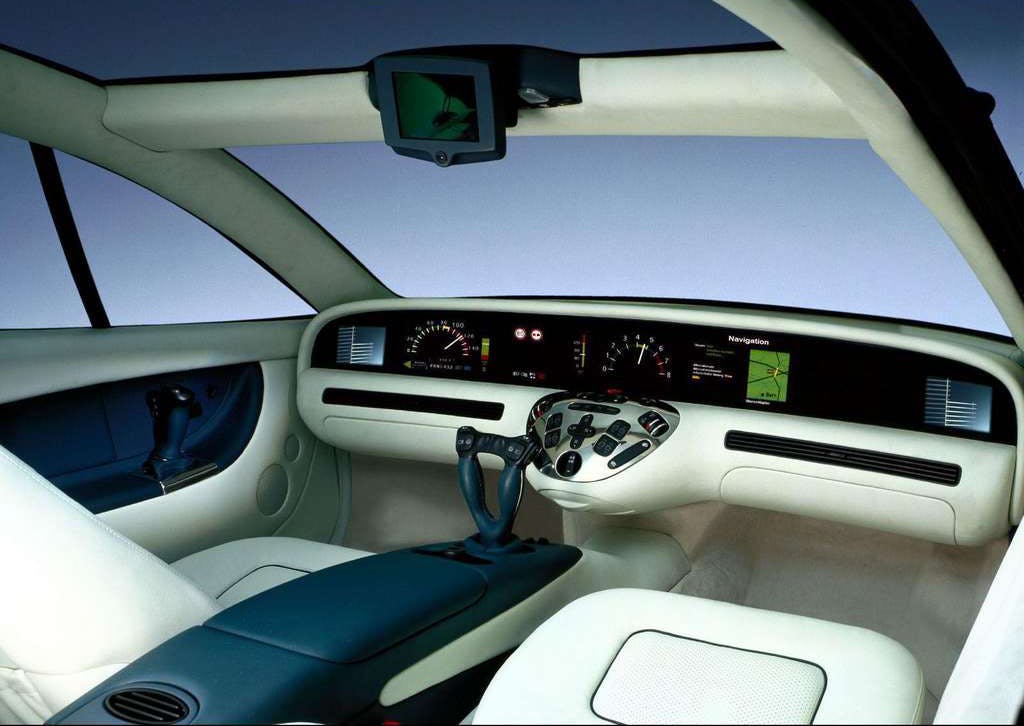

Of Dashboards And Sandpaper

DUB6: Oh man, Sajeev, under-dash wiring is indeed a nightmare to me, too. I’m a fairly large person, and in most cases, I need to remove front seats to just get in there to begin with. That gets me there, but then there is a) little maneuvering room, b) difficulty seeing, and c) the need to climb back out to get the one thing I forgot to place within reach.

But as much as I hate the above, post-body-work-and-pre-paint-prep is worse for me. Specifically: SANDING. GAWD how I hate sanding. And it seems to be a never-ending process. Work the metal, apply some filler, sand, sand, and sand some more. Put on a little primer and feel the surface. Then sand, sand, sand some more. I’m not really a big fan of the “applied patina” look, but I’m tempted every time I need to sand some bodywork to prep it for painting!

ParaboTech: Yes, this! I never knew I could experience claustrophobia until once time working under a dash in my twenties. I absolutely had to get outta there!

TG: I’m with DUB on dashes and post-metal bodywork. I’ll add doors and brake hydraulics

Anything Needing A Lift

Kevin: I don’t own a lift, I never have, so for me it is exhaust, drive shaft, clutch. . .anything that can involve significant time lying on the floor under the car on jack stands. Brakes, suspension, steering, etc typically can be done NEXT to the car on jack stands rather than UNDER it.

DUB6: Amen, Kevin. I’ve told this story before, but when I was about 16, a ’55 Chevy dropped on me and the lower A-arm—thock!—put a dent/cut in the area of my right eyebrow. Had it not been for the 14″ steelie rim I’d placed under the K-frame crossmember—well, Gallagher and his melon-smashing act comes to mind. Since then, I’ve never been totally comfortable lying under a vehicle—so I tend to over-support it with all sorts of “anti-dropping devices”!

TG: My neighbor has a lift which I use frequently. Even with the lift available, I find there are certain jobs (anything that involves transmission removal) on the ground. Lifts are extremely dangerous if there is anything in contact with the car and ground other than the lift itself. Also, you generally cannot get the car doors all the way open with cars on lifts, and any job that requires getting in and out of the car frequently are lift no-gos for me.

The Need To Improvise

Lewis: My least faves have changed as I’ve gotten older. Working under the dash of my ’63 Pontiac wasn’t a big deal at 18. I’d just position myself upside down, with my feet up on the seat and my head down on the floor, looking up. At 64, I can’t contort myself like that anymore. So, this kind of work has dropped from my “I don’t really mind” list to “oh, g-d, why me?” list.

Likewise, things that require more finger dexterity have fallen from the “that might not be so bad” list. I had carpal tunnel release surgery on both hands a few years ago. The pain relief was amazing, but so has been my loss of ability to pick up small things with my fingertips or manipulate small connectors in tight spaces (where I can’t resort to needle nose pliers).

In general, though, my least favorite thing to do is anything requiring some tool that I don’t have, forcing me to improvise. I don’t mind the improvisation itself; it’s the time and attention lost in the process, whereas having the right tool for the job in the first place just gets it done.

It’s Exhausting

Scott: Exhaust systems. Big. Heavy. Dirty. You assume every fastener is seized, or about to break off. You get to find out that the last guy saved by welding it all into one piece. You get a cat back only to find that the 1500$ cats are junk. I hate anything with a tailpipe.

ParaboTech: Exhaust systems for sure. Exhaust manifolds are the worst. Cramped work areas, special or customized wrenches and tools, penetrating lubes, waiting times, broken bolts in the worst places, and the ongoing threat that you will probably have to pull the engine to fix something that you broke while trying to fix something.

Bryan P: Any exhaust system work for sure. It’s the one thing I will gladly pay to have fixed.

Conversions/Restomods

Andy: Although I have not started it yet (I have the parts), switching from an FMX auto tranny to a five-speed. The clutch pedal assembly will require taking half the dash apart and removing the steering column and brake/clutch support. The actual tranny install looks straightforward.

Not old not grumpy: I inherited my brother’s 1967 Mustang convertible “restomod”. It has been cut up and abused by so many different people not least of all him that doing anything requires reinventing the wheel. It’s an adventure! I’m currently attempting to finish installing the aftermarket air conditioning he started. Finding room for those hoses and the fuel injection harness and the auto meter gauges and the aftermarket stereo is a bit of a challenge.

cdlamb: I have a ’31 Model A Ford Tudor and electrical was somewhat of a problem since I converted to LED lights, 12 volts (which required total rewiring), plus some added accessories too. My biggest problem has been the fuel system, and a trashy gas tank. I refuse to remove the tank since the car has a relatively new paint job and that would destroy a good portion of the front-end paint. being a gravity-fed system, the slightest particle will plug the carburetor. At 79, climbing under the dash to change the tank filter and address any wiring issues is all but impossible. Almost to the stage of hiring to get it done.

About Overengineering…

Binksman: Working on my wife’s 2001 CLK320. Best I can figure is that Mercedes hires engineers with sadistic bracket fetishes intended to cause harm and suffering to anyone who ever might need to service the car. My Dodge Magnum has the same NAG1 transmission, and both had a leak from the transmission plug port: a 10-minute job in the Dodge, two-hour job in the Merc. Layers of brackets, many unnecessary, all leading to me use up all of my known list swear words while wondering how Dante could have missed the “engineers who never turned a wrench” level in hell.

Organizational Issues

norm1200: keeping my shop organized and uncluttered. Yes, this to me is a project, and one that sometimes gets a really good sigh outta me. Getting organized is an ongoing project that’ll probably take me into the next century, maybe millennium: I still have glimpses of my first house—900 sq ft, 1-car garage w/ port, all dialed in after four years of weekend work, and working on my cars at the dealer.

I’ve been kinda lucky not mixing up metric & SAE fasteners. It’s something that, if let go for too long, can be a one-way trip down that rabbit hole. Fortunately, I can tell the difference between Nissan, Toyota, and other foreign hardware, let alone 60s-80s SAE bits. Staying uncluttered? It’s been a long while since it’s been that way, but I keep chipping away at it. I just bought $400 worth of plastic containers for my pic-a-part treasures, etc. and at that cost, I’d like to think it’s enough.

Everything But Driving?

Ben: I gotta say that at 75 years old, I love to drive cars but I hate working on them or cleaning and polishing them.

I check my oil, etc

I wax my car

I clean the interior

…all else, it goes to “my guy”.

-Lexus SC430 is my joy ride now….and a Sequoia for towing TT…and Highlander for DD.

P.S. I’m now 74, have rebuilt, restored dozens of cars of every breed. But that was then…

I’m with you, 74 as well, I have lost interest in working on cars and they have been a hobby all my life, I have sold off most of my cars, no desire to start another one.

Least favorite – Fixing one problem and learning I have caused another.

My wife has a theory, be it automotive or household. Always leave one thing broken, because, as soon a we repair that last thing, something else will go bad.

I have a very similar theory, but its very off-topic! Playing a computer game where groups of enemies come at you, seemingly relentlessly – solution, leave one enemy standing and the game doesn’t spawn another group until he bites the dust! Sorry about the subject change, but its very true!

The toughest job for me was to replace the rear wheel bearings on my Pantera. The half shafts had to be removed. Fortunately, a friend who also had a Pantera owned a machine shop so we could remove the old bearings and press in the new ones.

Least favorite, very heavy objects needing work without having the tools to do the work.

I’m with yes dear. I’m a year younger. If it won’t fit on my bench I’m not interested. I even sold my lift, I knew that if it was still here, I’d want to buy another car. The problem is that the mind is willing, but, the body’s not on the same page. Don’t worry I’m perpetuating the car desire Gean. I’m giving my 70 Fairlane to my grandson.

Anything involving a GM Optispark on an LT1. Especially in a 90s Camaro.

I’m 74 now and I’ve done ALL of these jobs many times on countless vehicles of all stripes. And boats, too. Had a lot of fun, busted a lot of knuckles, cussed beyond belief. No more. I check fluids only now and polish the cars. All else goes to “my guy” now. I bought a pristine Lexus SC430 and that’s my toy. And a Sequoia to tow the travel trailer and a Highlander for daily driver. I kinda miss the old days, but hey, gotta roll with changing realities. Its all good!

Cleaning and relining a 45-year-old gas tank using one of those kits. In the winter.

I have a brake job that I need to do to my ‘40 Olds, that includes all brake lines, flexible brake lines, wheel cylinders, and master cylinder. Unfortunately I have no lift, so I have the car up on blocks and jack stands, and will have to lay under it for all the brake line fabrication and installation. I did just install dual exhaust from the manifolds back, so am aware of what I’m up against. It’s just tough after two major back surgeries…

Most people are ill-equipped to do electrical work correctly, let alone troubleshooting it.

Don’t even bother unless you have the aptitude, plenty of time, knowledge and the right tools. A blow torch and plumbing solder is the fastest way to fail.

I am famous for ‘yeah, I can do that myself, shouldn’t take more than a couple of hours.” 3 days later, I’m waiting for special tools and replacement parts for those that I broke trying to solve the original problem.

Changing a fuse on a Hillman Imp, or replacing timing belt and water pump on a ’68 VW Beetle !

Making the “I’ve seen this before” instant diagnosis, doing a lot of tedious work – and discovering you made a bad diagnoses. I just finished re-assembling an M-41 transmission that was popping out of 3rd gear – common problem when the brass shift fork is bent. Overlooked the stuck detent ball until the very end. A couple of quick passes with a .30 cal bore brush and it’s fine. I’m also an 80y/o – it took 2 days for a 2.5 hour job.

Finally succeeded in removing the engine from my 289 AC Cobra, but it sure was not easy, and not my favorite task. First- remove the seats but the 1/4- 20 retention nuts are buried in tight quarters under the floor; used an open end and only got 1/12 turn at a time. Then- remove the entire transmission tunnel to gain access to the aluminum T-10 four speed- BUT one Riv-Nut turned so had to buzz it out. Remove the hood (“bonnet”)- quite difficult; First…remove the grille to access the pivot bots. Have 2 car-smart friends maneuver the fixed hood hinge so it does not hit the aluminum nose. Had less than 1/8 inch clearance to get it off. Pull the T-10 back and out into the cockpit; heavy when you are bending over. Near zero clearance on fuel pump to bracing, so out comes the fuel pump. Then- finally; lift and tilt. Thank goodness for friends who helped with this. Viola!!

What a bunch of whiners