True tales of a roadside diagnosis by phone

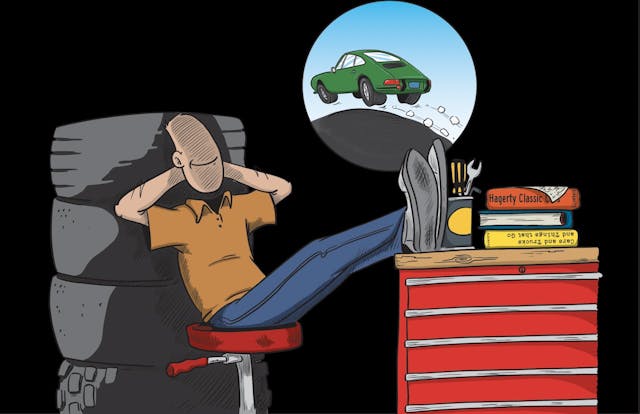

Like many things, being in a relationship with a classic car can be a double-edged sword. Moments of joy are sometimes interrupted by breakdowns, literally, and the bloom falls off the rose for a bit. Having spent decades nursing marginal machines onto and off of the road, again and again, I have come to accept that the risk is much less than the reward. Nonetheless, we all expose ourselves to mechanical breakdowns when we take our decades-old cars out for a spin.

This exposure led me to be on the receiving end of a call the other Saturday from a friend whose air-cooled Porsche 911 had left him stranded on the side the road. Now, this friend is a very intelligent gentleman, with great optimism about fixing problems, but his familiarity with car repair is only recently emerging. So, we began the dance of a road-side diagnosis by phone, and I guided him as best I could, mimicking my late father’s best bedside manner.

“Describe the symptoms—what happened right before it died?” I implored my friend.

“I was driving along and heard a loud ‘pop’ and then the engine went dead,” said Steve.

Step One in diagnosing a dead car on the side of the road is its behavior right before the incident. Fuel delivery failures generally are less dramatic, with lots of associated wheezing and limping, as dying not with a bang but a whimper. They show up as surging and poor running that quickly gets worse, and then become terminal. Ignition problems, on the other hand, typically start as a misfire that may last for the rest of the trip, or as immediate mortality with little warning.

“How long had you been driving? Was the car warmed up yet? Was there any surging or weakness before the ‘pop’ occurred?” I asked.

“No, it just popped and went dead. I’d been driving for about 20 minutes” he replied. This led me away from a fuel pump failure (sometimes common on cars that sit a lot—the pumps themselves and the associated relays, etc.).

“Are you in a safe spot?” I asked, paraphrasing the first line of most 9-1-1 call operator’s scripts. The good news was that this was a ’71 911 with manual everything, so having the engine lose life does not cause lots of other “maneuverability” problems, and my friend was able to easily coast to a safe spot on a side street.

“I’ve called a tow truck,” Steve said, which could have ended our need for a discussion right then and there, but I don’t often back down from an automotive challenge.

“Let’s try to diagnose it while you’re waiting,” I said, since I presumed that he had nothing better to do at the moment. Captive audiences are the best.

“Sure, I’m game” came the reply. And so we began.

Engines need three things to start: Fuel, spark, and compression created by at least about 60 revs per minute of rotation (whether it is provided by a starter, a roll-start, or the explosion of a gun shell in one cylinder—see Coffman starter—an engine does not care). Compression failures rarely happen to all cylinders at once, so roadside failures of this sort seldom occur. “Does the engine crank over?”

“Yes,” Steve responded. So, the battery has charge and the pistons should be making compression.

“Crank the engine for ten seconds with the throttle wide open,” came my first instruction, invoking my 10-second rule for cranking dead engines; starters get real hot real fast with dead-cranking. “Then stick your nose right up to the tail pipe and tell me if you smell gas.” No spark will mean raw gas will be sent out the exhaust system, unburnt, and will be easy to detect with a good sniffer. No fuel will mean the exhaust smells “dry.” This applies to carbureted and fuel-injected engines alike. The wide open throttle moves the most air to get any unburnt gases to the tailpipe with the least cranking.

I heard the phone being tossed onto the seat, some muffled rustling, and then the sweet sound of an air-cooled six-cylinder being cranked over at brisk rpm, but no combustion. More rustling and Steve came back on the line. “I smell gas at the tailpipe,” he reported. “Is that good?”

