Wrenchin’ Wednesday: Stop hacking up factory harnesses

When you’re modifying a car, the method of your madness will decide the ultimate fate of your upgrades. All too commonly, we’ve all seen someone’s car locked in electrical purgatory from botched stereo installs and other wiring mishaps, but with some prior planning and a little hunting, it can be easy to drop in additional circuits without ever having to disturb the sanctity of the original harness.

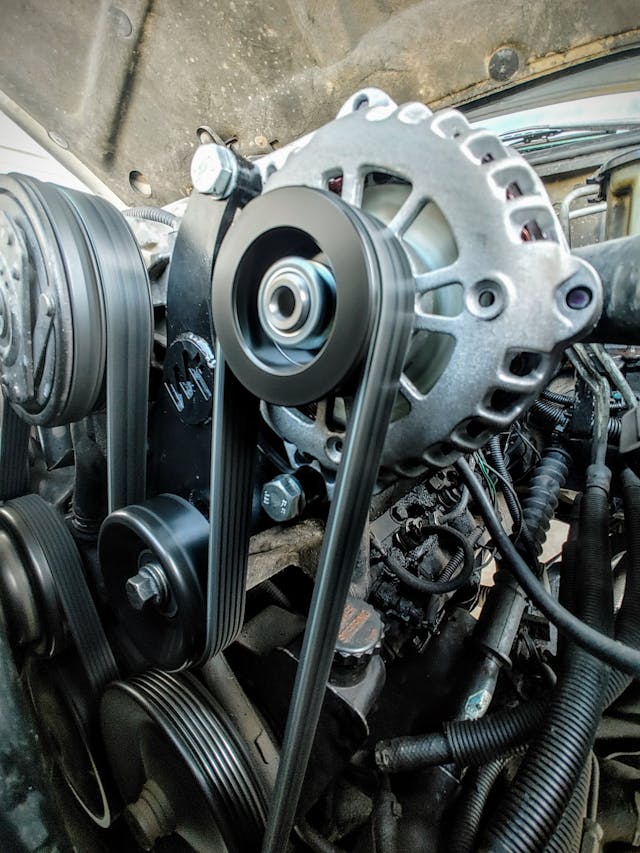

The project in particular was adding a secondary alternator to my 1996 Suburban K2500. It was a factory option that the aftermarket now had replaced, so wiring it up wasn’t going to be too complicated as there was already a circuit diagram to reference. Where we enter today’s Wrenchin’ Wednesday is in building a sub-harness that will break out the necessary wire we need without modifying and possibly mangling the 25-year-old factory harness that’s in the truck already.

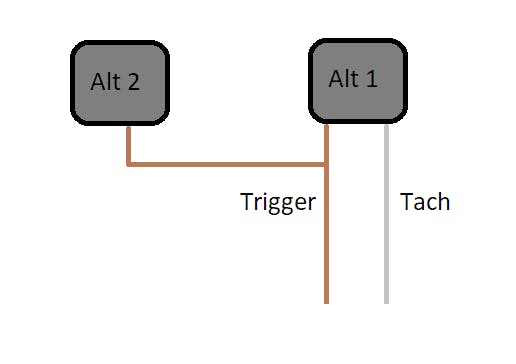

For many of GM’s internally regulated alternators, they only really need an ignition switched source to enable them, one wire at a minimum, but in the 6.2L and 6.5L diesels, the alternator is also used to generate the tachometer signal for the dashboard. We could easily cut and splice in a new wire in parallel with the switched trigger wire, but the risk of damaging the harness or creating issues that will be difficult to resolve after splicing the original harness. Instead, we’re going to exploit the connector that sits between the alternator and main harness to plug in our own extension harness, making the modified connections plug-and-play.

