Even self-learning EFI sometimes needs an expert tutor

This shouldn’t be a case of teaching an old dog new tricks. I mean, these modern self-learning EFI systems are easy to install and tune, not to mention this particular dog’s been in the throttle body fuel injection game since Ford’s EEC-III computer met the small-block V-8 circa 1980. And yet here I am, in need of an expert to troubleshoot a seemingly impossible issue with FiTech’s EFI system installed on a 1972 Continental Mark IV.

For starters, I did not install the FiTech setup pictured here, as I am no fan of dropping a gas tank to fit an EFI-friendly fuel pump on a car that lacks an engineered conversion kit. (Cough, Mustang.) Once the conversion was complete, I performed my modus operandi of finishing minor details in the generally pointless pursuit of total perfection.

While making a perfect classic car is akin to chasing a moving target, I had a new problem to track down. After 100+ miles under its belt, the EFI system had an overly rich idle, stinking to the point that when stuck in traffic I smelled like unburned gas fumes. Then there developed a dangerously lean condition under load, which worsened as the weather grew colder; Totally fine near 100-degree ambient air, but life-threatening below 60 degrees. All of this made me wonder: Why was this self-learning system, complete with a wide band O2 sensor, running both rich and lean?

After replacing the ignition coil (with a broken stud) and confirming base timing was acceptable, I dug deep into FiTech’s setup instructions. These steps were already performed by the installer, but it never hurts to look again. Reaching something close to stoichiometric was out of my reach, as my skill set was officially maxed out. To be clear, this isn’t a slam on the fine folks at FiTech, I just needed someone with more knowledge, more patience … and a vintage IBM ThinkPad.

A local specialist tuner had the hat trick of required items and made the time to see me. After a few minutes of idling and several runs to 2500 rpm, he leaned out the mixture roughly 30 percent. The change was immediate; judging by my clothes and lungs, I could feel that the catalytic-converter free Continental Mark IV was far less disgusting.

Regarding the problem of engine detonation under load, the shop realized the ignition’s vacuum advance wasn’t getting enough vacuum, so the correct source was located on the FiTech throttle body. (Thanks Google!) Once buttoned up, they were confident a run on the Dynojet was the last step to ensure the system’s functionality.

Take a listen to that big-block while you geek out on the relevant details:

- Ported D0VE heads with Cobra Jet valves

- Custom grind camshaft (close to an RV cam)

- Hooker long tube headers (intended for a 429-equipped 1972 Ford Torino)

- Edelbrock Performer 460 intake

- FiTech EFI

- Rebuilt C6 transmission with roller bearings (less parasitic drag)

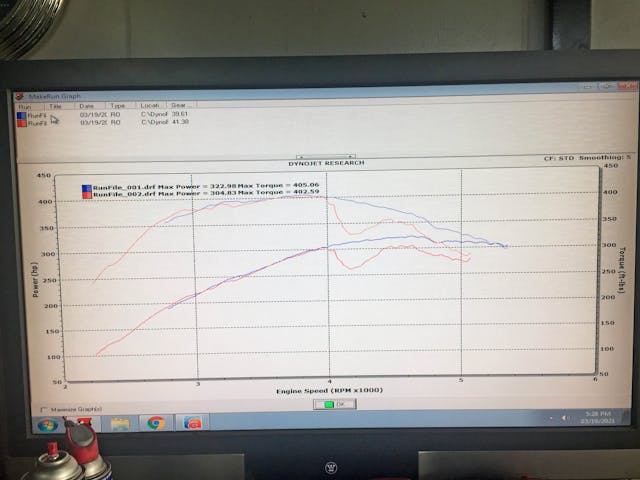

Just in case you missed it in the video, here’s the end result:

The power curve isn’t as impressive as those where the car can be locked into the transmission’s 1:1 gear ratio for the duration of the test, because you have to roll into the throttle on a Ford C6 so it won’t downshift into second gear. That said, the end result of 322 horsepower with a stonking 405 lb-ft of torque is impressive for an air-conditioned, conservatively cammed engine transmitting power through a huge C6 gearbox and a power hungry 9-inch rear end.

While the second run was significantly lower, that’s likely due to the fact that the Continental ran out of gas shortly thereafter. No matter, unlike all those bench racing braggers who throw out power figures all willy-nilly, I know I am making about 390 horsepower at the crank.

As if I cared about such nonsense, because once again, my interest in chasing perfection is indeed pointless. Now that the EFI system is working as intended (the computer will likely learn more after several trips around town) my new Mark of Success is watching this glorious hood rise to the heavens when flooring that finely tuned 460. Pure bliss!