Pontiac’s stripped-down ’63 Tempest was Super (Duty) quick

Before the 1964 GTO burned rubber in Anytown, USA, Pontiac’s full-size Catalinas—powered by the ferocious 421-cubic-inch Super Duty V-8—were burning up drag strips and taking down competitors in early-’60s Super Stock battles.

And suddenly, the Super Duty was super done. On January 24, 1963, Pontiac zone managers received a note announcing the immediate cancellation of Super Duty engines and instructing them to “advise dealers who normally handle this type of business.” The abrupt notice came in advance of a General Motors ban on all factory-supported racing.

By then, success in drag racing and NASCAR had revved up Pontiac’s image and helped drive the Division to #3 in new car sales. The racing ban might not have hurt the overall numbers, but it did cut short production of Pontiac’s most formidable (and oddest) factory drag racer, the 1963 Super Duty Tempest.

Smaller is Lighter

Pontiac Engineering had taken out as much weight as possible from the 1962–63 Super Duty Catalina drag cars, using aluminum for front sheetmetal and other parts, which also improved weight distribution. For 1963, drilling holes in the frames was a precarious step that earned the big Cat the “Swiss cheese” nickname. But big is big, and the Dodges and Plymouths had the advantage of smaller, lighter bodies.

Inspired by racers, Pontiac went radical.

In 1962, Mickey Thompson and the Royal Pontiac dealership in Royal Oak, Michigan, both put Super Duty 421s into modified compact Tempests to compete in the NHRA’s Factory Experimental class. Pontiac liked the idea enough to build two 1963 Super Duty Tempest coupe prototypes and a dozen production models (six Tempest LeMans coupes and six Tempest wagons).

Five of the 14 have been found, and three have been restored, including the coupe originally campaigned by George DeLorean, brother of Pontiac’s then-chief engineer John DeLorean. Owned today by Irwin Kroiz, a collector of rare Super Stockers and other race cars, the car retains its original four-speed transaxle, a rare piece central to the car’s oddball nature.

“I followed these cars when they ran in the ’60s,” Kroiz says. “It’s what I grew up with. There were at least six tracks within driving distance from where I lived, just outside Philadelphia.”

DeLorean’s Baby

The Tempest was one of GM’s new-for-1961 Y-body compacts, which also included the Buick Special and Oldsmobile F-85. With the Tempest, John DeLorean sought better weight distribution and improved handling by adopting the transaxle and independent rear suspension from the smaller, rear-engine Chevy Corvair.

Truly odd was the Tempest’s three-quarter-inch flexible-steel driveshaft, which connected the crankshaft in Pontiac’s big four-cylinder engine (essentially half of a 389-cu-in V-8) to the rear-mounted transaxle, running in a curved “torque tube.” The setup allowed a flat floor inside the car.

The updated 1963 model offered Pontiac’s 326 V-8 (actually 336 cubic inches in 1963) as an option. Since all Pontiac V-8 engine blocks were the same size, the Super Duty 421 was a drop-in.

Weird Science

While the Thompson and Royal Pontiac Tempests used a conventional drivetrain and solid rear axle, Pontiac made the radical choice to keep the transaxle and independent rear suspension. The unusual driveshaft was retained, since it needed to transmit only engine torque, not output from a transmission.

Pontiac built a four-speed version of the Tempest’s two-speed automatic transmission, essentially grafting on a second planetary unit in an aluminum case behind the transaxle. Called PowerShift, the new four-speed transmission replaced the torque converter with a hydraulic clutch on the tail end. The clutch was used to engage first and reverse, and the driver manually shifted into second through fourth. A rear-mounted starter engaged a ring gear on the flywheel.

Torque from the driveshaft flowed via splined input shaft through the front transmission case, final drive, and rear transmission case to the flywheel. From the clutch, it flowed forward via concentric shaft through the two transmission units, and then back through another shaft to the pinion gear.

The rear differential was modified to function like a spool, locking the axle shafts, says Tom Schlauch, a collector known in the hobby for his Ram Air V-powered Pontiacs. In 1963, Schlauch worked with Pontiac drag racer Jess Tyree and then in 1964 built and raced a Super Duty LeMans clone. A half-century later, Schlauch provided technical advice on the full restoration of George DeLorean’s Super Duty LeMans.

