Fifty years ago, the government decided to clean up car exhaust. It’s still at it.

Even as he sat down to sign the most sweeping environmental protection law in the nation’s history, Richard Nixon couldn’t help taking a swipe at one of his enemies. Notably absent from the signing ceremony for the landmark 1970 Clean Air Act was Edmund Muskie, the Maine Democrat who had steered “that Muskie bill” through the Senate and who was expected to run for president against Nixon in 1972. Muskie said he hadn’t been told the bill would be signed that day.

Though the political intrigues were soon forgotten, the revisions to Title 42, Chapter 85 of the United States Code are still making an impact 50 years later. The law Nixon signed on December 31, 1970, forever changed the vehicles that Americans bought and drove, and it continues to do so today. It gave the newly created Environmental Protection Agency the regulatory bludgeon it needed to make cleaner air actually happen. And where it came to automobiles, the EPA effectively handed that bludgeon to a small group of engineers and regulators in the smoggy suburbs of Los Angeles. If you own any car built and certified for sale in the United States after 1975, it has their fingerprints all over it. “I was kind of astonished at the power that I had,” recalls Steve Albu, who spent 31 years helping set emissions standards for the California Air Resources Board (CARB), a state regulatory body that ended up having an enormous role in setting the course of the nation’s auto emissions laws. “I didn’t really understand what I was getting into.”

The “goop” in the air

The U.S. Weather Bureau credited the city of Indianapolis with popularizing the word smog, a contraction of the words smoke and fog, when it adopted the term in 1926 as an official weather condition. However, it was already in wide use in cities ranging from Chicago to Birmingham, Alabama. Civic leaders in New York City worried about the health of the smog-shrouded trees in Central Park, while enterprising haberdashers in St. Louis marketed smog-proof hats. In 1929, The Pittsburgh Press made front-page hay for months with a campaign to expose gross polluters in the city. But soon the Great Depression set in, and there were greater predicaments to deal with in a world that was also lurching toward war.

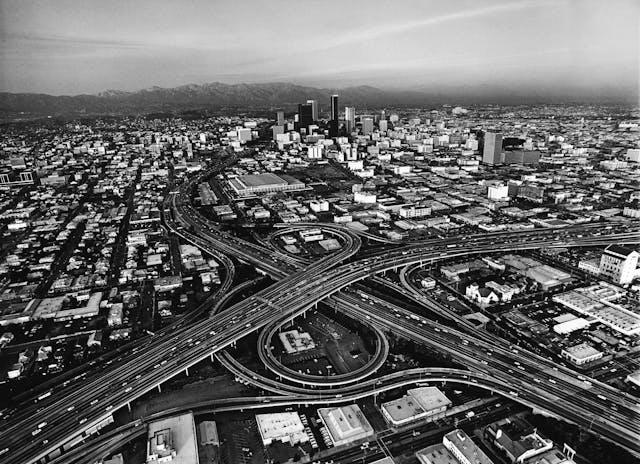

Out west in Los Angeles, a city hemmed in by mountains that prevent winds from blowing away pollutants, the first “smog day” was in summer 1943, when visibility dropped to three blocks and hospital emergency rooms filled with people suffering burning eyes and lungs. The government called it a “gas attack” and blamed it on a war plant that made butadiene for the production of synthetic rubber. The plant was shut, briefly, but the gray haze endured, an ominous harbinger of the days and years that lay ahead for the City of Angels.

In nearby Pasadena, at the California Institute of Technology, a Dutch-born biochemistry professor named Arie Haagen-Smit had no interest in smog. He was trying to determine why different vegetables tasted the way they did by heating them and collecting the vapors in condensers for chemical analysis. But one day in 1949 when, as he said, “the smog was thick enough to touch even a chemist’s senses,” he decided to run a couple hundred cubic feet of outside air through the process. Observing the vial of smelly brown water that resulted, Haagen-Smit decided that he wanted to know more about what he called “the goop in the air.”

Haagen-Smit knew that gasoline is a liquid chemical that is distilled from petroleum and made up largely of hydrogen and carbon joined in big molecules, hence gasoline’s scientific nickname, “hydrocarbon.” A car engine is basically a chemistry set in which the hydrocarbons in the fuel get mixed with air, which is primarily nitrogen and oxygen, and are then heated by a spark. With oxygen acting as the little homewrecker, the carbon in the fuel violently splits away from the hydrogen in favor of some new shotgun marriages. Carbon and oxygen go off together as carbon dioxide and the deadlier carbon monoxide. And nitrogen and oxygen, which live happily separate in the atmosphere, get forced together by the intense heat and pressure of the cylinder into a mutant marriage called oxides of nitrogen.

