A Turbine for Your Hot Rod? Latham Says Yes

Supercharging has interesting roots (pun intended) in the automotive world. The idea of pressure-feeding air into an engine for a car is only a few years younger than the automobile itself. The first production examples were available on Mercedes models in 1922, and it has only become more popular since. As with many examples of technology, there were some interesting attempts at supercharging that didn’t last and ended up on the side of the long road that is automotive history. One such example is the Latham axial flow supercharger.

Supercharging an engine relies on the crankshaft to drive on a compressor that forces air into the intake, effectively increasing the volumetric efficiency of the engine by cramming more air into the cylinders than it would pull in on its own during the vacuum created by the intake stroke. The most common forms of superchargers are centrifugal, roots, screw, and scroll. Before the market settled on the common types we’re familiar with today, there were several efforts to create the next best thing. Norman Latham of West Palm Beach, Florida, hoped his new product would be a must-have performance bolt-on.

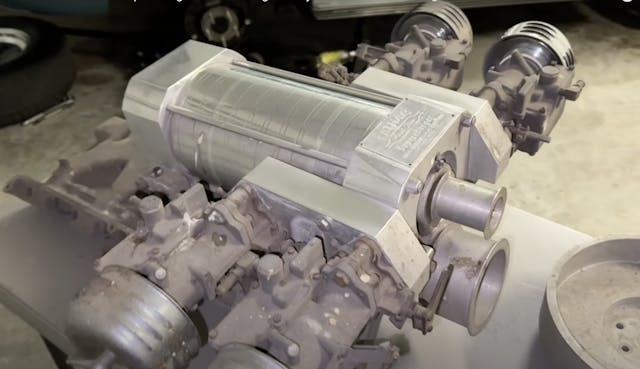

Latham’s idea was to create an axial supercharger. This is essentially a turbine, where the supercharger housing contains “fans” that can create positive manifold pressure. Latham’s design went into production in 1956 and was sold until 1965. It was radically different than a roots or centrifugal supercharger, yet also combined a few of the better parts of each. A centrifugal supercharger was a bear to tune 70 years ago because carburetors were still the most popular way of mixing the air and fuel entering an engine.

Carburetors rely on the incoming air to pull in the fuel into the airstream from the float bowl. If the throat of the carburetor is under pressure rather than vacuum, that fuel draw doesn’t work very well. This made centrifugal superchargers finicky. Roots-style blowers could more effectively be set up to draw air through carburetors, but the size and location made packaging tough. Latham used the long and low design of the axial supercharger to put the blower low and further forward with the carbs off to the side, keeping a lower profile. The air and fuel are drawn in through two or four carbs, depending on the model, before being compressed through the turbine and then fed into the intake manifold.

The problem is that axial compressors tend to be less efficient than the more popular styles of supercharging. Their peak efficiency orrurs during a very narrow window and prefer steady-state running at that speed rather than changing RPM quickly like most automotive engines tend to do. It was a solution, but we know now that it was not the best solution.

The design still caught people’s attention though. After an eight-page spread in the June 1956 issue of Hot Rod things seemed to take off. Over 600 Latham superchargers were built and are now highly sought after. The company was sold in 1982 and transitioned to producing a modern interpretation of the axial design. The vintage units stand as an interesting reminder of the times when its innovation was almost as rapid as the cars it was going into.

***

Check out the Hagerty Media homepage so you don’t miss a single story, or better yet, bookmark it. To get our best stories delivered right to your inbox, subscribe to our newsletters.

This kind of stuff is the cool stuff to have.

The show I went to this weekend had 20 cars with superchargers and they all were the same unit.

I like the dare to be different.

Very interesting article, but an explanation of how the different types of superchargers WORK, would be of great value.

Never seen that type before. it is very cool. Still spinning just fine after all these years.

I’ve living in the West Palm Beach area since the early 60’s but don’t remember this company being here. I wonder if he had any connection with Briggs Cunningham when the latter was building race cars here in the early 50’s?

If you explained how the Latham ‘Axial Flow’ blower worked, you’d have to admit it really isn’t a turbo, little feller. A turbo charger uses exhaust thrust pressure to turn a turbine wheel, not belts. The usual ‘snail’ turbocharger has a double-sided impeller, and that can also be used with crankshaft power.

Turbochargers were being experimented with during WWI (not WWII !) in USA and I understand some other places; like Chermany. The axial flow is used in ‘turbo-jet’ engines, as opposed to centrifugal flow, though the latter became dominant. But a ‘turbo’ it is not. Please recant!! Wick

You’re comment made me go back and read a little more carefully and I couldn’t find where the author called this a turbocharger? What are you talking about, little feller?

I’m building a 63 Avanti with a Lathem supercharger, I enjoyed your article about them. How can I send you pictures??

An interesting article. Years ago I discovered “superchargers” were used on mass produced vehicles as far back as the 1930’s! Ford trucks of the 1930’s were modestly powered by today’s standards and increasing engine power meant you could haul bigger/ heavier loads per run that increased profits. The “flat head” engines were difficult to get more power out of because modifying the head for better breathing tended to lower the compression ratio. It could be done, but was relatively expensive. A lower cost solution was to bolt on a supercharger to boost torque and power by overcoming the the restricted “breathing” of the stock engine. Even to this day many don’t realize superchargers were popular on Ford trucks back then.