From the Assembly Line (sort of)

The production Super Duty Tempests were built as rollers at the Pontiac Assembly Plant in Pontiac, Michigan, equipped with the aluminum front end but without a radio, heater, sound deadener, or spare tire. All were painted Cameo Ivory with a blue bucket-seat interior.

The cars then went to Pontiac Engineering for installation of the Super Duty 421 engine, PowerShift transaxle, and other modifications. Bumpers were steel, but acid-dipped for lightness. All body glass, including the windshield, was replaced with Plexiglas. The hood scoop was a Ford part, coincidentally from its Super Duty truck line.

To make room for the longer transmission, the fuel tank was cut in half and used to make a smaller one. A hole in the trunk floor, covered by a black sheetmetal box, provided access to the ring and pinion. The battery was moved to the trunk.

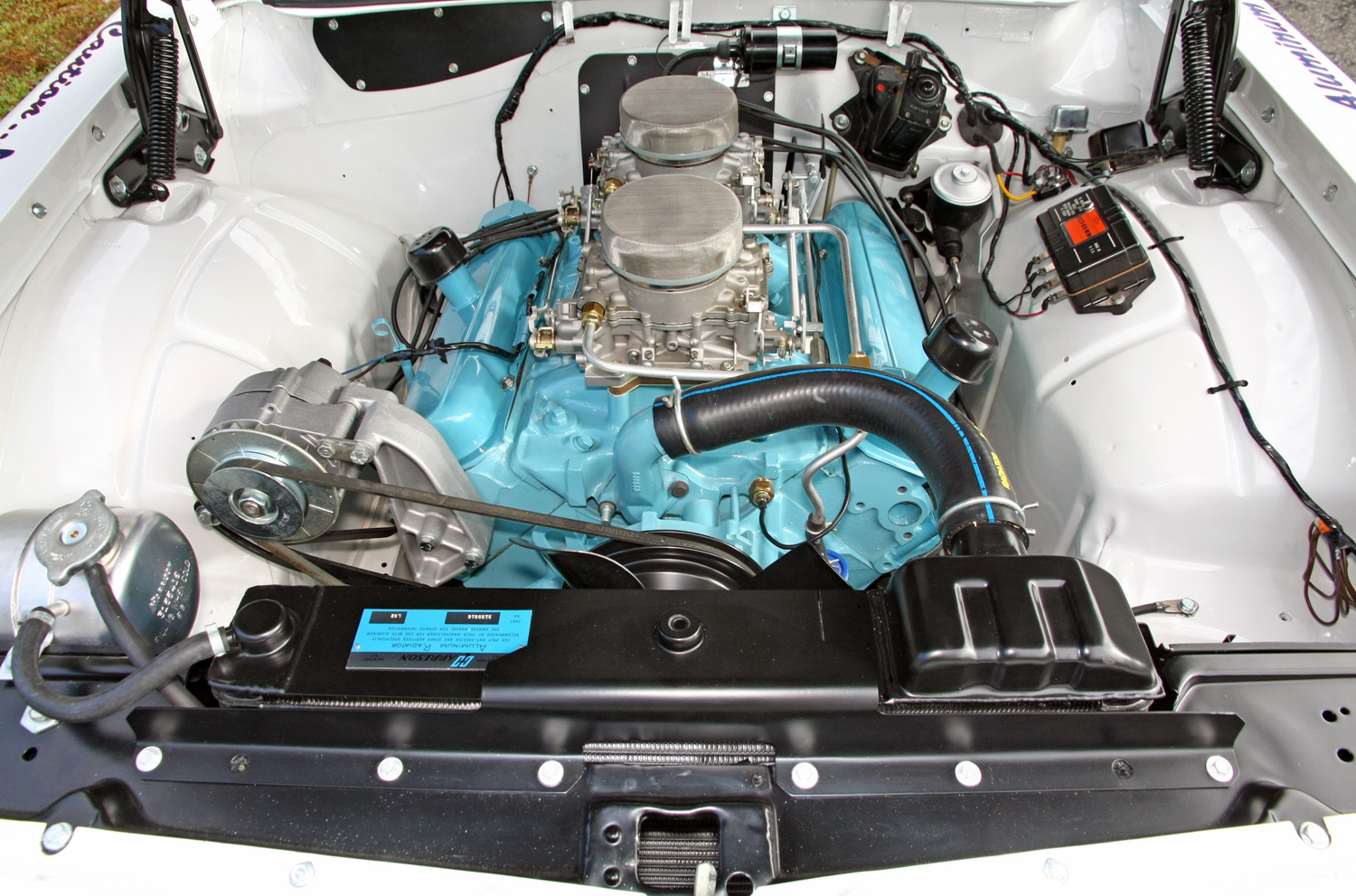

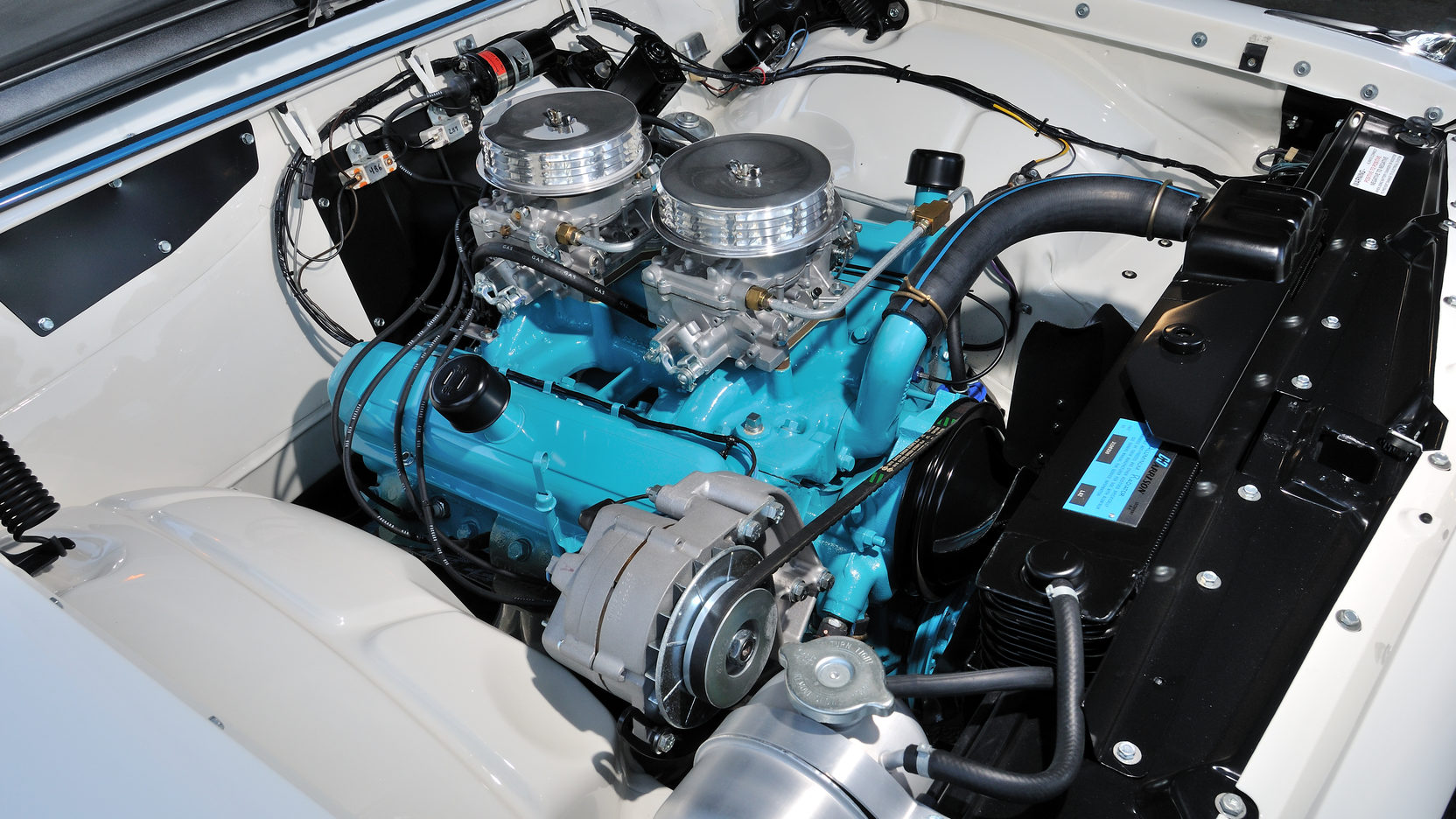

With 12:1 compression, the dual-quad Super Duty 421 was rated at 405 horsepower. The cars were good for low 12-second passes at over 115 mph. Bill Shrewsberry, driving Thompson’s coupe, won the A/FX class at the 1963 NHRA Winternationals with a 12.04-second @ 116.29 mph run. At the end of the year, Arlen Vanke’s Tempest held the A/FX record with an 11.89 @ 123.11 mph pass.