“Fuel pump and carbs are working,” I said. “It’s probably your ignition.” We had compression, we had fuel, and the immediate stopping of the engine was confirming where we were going with our diagnosis. The battery was good, so the ignition system should be getting juice as well. Now it was time to look at the hardware that makes and delivers the missing sparks. I instructed him to open his engine lid and look for the ignition distributor.

“What’s it look like?” came the reply. So began a game of Clue using verbal instructions. My buddy was a smart guy. We could do this. Like a movie scene where a surgeon guides a layperson in removing a burst appendix over a phone line, we dug in.

“Look for a black thingy on the engine that has seven black wires coming out of it.”

“Like an octopus?” he asked.

“Yes, an irregular octopus,” I said. “A septopus.”

“Hmm. I think I found it.”

“Six black wires in a circle and one in the middle?”

“Yessir! Now grab the head of the septopus firmly and wiggle it.” Words I had never spoken in my 60 years of language. “Is it loose, or pretty solid?” This was the beginning of finding any problems with the distributor. If wires are not connected or parts are loose, issues arise.

“Solid,” came his reply. So the distributor cap itself was in place and probably not the culprit. I contemplated having him pop off the cap to go deeper into the rotor button and points, which are prone to problems, especially with modern off-shore parts. However, I remembered the golden rule of diagnostics: Look for the simple problems first. So, I kept it simple.

“Find the septopus’s center wire and follow it to a small, black soup can thingy somewhere on the engine,” I said. Losing one cylinder from one bad spark plug wire would have kept him running on five cylinders, but he had a total failure of all cylinders at once, and we had already determined that he had fuel flow, so I suspected it might be the ignition coil.

“I found it, the small soup can thing is on the cooling fan shroud.”

“Is the soup can hot?” I asked—one symptom of a fried coil.

“No, warm but not hot.”

“Press the black wire deeper into the coil. Is it loose? Check the other end as well.” Again, all cylinders dying at once meant that all the sparking was not getting to any of the plugs.

“Both are good.”

I was running out of cards to play but asked the next question with expectation. “There will be two small wires going to either side of the soup can, like an old dry-cell battery. Do you see these?” Luckily Steve is over 40 years old and knows what a dry-cell battery looks like.

“Yes,” he said.

“How do they look? Tug on them to make sure they are connected.”

“One is connected, the other one is loose.”

Bingo! Houston, we found our problem. A previous mechanic or owner had used a crimp connection on the wire’s terminal end, without adding soldering and covering it with heat-shrink tubing. For a mission-critical wire such as this, and one that lives in an open engine bay with moisture and dirt, this was unforgiveable.

“Do you have any tools on you, like pliers?”

“This is the one time I left the house without my toolkit,” Steve said. “I was just going for a 30-minute drive.”

“Well, that’s your problem. You can stuff the wire back into the crimp connector, but it may just wiggle loose again. It needs to be soldered and covered with heat shrink. Maybe the tow truck driver can help you when he arrives.”

And that is just what happened. A simple re-insertion of the wire and a quick crimp with the tow driver’s pliers got my friend back on the road. The tow was not consummated, and a crisis was avoided.

Now my friend is watching YouTube videos on how to solder so he can fix the wire’s end correctly, himself. Welcome to the ‘fix it yourself’ club, Steve. Bask in the accomplishment of reversing a seemingly desperate situation with a little Yankee know-how. But keep that Hagerty Roadside number nearby. It sounds like your fuel pump is whining a little too loudly…

***

Check out the Hagerty Media homepage so you don’t miss a single story, or better yet, bookmark it. To get our best stories delivered right to your inbox, subscribe to our newsletters.

I am not sure how many cars I have fixed over the phone. Having worked Customer Service for a parts company I have solved many an issue for many self proclaimed experts.

So many call in with the same issues and same things to say. Back in the 5.0 Mustang era we had a number of cams that depending on if it was going into a 302 or a 351W the firing order will change. People will not believe you and scream they have the wrong cam. Once you finally talk them into moving the firing order and it fired up with no issue you would get a thank you some times.

Another was the Mustang has a cable for the clutch with a nylon adjuster. So many would put a heavy clutch in and it would break the adjuster. The clutch would then slip and fail soon after. As soon as they started talking you know what happen.

I had a GM Tech that ripped me up one side and down the other. His stroker crank would not fit the block. He swore I sent the wrong crank. I asked did you clearance the block and get the new Oil Pan. He said I don’t have to do that!