Also exiting the tailpipe is a certain amount of raw fuel that a fast-moving engine doesn’t have time to combust. Haagen-Smit concluded that the goop was the byproduct of the unburned fuel from cars (as well as refineries) mixing with oxides of nitrogen and being roasted together in the sun into a thick layer of ground-level ozone. Or smog. The discovery earned Haagen-Smit the dubious title of “The Father of Smog” and elicited little response at first. But the public’s distaste for choking air eventually swelled, as did its determination to vote in leaders willing to do something about it.

Government: Go invent your way out

The perfect storm of the 1960s, characterized by men on the moon and marchers in the streets, produced a burgeoning environmental movement. Cleveland’s Cuyahoga River caught fire in 1969 and superheated the nation’s growing concern about its environment. At the time of the first Earth Day on April 22, 1970, air and water pollution ranked high on the list of voter issues. What good was moonshot technology if it couldn’t help fix the problems on Earth? Nixon devoted a significant portion of his 1970 State of the Union to the subject, singling out the automobile as “our worst polluter of the air.”

“We shall intensify our research,” he went on, “set increasingly strict standards, and strengthen enforcement procedures—and we shall do it now.” And though it sounds strange in this era of strangled government, that’s exactly what happened. The Muskie Bill was a new kind of regulation, a strategy to force the auto industry to invent its way out of the problem of smog.

The government “saw the necessity to mandate technology that nobody knew how to do at the time,” says John German, a long-serving former EPA administrator who in retirement helped uncover the Volkswagen diesel scandal. “Car companies are risk-averse environments. They are afraid to put things into production quickly so as to limit the damage when it goes wrong. Things like catalytic converters were black magic. Most people didn’t really know how they worked.”

In the 1970 Clean Air Act, federal and state regulatory agencies could set air-quality targets that were binding. And vehicles were treated differently in the law than other polluters, notes Tom Cackette, who helped write some of the most significant auto emissions regulations during a long career at CARB. While stationary polluters such as powerplants were allowed to use off-the-shelf technology to scrub their stacks, automakers were told that if the technology didn’t exist to meet the standards, then they should go out and invent it.

“If you read Title II of the Clean Air Act,” says Cackette, “it tells the EPA to set the standards based on the best technology given lead time and cost considerations. It basically says these are technology-forcing regulations.”