Along that line, trucks were the primary market for OHV and F head conversions of Ford Flatheads because moving the valves out of the block improves cooling which is important in truck applications. Drag racing doesn’t the same problems with sustained operations so most hot rods used tuned flat heads rather than shell out for Ardun OHV heads

This is,of course, the type of compressor used on ALL jet engines, so it is hardly without merit, though perhaps not idea for a car engine and its wide rpm range.

Latham Axial-Flow blower was expensive and awkwardly packaged, thought a very high-class act! If a turbine, it certainly is at variance with the classic snail-impeller centrifugal blowers pioneered by Duesenberg and Miller (in cars) and a number of engineers–Dr. Moss, prominently in the USA– with their usually two-sided impeller discs.

On a V-8, it forced the air to make a lot of acute turns, incoming and out going, which lower efficiency and create heat: the carbs are perched at one end, and the forced-induction route had to do a 180-degree and a 90-degree route to get to the ports. Besides, four Carter YH side-drafts aren’t a lot of venturi area, and you have the chore of synching them to boot! If you dor a diagram with directional arrows in your imagination, you can see the convolutions that the mixture had to follow and how it decreased efficiency. Plus you know they were spendy: Bill Harrah favored them (famous ’58 Bonneville wagon that tested NV’s new highway system in the fifties) and he had dough to burn.

Still, as eye-candy and a crowd-drawer, this unit would be hard to beat at a show, and I’ll bet it sounded something terriffic when revved up! An expensive baloney slicer! Want one! Wick

Sorry; my syntax is getting the better of me! Darned little keyboards! I meant to remark that Sanford Moss (and others) did research for aircraft, specifically, with the turbo-charger which was of course powered by exhaust pressure. Someone should write a history of the supercharger in book form. There was a “Half Hour History of the Supercharger” in SPECIAL INTEREST AUTOS Magazine back in the ‘seventies, by Jan Norybe, I believe. I miss my time writing for that mag — heck, I miss reading it even more! Thanks, Mike Lamm! Wick

I remember the adds in Hot Rod magazine. I believe it was a 1958 Pontiac Bonneville and one part of the add claimed improved gas mileage! This would have been around 1960-1962.

When I was 13 a fellow in my area bought a brand new maroon convertible 64 gto, 389 with 3 deuces and a four speed… He was a farmer type but liked to go fast. I detailed the car for him after a couple years ownership. Shortly thereafter he ended up installing the Latham with four carbs setup… Don’t really recall seeing it after that time. Just remember that setup. I dont think the hood fit with it installed… A few years later he was prosecuted for illegal gun running to some third world banana republics… He went quickly to jail I believe

Unbelieveable! History at it’s best! Thank you for sharing this experience!

The Latham supercharger must have made at least a little bit of a splash at the time, because I have a firm, if a little fuzzy, recollection of it appearing in a plastic model kit of my youth. It was probably an AMT 1/25 kit, since that was what I built mostly. I recall it being perched atop a large Lincoln V8 in some type of street rod, possibly a Model T. Anybody else remember that, or has my memory gone kaput in old age?

OK, answering my own question: It was the AMT “Double T” kit, first issued in 1960. You could build two complete 1925 T models, one stock and one chopped coupe hot rod. The hot rod version did indeed include a Lincoln V8 with a Latham blower. 64 years later, the kit is still available as a reissue!

My older brother had a 56 Ford 312. Somewhere he got hold of a Latham with 4 carbs and mounted it on his 56. He had to have roll bar in the car to run at the drag strip which was Indianapolis Raceway Park. He being a welder at work, designed a removable roll bar to be used on Sunday and then removed to take his girl friend out during the week nights. At the strip he ran CG/S. There was no one in his class so he won a trophy each Sunday. Then along came George Montgomery from Ohio. George had a Willies that ran AG/S. He and Done were the only ones in Supercharged class that time and so they ran against each other. Of course George won. I think Don was running in the low 14’s with his set up. I was very young at the time, maybe only 10 years old, but I do remember his car. Later on , Done removed the blower and sold it to Emerson Dismore who Don raced go carts with. Dismore mounted it on a 65 Mustang 298 HP engine. He could still close the hood without anyone knowing he had a blower. Dismore soon started Comet Cart Sales and sold his Mustang. Mark Dismore raced go carts with both his da and my brother and went on to race at The Indianapolis 500. He quit that after having a terrible wreck which almost took his life. Mark now owns Comet Cart Sales as his father has passed. Lots of wonderful memories all from someone owning a Latham.

My early reckoning of anything supercharged was at my first job after high school (1955) working at E&L Transport in Dearborn Michigan They were exclusively dedicated to hauling Ford Motor Company vehicles. They used these all Ford truck tractors as testing units for various Ford and Lincoln engines. They used the Mccullough centrifical “blowers” as they were called back then. They had a cool sounding whine sound as the r.p.m. picked up.Of course, there were many of those being adapted to hod rods, and you knew when they were under the hood from the tell tale whine they had.