Well I asked him if he increased the stroke where is all that going to go? I advised I am sure he was a great GM tech but this is something GM never made. Once I got his attention we got him the needed parts and on the road,

So many miss measure bolt patterns and or break in cams.

I had a guy say he had a defective cam. I asked how he broke it in. We took it up on the 4 lane and hit a lick.

Same for the guys who claim Cams had a soft lobe. Most times they have guide issues or geometry issues on the rockers. Cams are forged units made of the same metal. Often people would reuse a flat tappet lifers too.

Fixing things over the phone is a skill beyond working on a car. Some people are great and let you help them some just don’t want to accept they made a mistake.

One of the biggest problems I have encountered with remote diagnosis is that even folks with minimal mechanical knowledge will attempt to diagnose the problem themselves, then feed you symptoms that align with their diagnosis (ignoring non-conforming symptoms). Most times I end up with bring it to me or bring me to it.

I worked for GM Technical assistance for a lot of years. That was something I told the guys I talked to and what I told the people who had problems with their cars. Don’t diagnose it, tell me what it does, not what you think caused it.

I do hope this becomes a regular style column, though not at the sake of your friends misfortune. Reminds me of my weekly automotive mysteries with Click and Clack!

We had an older very used 93 Ford 460 in a Motorhome that kept dying on the road but would restart later. I called my friends at work, all engineers, to help diagnose the problem. It was like a scene in Apollo 13 where a team was helping the astronauts out in space. 2000 miles from home, in a desolate place with a decaying animal next to us and six kids, we determined that it indeed was a fuel delivery issue. It was fuel injected with a recirculating system, so we tried pinching off the return line to up the pressure in case it was a bad regulator, which seemed to work. Long story short, it was a weak fuel pump that would work until the fuel in the tank got too hot and/or the altitude was too high. The cooler the fuel, the longer it would run. It made for spooky driving on mountain passes. I carried an arsenal of tools with me, and a fuel pump, because it sounded loud to me and I had no time to replace it before we left. The underside had some apparent mods and the huge tank would be hard to drop, so I got a portable reciprocating saw and cut a hole in the floor and replaced the pump and all was well. There were other stories from that memorable 5000 mile trip, but that was the most relevant one.

I have found one of the biggest problems helping people on the phone is vocabulary. I’ll have to remember “Pentapus” next time. One of the most common things I hear “It doesn’t crank over”. So, starter or battery? “No, it spins okay”. Hmmm.

On the receiving end of phone help – I had a favorite parts guy that I dealt with as he moved through three dealerships. If I had narrowed a problem down to A or B, he would check his computer inventory and tell me something like “I have sold 2 of A and 25 of B, so I’d order B and the car would get fixed with one small gamble.

Funny article! I did something like this in person. I had (emphasize HAD) a classic Mini, and the coil wire was always coming off, with the expected results. One day I was with my husband coming home from a big car event a couple of hundred miles away. We had radios to communicate, as we were in two cars. He called me to say he was on the side of the road because the engine just quit in his Porsche 356 SC. I pulled back around in my 986 S Boxster–what I bought when I got rid of the troublesome Mini–and he already had the engine lid open and was just starting to investigate. I saw it immediately–that loose coil wire! After half a dozen times on the roadside with the Mini, my eyes were quick to spot such an anomaly. Two minutes with a tool and we were on the road again. Hubby was impressed! (So was I.)

Hey that’s a pretty good story and solid troubleshooting advice. Well done!

This article was a revelation. I bought my first Hot Rod magazine in 1967 and I’ve been working on cars ever since. Not once did I read or hear about anyone suggesting an exhaust pipe smell test. I wondered if I was the only one on earth that would promote such behavior. I feel much saner now.

Soldering and heatshrinking a crimp connecter isn’t recommended in the electronics world, at least in the part I worked in (marine). The solder tends to make the wire brittle and break, been there chased that A properly crimped connector is just as good as a well done solder connector.

Our son once was driving his ’71 SuperBeetle on the road–when the engine quit–dead quit.

He called a tow truck–then his mother. I was at work. But, I could not have bested my wife’s response to our son’s call. “Did the car sputter and die?”, she asked, “or did it outright die?” “It just outright died!” he replied. “Go to the engine compartment and check the two wires to the coil.” she instructed. “One of them has fallen off.” Sure enough–that was the case. The tow truck came and the bill paid–but the son drove his Beetle home–after reattaching the wire. How’s that for Mama Hen who knew her stuff. I could not have done better! We placed her on the proverbial pedestal!