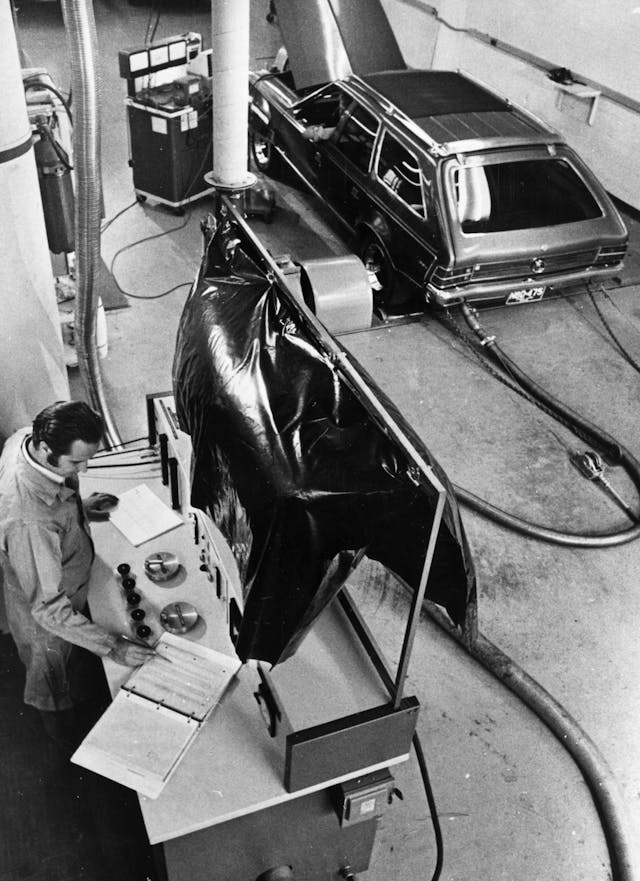

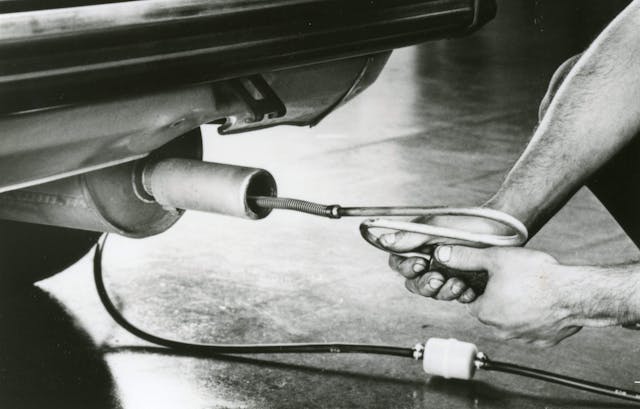

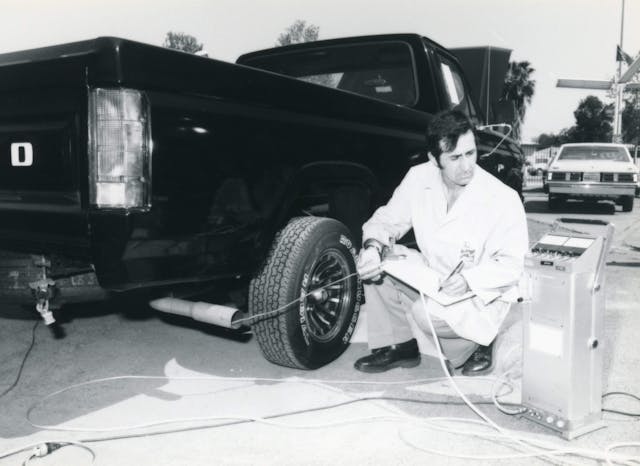

California’s role in the shaping of the modern car can’t be understated. The Los Angeles County Air Pollution Control District, established in 1947, was the first regulatory body of its kind anywhere in the nation. In 1965, state air-quality researchers were the first to start creating a system of tests to precisely measure a car’s tail-pipe emissions. That fall, they deployed seven vehicles, ranging from a 1957 Ford to a 1966 Chevy II, on a 12-mile loop (eventually shortened to 7.5 miles) around the agency’s lab, then located in downtown Los Angeles.

The goal was to mimic a normal commute. Using precise acceleration, idling, and cruise traces from five different drivers, the team developed the first composite drive cycles that could be taken inside and duplicated on dynamometers, where exhaust gases could be better captured and measured. Those first drive cycles, with names like “LA4” and “XC-15,” formed the basis for the vehicle emissions tests still used today.

By 1966, California was ready to institute a statewide vehicle emissions standard for new cars, the first such measure in the nation. It required pressurized crankcase ventilators, or the plumbing of crankcase fumes thick with hydrocarbons into the intake manifold rather than out to the atmosphere. There was no mechanism to stop California from doing this; at the time, overriding federal emissions legislation simply didn’t exist. That didn’t come until the Air Quality Act in 1967, a successor to federal laws passed in 1955 and 1964 but a still largely toothless opening salvo in the country’s coming war on smog.

In 1970, everything changed. The newly formed EPA was handed the power to set binding standards, and it deferred largely to California on vehicle emissions because the state already was leading the nation in that area. Washington was also yielding to a petition from California’s then governor, Ronald Reagan, to allow California to retain its authority to set its own emissions standards owing to its unique topography and climate conditions. The so-called “California waiver” was born, and it remains in the books (and controversial) today.

The industry’s first stumbling steps are well-known to—and well despised by—car collectors. The first set of standards attacked smog head-on, basically mandating that automakers cut hydrocarbon and oxides of nitrogen (NOx) emissions by more than 50 percent by 1975. The muscle car era died when automakers retarded the ignition to lower NOx production and retuned the carburetors to be less rich, and the carburetors grew dashpots and other barnacles to prevent sudden gusts of unburned fuel when the throttle snapped closed.

Compression ratios plummeted so temperatures and pressures inside the cylinder would be less severe and produce less NOx. Exhaust-gas recirculation (EGR), in which some exhaust gas was returned to the intake to further lower temperatures, became a thing. Because the engines now had to pass emissions tests, they were sealed up against shadetree tinkering, their carburetor adjusting screws either stripped off or hidden. Backyard speed tuners began to feel the first squeeze of the law, and their magazines railed against the new restrictions.

“Surely the government has laid on an imposing dose of garbled, D.C.-style, civil-service, fat-brain rules, directives, amendments, bulletins, acts, advisories and sub-paragraphs,” opined Car and Driver in 1972. “Much of it is unvarnished, self-defeating nonsense.” And indeed, the first emissions controls were hasty and improvised. Immediately there were problems. New cars were failing to meet the standards right off the assembly line. Government testing in the early ’70s showed that one in four new vehicles were too dirty to meet the new standards, and the failure rate increased as the miles rolled up. The industry protested that catalytic converters wouldn’t be ready by 1975 and demanded extensions. Some companies tried to tune their engines with lean-burn strategies that would save them the cost of fitting up catalysts, or that would rely on the catalysts less, and new cars began stalling out practically in front of the dealerships.

Longtime Car and Driver editor Patrick Bedard remembers visiting Detroit for a car launch around 1974 when the new Plymouth he was driving “gave a cough, a gasp, and died,” whereupon he was rear-ended. “It was one of those coffin-nosed AMC Ambassadors with a kind of projection coming out of the bumper, and WHAM! My neck hurt for six weeks after that.”

Albu, the California regulator, joined Chrysler in 1969, and by 1971, he was working in the company’s Los Angeles outpost trying to figure out why brand-new cars were failing California’s smog checks. “Calibrations were done [in Michigan] at the proving grounds,” he says. “They just took the federal calibrations and dumped more EGR into them and more retarded timing and leaned out the carburetors to try to get them to pass. Honestly, they drove like crap.”

The problem with technology-forcing regulations, says Paul Baltusis, an emissions compliance consultant who spent more than 30 years at Ford and 18 of them as the company’s onboard diagnostics technical leader, is that they force automakers to pull technology out of the oven before it’s fully baked. “CARB asks manufacturers to do something that has not been proven to be technically feasible, but you are on a timetable to put it in production and take the risk if it fails,” he says.

Even so, California and the EPA held firm on their timelines, and the first catalytic converters sprouted in vehicle exhaust pipes in 1975. The canister-like devices, still in use today in more sophisticated form, are filled with long, mesh screens composed of a type of metal that breaks apart some of the weird marriages formed by combustion. In the early “two-way” catalysts, carbon monoxide became more benign carbon dioxide, and hydrocarbons become carbon dioxide and water. Later three-way catalysts that arrived in the early 1980s also split up smog-forming NOx into harmless nitrogen and carbon dioxide.

Some car companies rode out the regulatory earthquake better than others. “Around 1977, when NOx standards tightened in California, the cars got really bad, and I complained bitterly about it,” says Albu, then still at Chrysler. The Los Angeles office pushed the engineers back in Michigan for improved calibrations, but “one guy said in exasperation, ‘California—land of fruits and nuts, who cares?’” Eventually Albu received permission to create unique calibrations for California after renting some Ford and GM vehicles and demonstrating how much better Chrysler’s competitors were at meeting the new regulations. “I drove the GM cars, and it was night and day. GM was involved extensively in inventing the catalytic converter, and they were doing was using it to its maximum extent with their calibrations right out of the gate. Ford and especially Chrysler had some catching up to do.”

The catalytic converter is a highly effective pollution-control device, but it’s sensitive to overheating without the exact fuel metering of fuel injection or the sophisticated computer controls we have today. “Precise air-fuel control is so important,” says former EPA administrator German. “Imagine these poor engineers trying to do this in the mid-’70s. They had huge computer rooms filled with tape machines running day and night to analyze this stuff.”

CARB’s Cackette recalls the struggles of the automakers. “I remember one unnamed company,” he says. “The first time one of their cars passed, my staff went out and bought them a cake to celebrate, because it was almost a known that they were going to fail.”

Car and Driver’s Bedard, whose first job was also at Chrysler and also in its emissions lab, was a young speed-crazed engineer haplessly standing for hours next to cars being tested on dynos, watching “the ink-slinger recorder zigzagging across paper.” After he moved over to auto journalism, he recalls the sinking feeling as regulations in the 1970s drained the fun out of cars. “I remember those times vividly,” he says. “There was real gloom around the magazine at what was happening to cars and the whole car-enthusiast world.”

