The 55-year reign of Ford’s Twin I-Beam

Few suspension designs are as rare today as Ford’s Twin I-Beam, a 55-year answer to demand for a more comfortable work-truck. The Twin I-Beam arrived in 1965, created at a time when pickups were first becoming civilized transportation. Ford eschewed the idea of adopting dual A-arm suspension for its evolution of the beam suspension rooted in the bones of the Model T. The Blue Oval to this day uses the Twin I-Beam for its 3/4-ton and 1-ton trucks, so what makes it unique, and why isn’t it found in Ford’s current half-tons?

Prior to WWII, cost and function were the focus of American truck design. Over time, pickups began to adopt a number of advancements seen in passenger cars, in a bid to capture some of the mainstream automobile market. While the cabs were the first to benefit from this shift, gaining such luxuries as seat belts and carpet, the foundations beneath them didn’t begin to change until the 1960s.

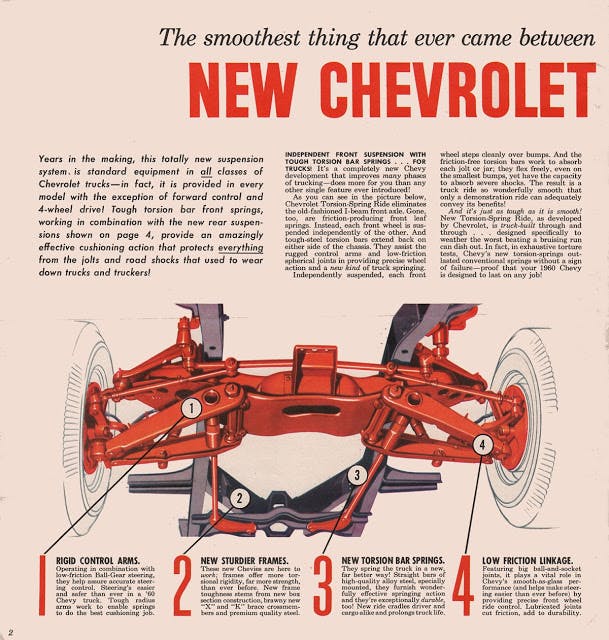

For the first half of the century, pickups had relied on I-beam front suspensions, which meant both front wheels were carried together on the same axle, usually located and suspended by a pair of leaf springs. In 1960, General Motors introduced the first half-ton pickup with independent front suspension. Of course, we’re ignoring the Impala-based El Camino and Ford’s own Ranchero, but GM’s truck similarly used a dual wishbone front suspension with a coil spring on either side. While it shared the basic suspension type with GM passenger cars, every component for the half-ton was beefed up and the trucks retained their own unique control arms, knuckles, and brakes. Coinciding with the new coil-sprung, trailing arm rear suspension in the C-series of pickups, General Motors set the bar for ride quality and handling at the start of the decade.

The new-for-1961 fourth-generation Ford F-series was agrarian by comparison. Not only did it still use a leaf-sprung rear axle, but the story was the same up front. I-beams were still the standard for light- and heavy-duty trucks, and even some passenger cars at that point, but buyers began to notice the huge benefits offered by independent suspension. The problem with I-beams is the same as you find with solid rear axles: when one side hits a bump, the other side is affected as the housing rides over the obstacle. By freeing the front wheels from one other, ride quality improves substantially and handling over rough roads experiences a night-and-day difference.

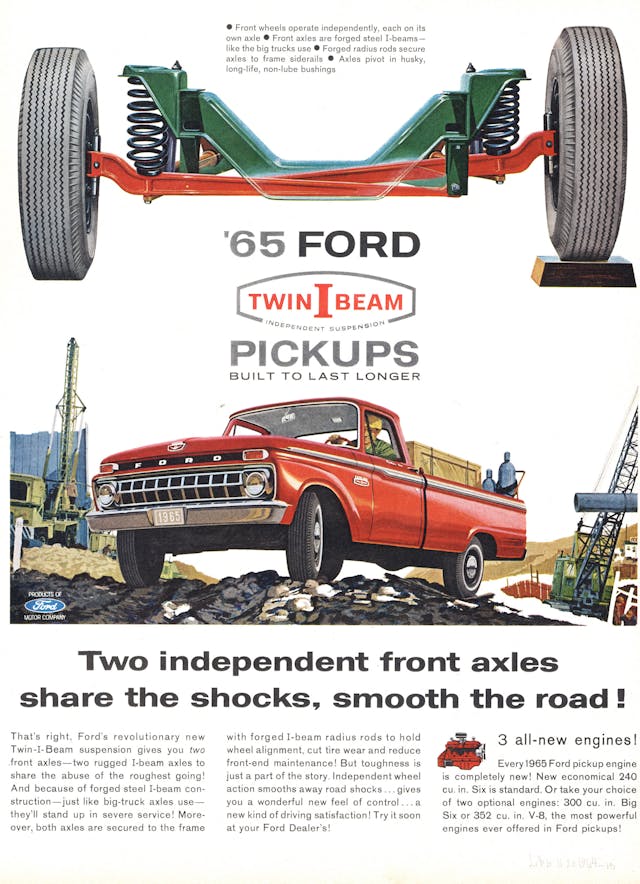

Ford knew it had to answer the shot from across Detroit, and it had begun work in 1959 to design an in-house independent front suspension. Ford had noted the arguments against A-arm suspension—durability and tire wear, among them—in a 1965 SAE paper suitably titled, “Twin-I-Beam: A Unique Truck Independent Front Suspension.” Ford engineers recognized the advantages of what they referred to as short/long-arm suspension—stable geometry with suspension travel, easy packaging, and good ride—but criticized double-wishbones for their complexity, perceived fragility, and tire wear. They knew that the people they needed to impress weren’t General Motors buyers, but instead, customers who refused to abandon their sturdy I-beam trucks for any independent front suspension whatsoever. So, Ford gave them what they wanted for each wheel.

