Watch Bentley hand-build its unique W-12 engine

Most VW Group engines, including some of the Lamborghini V-10s, are made at Audi’s Hungarian plant in Győr. However, that does not include Bentley’s twin-turbo V-8 or its 6.0-liter twin-turbo W-12. Those limited-production engines are hand-assembled at Bentley’s home in Crewe, England, and if you have roughly as many minutes as a Flying Spur has cylinders to watch the video below, you can live through the entire build process.

In case case you wish to know more about the W-12 first, here’s what I can say about it:

Audi’s 4.2-liter V-8 was so capable that both Lamborghini, Spyker, and Koenigsegg wanted a piece of it. In the end, only the former Dutch company got there, but no matter how solid and tuneable the V-8 may have been, that ’80s-derived engine just wasn’t meant to carry the top of the Volkswagen Group into the 21st century.

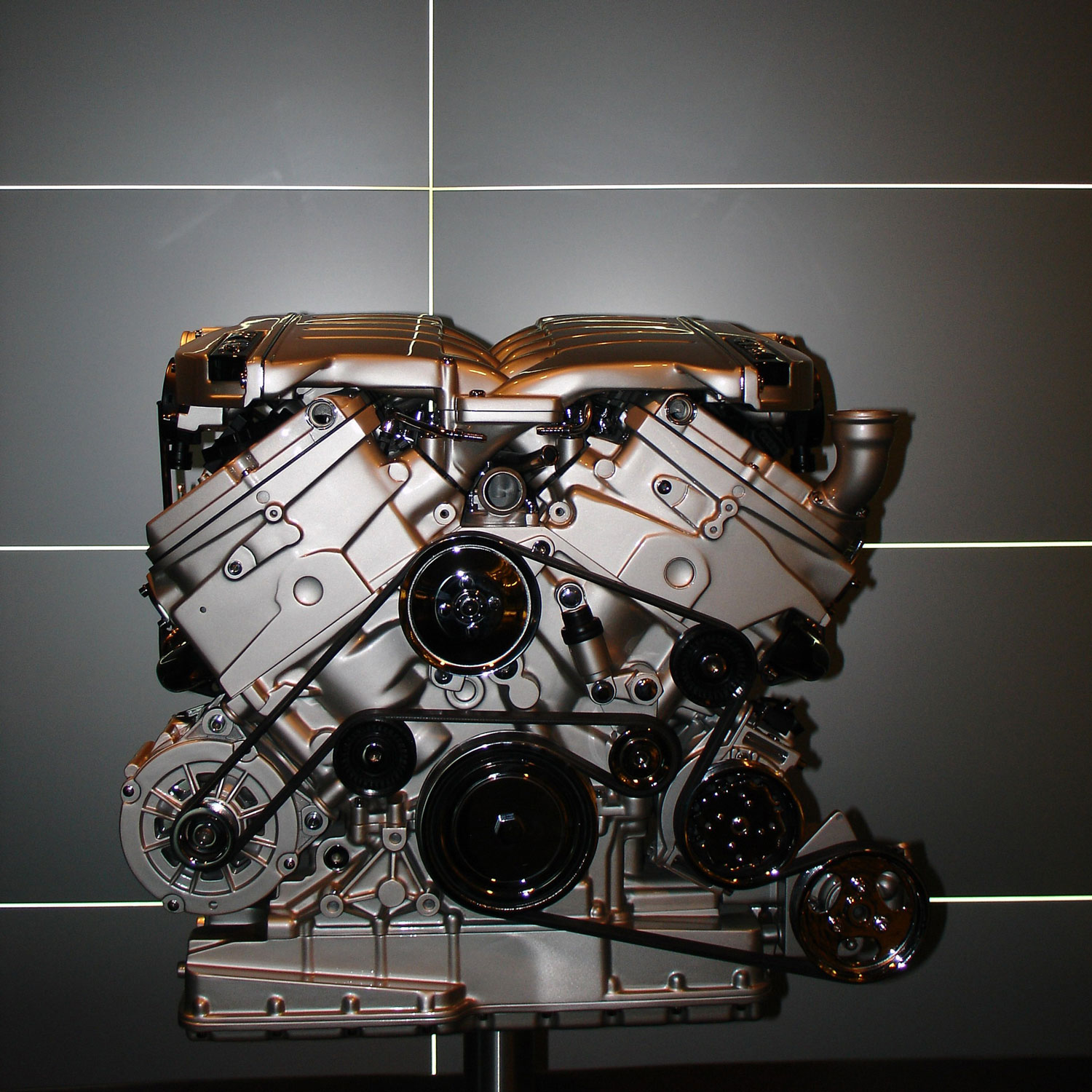

In the 1990s, Volkswagen’s pride was its narrow-angle VR6 engine, which allowed for four-cylinder engine bays to be fitted with six-cylinder power. The W-12 is the same “stacked banks with a single camshaft” idea, only designed to replace V-8s and V-12s instead of an inline-four.