The mountains begin to reappear

But the measures were working, especially in California where the air quality was the worst and the regulations were the toughest. Tailpipe emissions of hydrocarbons and NOx, the two main pollutants contributing to smog, had plummeted from an average of 14 grams per mile in 1965-model cars to 3 grams per mile by 1975. By 1981, as fuel injection, three-way catalytic converters, oxygen sensors, and early computers started coming online, the figure had dropped to 1.5 grams per mile. The mountains were slowly reappearing from the goop.

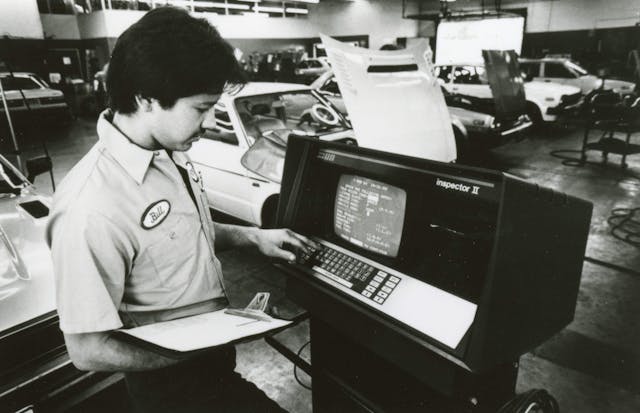

By then, Albu had taken a job working for CARB, its rulemaking board a group of 14 citizens appointed by the governor from across the state’s legal, political, and professional spectrum. The board took data generated by its staff of roughly 30 laboratory researchers and then set the standards for the state—and ultimately the nation, as California’s rules would typically be adopted by the EPA three to four years later. Albu says the EPA deferred to California because the Golden State was pushing hardest for cleaner cars and had built a solid team of engineers and scientists at a new laboratory in the suburb of El Monte, about 20 minutes east of downtown Los Angeles.

“I worked with Caltech graduates, Stanford graduates, people from back east,” he says. “From my Chrysler days, I knew the guys at Carter and Holley fuel systems and all the reps from the catalyst suppliers like Corning, Engelhard, and Johnson Matthey. They showed us their most advanced stuff because they were interested in selling their new technologies.”

Albu and his colleagues were working on a host of programs in the 1980s to further reduce smog, including ratcheting down tailpipe hydrocarbons and NOx standards, addressing diesel, motorcycle, and off-highway emissions from farm equipment and other sources, and introducing cleaner-burning gasoline. As new technologies arrived, such as three-way catalysts in 1980 and widespread electronic fuel injection soon after, emissions benefited. Even so, new cars still emitted twice as much hydrocarbons and NOx as they do today.

The engineers in El Monte decided in 1986 to build a test car themselves with the most sophisticated prototype pollution controls they could get their hands on from the suppliers. “I chose a Buick LeSabre with a V-6, and we basically built it up to see what level of emissions we could achieve and still have good drivability and fuel economy,” Albu says. “Having worked at a car company, I was really pedantic about drivability. I didn’t want the cars to be stumbling, surging, any of that stuff. I felt if we couldn’t set a standard without any of that, then I didn’t want to do the standard.”

To prove the Buick was commercially salable, Albu loaned it to the manufacturer reps to drive it on the streets after soaking the car in a cold storage room at the lab to reset it so that the starting and running conditions were always the same. The researchers took their results to CARB, and the real-world data from an actual running prototype was powerful enough to override automaker complaints that it couldn’t be done. “We used that approach to drive the standards down for a decade,” Albu says.

Relations with the automakers waxed and waned. “It went through periods,” recalls Cackette. “It depended on how strong the environmental movement was in relation to the economy, and who was running the car companies.” When Robert Stempel joined the GM board in 1986 and became the company’s CEO in 1990, it represented a changing of the guard. “He was a catalyst engineer,” says Cackette, “so you started to have people who grew up with emissions controls rather than seeing it as this thing forced on them.”

Albu adds that no progress would have happened without cooperation in the sometimes-daily meetings between the factory reps and the regulators. “Over time, we developed a rapport with the industry, and that’s what I credit most with finally getting to the goal. We treated them with respect, we listened to them, we didn’t just act like know-it-all bureaucrats.”

