How Ford’s experimental aluminum Mercury Sable gave way to modern mixed materials

Ford made a big deal out of the aluminum body on its venerable F-150 when the lighter, more efficient yet bigger truck debuted in 2015. Using the stuff shaved as much as 700 pounds from the pickup. A big part of Ford’s history with aluminum, took place 25 years earlier. Back then, you wouldn’t be out of line to think that aluminum was the future.

Instead, aluminum is just a part of our current future. Some automakers are heavily invested (no pun intended)—Audi and Jaguar Land Rover still use a lot of it, as does Tesla. Even traditionalists like Morgan, which just introduced an all-new aluminum platform in the Plus Six, sing its praises. But Ford and other mass-market automakers use aluminum strategically, where it makes sense from a cost and engineering standpoint.

Ford’s experiments with aluminum started in the early 1990s with the Aluminum Intensive Vehicle program, which led to the creation of innovative new ways of forming, welding, and bonding a material that can be tricky to work with. To prove the techniques worked, the team built 40 Mercury Sables. The results were substantial.

The cars, which have achieved near mythical status among Ford fanatics, weighed 400 pounds less than a conventional Sable. Outfitted with the Taurus SHO’s 220-horsepower V-6, the super Sable featured a power-to-weight ratio on par with sports cars of the time. The car proved potent enough to place 15th in the 1995 One Lap of America race. Sadly, Ford collected most of these lightweight prototypes, tucking some of them away in storage and condemning the rest to a date with the crusher. A handful still run wild, though, and you’ll find reports of alumicorn sightings on SHO forums now and again.

Some of the tricks Ford learned developing the super Sable made their way across the pond to its subsidiaries Jaguar and Aston Martin, which applied them to their own models. Ford didn’t do much with the techniques in its regular production lineup until fuel prices started going up about a decade ago. At that point, Ford applied some of the Aluminum Intensive Vehicle lessons to the latest F-150, which went the full beer-can route when it debuted in 2015.

Nearly every panel on Ford’s best-seller was formed from aluminum, shaving as much as 700 pounds from the weight of the truck without changing its overall footprint. The pickup’s use of the material has been the most widespread of any single mass-produced Ford thus far, but the high risk seems to have only offered modest rewards. Alan Mulally, the company’s CEO during the decision, promised to shave weight from every model in the lineup.

It made sense at the time, given that gas prices were climbing and consumers wanted more fuel efficient cars—without sacrificing power or size. Aluminum offered one way of doing that, but fuel prices fell and aluminum prices rose (they’re up about 20 percent since 2015) and Ford took another look at the math. The F Super Duty and Expedition took on aluminum bodies in their latest redesigns, but Ford’s use of the material has remained more conservative in the rest of their models. Nevertheless, the weight savings Mulally promised are still proving to be true, reflecting the fact that how materials are used is just as important to what materials are used to achieve weight savings.

In other words, don’t expect to see an aluminum-bodied superleggera Mustang any time soon. Ford, and most automakers, seem inclined to trim weight by using more high-strength steel, which uses additional alloying elements—such as molybdenum, vanadium, and manganese—to create a material that physically and chemically stronger than conventional steel. Although it’s not quite as light as aluminum, it’s a whole lot cheaper and easier to form and weld. Even Audi is using more high-strength steel in cars like the A8, which was as much as 92 percent aluminum.

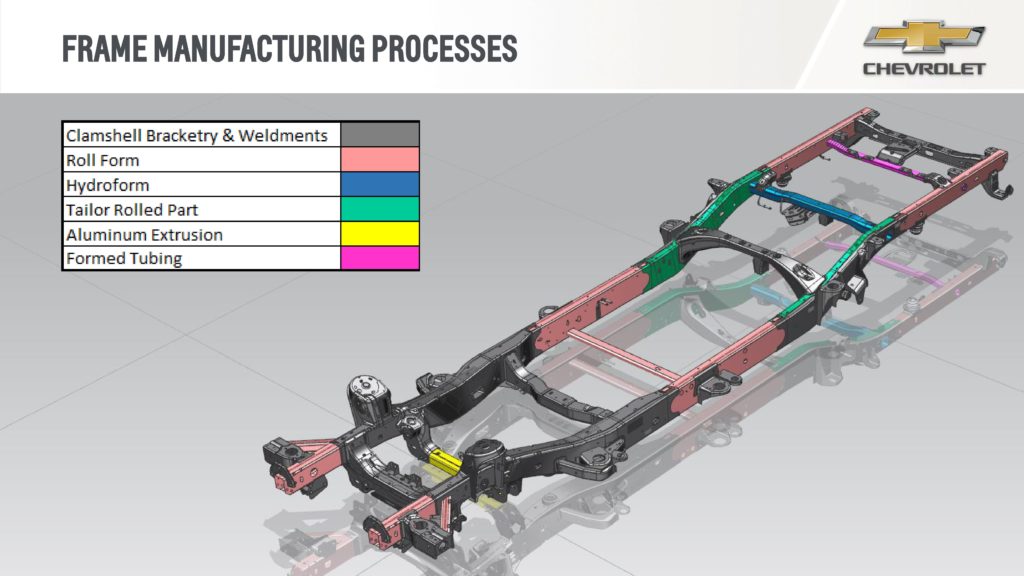

Automakers are also using more carbon fiber and other composites, typically in limited applications. General Motors plans to offer the material, once found exclusively in race cars and exotics, in the CarbonPro bed in the 2019 Sierra. Pricing is still to be determined, but the option will save 62 pounds over the steel bed. Carbon remains tricky to make, but much of the expense lies in the equipment needed to make the parts. Once a company like GM makes the capital expenditure, cranking out parts becomes relatively cheap.

Going forward, you can expect to see all of these materials in cars, because each offers its own unique attributes. Engineering requirements, consumer tastes, and market forces will dictate how much of each is used, and in what vehicles. If we’ve got anything to say about it, we’d like to see Ford use everything learned from the Aluminum Intensive Vehicle program to build that superleggera Mustang.

Editor’s Note: A previous version of this story stated that when the 2015 F-150 debuted, Ford promised extensive use of aluminum in other models. A Ford spokesperson reached out to clarify that the company only promised weight savings on new models without specifics to the materials. The story has been updated to clarify that point.