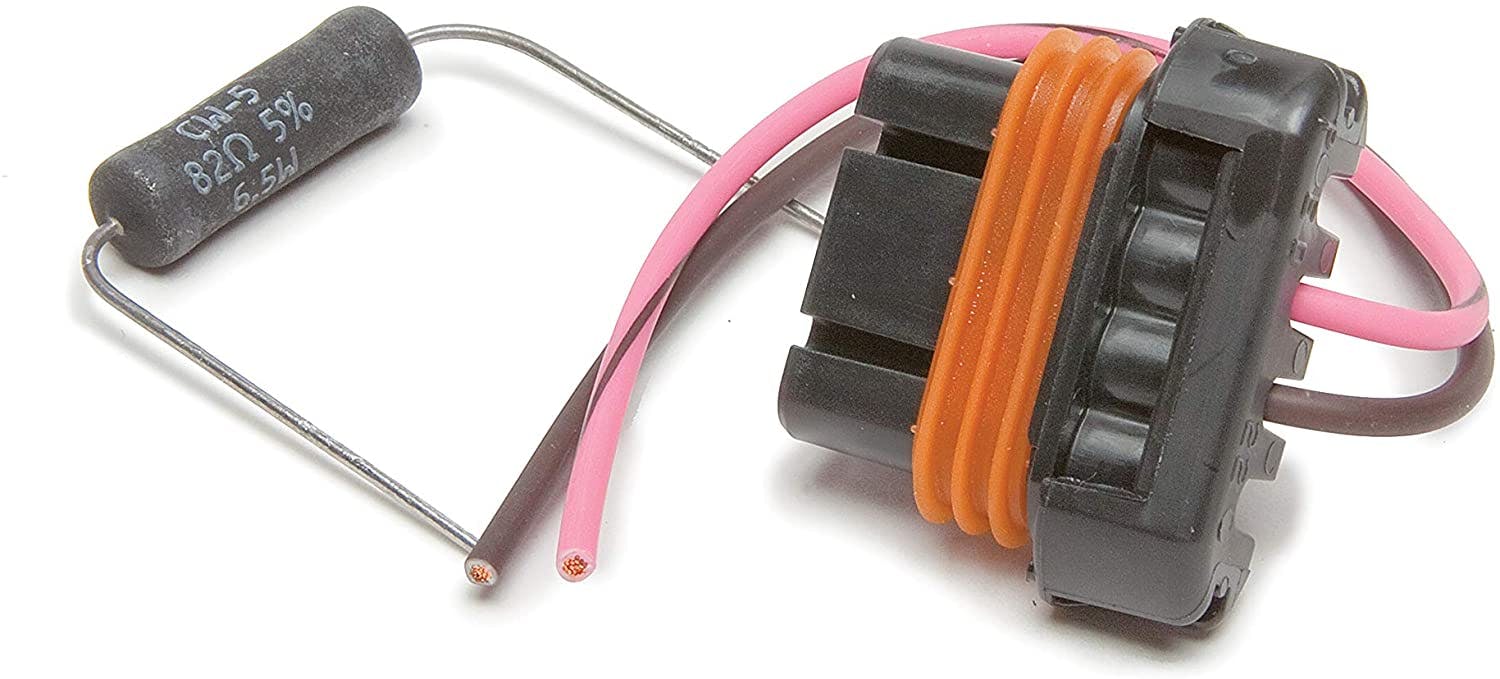

There are several sources for pre-terminated pigtails, which have their pins already crimped onto short lengths of wire that you can easily use to build a full harness out of. This saves a few bucks for individual projects since you’re only buying what you need and won’t have to dive into the world of specialty crimp tools. However, if you’re undertaking a large project where you maybe be modifying or building several harnesses, the scales flip in favor of building them from terminal kits.

You can usually find these pre-made pigtails at dealerships, and a handful of connector types are sold through the usual parts stores too. Buying online tends to be the most cost-effective in some cases, as dealers will carry the highest mark-ups, and local parts stores may not stock less common connectors.

And if you didn’t know any better, you might just be fooled into thinking its factory, too. If my workmanship ever causes a problem in the future, it’s trivial to simply unplug the new harness and bypass it entirely by plugging the stock harness back together without it. But more importantly, by preserving the stock harness, there’s a substantially lower chance of any future electrical failure.