The next crusade: Self-doctoring cars

A problem was looming, however: To meet the ever-tightening standards, cars were becoming so complex that technicians couldn’t diagnose and repair them. In the early days of regulation, a car’s emissions performance was often down to machining tolerances on carburetor shafts, pressure valves, and ignition parts, which tended to have some variability in mass production. That was hard enough to diagnose. With the arrival of three-way catalysts and the attending closed-loop feedback controls run by black boxes, diagnosis and repair were becoming almost impossible.

Albu says he suggested to his superiors that the cars should come with some sort of onboard system that could self-diagnose problems with the emissions system, and a check-engine light on the dash to tell the driver when to take the car in for repair. A car that could doctor its own diseases seemed like a fairy tale in the early 1980s, and making it a reality seemed to have an almost limitless number of zeros after the dollar sign. “The industry hated that, hated it to death,” says Albu. “It was the worst fight of our lives.”

After the frontal attack on smog with catalytic converters, onboard diagnostics became the second great crusade to be undertaken by air-quality regulators. The technical hurdles were enormous. An onboard monitoring computer had to know the health of the oxygen sensors, the exhaust-gas recirculation system, the fuel-delivery system, the powertrain-control module, and any other systems involved in tailpipe exhaust or evaporative emissions—and to be able to relay any fault with those components to a technician, initially through dash lights flashing in code, later by a standardized data port. Because any fuel escaping through evaporation was the same as hydrocarbons coming out of the tailpipe, the car had to be able to pressurize its own fuel system with air and measure any leak-down. A leak anywhere in the system of just a few thousandths of an inch could cause the check-engine light to come on.

“In 1988 and 1989,” says Baltusis, the former Ford OBD leader, “no one really knew how to monitor a catalytic converter or how to do misfire detection. Manufacturers would try different concepts using cobbled hardware and prototype software to show CARB the progress they were making” toward meeting the deadlines, especially for the tougher OBD-II upgrade that followed in the mid-1990s—which, among other things, standardized the fault codes across the industry, as well as the data port. “It was like a big science experiment.”

And the industry would have to ensure the system worked much longer. Previously, automakers had only been required to ensure that emissions measured during certification would remain within the required standards for a statutory limit of 120,000 miles. Perhaps most galling about the proposed onboard diagnostic system was that it had to work “for the life of the vehicle.” That wording in the regulation was a backdoor way for the regulators to ensure that, without actually changing the law, cars would be designed to drive cleaner for longer. “They hollered like crazy,” recalls Albu. The automakers didn’t like the prospect of having to build cars with a check-engine light that could potentially be triggered by dozens of components at any time over the years and decades of the car’s life. “They said it’ll cost billions, that it’s not feasible,” says Albu. “But we couldn’t achieve our goal without it. It’s that simple.”

California’s initial 1988 regulation was a brief, two-page mandate that left a lot of room for automakers to proceed as they wanted. The result was a hodgepodge of systems and giant loopholes. The follow-up OBD-II regulation adopted in 1996 had a list of requirements that ran 120 pages. The industry lawyered up, and Albu found himself in a room squaring off against eight opposition attorneys. “They would ask me questions like, ‘Did you cost out the costs for a Chevy Malibu with a 350 engine? Did you cost out a Ford Fairlane with a 302? On and on for 12 hours. I almost wanted to quit.”

Eventually, says CARB’s Cackette, automakers came to the same conclusion as the regulators: Cars were becoming too complex to repair without onboard diagnostics, and the alternative was cars that failed emissions tests and massive recalls, an unhappy prospect. It did cost billions, however, and it absorbed the labor of thousands as automakers had to change everything, from the computers that ran the engines to the sensors that monitored their operation to the service tools in the dealerships.

And it’s still ongoing. “The thing about OBD is that it never ends,” says Baltusis. “CARB changes the regulations every two to three years, so you are never done. They have always underestimated the cost of OBD, both the hardware and the software development and testing cost.” A vehicle’s OBD system has thousands of lines of code that must be validated and thousands of parameters that must be calibrated and validated by engineers who take years to learn their jobs, says Baltusis. Any small error can cause a drivability issue or emissions problem that leads to an expensive recall. The onboard diagnostics regulation “is a never-ending escalation of requirements with increasing stringency,” he says. “It is causing problems to this very day as technology changes. Hybrid vehicles and diesel engine technology require constant reinterpretation of the regs for both manufacturers and CARB staff.”