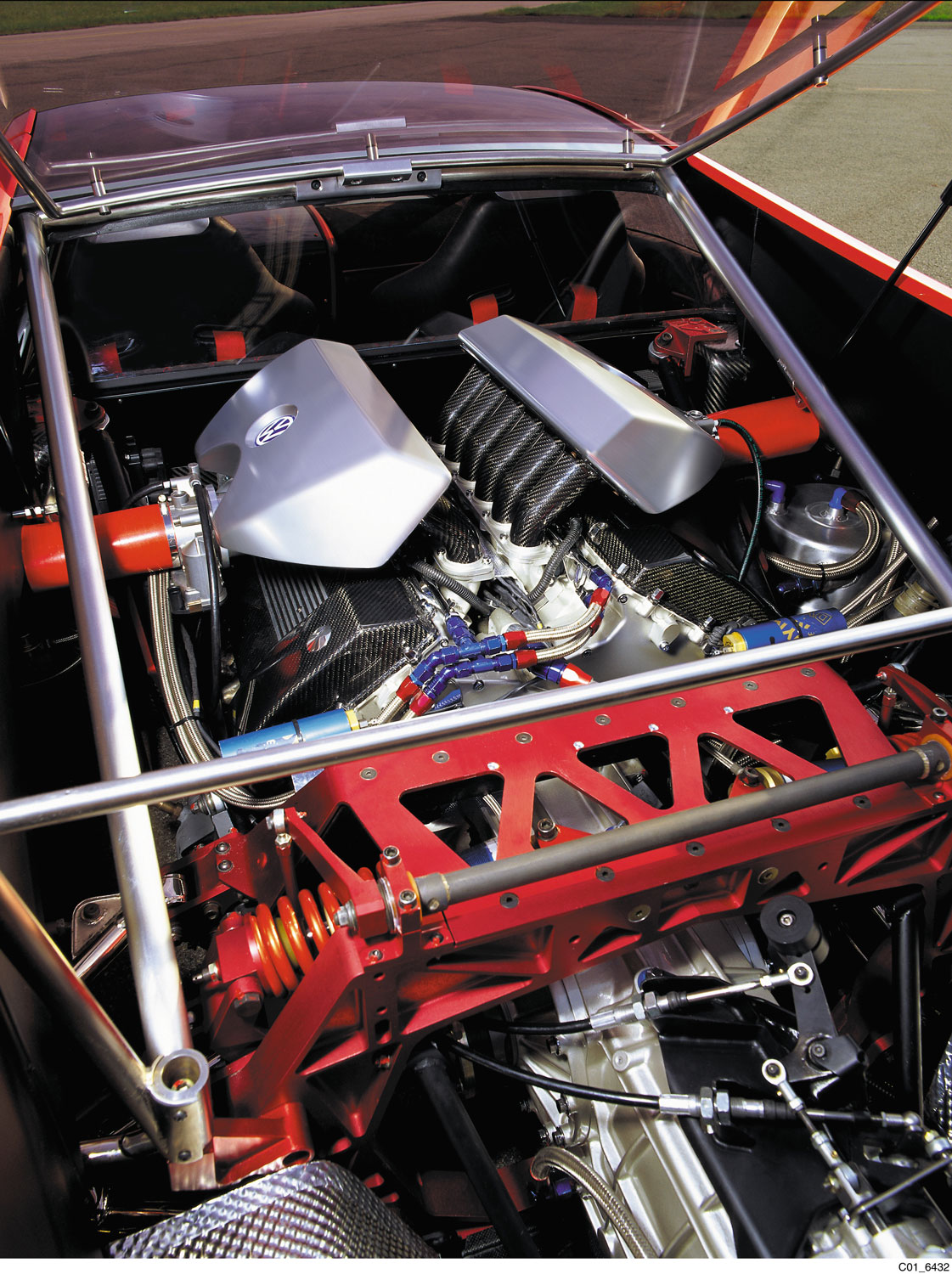

Before the W-12 could debut for the final two years of the first-generation Audi A8L, Volkswagen sent out its heavily upgraded Nardò W12 Coupé concept study to the famous Italian circuit, only to set a 24-hour world endurance record. The prototype covered 4402.8 miles at an average speed of 183 mph.

Since its first appearance in 1997, Volkswagen’s W-12 grew from its initial 5.6 liters into a 6.3-liter, naturally-aspirated statue of smoothness—only to be replaced by a more eager 6.0-liter twin-turbo version producing as much as 700 horsepower in the nose of a 2017 Bentley Continental Supersports.

Spotted by our friends at Road & Track, here’s how Bentley’s W-12 blocks become the monsters powering Continental GTs, Flying Spurs, and Bentaygas all over the world: