Ragtops & Roadsters Redux: Pennsylvania Resto Shop Turns a Corner

The town of Perkasie, Pennsylvania, can trace its name back to a native Lenape tribe phrase that means “the place one goes to crack nuts.” Fitting, then, that this charming town, about 40 miles north of Philadelphia, has deep industrial roots, which in the 20th century included lumber, silk, and crushed stone. The painted brick building in front of us, however, has specialized in one thing for more than three decades: repairing and restoring vintage cars, mostly of the British sporting variety.

This is not my first time in Perkasie (pronounced PUR-kuh-see), nor am I unfamiliar with Ragtops & Roadsters. I grew up near Philadelphia, frequently attending British car meets and road rallies with my father and his 1963 Morgan. In the 1990s and 2000s, Ragtops had a sterling reputation for quality mechanical and restoration work, and after hearing that the business had come into new ownership in recent years, I was curious how the shop’s legacy would endure. Car restoration is a tough business, and too often, when the founder and lifeblood of an enterprise moves on—either to another outfit, into retirement, or entirely off this mortal coil—the nuts, well, stop cracking.

Not so at Ragtops & Roadsters. A green Triumph Spitfire idles on the front entry ramp as I approach, and I am greeted by the 1500 engine’s content tapping of tappets. Wood planks, mismatched and worn to a dull gleam by a century of busy soles, line the building’s floors. It’s the only touch of nature in this otherwise mechanical orchestra; against the walls are endless tool drawers, shelving for parts and various-colored cans of fluid, all surrounding neat rows of beautiful, yet needy British sports cars.

And beautiful they are, even mid-surgery. First to catch my eye is a fiberglass Devin-bodied Healey 100-6, with a race engine by Ken Rudd that wears his “Ruddspeed” stamp on its top end. Within feet is another Healey, a sparkling 3000, as well as a handsome Morgan on jack stands. I’m moments away from vanishing inside the open clamshell hood of a Jaguar E-Type when Sylvaine Aust, Ragtops & Roadsters’ co-owner, extends her hand in greeting.

Aust is French, originally from Paris, and fashionably put together. She bops around the shop with me, pointing out various projects and expounding on the different owners’ stories with a somewhat intense congeniality. The history of the vehicles, she remarks, is a source of constant amazement.

“It’s fascinating to go on these sleuthing expeditions. You can learn the history of a whole country—the technology, the industry, the people. And when one of our customers talks about their car, their eyes go wide and their face loses 20 years. We’re car people, but the clientele are what attracted us to the business.”

Sylvaine and her husband, Duncan Aust, an agricultural biotech executive with a PhD, bought Ragtops & Roadsters in 2021. The outfit was by then a well-established and respected name in Philadelphia’s British-car restoration world, thanks to the work of its founder, career mechanic Mike Engard. What started as a rented three-bay Perkasie garage in 1990 evolved into a vibrant operation known for churning out show-winning work.

Former customers from those days praise Engard’s technical expertise and his success in building up the operation. Everyone knew he was top-notch, but it came at a steep price.

Just before the financial crisis in 2008, Engard expanded. He purchased Pollock Auto Restorations—a 30,000-square-foot restoration facility mostly dedicated to Brass Era and other early American cars—in Pottstown, Pennsylvania, 27 miles away. Engard effectively ran these two operations as separate businesses; much of his post-recession efforts went to rehabbing the aging Pollock facility as he fought to keep the flame burning at Ragtops in Perkasie.

“By 2016, we had years of backup work and a reputation for being expensive but good. I was OK with that,” Engard later told me, via phone. Around that time, however, he’d lost his enthusiasm, his original entrepreneurial spirit having diminished under the load of day-to-day management. “I started Ragtops & Roadsters because I liked working on cars, and then I spent 30 years running a business,” he said.

The current management could hardly be more of a departure. Aust, who has experience in biotech sales and a stretch running a fabric business, plus some legal training, is a font of energy. She periodically steps away from our chat to take phone calls, her voice fiery and her hands animated as she paces. She just started a racing training course, and she plans to get behind the wheel of her 1936 MG Magnette N-type replica and 1960 Kieft Formula Junior, both here on the shop floor. The latter—an aluminum-bodied Formula 3 car with Cosworth connecting rods, Koni shocks, and drum brakes—looks like a hummingbird suspended on four wheels.

Aust claims no background in auto restoration. She and her husband have owned more than 60 vintage cars, dealing with many such shops in the process, and not always with positive experiences. “Transparency is essential for the customer,” she says, hands half-raised in the air, elbows at right angles, all ten fingers splayed out as if in frustration. “Especially as a woman, people would tell me nonsense. I hated that feeling of being played.”

She and Duncan dreamed of their own place, where the customer would be fully informed and empowered to make decisions. When they saw Ragtops for sale, they jumped. “We’d managed operations before,” she says. “The deep restoration knowledge is for the techs. They’re the specialists.”

When we meet Craig Bentley, one of said specialist mechanics, the rear fender of a red MGA appears to be swallowing him whole, Jonah-style, as he tends to the car’s wheel bearings. He’s a Triumph guy at heart, but lately, Bentley says, working on several customers’ Alfa Romeos has proved alluring. “They’re usable to drive and maintain, more so than the Brits,” he explains, “but I really love anything mechanical.”

Bentley’s tastes are eclectic—he’s a certified Audi mechanic, owns both an old Ford truck and an ’83 VW Rabbit GTI, and he is a veteran Lemons racer. “Sylvaine calls me her wise old owl, or, depending on the day, her pain in the ass.” The Bentley banner hanging on the shop wall, with its winged “B” logo, strikes me as a personal touch more than a nod to the boys back in Crewe.

As much as he loves old cars, Bentley doesn’t romanticize working on them. “People say old cars are simpler, but they’re not. On modern cars, parts fit, and electronics are sophisticated but not complicated. A vintage Jaguar has a linkage from your foot to the carburetor that could have 150 pieces.”

I wander downstairs, following the smell of oil. A transmission and 1275-cc Mini sit on stands, cracked open as a younger goateed tech, Eugene Toner, works on the timing gear. A common issue with replacement parts for the gearboxes, he tells me, are low-quality gears and synchros with the wrong coatings. Once the coatings wear off, the gears grind. Parts for old cars are a crapshoot these days, largely because the volume isn’t there for the manufacturer to make a profit at a price point the customer will accept.

“Whenever possible we’ll opt for a used part that we can clean up or fix, rather than roll the dice on a new part,” Toner says. The evidence for that is behind him—ceiling-high shelving packed with everything from Bugeye fenders and SU carburetors to TR7 steering wheels and MGB headlights to miscellaneous fuel pumps and brake servos.

The floors above us creak as the two techs upstairs move about. I crane my neck upward, following the sound. “Sometimes, old pieces of leather fall out from up there,” Toner says. “This building used to stitch together major-league baseballs.” That was from 1968 until 1990; before, it had been a slot car racetrack, a Chrysler-Plymouth dealership, a silk hosiery workshop, and a storage building for a local trucking company.

This Perkasie location is where most of Ragtops & Roadsters’ powertrain, suspension, and general service work takes place. The so-called Pollock Works in Pottstown is more restoration-focused: body, paint, trim, and interior work. Engard employed eight techs, but under the Austs the staff has grown to 15. That team now manages an astonishing 72 active projects—an uncommon size and scale that Sylvaine says is advantageous, allowing Ragtops to do all of its work in-house.

***

Uniting both shops under one banner was Sylvaine Aust’s first major goal. To see the Pollock Works, we hop in the car and drive 45 minutes to Pottstown, a small city more than twice the size of Perkasie. The feel here is quite different: more aging urban infrastructure than leafy streets and horse-stable charm. We find the building—a former furniture and upholstery factory—tucked away next to a railroad bridge. Making our way around back, we arrive just in time to see staff members rolling an enormous, white Cadillac Fleetwood down from an even more enormous second-story ramp. We’ve clearly branched out from the Brit cars.

The Pollock Works is home base for Jeff Swider, Ragtops & Roadsters’ managing director since 2022. A big, tough-looking, tattooed guy, he is—like the new owners—also fresh to auto restoration. His father owned a garage for 40 years, however, and Swider is well versed in project management, having done it for a major concrete waterproofing outfit as well as a party tent rental company. His reputation around the shop is that of a numbers guy who is attentive and on top of things.

In Swider’s office, there’s a large TV screen up on the wall above his desk displaying details for several active projects. He periodically stares at it, wiping sweat from his shaved head. Swider is a volunteer firefighter, so he knows how to stay cool under pressure, and he has moonlighted as an Elvis impersonator, which means the guy can’t take himself too seriously.

“This operation, more than 70 cars across two locations, is a huge elephant to feed,” Swider says. “But we all want the same thing, which is for the cars to come out of the shop perfect. The customer should drive it home and be smiling from ear to ear.”

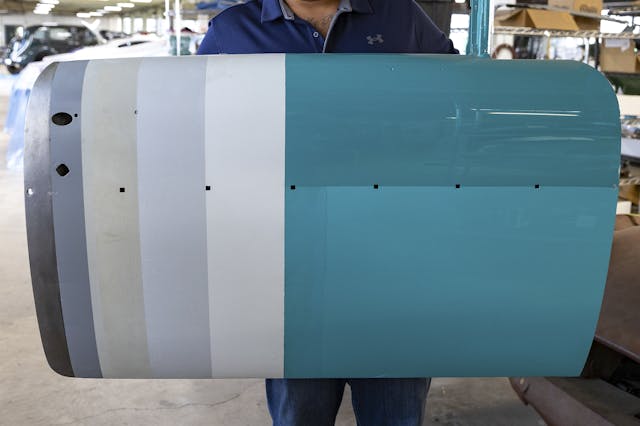

Getting to that place can be an arduous process, as any restorer or client knows. True restoration work is an involved affair, something that novice clients do not always fully understand. To help them, Swider holds up a car door that demonstrates each meticulous stage of the painting process—the stripping, the hand-sanding, priming, and various layers. That high number of estimated labor hours suddenly makes sense.

All the planning in the world, of course, can’t account for the unexpected. A snapped bolt or unforeseen part failure can set back timelines by weeks, and these types of diversions are unavoidable with old cars. “Our job is restoration. If we need to put a battery in and the hold-down looks corroded, we’re gonna replace it. If the wiper motor doesn’t sound right, it’s getting cleaned and properly re-installed,” Swider explains. “Our best customers understand that we’re not a basic repair shop.”

Keeping projects moving forward requires great techs, and Swider has nothing but praise for his crew. In one instance, he tells me, a customer needed an unobtainium ball joint for a rare Swallow Doretti; one of the Ragtops fabricators solved the problem by manufacturing a new one, more or less from scratch, in a couple of days. “The stuff these guys can do—I’ve never seen anything like it,” says Swider.

Finally, I make my way into the Pollock Works shop. It’s a massive, no-nonsense space, packed with more cars and tools and machines than I can count. Mechanical clatter fights with whirring air conditioners and thrumming fans. Grids of square factory windows bathe the concrete floor in daylight.

Dorian Custodia, a Ragtop & Roadsters veteran since 1997 (unofficially since 1992, he says), is kind enough to step away from the new rockers and wheel well on a BMW 2002 so we can chat. Stripping the car down, he explains, revealed rotten metal. “Had to have been in an accident at some point, suffering all kinds of nasty sins.”

Within Custodia’s reach are several tools of the trade: an all-purpose metalworking machine called a Pullmax, used for shrinking, stretching, and cutting; an old-school English wheel; a pile of heel and railroad dollies, for shaping; an incomplete wooden shaping stump that he’s been whittling away at in his spare time.

Elsewhere on the Pollock ground floor: MGs, Triumphs. A row of prewar beauties—Pierce-Arrow, maybe?—convalescing under plastic sheets. But Ragtops & Roadsters isn’t exclusively for Brits and Brass; we also spot a dusty Fox-body Mustang, a resto-modded Pontiac GTO with mirror-shine paint, and an air-cooled Porsche 911 assuming the position with its rump hoisted in the air. Some cars are here for a quick overhaul before sale, others just to get into shape to spend life as a driver. A handful will be blessed with a full concours-quality restoration, fueled by dreams of confetti and trophies; these are the projects that let Ragtops & Roadsters showcase the full scope of its skill and expertise.

What I don’t see is a wandering shop manager to keep everyone on task. That’s intentional, Swider tells me, for two reasons. First: Several of these techs have run their own shops and don’t need anybody looking over their shoulder, and a measure of autonomy gives them a sense of ownership over the job. One tech, Tim Supplee, told me that the freedom lets him “send the car out when it’s done like it’s mine.”

Second: A piece of software called Shopmonkey keeps all the proverbial trains running on time. The program lets techs document every step of their work via iPad; both management and customers can see pictures and descriptions of the restoration process, letting Ragtops stay on schedule and open up evidence-based conversations about next steps when left turns happen. Shopmonkey also gives customers a direct line to the techs, which most of them prefer.

If a routine transmission fluid flush, for example, reveals that the car’s previous owner used the wrong type of oil and caused internal damage, the customer will be notified via email, perhaps including a photo of the old fluid shimmering with pools of yellow metal. “From there, it’s their call,” Swider says. “We’ll ask: ‘Do you want us to handle it?’ Some of these guys can fix some things themselves, so they might want to.”

Agency over those decisions also helps keep customers in charge of their budget, which is a factor for most people. Client advisor Dave Hutchison, a longtime Ragtops & Roadsters employee since the early Engard days, notes how the shop’s customers have changed over the years. “Whereas years ago we were dealing more with a lot of full restorations from clients with high discretionary income, these days it’s a lot of second- or third-generation owners looking to keep family cars alive and driving.”

Upstairs, where the paint and trim departments live, more treasures abound. A rotisserie showcases a bare ’61 Jaguar Mark II at uncommon angles. One tech sands the wing of a ’39 Packard, aiming for a perfect texture onto which paint can bond. One of the newest staff members, by far the youngest on site, is focused on the intricate work of assembling a 1964 Lincoln Continental interior. In the back of the shop I spot a lovely Pontiac Firebird Formula 400, which I’m told belongs to a schoolteacher.

Beyond the digital check-ins afforded by Shopmonkey, customers are invited to come by the shop to see their car’s progress. And who wouldn’t love to browse the rest of the place while they’re at it? Walking around the Pollock Works (or the Perkasie shop, for that matter) is like visiting old-car heaven.

For customer Steven Sheronas, these shop visits are especially enjoyable. He loves seeing all the wonderful metal scattered about. But more than that, he feels particular gratitude to Ragtops & Roadsters’ new owners, who have completely overhauled his 1967 Chevrolet Camaro RS convertible at no additional cost to him.

Sheronas brought his prized Camaro into Ragtops & Roadsters in 2019, prior to the ownership change. The restoration, he says, spun out of control to the tune of twice his modest budget, and he wasn’t pleased with the direction and quality of the work. When Aust and Swider saw an opportunity to win back Sheronas’ business, they decided to take over the project on a full-warranty basis.

Displayed on Swider’s office TV I saw the number of labor hours the Camaro has since received. At a shop rate of $135 per hour, the total comes to about $140,000 alone, leaving aside parts. The work has included an LS3 crate V-8, FiTech injection, new wiring, a repaired convertible top, new fuel system components, and a Currie rear end.

“The thing that really impressed me is how Jeff and Sylvaine made the decision to invest so much time, money, and goodwill into getting the project done the way I wanted it from the get-go,” says Sheronas. “They went through the whole car with a fine-toothed comb, and I didn’t pay a cent more. It’s a testament to the kind of people they are and the kind of business they want to run.” Ragtops & Roadsters has since taken on four other warranty projects.

Three years into its new era, the business is as busy as ever. Aust and Swider may be new to the restoration world, but they’re quick studies, and their outsider perspectives seem to be paying off. “We are doing this for history, preservation, and enjoyment,” Aust says. “It is about passion—ours and the customer’s.” In a nutshell, Ragtops & Roadsters is in good hands.

An Allen Syncrograph distributor analysis tool, last overhauled in 1973.Thom Carroll

This 1951 Nash Rambler was acquired as an extremely rusted barn find.Thom Carroll

Stephen Malen reupholsters a door panel from a 1964 Lincoln Continental.Thom Carroll

Paul Wolfrey examines the wiring

system of this Pontiac Firebird Formula 400.Thom Carroll

Looks like a cool place with nice, caring people…too bad all shops aren’t like it.

When you love what you do for a living, you’ll never work a day in your life.

Vraiment formidable!

Dommage one la voir pas une voiture francaise..

In the early ‘00, I had the pleasure of working with Mike Engard and his band of mechanical merrymen on a restoro-mod I thought would someday become my daily driver. I purchased a ‘77 Jag XJ6 coupe from CA and had it shipped east. Mike helped me find a late model LT1 out of a wrecked police cruiser and we did a power train exchange while modifying some gearing to fully experience the LT1-1’s grunt. Mike and his team did such a great job I decided it was too nice to use as a daily driver. The wife was none to pleased! Mike, good luck on your next phase of life, and to the new owners, I hope to work with you at some time in the future when time and $ allows.

That’s a very cool looking shop. Love the cars I see there.

I recently purchased a 71 hemi orange Roadrunner that was restored at Polack Motors between 2010 and 2012, The car hasn’t been driven much since them and is still very nice. The owner at that time wanted some standard upgrades made to it including console, bucket seats from bench seat, an air grabber hood, a Magnum Force suspension system, and an aftermarket AC system. Other than the aftermarket parts the replacement upgrades are options one might have selected when ordering. I’m not a fan of the Magnum Force suspension and I’m in the process of putting it back to stock,

Was one of the first clients to have a complete frame off restoration starting in 1993 on my 1961 triumph tr3. It was a fantastic experience and won many car shows. I kept the car until 2012 when Icouldn;t get out of it anymore. Wish I still had it. Great job Mike & Dave

I also had an issue with one of the repairs done on my vehicle just prior to current ownership. Once the problem was located, it was gracefully redone by the new owners and within the time frame needed to get it to my event in Kentucky.

This just makes my stomach hurt.

I guess if you wanted to write an article that would lay bear the soul-crushing economics of the collector car hobby, this is as good as any.

I have loved these beautiful machines my whole life, but they are truly money potshots and the whole “restoration“ industry is built on the boyhood dreams of middle aged men, drawing them in to spending ridiculous amounts of money on things that are worth $.50 or less on the dollar the day they (finally) take them home.

I am down to one classic and reading this just makes me want to finally let it go.

Not every investment pays dividends in dollars. We spend our money on things that make us happy. A nice meal at a fine restaurant, a ticket to a sporting event, a charitable contribution, a vintage vehicle. Money well spent.

Yep, that’s the standard cognitive dissonance.

We also lie to ourselves about the true cost of these irrational “wants” (I’ve been as guilty as anyone over the years). For example, in this article 1990.2 hrs at $135/hr becomes “about $140k”.

“the number of labor hours the Camaro has since received: 1990.2. At a shop rate of $135 per hour, that’s about $140,000 alone”

FWIW 1990×135= 268,677

That’s my error, I put down the wrong labor hours and didn’t check the math in my notes. Story has been updated.

What a well presented and readable article. Some of the best content from this media source all year. Thank you.

Wow, thanks 964! Much appreciated and thank you for reading.

A really nice read about a place and people that actually delivers on promises. Better yet that it managed by a woman as, from my own experience, they are often more details-oriented than most of their (far-from-incompetent) male counterparts. I too noticed no French cars receiving work, but then having owned 3 of them, although they were all marvelous when they were working, never again as I simply do not have the patience to deal with their continuous appetite for failure at the worst possible times. I wish this company continued success,

Wow a shop of skilled craftspersons that isn’t flogged for quotas or micromanaged into misery, and air conditioned to boot! It seems like such a straight forward mindset to keep customers, techs and management happy but so many shops get it wrong. May Ragtops and Roadsters enjoy continued success for decades to come, while serving as a working example of an ideal shop model.

Boy, do I hope it has complete changed from previous.

Simply…they were extreme thief’s…not “high priced” but thief’s. That is a common frustration expressed by many of us in the clubs here. Yup, loved their sponsorship…but to a person:”Never again”

Your write up advertisement would need to reflect an amazing change. You say Dave Hutchinson….who used to be their intake and trailer in salesman getting work in the door…and only seen after extending his regrets and apologies. Otherwise….can a Tiger change its stripes?

I was pleased to see my 1973 MGB GTIII in Damask Red (“Elliott”) peeking around the right corner of a picture from the lower level garage. Very clear from the comments that certainly SOME of your experience is going to be a feature (bug) of what you bring to the experience. Can it be expensive to maintain a classic car? Sure! Can you figure out reasonable and reliable ways to turn your own wrench and save some of that? Also yes.

I’ve had very solid and positive experiences at R&R. I bought my MGB 7 years ago now from Bring-a-Trailer, and Haggerty has been my insurer ever since. R&R helped me sort out some key things that were outside my expertise when I first bought the car, and just this year, having saved up some money over the last 7 years did several more things outside my skill set. I worked with the Engard brothers at first, and now with the new owners. Both experiences will bring me back again where my skill set can’t match.

Overall, if you’re ever in the area, be sure to call ahead & drop in! It’s a wonderful facility, and staffed by great people.

I have a car with their Pottstown PA location now. They are 100% transparent and always accommodating, even when I show up unannounced. This is the mark of a truly professional shop that maintains accountability and has NOTHING to hide.