As anyone who has had a check-engine light repeatedly come on because of a loose gas cap can confirm, onboard diagnostics technology did not arrive without problems. Though, says CARB’s Cackette, “I give the automakers huge compliments for what they’ve been able to do to improve the environment. I believe that they and the heavy-duty [truck] guys are the most technically capable organizations that make hardware in the world.”

There was cheating, too, especially in the early days. Cackette remembers one Ford that had a subtle switch triggered by opening the hood. The emissions controls worked when the hood was up, as it would be during a smog test, and not when it wasn’t. But as onboard diagnostics came in, the ability to cheat withered away. Into the 1990s, all of the cars that CARB and the EPA tested were passing, whether new or with miles on them, and eventually both agencies cut back on their testing to allocate resources elsewhere. The high pass rate “told us that they weren’t cheating, and that was the general belief until the VW thing came along,” says Cackette. “Nobody thought anyone would have the balls to do that.”

In 2014, tipped off by independent researchers that diesel-powered Volkswagens were running dirty, regulators in California determined that the company had installed a “cheat device,” or software that made the car’s emissions controls work harder during government tests and then slack off the rest of the time. Thus far, VW has paid more than $34 billion in fines and settlement costs. Outside of that incident, the regulators and the industry engineers, forced to work together by society’s demand for cleaner cars, have largely labored in harmony through the decades, say both regulators and retired engineers.

That is, until greenhouse-gas standards.

The CO2 war begins

The third great crusade by the emissions regulators in California takes on global warming by reducing the amount of carbon dioxide coming out of vehicle tail-pipes. The initiative has smashed the close working relationship CARB enjoyed with the industry, and it has driven a wedge between California and its longtime partner in Washington, the EPA. When California decided it was in the greenhouse-gas-reduction business, “another load of crap came down on us,” says Albu. “The industry blew up. People stopped returning our calls.”

Reducing carbon dioxide is the same as increasing fuel economy, and under our screwy system, corporate average fuel-economy standards are the purview of yet another federal agency, the National Highway Traffic Safety Administration. The matter seemed settled in 2012 when the industry, California, and the Obama administration agreed on a 54.5-mpg standard by 2025. But that agreement unraveled under the succeeding Trump administration, which is trying to ease the regulatory burden for automakers. California says it’s standing by the original deal—with the concurrence of Ford, BMW, Honda, and Volkswagen—while the federal government says California doesn’t have that power.

As of this writing, the Trump administration wants to partly strip California of its 50-year-old waiver allowing it to set its own rules and make the state heed the federal dictates on fuel economy. Sacramento has basically said, “We’ll see you in court, buckaroo.” The industry is divided but wishes all the regulators would make nice and adopt one national standard. And there’s a looming presidential election that could change everything.

Just as in 1970, the fate of the nation’s automobile regulations hinges on political intrigues. But with 717-hp Dodge Challenger Hellcats available today that meet all emissions requirements, it’s hard to argue that there hasn’t been huge progress in 50 years. “It’s really a heroic achievement in my lifetime,” acknowledges Car and Driver’s Bedard. “My record is thick with my inveighing against the EPA particularly, and government regulations in general. In some measure, they were just that of an immature person not well-informed about all the problems of the world.”

Albu, a California native who in retirement restores and maintains a fleet of 20 vintage Mopars—“The modeling shows that classic cars don’t contribute that much to smog due to limited use”—is grateful to have played a role in helping clean up his home state. “My dad was kind of a tough guy,” he says. “He made me go out and mow the lawn when the smog was the worst. When I came in from mowing the lawn, I could hardly breathe.” Though Los Angeles still fails to meet EPA standards for clean air and is leading the push for electric vehicles, the goop in the air is vastly reduced since then, he says.

“If we had this many vehicles in America without any cleanup, it would be impossible to live here.”

This is superbly researched and written. Well done, Aaron.

I found this very well done for a layman like myself to understand.

Excellent article

Very good read. I have noticed that the mention of greenhouse gases only shows up at the end of the article and they were not a target of the EPA for a very long time, thanks to catalysts, I assure you. The greenhouse gases, post catalyst, are actually worse than a non-catalyst vehicle thanks to what is happening inside a catalytic converter. It’s also why warming has only intensified since catalysts were mandated on every vehicle produced. Do the math, look at the dates, look at the information prior as well. Legitimate information, not charts thrown out by legacy news agencies that have bought their way into our politics. Anything from most universities prior to 2000-2009 was still accurate and not tinged by bias or bribery.