Wrenchin’ Wednesday: How to check yourself before you wreck yourself

It’s one of those gearhead rights of passage. You’re sure every last bolt is tightened and the hood is closed. You go out into the world with the product of your labor—only to find that something has just rattled off and left the party because somewhere in the slog you forgot to final-torque some piece of hardware.

Even if you don’t prove to be own worst enemy, the vibrations that resonate through a vehicle can eventually work things loose, especially if your vehicle’s engine that shakes a lot or if you frequently travel off-road. Today’s Wrenchin’ Wednesday is about building a habit to check yourself before you literally wreck yourself due to a fallen nut or bolt.

Ignoring the aforementioned chassis harmonics, fasteners are often left loose because you only partially tightened them during assembly, and that final round of torquing never happened. Leaving bolts slightly loose can help you align the holes between two parts by allowing for a little wiggle room until each component is happy. Unless you go through a mental checklist—which, let’s be honest, can be hard to do after a long project—it’s easy to miss these stragglers and assume everything’s wrapped up.

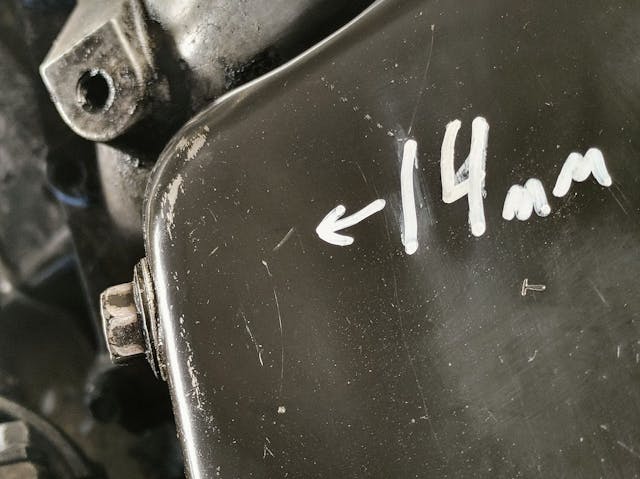

This is where a marking tool comes in—I prefer grease and paint pens, but grab whatever you have on hand. Even white-out pens and Sharpies fulfill the task. While you’re working through the final assembly, mark the hardware with a line that locates its position relative to some fixed component. A bolt head and the bracket it seats up against, or even between the bolt threads and the nut on an otherwise free-floating fastener, such as a shock mount. You can apply this habit to everything from suspension bolts to rocker arm adjustments—once you get into it and have a couple marking tools on-hand, it becomes second nature.

The goal here is two-fold. First off, you’re creating a living checklist of what you’ve tightened to final spec. You’re not just double-checking your work, though. By leaving yourself a visual method to diagnose loose fasteners, you’re making long-term maintenance easier because you can spot problems before they escalate into show-stopping situations.

Bonus tip: Leave yourself notes! If you’re like me, you’ve probably got a handful of projects which use different sets of sockets and wrenches (and if you’re not like me, you’re probably fiscally responsible). For common maintenance items, notes on tool sizes, fluid capacities, and various modifications will make life easier for you—or your project’s next owner.

When I first picked this 1996 Chevy Suburban K2500 up with the 6.5-liter turbodiesel, it had already rattled out numerous fasteners over its lifetime—including the transmission mount bolts. Between the overlanding miles on washboarded trails and the lifetime of vibration by the Detroit block under the hood, marking fasteners has become an essential part of my regular maintenance on the truck. While the marking method is rooted in motorsports, it’s just as important that a vehicle you depend on gets every chance it can to perform flawlessly. Plus, we’re only human—the living checklist of markings on your machine will help you avoid ultimately fatal issues.