Transaxle Troubles

Renowned Pontiac racer and collector Bill Blair, who campaigned and collected Super Duty Catalinas, raced one of the prototype Tempest coupes and also a wagon. He recalls that the PowerShift transaxle worked well, when it worked. The small 7.5-inch ring and pinion was a weak point.

“You’d make 10 or 12 runs, and it would start howling, and then you knew it was time to rebuild,” Blair recalls. “You’d open it up and see all the teeth on the ring gear laid over.”

Another drawback was the 3.90 ratio, the biggest the unit could handle. Blair says the Super Duty 421 worked best with a 4.11 gear. He ultimately replaced the transaxle and independent rear with a conventional rear axle from a ’61 Pontiac.

Other Super Duty Tempest racers adopted similar setups, but George DeLorean’s car kept the transaxle. He and Roger Schmidt campaigned the coupe in the Midwest in A/Modified Production, with sponsorship from Wynn Engineering. The car survived in mostly original condition. The one surviving wagon, which was restored by Scott Tiemann’s Supercar Specialties shop in Portland, Michigan, in 1999, also has its PowerShift transaxle.

Tiemann confirms that, before Kroiz bought the George DeLorean LeMans at Mecum’s Indianapolis auction in 2010, it had received a major freshening at his shop. The wagon, which like the coupe was also part of Dana Mecum’s personal collection, sold at the same auction.

Tiemann also restored the coupe originally raced by Stan Antlocer, which before the restoration had sold on eBay in 2008 for nearly a quarter-million dollars.

The Restoration

For the George DeLorean LeMans, Kroiz commissioned a full rotisserie restoration by Billy Bob’s Fast Cars in Jackson, New Jersey, run by partners Bob Caruso and Bob Russo. The year-and-a-half job was finished in April 2017.

“This car was raced but not abused,” Russo says. “All the parts were there, but there was some incorrect hardware under the hood.”

Russo consulted with Schlauch for technical accuracy. Correct hardware was sourced from standard Tempests found in Desert Valley Auto Parts in Arizona.

The car’s original 421 Super Duty engine and transaxle were rebuilt, with one of the shop’s techs, Greg Roberts, doing much of the mechanical work. The original block, heads, intake, and forged crank and rods remained, but new aluminum-alloy pistons had to be custom-made. The transaxle and George DeLorean’s custom tri-y headers required some special machine work, done by Jeff Buck.

“The interior was all original, even the headliner,” Russo says. “Just a small section of piping on one seat had to be repaired. We took out all the Plexiglas and polished it. That was a painstaking and long job. We repaired an old set of the authentic pie-crust slicks, but just for rolling on and off the show field.”

Finally, Kroiz had the car lettered by Philadelphia-area pinstriping artist Ed Foody.

If not for GM’s racing ban, perhaps Pontiac would have built enough Super Duty Tempests to qualify for Super Stock. Even so, the small group of oddball Ponchos made drag racing history.

Not forgetting possibly the fastest (top end) factory-stock — if you grant that the dozen or so SuperDuty or “Powershift” Tempests were a production run — car in the world at that time, the Goldsmith/Nichels race #50 car. It won the USAC Daytona Challenge Cup 250 versus Pedro Rodriguez in a Ferrari GTO and AJ Foyt in a similarly limited production Corvette Gran Sport in 1963, and going away! Even TIME Magazine did a feature in the ‘Sport’ columns on it, the car ‘with the aerodynamics of a 2X4″,’ they said, humbling the sports car big bores. It must have been, because as the story goes, a prestige manufacturer from Stuttgart made Nichels an offer he couldn’t refuse, and the Tempest was exported into oblivion!

awsume story i am a retired GM master mechanic and a life long Pontiac fan we used to put 389 Pontiacs in 55 & 57 chevs also in my 56 starchief convetible with pontiac selector style manual trans. still have a 66 GTO with 4 engines Thanks for great story

i do not know what you want me to comment

Who has wiring harness for 1963 Tempest??? tail lights, under dash, engine compartment.