The Twin I-Beams would attach on the opposite frame rail of the wheel it supported, with a radius arm running fore and aft to keep the tire centered in the fender. Ford engineers stated in the SAE paper that, “it is usually easier to design a good beam than a good attachment [point],” referring to the amount of leverage a dual A-arm suspension has on its mounting points when taking large impacts—like pulling a tree from the canopy. With the radius arm, impacts could be directed linearly into the frame, reinforcing the suspension against rutted roads and … miles of railroad ties, as Ford was so fond of using in period advertising.

It would retain the kingpin steering knuckles used in Ford’s traditional I-beams, but this design would dump the leaf springs in favor of coil springs to further improve ride quality. Ford maintained that the kingpins solved multiple issues with tire wear over A-arms suspension, with consistent Ackerman angle preventing low-speed tire scrub while the rigid positioning of the kingpin meant that caster and camber were fixed and “maintenance-free,” reducing projected ownership expenses. “Work like a truck, ride like a car” was the motto here, and when Ford introduced the refreshed fourth-generation F-series with the new Twin I-Beam suspension, the promise seemed earnest.

For Ford, the results paid off, and buyers adopted the Twin I-Beam trucks. The suspension wasn’t without its quirks, though. The SAE paper observed that it had “considerably more camber change” than a dual A-arm suspension as the result of any change in ride height, but it stood the test to be at least as durable as the solid front axles it replaced. A decade later, Ford would begin to develop a 4×4 adaptation of the Twin I-Beams in a partnership with Dana.

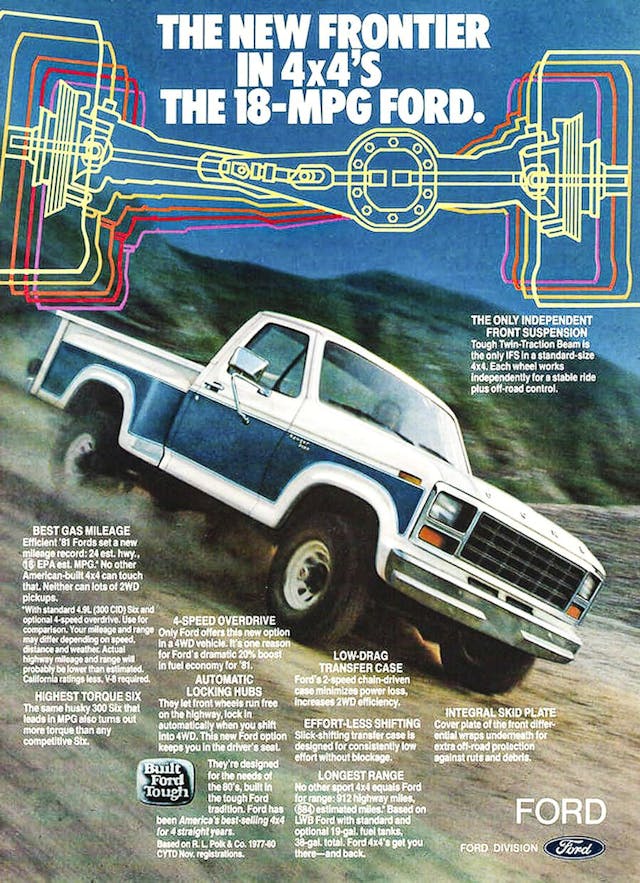

Dana would provide the differential assembly, with Ford splicing a housing onto the passenger I-beam and hanging a half-shaft off the other I-beam with a slip yoke connecting it to the pumpkin. Ford once again emphasized that its beam suspensions were more robust and less complicated than contemporary alternatives for combining independent front suspension with a 4×4 system in trucks.

When the Twin-Traction Beam suspension was introduced in 1980, it still carried many of the same downsides as the Twin I-Beam, like gaining positive camber with any lift, but the large radius of the traction beams themselves gave exceptional wheel travel compared to a dual A-arm design. Ford retained solid front axles in heavier-duty applications, but the new 4×4 independent-front suspension would eventually trickle down from the half-tons and into Ford’s compacts, like the Ranger and Explorer.

Today, Ford still uses Twin I-Beam suspension in the F250 and F350, though it’s no longer on the front page of advertisements; instead, it’s buried deep in the spec sheets for two-wheel drive highway machines. The irony of this whole series of events is that the entire industry, including Ford, would transition into dual A-arms for half-ton pickups—even the 4x4s. Ford ultimately wised up to the compact packaging, more precise control over wheel alignment, and smoother ride thanks to the reduced unsprung weight that cemented dual A-arms into widespread use. Those who check the right boxes, however, can still get a slice of ’60s nostalgia and brute force for their work trucks.

The twin I beam was so tough and simple Parnelli Jones used it on “Big Oly” his Baja winning off road “Bronco” (not really a Bronco just looked like one).

If someone came out with a simple bolt on idler arm for the old twin I beam/traction beam F150 trucks, They’d be a trillionaire…something that actually worked